Enertronica Santerno ASAC-1 Series User manual

Enertronica Santerno S.p.A.

Via della Concia, 7 - 40023 Castel Guelfo (BO) Italy

Tel. +39 0542 489711 –Fax +39 0542 489722

www.santerno.com - info@santerno.com

- 15P0071B600 -

ASAC-1

SOFT STARTER

Issued on 1/11/19

R. 04

•

This manual is integrant and essential to the product. Carefully read the instructions contained herein as they provide

important hints for use and maintenance safety.

•This device is to be used only for the purposes it has been designed to. Other uses should be considered improper and

dangerous. The manufacturer is not responsible for possible damages caused by improper, erroneous andirrational uses.

•Enertronica Santerno is responsible for the device in its original setting.

•Any changes to the structure or operating cycle of the device must be performed or authorized by the Engineering

Department of Enertronica Santerno.

•Enertronica Santerno assumes no responsibility for the consequences resulting by the use of non-original spare parts.

•Enertronica Santerno reserves the right to make anytechnical changes to this manual and to the device without prior

notice. If printing errors or similar are detected, the corrections will be included in the new releases of the manual.

•The information contained herein is the property of Enertronica Santerno and cannot be reproduced. Enertronica Santerno

enforces its rights on the drawings and catalogues according to the law.

Contents

1Caution Statements............................................................................................................................................2

1.1 Avertissements à l'attention des clients canadiens................................................................................................................2

2Mechanical Installation.......................................................................................................................................3

2.1 Dimensions and Weights.....................................................................................................................................................3

2.2 Physical Installation.............................................................................................................................................................3

3Electrical Installation..........................................................................................................................................4

3.1 Power Terminations.............................................................................................................................................................4

3.2 Control Voltage ...................................................................................................................................................................4

3.3 Control Circuits....................................................................................................................................................................4

3.4 Outputs...............................................................................................................................................................................5

3.5 Electrical Schematics...........................................................................................................................................................5

4Adjustments.......................................................................................................................................................6

5Troubleshooting.................................................................................................................................................8

5.1 Feedback LEDs...................................................................................................................................................................8

5.2 Trip Codes..........................................................................................................................................................................8

5.3 Protections..........................................................................................................................................................................8

5.4 Reset..................................................................................................................................................................................9

6Accessories......................................................................................................................................................10

6.1 Finger Guard Kit................................................................................................................................................................10

6.2 Remote Operator...............................................................................................................................................................10

6.3 Communication Modules...................................................................................................................................................10

6.4 PC Software......................................................................................................................................................................10

7Specifications...................................................................................................................................................11

7.1 Current Ratings.................................................................................................................................................................11

7.2 Semiconductor Fuses........................................................................................................................................................11

7.3 General Technical Data.....................................................................................................................................................12

7.4 Model Code.......................................................................................................................................................................13

2/14

ASAC-1

1Caution Statements

Caution Statements cannot cover every potential cause of equipment damage but can highlight common causes of damage. It is the

installer's responsibility to read and understand all instructions in this manual prior to installing, operating or maintaining the equipment,

to followgood electrical practice including applying appropriate personal protective equipment and to seek advice before operating this

equipment in a manner other than as described in this manual.

•Isolate the ASAC-1 completely from the power supply before attempting any work on the ASAC-1 or motor.

•Cables to the control inputs must be segregated from mains voltage and motor cabling.

•Some electronic contactor coils are not suitable for direct switching with PCB mount relays. Consult the contactor

manufacturer/supplier to confirm suitability.

•Do not apply incorrect voltages to the control input terminals.

CAUTION

Power factor correction capacitors must be connected to the input side of the soft starter. Connecting power factor

correction capacitors to the output side will damage thesoft starter.

The examples and diagrams in this manual are included solely for illustrative purposes. The information contained inthis manual is

subject to change at any time and without prior notice. In no event will responsibility or liability be accepted for direct, indirect or

consequential damages resulting from the use or application of this equipment.

WARNING – ELECTRICAL SHOCK HAZARD

The ASAC-1 contains dangerous voltages when connected to mains voltage. Only a qualified electrician should carry out the

electrical installation. Improper installation of the motor or the soft starter may cause equipment failure, serious injury or

death. Follow this manual and local electrical safety codes.

GROUNDING AND BRANCH CIRCUIT PROTECTION

It is the responsibility of the user or person installing the ASAC-1 to provide proper grounding and branch circuit protection

according to local electrical safety codes.

SHORT CIRCUIT

The ASAC-1 is not shortcircuit proof. After severe overload or short circuit, the operation of the ASAC-1 should be fully

tested byan authorised service agent.

1.1 Avertissements à l'attention des clients canadiens

AVERTISSEMENT

L'icône AVERTISSEMENT ci-contre signale les informations concernant des risques pouvant entraîner des blessures

graves, voire mortelles. Pour votre sécurité, veuillez consulter les avertissements sur cette page ou demander une copie du

présent manuel en français auprès devotre distributeur local.

AVERTISSEMENT - DANGER D'ÉLECTROCUTION

L’ASAC-1 contient des tensions dangereuses lorsqu'il est raccordé à l'alimentation secteur. Seul un électricien compétent

peut effectuer l'installation électrique. Une mauvaise installation du moteur ou de l’ASAC-1 peut déclencher une panne

d'équipement, provoquer de graves blessures ou même la mort. Suivre les instructions de ce manuel et des codes locaux

concernant la sécurité électrique.

AVERTISSEMENT

Toujours appliquer la tension de commande avant (ou en même temps que) la tension secteur.

AVERTISSEMENT

Isoler complètement l’ASAC-1 del'alimentation secteur avant de tenter toute intervention sur l’ASAC-1 ou sur le moteur.

Les bornes de commande peuvent être au potentiel de la tension de phase.

ASAC-1

3/14

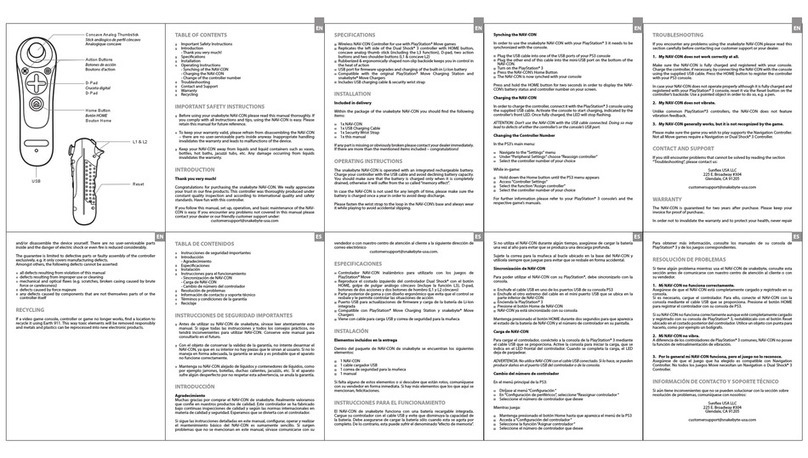

2Mechanical Installation

2.1 Dimensions and Weights

08240.E

B

D

C

AE

HH

G

F

Width

mm (inch)

Height

mm (inch)

Depth

mm (inch)

mm (inch)

mm (inch)

mm (inch)

Weight

kg (lb)

Model

A

B

C

D

E

F

G

H

ASAC-1/007

ASAC-1/015

ASAC-1/018

98

82

201

188

165

55

90.5

23

2.2

ASAC-1/022

(3.85)

(3.22)

(7.91)

(7.40)

(6.49)

(2.16)

(3.6)

(0.9)

(4.85)

ASAC-1/030

ASAC-1/037

ASAC-1/045

145

124

215

196

193

-

110.5

37

4.0

ASAC-1/055

(5.70)

(4.88)

(8.46)

(7.71)

(7.59)

(4.4)

(1.5)

(8.81)

ASAC-1/075

ASAC-1/090

200

160

240

216

214

-

114.5

51

6.5

ASAC-1/110

(7.87)

(6.30)

(9.44)

(8.50)

(8.43)

(4.5)

(2.0)

(14.33)

2.2 Physical Installation

1

ASAC-1/007 ~ ASAC-1/055: Allow 100 mm (3.9 inch) between soft starters.

ASAC-1/075 ~ ASAC-1/110: Allow 200 mm (7.9 inch) between soft starters.

2

ASAC-1/007 ~ ASAC-1/055: Allow 50 mm (2.0 inch) between the soft starter and solid surfaces.

ASAC-1/075 ~ ASAC-1/110: Allow 200 mm (7.9 inch) between the soft starter and solid surfaces.

3

Soft starters may bemounted side by side with no clearance (that is, if mounted without communications modules).

4

The soft starter may be mounted on its side. Derate the soft starter's rated current by 15%.

12

3

4

08241.D

4/14

ASAC-1

3Electrical Installation

3.1 Power Terminations

1/L1, 3/L2, 5/L3, 2/T1, 4/T2, 6/T3

mm

2

(AWG)

A1, A2, A3, 01, 02, B4, B5, 13,

14, 23, 24 mm

2

(AWG)

007 - 030

037 - 055

075 - 110

007 - 110

10427.A

10 - 35

(8 - 2)

10428.A

14 mm

(0.55 inch)

25 - 50

(4 - 1/10)

10428.A

14 mm

(0.55 inch)

n/a

26

(1.02)

11

(0.43)

Ø 8.5

(0.33)

10429.A

mm (inch)

0.14 - 1.5

(26 - 16)

10428.A

6 mm

(0.24 inch)

Torx (T20)

3 Nm

2.2 ft-lb

Torx (T20)

4 Nm

2.9 ft-lb

n/a

n/a

7 mm

3 Nm

2.2 ft-lb

7 mm

4 Nm

2.9 ft-lb

n/a

3.5 mm

0.5 Nm max

4.4 in-lb max

3.2 Control Voltage

•ASAC-1/xxx/x/1 (110~240 VAC): A1, A2

•ASAC-1/xxx/x/1 (380-440 VAC): A2, A3

•ASAC-1/xxx/x/2 (24 VAC/VDC): A1, A2

WARNING

Always apply control voltage before (or with) mains voltage.

CAUTION

With 24 VAC/VDC use contacts rated for low voltage and low current (gold flash or similar).

3.3 Control Circuits

WARNING

Isolate the ASAC-1 completely from the power supply before attempting any work on the ASAC-1 or motor. Control

terminals may be at phase voltage potential.

CAUTION

For ASAC-1/xxx/x/2 (24 VAC/VDCcontrol voltage) units you can connect an external 24 VDC supply into thecontrol input

terminals 01, 02.

Two-wire control

Three-wire control

110~240 VAC

&

24 VAC/VDC

A3

A1 (+)

A2 (-)

01

02

A3

A1

A2

01

02

1

1

03241.D

A3

A1 (+)

A2 (-)

01

02

A3

A1

A2

01

02

2

3

2

3

03242.E

380-440 VAC

1

Start/Stop. Toreset atrip, open thenclose 02.

2

Start.

3

Stop. To reset a trip, open then close 02.

ASAC-1

5/14

3.3.1 Motor Thermistor

Motor thermistors can be connected directly to theASAC-1 terminals B4, B5. If motor thermistors are not used, there must be a link

between B4, B5 (the ASAC-1 is supplied with a link fitted).

B4

B5

B4

B5

B4

B5

03247.A

OK OK

3.4 Outputs

3.4.1 Main Contactor Output

The Main Contactor output (terminals 13, 14) closes as soon as thesoft starter receives astart command and remains closed while the

soft starter is controlling the motor (until the motor starts a coast to stop, or until the end of a soft stop). The Main Contactor output will

also open if the soft starter trips.

The Main Contactor output can be usedto directly control a main contactor coil.

3.4.2 Programmable Output

The programmable output relay (terminals 23, 24) can be used to signal either trip or run status. This relay is normally open.

Trip:

The relay closes when the ASAC-1 trips. The relay can be used to operate theshunt-trip mechanism of an upstream circuit breaker (in

order to isolatethe motor branch circuit), or to signal the trip to an automation system or externally. The relay will open when the trip is

reset.

Run:

The relay operates when the soft start is complete, the bypass relays are closed and full voltage is beingapplied to the motor. The

relay can be used tooperate a contactor for power factor correction capacitors, or to signal soft starter runstatus to an automation

system.

3.5 Electrical Schematics

Soft starter installed with fuses and a main contactor.

6/T3

4/T2

2/T1

5/L3

3/L2

1/L1

13

14

M

K1

23

24

K1

03249.F

M

Motor (three phase)

K1

Main contactor

13, 14

Main contactor output

23, 24

Programmable output (set to Trip)

6/14

ASAC-1

4Adjustments

350%

90%

80%

70%

60%

400%

300%

50%100%

16s

8s 1

2s

10s

No

Soft Stop

450%250%

6s

4s2s

14s

20s

16

8 12

10

OFF

6

42

14

20

16

8 12

10

OFFTRIPRUN

ANY ANY

FWD FWD

6

42

5s

2s15s

5s

OFF

15s

5s2s

2s

15s

14

20

14244.C

1

2

3

78

6

5

4

1

Current Ramp

2

Current Limit

3

Motor Trip Class

4

Motor FLC

5

Soft Stop Time

6

Excess Start Time

7

Auxiliary Relay Function

8

Phase Sequence Protection

1

Current Ramp

Select the initial start current (A) and ramp time (B).

Current ramp starting extends the time soft starter takes to reach the

current limit and is suitable for generator set supplies, loads requiring

an extended start time or applications with extreme load variation

between starts.

The ramp time does not control the time the motor will take to reach

full speed.

Current

Time

2

Current Limit

Select the current limit (C).

The current limit is the maximum level of current the soft starter will

deliver to themotor during the soft start.

Current

Time

3

Motor Trip Class

Select the trip class for motor overload protection.

The trip class reflects the maximum time (in seconds) that the motor

can run at locked rotor current. The Motor Trip Class setting

assumes a locked rotor current of 600%.

Setting the motor trip class to "Off" disables motor overload

protection.

4

Motor FLC

Configure the soft starter to match the motor's full load current (FLC).

Configure according to the motor's nameplate current. Divide the

motor's FLC by the soft starter's maximum current rating (on the soft

starter's nameplate label).

08239.A

INPUTRATING: 200-440VAC, 50/60Hz,3PH

OUTPUTFLC: xxAAC53b4-6:354,30 kW@ 400V

AUXILIARYCONTACTS: 5A@ 250VAC/360VA,5A@30VDCResistive

WITHSTANDCURRENT: 5000ARMS,600VACmax.

POWERCONTACTS: #10 -#2AWG,6 -35 mm2(3-5Nm,2.2-3.7lb-ft)

AUXILIARY CONTACTS: 20 -16AWG,0.75- 1.5mm2(0.5 Nm, 4.5 lb-in)

Motor FLC

Soft starter FLC

ASAC-1

7/14

5

Soft Stop Time

Select the soft stop ramp time (D).

Soft stop extends the time soft starter takes to reduce voltage tozero.

The ramp time does not control the time the motor will take to stop

completely.

Voltage

Time

6

Excess Start Time

Configure the soft starter's excess start time protection.

Select a time slightly longer than the motor requires for a normal

healthy start. The soft starter will trip if the start does not complete

within the selected time (E).

Current

Time

7

Auxiliary Relay Function

Select the function ofthe soft starter's programmable output

(terminals 23, 24).

When set to "Run", the relay will operate when thesoft start is

complete. When set to "Trip", the relay will operate when thesoft

starter trips.

Time

8

Phase Sequence Protection

Configure the soft starter's phase sequence protection.

Select the allowable phase sequences. A setting of "Fwd" allows

forward sequence (positive rotation) only and a setting of "Any"

defeats the protection.

NOTE

Auxiliary relayfunction and phase sequence are configured using a shared switch. Set the auxiliary relay function as

required, then set phase sequence protection.

8/14

ASAC-1

5Troubleshooting

5.1 Feedback LEDs

LED Status

Ready

Run

Off

No control power

Motor not running

On

Ready

Motor running at full speed

Flash

Starter tripped

Motor starting or stopping

5.2 Trip Codes

The Ready LED will flash a different number of times to indicate the cause of the trip.

Ready LED

Description

x 1

Power Circuit: Check mains supply (L1, L2, L3), motor circuit (T1, T2, T3), soft starter SCRs and bypass relays.

x 2

Excess Start Time: Check load, increase Current Limit or adjust Excess Start Timesetting.

x 3

Motor Overload: Allow motor to cool, reset soft starter and restart.

The soft starter cannot be reset until the motor has cooled.

x 4

Motor Thermistor: Check motor ventilation and thermistor connection B4, B5. Allow motor to cool.

x 5

Current imbalance: Check for mains supply or linecurrent imbalance (L1, L2, L3).

x 6

Supply Frequency: Check mains voltage is available and supply frequency is in range.

x 7

Phase sequence: Check for correct phase sequence.

x 8

Network Communication Failure (between module and network): Check network connections, settings and

configuration.

x 9

Starter Communication Failure (between starter and module): Remove and refit accessory module.

x 10

Bypass Overload: Starter rating may betoo low for the application.

5.3 Protections

The ASAC-1 includes the following types of protection for the motor and starter:

5.3.1 Excess Start Time Protection

The ASAC-1 will trip on excess start time if themotor does not successfully start within the time selected in the Excess Start Time

setting. This may indicate that the load hasstalled.

If the soft starter frequently trips on excess start time:

•check that the Current Limit setting is high enough for the application

•check that the Excess Start Timesetting is long enough for the application

•check that the load has not stalled or increased since thesoft starter was installed

5.3.2 Motor Overload Protection

The ASAC-1 will trip on motor overload if it calculates that the motor has been runningabove its operating range for longer than the time

selected in the Motor Trip Class setting. Motor Trip Class should be set tomatch the motor's locked rotor time. If this information is

not available from the motor datasheet, use the default setting (Motor Trip Class = 10). Using a higher setting can damage the motor.

NOTE

Motor overload protection does not protect the soft starter, and does not protect the motor from short circuit.

14243.A

Ready

Run

Ready

Run

Reset

350 %

90%

80%

70%

60%

400%300%

50%100 %

16s

8s 12s

10s

No

S oft Stop

450%

250%

6s

4s

2s

14s

20s

16

812

10

OF F

6

4

2

14

20

16

812

10

OFFTRIPR U N

FWD F WD

AN Y ANY

6

4

2

5s

2s 1 5s

5s

OFF

15s

5s

2s

2s

15s

4

2

14

20

ASAC-1

9/14

5.3.3 Current Imbalance Protection

The ASAC-1 will trip on current imbalance if the highest and lowest currents on the three phases vary by an average of 30% for more

than 3 seconds. Current imbalance protection is not adjustable, and is only active when the average motor current is 50% or more of

the programmed motor FLC.

If the soft starter frequently trips on current imbalance:

•check that there is no imbalance on the mains voltage (on the input side of the soft starter)

•insulation test the motor

•move all input cables over one position (move L1 cable to L2,move L2 cable to L3, move L3 cable to L1) to rule out acabling

fault

5.3.4 Supply Frequency Protection

The soft starter will trip onsupply frequency if thefrequency rises above 72 Hz orfalls below 40Hz for morethan five seconds while the

soft starter is running. These trip points are not adjustable.

In pre-start, starting and stopping modes the high and low frequency limits both apply with no time delay.

A supply frequency trip will also occur if:

•all three input phases are lost while the soft starter is running

•all three input phases fall below 120 VAC at start or while the soft starter is running

•the line contactor opens while running

5.3.5 Bypass Overload Protection

Bypass overload protection protects the soft starter from severe operating overloads while running. The protection is not adjustable and

has two components:

•The soft starter will trip if it detects overcurrent at 600% of the programmed motor full load current.

•The soft starter models the temperature ofthe internal bypass relays and will trip if the temperature exceeds the safe

operatinglevel.

If the trip occurs frequently, this indicates that the soft starter has not been selected correctly for the application.

5.4 Reset

Trips can be cleared by pressing the Reset button on the soft starter, sending a Reset commandfrom the serial communications

network, or by switching the control inputs.

To clear a trip via the control inputs, the soft starter requires a closed to open transition on the stop input (02).

•In three-wire control, use the external stop button to momentarily open thestop input (open A1-02).

•In two-wire control, if the soft startertripped with astart signal present, remove the start signal (open A1 to 01, 02).

•In two wire control, if the ASAC tripped with no start signal present (eg ASAC-1 motor thermistor trip), apply then remove the

start signal (close then reopen A1 to 01, 02).

The Reset button is located onthe front of the unit, above the adjustment switches.

The soft starter will trip again immediately if the cause of the trip still exists.

10/14

ASAC-1

6Accessories

6.1 Finger Guard Kit

Finger guards may bespecified for personnel safety. Finger guards fit over the soft starter terminals to prevent accidental contact with

live terminals. Finger guards provide IP20 protection when used with cable of diameter 22 mm or greater.

6.2 Remote Operator

The Remote Operator can control and monitor the soft starter's performance. Functionality includes:

•Operational control (Start, Stop, Reset, Quick stop)

•Starter status monitoring (Ready, Starting, Running, Stopping, Tripped)

•Performance monitoring (Motor current, Motor temperature)

•Trip code display

•4-20 mA analog output (Motor Current)

6.3 Communication Modules

ASAC-1 soft starters support network communication via easy-to-install communications modules. Each soft starter can support one

communications module at a time.

Available protocols:

Ethernet (Profinet, Modbus TCP, Ethernet/IP), Profibus, DeviceNet, Modbus RTU, and USB.

NOTE

Ethernet communication modules are not suitable for use with ASAC starters using 380/440 VAC control voltage.

6.4 PC Software

The software allows comprehensive management of soft starters. It provides the following functionality:

Operation of soft starter networks containing up to 254 individual soft starters

•Operational control (Start, Stop, Reset, Quick stop)

•Starter status monitoring (Ready, Starting, Running, Stopping, Tripped)

•Performance monitoring (Motor current, Motor temperature)

To use RemoteDrive with the ASAC-1, thesoft starter must be fitted with aUSB Module, Modbus Module or a Remote Operator.

ASAC-1

11/14

7Specifications

7.1 Current Ratings

For operating conditions not covered by these ratings charts, download Santerno's free WinStart selection application, or contact your

local supplier.

7.1.1 AC53b format

80 A

:

AC-53b

3.5

-

15

:

345

Off time (seconds)

Start time (seconds)

Start current (multiple of motor full load current)

Starter current rating (amperes)

7.1.2 Ratings

AC53b 4-6:354

< 1000 metres

AC53b 4-20:340

< 1000 metres

40 °C

50 °C

40 °C

50 °C

ASAC-1/007

18 A

17 A

17 A

15 A

ASAC-1/015

34 A

32 A

30 A

28 A

ASAC-1/018

42 A

40 A

36 A

33 A

ASAC-1/022

48 A

44 A

40 A

36 A

ASAC-1/030

60 A

55 A

49 A

45 A

AC53b 4-6:594

< 1000 metres

AC53b 4-20 580

< 1000 metres

40 °C

50 °C

40 °C

50 °C

ASAC-1/037

75 A

68 A

65 A

59 A

ASAC-1/045

85 A

78 A

73 A

67 A

ASAC-1/055

100 A

100 A

96 A

87 A

ASAC-1/075

140 A

133 A

120 A

110 A

ASAC-1/090

170 A

157 A

142 A

130 A

ASAC-1/110

200 A

186 A

165 A

152 A

7.2 Semiconductor Fuses

Semiconductor fuses can be used with ASAC-1 soft starters to reduce the potential for damage to SCRs from transient overload currents

and for Type 2 coordination. ASAC-1soft starters have been tested to achieve Type 2 coordination with semiconductor fuses. Suitable

Bussmann and Ferraz/Mersen semiconductor fuses are detailed below.

Model SCR I2t (A2s)

Ferraz/Mersen Fuse

European/IEC Style

(North American Style)

Bussmann Fuse

Square Body (170M) Bussmann Fuse

British Style (BS88)

ASAC-1/007 1150

6.6URD30xxxA0063

(A070URD30xxx0063)

170M-1314 63 FE

ASAC-1/015 8000

6.6URD30xxxA0125

(A070URD30xxx0125)

170M-1317 160 FEE

ASAC-1/018 10500

6.6URD30xxxA0160

(A070URD30xxx0160)

170M-1318 160 FEE

ASAC-1/022 15000

6.6URD30xxxA0160

(A070URD30xxx0160)

170M-1318 180 FM

ASAC-1/030 18000

6.6URD30xxxA0160

(A070URD30xxx0160)

170M-1319 180 FM

ASAC-1/037 51200

6.6URD30xxxA0250

(A070URD30xxx0250)

170M-1321 250 FM

ASAC-1/045 80000

6.6URD30xxxA0315

(A070URD30xxx0315)

170M-1321 250 FM

ASAC-1/055 97000

6.6URD30xxxA0315

(A070URD30xxx0315)

170M-1321 250 FM

ASAC-1/075 168000

6.6URD31xxxA0450

(A070URD31xxx0450)

170M-1322 500 FMM

ASAC-1/090 245000

6.6URD31xxxA0450

(A070URD31xxx0450)

170M-3022 500 FMM

ASAC-1/110 320000

6.6URD31xxxA0450

(A070URD31xxx0450)

170M-3022 500 FMM

xxx = Blade Type. Contact Ferraz/Mersen for options.

12/14

ASAC-1

7.3 General Technical Data

Mains Supply

Mains voltage (L1, L2, L3)

4 ................................................................................................................................ 3x 200 VAC ~ 440VAC (+ 10% / - 15%)

5 ................................................................................................................................ 3x 200 VAC ~ 575VAC (+ 10% / - 15%)

Mains frequency (at start) .......................................................................................................................................... 45 Hz to 66 Hz

Rated insulation voltage ..................................................................................................................................................... 600VAC

Form designation..............................................................................................................Bypassed semiconductor motor starter form 1

Control voltage (01, 02)

ASAC-1/xxx/x/1 ................................................................................................................................... 110-240 VAC (+ 10% / - 15%)

....................................................................................................................................................or 380-440 VAC (+ 10% / - 15%)

ASAC-1/xxx/x/2 ............................................................................................................................................... 24 VAC/VDC (± 20%)

Current consumption (during run) ...................................................................................................................................... < 100 mA

Current consumption (inrush)

ASAC-1/xxx/x/1 ................................................................................................................................................................. 10 A

ASAC-1/xxx/x/2 ................................................................................................................................................................... 2 A

Inputs

Start (terminal 01) ...................................................................................................................................................... Normally open

...........................................................................................................................150 kΩ@ 300 VAC and 5.6 kΩ@ 24VAC/VDC

Stop (terminal 02) .................................................................................................................................................... Normally closed

...........................................................................................................................150 kΩ@ 300 VAC and 5.6 kΩ@ 24VAC/VDC

Outputs

Main contactor relay (terminals 13, 14) ......................................................................................................................... Normally open

.............................................................................................................................................6 A, 30 VDC/ 6 A, 250 VAC resistive

Programmable relay (terminals 23, 24) ........................................................................................................................ Normally open

.............................................................................................................................................6 A, 30 VDC/ 6 A, 250 VAC resistive

Environmental

Degree of Protection ASAC-1/007 to ASAC-1/055 ...................................................................................................................... IP20

Degree of Protection ASAC-1/075 to ASAC-1/110 ...................................................................................................................... IP00

Operating temperature ......................................................................................................................................... - 10 °C to +60 °C

Storage temperature ............................................................................................ -25 °C~+ 60 °C(to +70°C for less than 24 hours)

Humidity ................................................................................................................................................. 5%~95% Relative Humidity

Pollution degree ................................................................................................................................................... Pollution Degree 3

Vibration ............................................................................................................................................. IEC 60068 Test Fc Sinusoidal

........................................................................................................................................ 4 Hz to 13.2 Hz: ± 1 mm displacement

.......................................................................................................................................................... 13.2 Hz to 200 Hz: ± 0.7 g

EMC Emission

Equipment class (EMC) ........................................................................................................................................................ Class B

Conducted radio frequency emission ....................................................................................... 0.15 MHz to 0.5 MHz: < 56-46 dB (µV)

................................................................................................................................................. 0.5 MHz to 5 MHz: < 46 dB (µV)

.................................................................................................................................................. 5 MHz to 30MHz: < 50 dB (µV)

Radiated radio frequency emission ............................................................................................. 30MHz to 230 MHz: < 30 dB(µV/m)

...................................................................................................................................... 230 MHz to 1000MHz: < 37dB (µV/m)

EMCImmunity

Electrostatic discharge ..................................................................................................... 4kV contact discharge, 8 kV air discharge

Radio frequency electromagnetic field ...................................................................................... 0.15 MHz to 1000 MHz: 140 dB (µV)

Rated impulse withstand voltage (Fast transients 5/50 ns) .............................................................. 2kV line to earth, 1 kV line to line

Voltage dip and short time interruption .............................................................................................. 100 ms (at 40% nominal voltage)

Harmonics and distortion ...................................................................................................... IEC61000-2-4 (Class 3), EN/IEC61800-3

................................................................................................................................................................. EAC TR TC 020/2011

Short Circuit

Rated short-circuit current ASAC-1/007 to ASAC-1/022 ............................................................................................................. 5kA 1

Rated short-circuit current ASAC-1/030 toASAC-1/110 ........................................................................................................... 10 kA 1

1These short circuit ratings are with fuses used as given in the table under Semiconductor Fuses on page 11.

Heat Dissipation

During Start ............................................................................................................................................................ 3 watts / ampere

During Run ............................................................................................................................................................... 10 watts typical

Standards Approvals

CE .............................................................................................................................................................................. EN 60947-4-2

EAC (formerly GOST) ............................................................................................................ TRTC 004/2011 and TR TC 020/2011

RoHS .................................................................................................................................. Compliant with EU Directive 2011/65/EU

UL / C-UL ................................................................................................................................................................................ UL 508

Operational Life

ASAC-1/007~055 ............................................................................................................................................. 1,000,000 operations

ASAC-1/075~110 .................................................................................................................................................. 30,000 operations

ASAC-1

13/14

7.4 Model Code

ASAC-1/

/

/

Control voltage

1 = 110~240 VAC & 380-440 VAC

2 = 24 VAC/VDC

Mains voltage

4 = 200~440 VAC

5 = 200~575 VAC

Nominal kW rating @400 VAC

007~030: AC53b 4-6-354

037~110: AC53b 4-6-594

14/14

ASAC-1

This manual suits for next models

11

Table of contents

Other Enertronica Santerno Controllers manuals

Popular Controllers manuals by other brands

Savant

Savant SmartMedia 6 Quick reference guide

Resource Data Management

Resource Data Management PR0750-MOB Installation & user guide

Snakebyte

Snakebyte Nav-Con user manual

3Ware

3Ware 9590SE Series User guide addendum

Exlar

Exlar Curtiss-Wright FTX Series Installation and service manual

Hamron

Hamron 002-832 operating instructions