manufacturer’s recommended discharge indicators

(imperative presence of a discharge limiter with an energy

cut-off at 1.83 vpc operating voltage at 80% DOD C5, when

the recharging time is 12 hours, and 1.87 vpc at 60 % DOD

C5 when the recharging time is 8 hours). Discharged

batteries must be recharged and never be left in a

discharged state for a long time.

Fiamm energy dry batteries can be used in normal duty

applications for a maximum 6 days per week.

Avoid applications where:

• no rest time is available allowing the battery to cool

• battery duty leads to a high increase of temperature

during operation.

2.2. Charging

A full charge shall be carried out every working day.

The charging time for a 80 % discharged battery shall be

12 hours, or 8 hours for a 60% discharged battery with the

appropriately assigned Fiamm Premium HF com/Premium

HF flex high frequency charger.

After any changing of cables on the charger, our technician

must visit the site to check the charger.

Fiamm energy dry batteries have a low gas emission.

Nevertheless, when charging, proper provision shall be

made for venting of the charging gases (EN 50272-3).

Battery container lids and the covers of battery

compartments shall be opened or removed. With the

charger switched off connect the battery, ensuring that the

polarity is correct. (Positive to positive, negative to

negative). Now switch on the charger.

2.3. Equalising charge

Equalising charges are used to optimise the life of the

battery and to maintain its capacity. A unique equalisation

charge is automatically carried out weekly 8 hours after the

end of the charge with a Fiamm Premium HF com/Premium

HF flex charger.

3. Battery life

The optimum lifetime of the battery depends on the

operating conditions (temperature and depth of discharge)

3.1. Temperature

The temperature range of use for the battery is between

+5 °C and + 35 °C. Any use outside of this range shall be

approved by a Fiamm service technician. Optimal battery

life is obtained for a battery temperature of 25-30 °C High

temperatures reduce battery life according to IEC 1431

technical report, lower temperatures reduce the capacity

available.

4. Maintenance

The electrolyte is immobilised in a gel.

The density of the electrolyte cannot be measured.

• Never refill with water!

• Never remove the safety valve from the cell

In case of accidental damage of the valve, contact our After

Sales Service for replacement.

The battery should always be kept clean and dry to prevent

current leakage. Any liquid in the battery tray shall be

extracted. Damage to the insulation of the tray should be

repaired after cleaning, to ensure a good insulation and to

prevent tray corrosion. If it is necessary to remove cells it is

best to call in our service department for this.

4.1. Daily

• Check that the plugs and sockets are in good condition.

4.2. Monthly / quarterly

• Carry out end of charge voltage readings at C5/100,

measure and record:

• the voltage of the battery

• the voltages of each cell

If significant changes from earlier measurements or

differences between the cells or bloc batteries are found,

please contact Fiamm Service.

• If the discharge time of the battery is not sufficient,

check:

• That the work required is compatible with the battery

capacity

• The settings of the charger

• The settings of the discharge limiter.

4.3. Annually or biannually

Internal dust removal from the charger.

Check with attention:

• the state of the plugs :be sure to have a good contact

between the plugs without trace of overheating.

• the state of the output cables.

If you check the torque loading, you shall use a torque

wrench with respect of recommended value : 25+/- 2 Nm.

In accordance with EN 1175-1 at least once per year, the

insulation resistance of the truck and the battery must be

checked by an electrical specialist.

The tests on the insulation resistance of the battery shall

be conducted in accordance with EN 1987 part 1.

The insulation resistance of the battery thus determined

must not be below a value of 50 Ωper Volt of nominal

voltage, in compliance with EN 50272-3. For batteries up

to 20 V nominal voltage the minimum value is 1000 Ω.

5. Storage

If batteries are taken out of service for a lengthy period they

should be stored, disconnected from the truck, in the fully

charged condition in a dry, frost-free room.

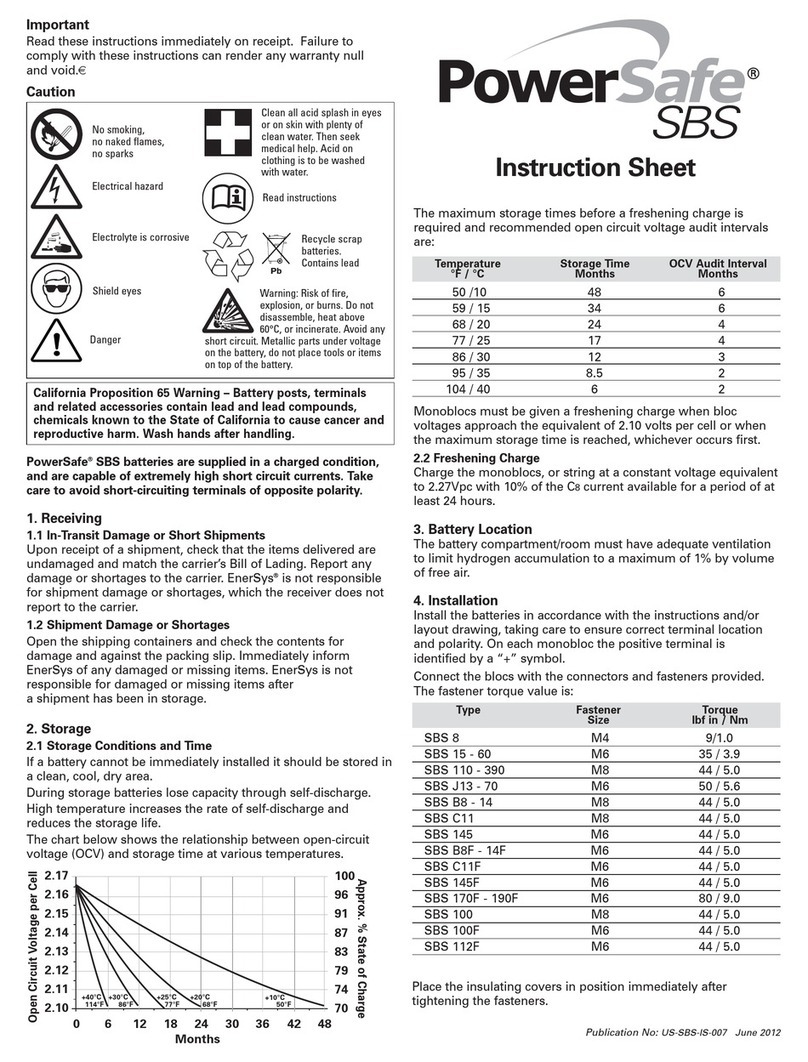

Batteries shall be recharged after a maximum storage time

of :

• 2 months at 30 °C

• 3 months at 20 °C

Effect a recharge before putting the battery into service. A

monthly refreshing charge is recommended. The storage

time should be taken into account when considering the life

of the battery. Never leave a battery connected to a truck for

a long time.

Storage at open circuit is not allowed when in discharged

state.

6. Malfunctions

If malfunctions are found on the battery or the charger our

service department should be called without delay. A

service contract with us makes it easier to detect and correct

faults in good time.

Back to the manufacturer!

Batteries with this sign must be recycled.

Batteries which are not returned for the recycling process must be disposed of as hazardous waste!