1. Receiving the battery

1.1 In-Transit Damage or Short Shipments

Upon receipt of a shipment, check that the items delivered are undamaged and

match the carrier’s Bill of Lading. Report any damage or shortages to the carrier.

EnerSys®is not responsible for shipment damage or shortages that the receiver

does not report to the carrier.

1.2 Shipment Damage or Shortages

Open the shipping containers and check the contents for damage and against the

packing slip. mmediately inform EnerSys of any damaged or missing items.

EnerSys is not responsible for damaged or missing items after a shipment has been

in storage.

2. Storage

2.1 Storage Conditions and Time

f a battery cannot be immediately installed it should be stored in a clean, cool, dry

area.

During storage, the battery’s state of charge is reduced due to self-discharge.

High temperature increases the rate of self-discharge and reduces the storage life.

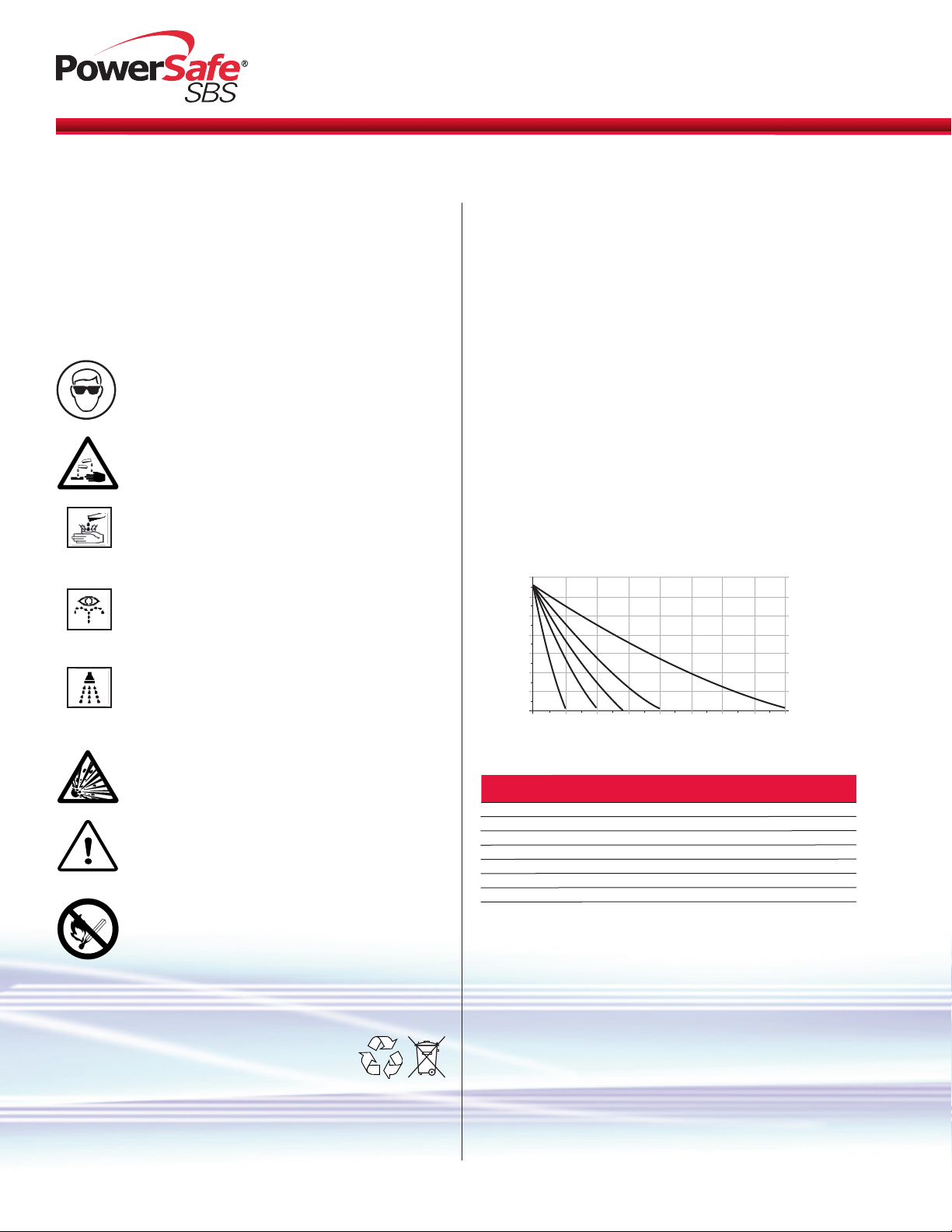

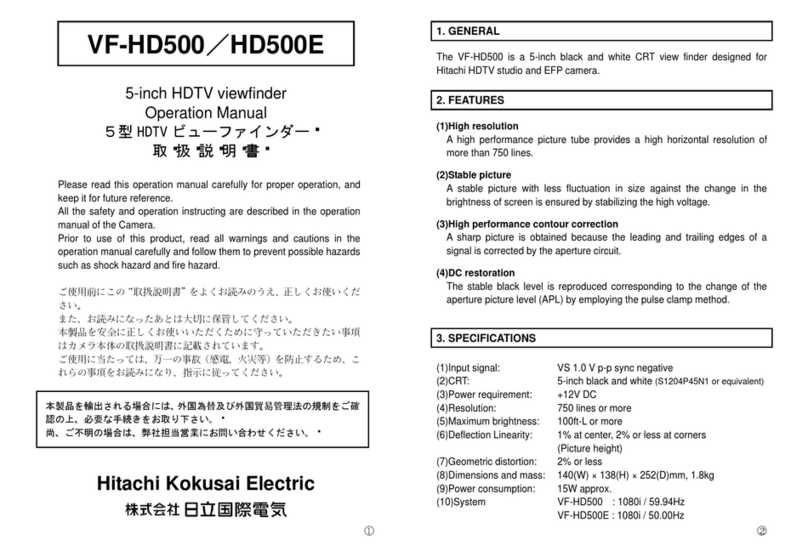

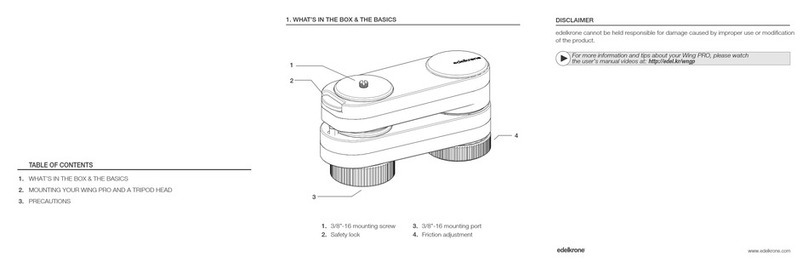

The chart below shows the relationship between Open-Circuit Voltage (OCV) and

storage time at various temperatures. While the batteries are in storage, OCV should

be measured according to the OCV audit intervals.

Do not store below -40ºF (-40ºC).

*Storage values indicated are based on constant temperatures.

**Recommended OCV audit interval.

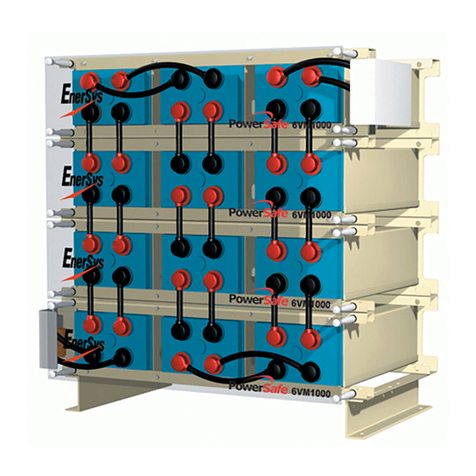

The PowerSafe SBS modules are made up of six cells and must be given a

freshening charge when bloc voltages approach the equivalent of 2.10 volts per cell

or when the maximum storage time is reached, whichever occurs first.

2.2 Freshening Charge

Charge the module or string of modules at a constant voltage equivalent to 2.27Vpc

with current limited to 10A per 100Ah nominal capacity for a period of at least 24

hours, but with a maximum of 48 hours. Use temperature compensation as indicated

in Section 5. Start monitoring the charging current 21 hours after initiating the

freshening charge. The charge is complete when the current stabilizes. Do not install

in an air tight enclosure.

Completing a freshening charge according to the instruction will reset the storage

OCV audit interval and suggested maximum storage time. f voltage drops below

2.10V contact EnerSys for instruction.

2www.enersys.com

When working on batteries wear safety glasses with side

shields, rubber gloves and protective clothing. All metallic

personal objects, such as rings, watches, bracelets, etc,

should be removed before starting work on the battery!

Only use insulated tools!

n case of SKI CO TACT with electrolyte, IMMEDIATELY

1. REMOVE contaminated CLOTHI G

2. FLUSH the area THOROUGHLY with WATER

3. Get MEDICAL ATTE TIO

Electrolyte is corrosive.

Do not allow flames, embers or sparks near the battery

due to the risk of explosion or fire!

WAR I G!

PowerSafe®SBS batteries are supplied in a charged state and are capable

of extremely high short circuit currents. Take care to avoid

short-circuiting terminals of opposite polarity.

Read these instructions immediately upon receipt. PowerSafe®SBS batteries

are safe when operated and handled properly. t is vitally important that you

observe the precautions recommended in this instruction sheet.

YOU SHOULD BE TRAI ED N HANDL NG, NSTALL NG, OPERAT NG

AND MA NTA N NG BATTER ES BEFORE YOU WORK ON A Y BATTERY

SYSTEM.

Spent batteries with this symbol are reusable products and

have to be put into a recycling system. Used batteries must

be disposed of as special waste in accordance with all

standards.

The nstruction Sheet must be strictly observed. Non-compliance with the

nstruction Sheet, use of non OEM spares or use of additives to the

electrolyte or unauthorized tampering will void the warranty.

Warning: batteries remain live even though they are

disconnected. No rings or metal bracelets should be worn

during the assembly of the battery. Do not place electrically

conductive objects such as tools etc. on top of the battery!

Warning: cells are heavy, use proper lifting technique.

Batteries can generate gases which, when released, can

explode, causing blindness and other serious personal injury.

n case of electrolyte CO TACT WITH CLOTHI G OR

MATERIAL, IMMEDIATELY

1. REMOVE CO TAMI ATED CLOTHI G

2. Apply large amounts of water to affected area.

3. Wash clothing as soon as possible.

n case of EYE CO TACT with electrolyte, IMMEDIATELY

1. FLUSH THOROUGHLY for at least 15 minutes with large

amounts of WATER.

2. Get MEDICAL ATTE TIO .

TemperatureStorage Time OCV Audit Interval

°F / °CMonths* Months**

50 / 1048.06

59 / 1534.06

68 / 20 24.0 4

77 / 25 17.0 4

86 / 30 12.0 3

95 / 35 8.5 2

104 / 40 6.0 2

2.17

2.16

2.15

2.14

2.13

2.12

2.11

2.10

100

96

91

87

83

79

74

70

Open-Circuit Voltage per Cell

Approx. % State of Charge

Months

0612 18 24 30 36 42 48

+40°C+30°C+25°C+20°C+10°C

114°F68°F50°F

77°F

86°F

California Proposition 65 Warning – Battery posts, terminals and related

accessories contain lead and lead compounds, chemicals known to the

State of California to cause cancer and reproductive harm. Wash hands

after handling.

Pb