. 4 .

Table of contents

1. About this manual ......................................................................................... 6

1.1 Purpose.................................................................................................. 6

1.2 Scope..................................................................................................... 6

2. Safety instructions........................................................................................ 7

2.1 Safety standards .................................................................................... 7

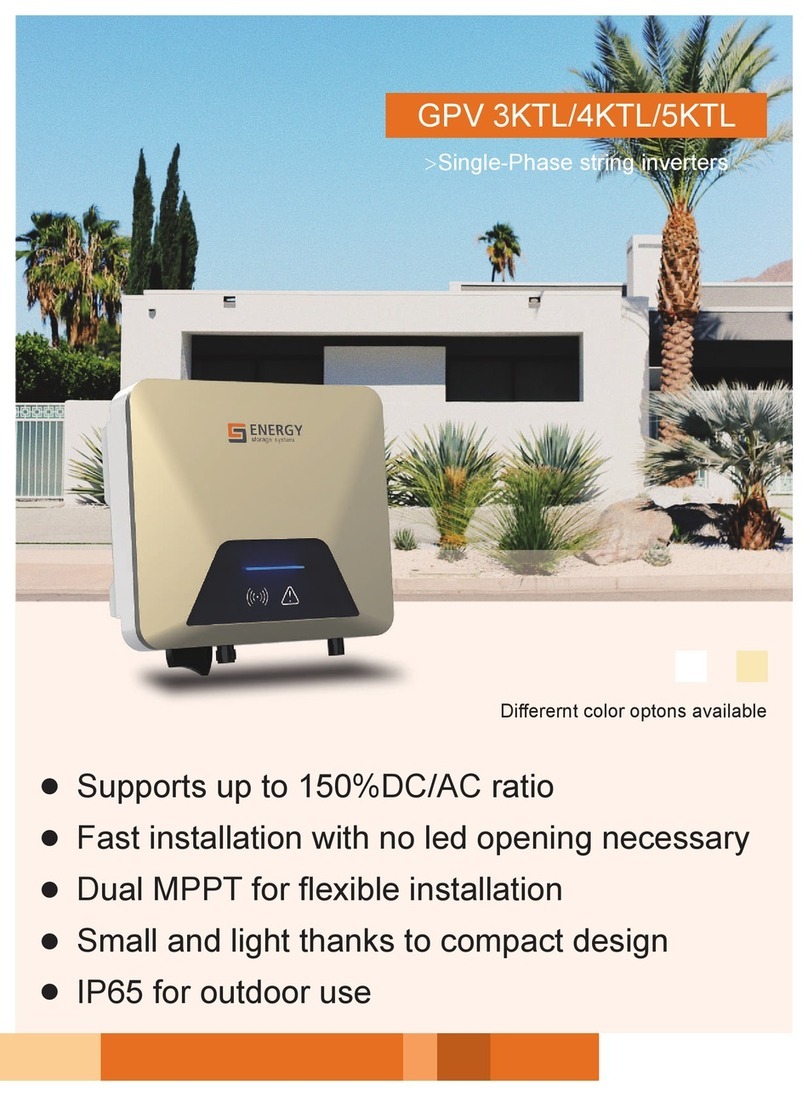

3. Introduction ................................................................................................... 8

3.1 Features ................................................................................................. 8

3.2 Basic System Architecture ..................................................................... 8

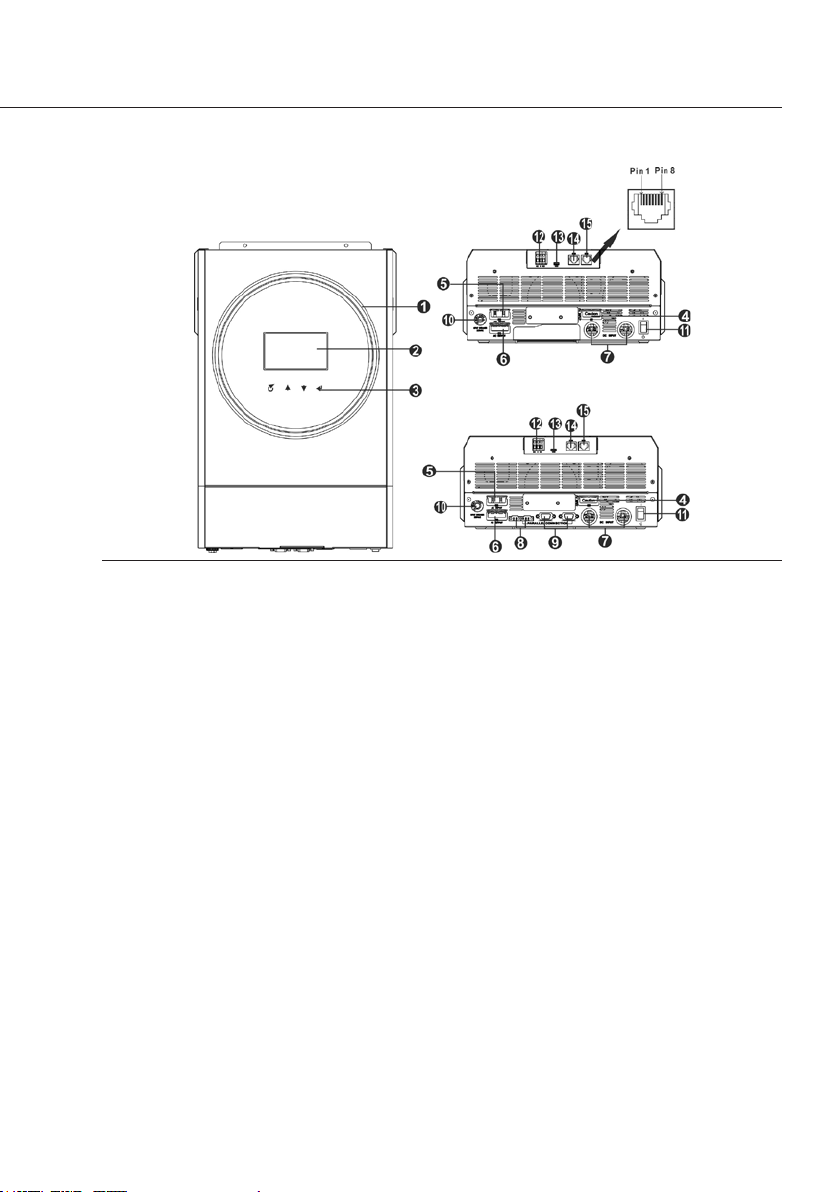

3.3 Product Overview................................................................................... 9

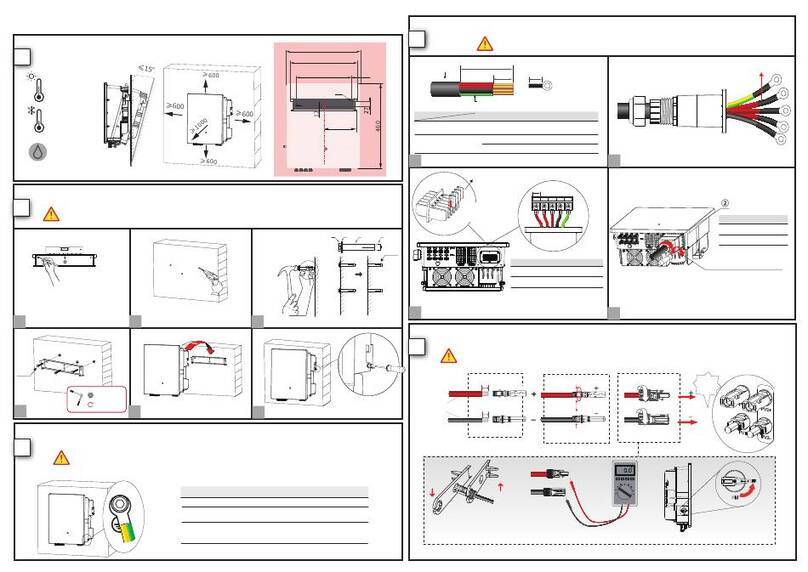

4. Installation ....................................................................................................10

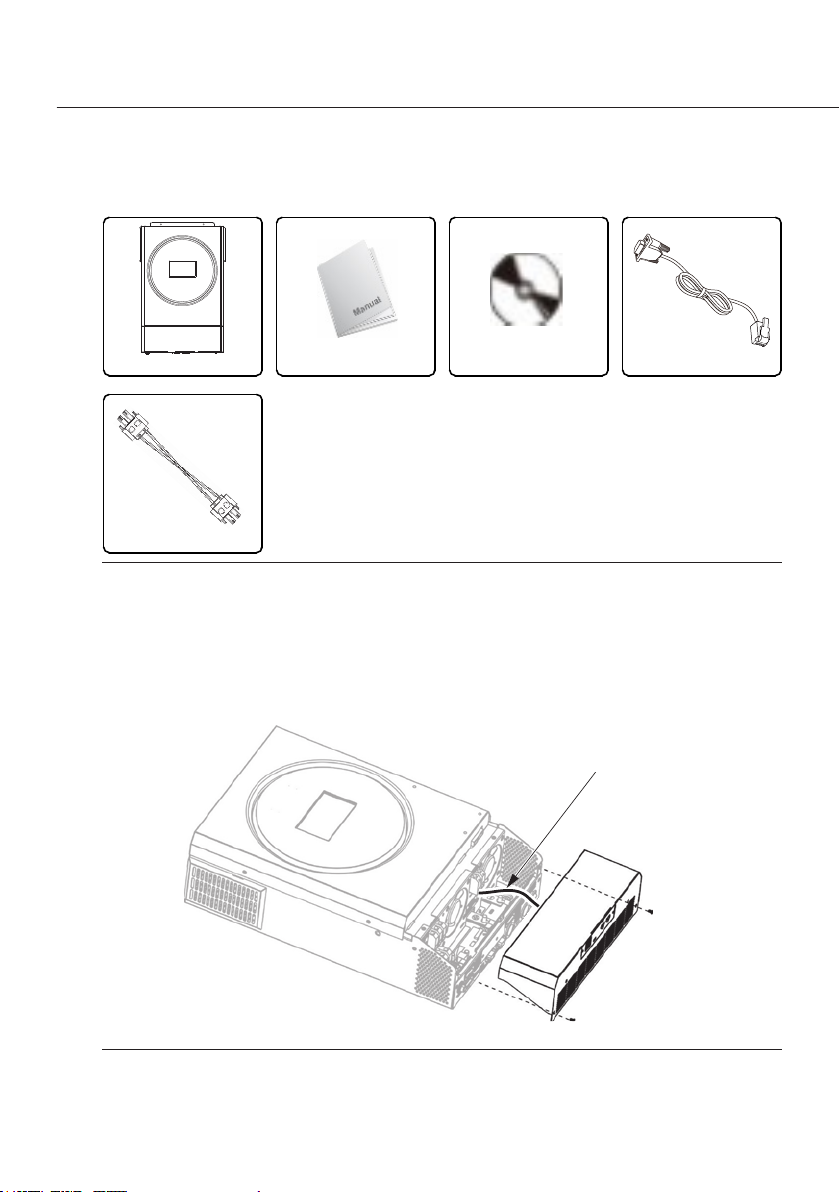

4.1 Unpacking and Inspection.....................................................................10

4.2 Preparation............................................................................................10

4.3 Mounting the Unit..................................................................................11

4.4 Battery Connection ...............................................................................12

4.5 AC Input/Output Connection.................................................................14

4.6 PV Connection ......................................................................................16

4.6.1 PV Module Selection ............................................................................. 17

4.7 Final Assembly......................................................................................18

4.8 Communication Connection..................................................................18

4.8.1 Serial Connection .................................................................................. 18

4.8.2 Wi-Fi Connection ................................................................................... 18

4.8.3 BMS Communication ............................................................................. 18

4.9 Dry Contact Signal............................................................................... 20

5. Operation ......................................................................................................21

5.1 Power ON/OFF .....................................................................................21

5.2 Operation and Display Panel ................................................................21

5.3 LCD Display Icons................................................................................ 22

5.4 LCD Setting.......................................................................................... 26

5.4.1 General Setting......................................................................................26

5.5 USB Function Setting........................................................................... 39

5.6 LCD Display ..........................................................................................41

5.7 Operating Mode Description ................................................................ 49

5.8 Faults Reference Code ........................................................................ 53

5.9 Warning Indicator................................................................................. 54

5.10 Battery equalization ........................................................................... 55

6. Specications.............................................................................................. 57

7. Trouble shooting ......................................................................................... 60

Appendix I: Parallel function.......................................................................... 62

Appendix II: BMS Communication Installation .............................................. 82

Appendix III: Wi-Fi Operation Guide ..............................................................91