4

Table of Contents

1.0 Denitions........................................................................................................6

2.0 Safety ...............................................................................................................8

2.1 Skillsofqualiedpersonnel.......................................................................8

2.2 Symbols ....................................................................................................8

2.3 Referencestandards...............................................................................11

2.4 Beforeconnection ...................................................................................11

2.5 Duringtheuse.........................................................................................12

3.0 Introduction ...................................................................................................13

3.1 ProductPresentation...............................................................................13

3.1.1 Schematicdiagramsolution.........................................................14

3.1.2 Workinglogic ...............................................................................16

3.2 Systemarchitectureandoperation .........................................................17

3.2.1 zeroCO2-XLSystem...................................................................17

3.2.2 zeroCO2-XLcapabilitycurve ......................................................18

3.2.3 zeroCO2-XLSystemparameters................................................19

3.2.4 zeroCO2 - BESS 125K..................................................................22

3.2.5 ParametrizeroCO2- BESS 125K ................................................23

4.0 Receptionandhandling ...............................................................................24

4.1 Controloftheworkingenvironmentofthestoragesystem .....................24

4.1.1 Cleaning.......................................................................................24

4.1.2 Temperature.................................................................................24

4.1.3 Fire-ghtingsystem .....................................................................24

4.1.4 Installationplacechecking...........................................................25

4.1.5 Safetyarea ..................................................................................25

4.2 zeroCO2-XLSystem ..............................................................................25

4.2.1 Unpackingmode..........................................................................26

4.2.2 Packinglist...................................................................................32

4.3 zeroCO2- BESS 125K ............................................................................33

4.3.1 Unpackingmode..........................................................................34

4.3.2 Packinglist...................................................................................42

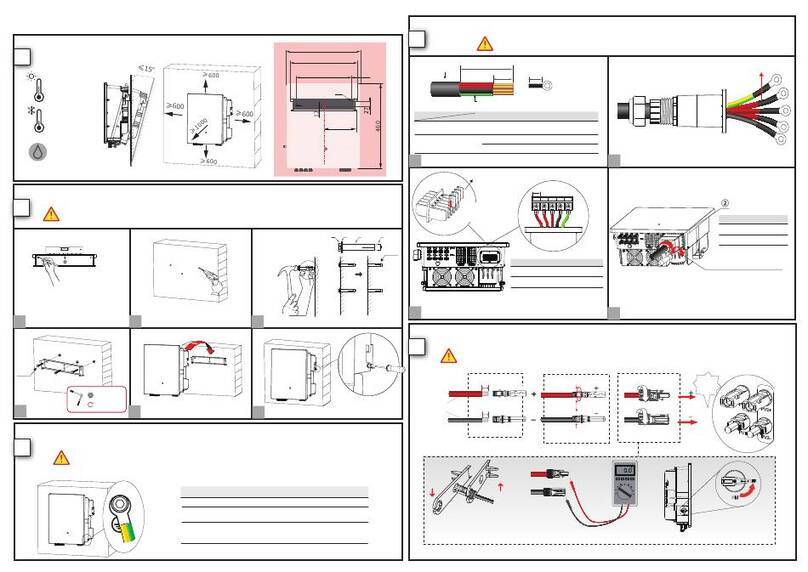

5.0 Installation .....................................................................................................44

5.1 Installationtools ......................................................................................44

5.2 Personalprotectiveequipment...............................................................45

5.3 zeroCO2-XLSysteminstallation ............................................................46

5.3.1 zeroCO2-XLSystemcableconnection.......................................46

5.3.2 MBMSADDSwitchsettings.........................................................50

5.4 BMScontrolmoduleandbatterybatterymoduleinstallation

inzeroCO2- BESS 125K.........................................................................52

5.4.1 Batterymoduleinterface..............................................................55

5.4.2 Controlmodule ...........................................................................56

5.4.3 zeroCO2-BESS125Kcablesconnection ...................................59

5.4.4 BMSADDSwitchsettings............................................................61