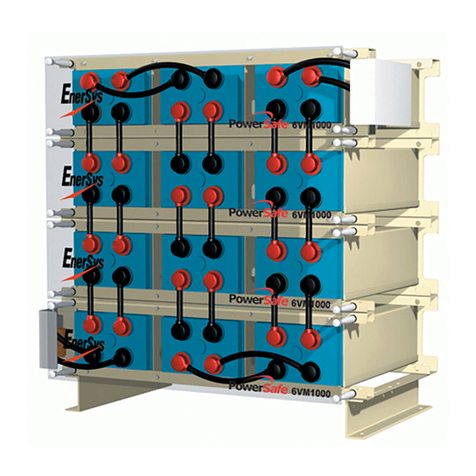

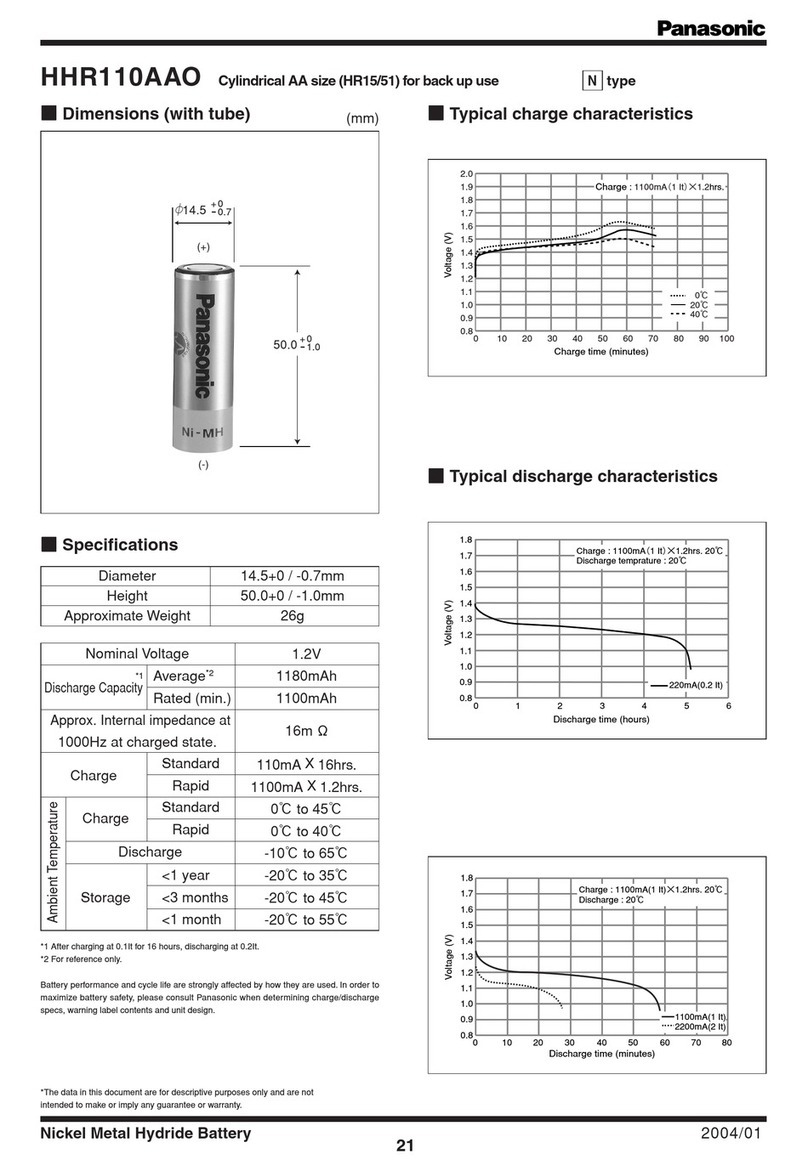

10 hr rate 8 hr rate Typical Short Circuit Internal

Battery Type(1) Nominal to 1.80Vpc to 1.75Vpc Length Depth(2) Height(3) Weight(4) Current(5) Resistance(5)

Voltage (V) @ 20°C @ 77°F mm mm mm kg (A) (mΩ)

12VM-200 12 200 200 665 330 218 104 3045 0.694

12VM-300 12 300 300 893 330 218 149 4094 0.517

12VM-400 12 400 400 843 516 218 199 4604 0.456

12VM-500 12 500 500 957 516 218 232 5542 0.376

12VM-600 12 600 580 1071 516 218 265 5921 0.354

6VM-850 6 850 840 801 516 218 191 9521 0.222

6VM-1000 6 1000 1000 915 516 218 225 10772 0.195

6VM-1000A 6 1000 1000 801 584 218 230 9754 0.216

6VM-1100 6 1100 1080 972 516 218 245 11069 0.188

6VM-1200 6 1200 1200 915 584 218 267 12054 0.174

6VM-1300 6 1300 1300 972 584 218 291 12864 0.163

6VM-1360 6 1360 1360 1145 516 218 316 14092 0.149

6VM-1500 6 1500 1500 915 558 278 354 14822 0.142

6VM-1600 6 1600 1600 1145 584 218 363 16504 0.127

6VM-1700 6 1700 1640 972 558 278 382 16296 0.129

4VM-2000 4 2000 2000 791 558 278 308 20033 0.105

2VM-2600 2 2600 2600 676 584 218 188 25728 0.082

2VM-3000A 2 3000 3000 801 584 218 230 29262 0.072

2VM-3000 2 3000 3000 638 558 278 236 29644 0.071

2VM-3600 2 3600 3600 915 584 218 267 36162 0.058

2VM-4000 2 4000 4000 791 558 278 308 40066 0.053

2VM-4500 2 4500 4500 915 558 278 354 44466 0.047

2VM-5000 2 5000 4920 972 558 278 382 48888 0.043

Nominal Capacity (Ah)

Nominal Dimensions (mm)

The following items are recommended to be available to ensure a safe and

successful installation:

a) Safety glasses with side shields or safety goggles

b) Acid resistant gloves

c) Protective rubber aprons

d) Safety shoes

e) Insulated tools - torque wrench and socket set

f) Hammer drill - for floor anchor bolts

g) Tape measure

h) Chalk line

j) Line cord

k) Wooden or plastic straight edge

l) Spirit level - plastic

m) Cleaning materials - paper towels, wire wool , brass wire brush etc

n) Lifting device of suitable capacity for the module weight

p) A supply of clean water to rinse the eyes and/or skin in the event of any

contact with electrolyte

q) Spill containment and electrolyte neutralizing materials

(e.g. dilute Sodium Hydroxide)

If the safety precautions and installation procedures are not fully understood

clarification must be sought from your EnerSys®representative.

Notes:

(1) The excellent flexibility afforded by the modular construction design provides for further combinations of capacity, voltage or footprint in addition to those

illustrated in the above tabulation, eg 2VM-3200, 2VM-4800, 4VM-1000, 4VM-1700 etc.

(2) The depth shown in the table is for the module only. Add 86mm to obtain the overall depth including the front panel.

(3) To calculate the total height of a battery stack multiply the module height by the number of modules in the stack and add 100mm for the base support except

for the VM -1500, 1700, 2000, 3000, 4000, 4500 and 5000 modules where 120mm must be added.

(4) The typical weight of the module excludes the connectors, terminal plates, front panels and base support.

(5) Values refer to 2V cells.

3. Technical Specifications

4. Receiving and Inspection

Upon receipt of a delivery each case should be inspected for damage at the

time of unloading. Should any damage be identified it should be further

investigated then noted down and reported in writing to both the carrier and

your EnerSys®representative. Remove the lids from the packing cases and

check the cells and hardware against the packing/material list. Any missing

items should be notified immediately in writing to both the carrier and your

EnerSys representative. EnerSys is not responsible for damage or missing

items not reported as above. The terminal voltage of each cell should be

checked to ensure that none are below 2.12 volts. Any low voltage readings

should be reported to your EnerSys representative immediately.

5. Storage and Freshening Charge

Any cells/modules that are not to be installed immediately should be put into

storage in a cool, clean, dry, well ventilated area. Recommended storage

temperature range is -18°C (0°F) to 32°C (90°F).

Cells are supplied filled and charged from the factory. Lead-acid cells are

subject to self discharge. If cells are to be stored for several months, they will

require a freshening charge at six monthly intervals following receipt to keep

them in good condition. The initial “freshening charge-by date” is clearly

shown on the label attached to each packing case. The freshening charge

should be completed with the lids removed from the packing cases in an

adequately ventilated area. As with normal float charge operation, the

freshening charge should only be completed using a constant potential

charger. The correct float voltage can be obtained from Appendix “A” and

should be applied for 48 hours. A record should be kept of all freshening

charges applied during any prolonged storage period to maintain the

warranty.

If the cells are to be stored at high temperatures for prolonged periods you

should consult your EnerSys representative for further advice on freshening

charging.

6. Battery Location

The battery location should have an adequately strong level floor and be

clean, cool and dry with good lighting and ventilation. It is recommended that

a minimum free space of 900mm (36 inch) is provided in front of the battery to

allow for service and inspection. As a separate battery room is not required,

the best location for the battery is in the room with it’s associated power

supplies and equipment.

3