III. Maintenance and Trouble Shootings

1. Maintenance

l External cleaning: To clean the heat pump unit, the power must be cut off, and a small amount

of neutral detergent dipped in a wet cloth shall be used to gently wipe. Do not use gasoline or

acid solution, alcohol, and finally dry with a dry cloth.

l Waterway cleaning: Empty and clean once every 3 months. Descaling materials: clean with

organic acids such as formic acid, citric acid, acetic acid, etc.

l Evaporator cleaning:A hard nylon brush can be used to clean the fins of the evaporator.A

vacuum cleaner must be used Before cleaning. If there is compressed air, a high-pressure air

tube can be used to clean the fins of the heat exchanger.

l Note: If the solar coil is optional, if the ambient temperature is lower than 2℃, anti-freeze

valves and pipelines shall be installed in the solar coil water channel and filled with anti-freeze

liquid, such as glycerin-aqueous solution or ethylene glycol aqueous solution.

l Note: If the ambient temperature is lower than 2℃, please install circulating water pump on the

customer's water side to avoid freezing of pipeline during use. When the machine is out of

order, the water of the machine and the water side pipeline should be drained in time to avoid

freezing of the pipeline.The installation of water pump is shown in “Installation”.

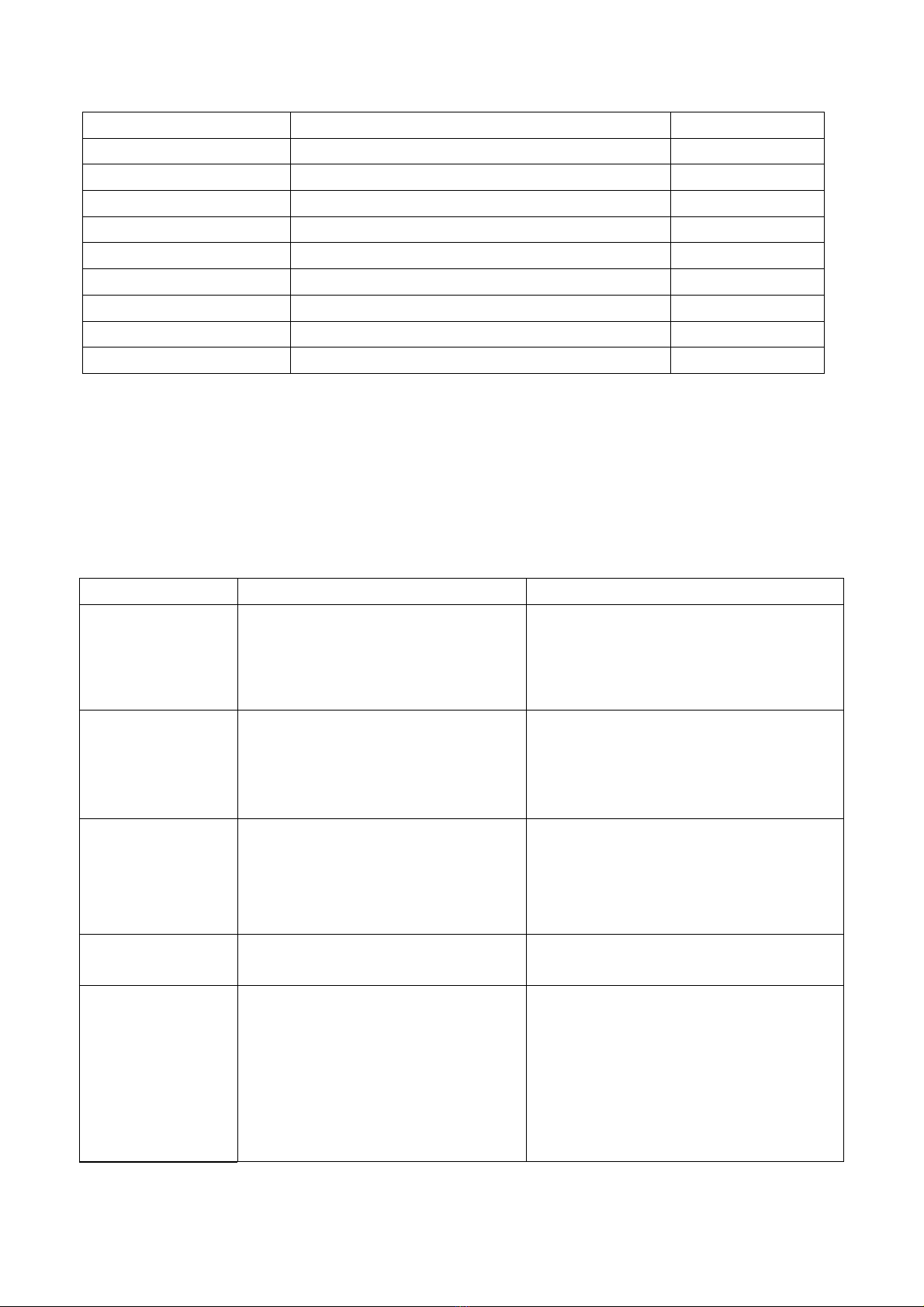

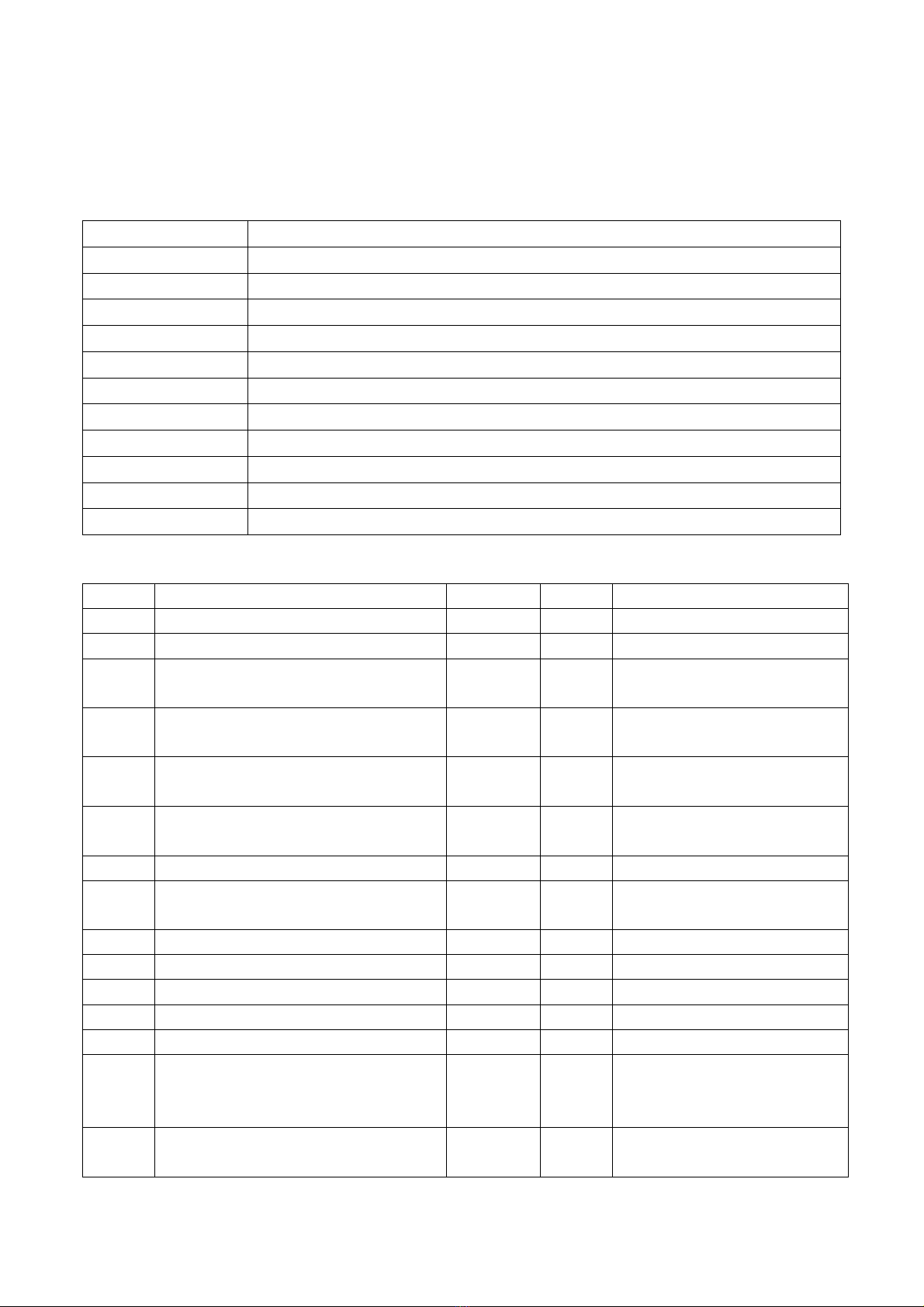

Reference table of target concentration and target freezing point of unit antifreeze.

Local lowest ambient temp. (℃)

Antifreeze mass target concentration percentage (kg/kg %)

Antifreeze target

antifreeze point (℃)

Local lowest ambient temp. (℃)

Antifreeze mass target concentration percentage (kg/kg %)

Antifreeze target

antifreeze point (℃)