Exlar Curtiss-Wright FTX Series Manual

Curtiss-Wright | FTX Series Rev. C PN71855 5/26/17

1

FTX and FTP Series

Installation and Service Manual

Information furnished by Curtiss-Wright, Exlar Corporation, is believed to be accurate and

reliable. However, no responsibility is assumed by Curtiss-Wright for its use. Curtiss-Wright

reserves the right to change the design and operation of the equipment described herein

and any associated motion products that may appear in this document. Information in this

document pertaining to equipment not furnished by Curtiss-Wright should be confirmed by

that equipment manufacturer. Curtiss-Wright assumes no responsibility for changes to

information by other manufacturers or errors in that information or the description of that

information. Information in this document is subject to change without notice.

This document does not contain any export controlled technical data.

Curtiss-Wright | FTX Series Rev. C PN71855 5/26/17

2

TABLE OF CONTENTS

1.0 Introduction

1.1 Warranty and Limitations of Liability................................................ 3

1.2 Safety Considerations ....................................................................4

1.3 FTX Series Linear Actuators Overview .........................................5

1.4 Basic Actuator Construction............................................................5

1.5 Actuator Drive Train Configurations................................................ 7

2.0 Installation

2.1 Mounting Configurations.................................................................9

2.2 Mounting Considerations ................................................................ 9

2.3 Motor Installation........................................................................... 10

2.4 Lubrication .................................................................................... 15

2.5 Anti-Rotate System ...................................................................... 23

3.0 Maintenance & Service

3.1 Seals............................................................................................. 24

3.2 Drive Train ................................................................................... 26

3.3 Belt Tensioning ............................................................................ 27

3.4 Roller Screw.................................................................................. 32

3.5 End of Stroke Cushions ................................................................ 32

3.6 Inspection and Lubrication Procedure........................................... 33

4.0 Optional Equipment

4.1 Mounting Options ......................................................................... 38

4.2 Standard Motor Mounting Configurations ..................................... 38

4.3 Limit Switches .............................................................................. 38

4.4 Rod Ends ..................................................................................... 40

4.5 Motors .......................................................................................... 40

4.6 Electronics ................................................................................... 40

5.0 Specifications

5.1 Life Calculations ........................................................................... 40

5.2 Load, Torque, and Linear Speed Calculations ............................. 40

5.3 Load and Speed Ratings .............................................................. 41

6.0 Troubleshooting

6.1 Mechanical Problems ................................................................... 42

6.2 Electrical Problems ...................................................................... 42

6.3 Returning a Product for Repair ..................................................... 43

7.0 Torque Spec

7.1 FTX095 Torque Specifications ..................................................... 44

7.1 FTX125 Torque Specifications ..................................................... 45

7.2 FTX215 Torque Specifications...................................................... 46

7.3 FTP215 Torque Specifications...................................................... 47

7.4 Motor Fastener Torque Specifications ......................................... 48

Curtiss-Wright | FTX Series Rev. C PN71855 5/26/17

3

1.0 Introduction

1.1 Warranty and Limitation of Liability

Products are warranted for two years from date of manufacture as determined by the serial number

on the product label. Labels are generated and applied to the product at the time of shipment. The first

and second digits are the year and the third and fourth digits represent the manufacturing week.

Product repairs are warranted for 90 days from the date of the repair. The date of repair is recorded

within Exlar’s database tracked by individual product serial number.

Exlar Corporation warrants its product(s) to the original purchaser and in the case of original

equipment manufacturers, to their original customer to be free from defects in material and

workmanship and to be made only in accordance with Exlar’s standard published catalog specifications

for the product(s) as published at the time of purchase. Warranty or performance to any other

specifications is not covered by this warranty unless otherwise agreed to in writing by Exlar and

documented as part of any and all contracts, including but not limited to purchase orders, sales orders,

order confirmations, purchase contracts and purchase agreements. In no event shall Exlar be liable or

have any responsibility under such warranty if the product(s) has been improperly stored, installed,

used or maintained, or if Buyer has permitted any unauthorized modifications, adjustments and/or

repairs to such product(s). Seller's obligation hereunder is limited solely to repairing or replacing (at its

opinion), at the factory any product(s), or parts thereof, which prove to Seller's satisfaction to be

defective as a result of defective materials, or workmanship and within the period of time, in

accordance with the Seller's stated product warranty (see Terms and Conditions above), provided,

however, that written notice of claimed defects shall have been given to Exlar within thirty (30) days

from the date of any such defect is first discovered. The product(s) claimed to be defective must be

returned to Exlar, transportation prepaid by Buyer, with written specification of the claimed defect.

Evidence acceptable to Exlar must be furnished that the claimed defects were not caused by misuse,

abuse, or neglect by anyone other than Exlar.

Components such as seals, wipers, bearings, brakes, bushings, gears, splines, and roller screw

parts are considered wear parts and must be inspected and serviced on a regular basis. Any damage

caused by failure to properly lubricate Exlar products and/or to replace wear parts at appropriate times,

is not covered by this warranty. Any damage due to excessive loading is not covered by this warranty.

The use of products or components under load such that they reach the end of their expected life is

a normal characteristic of the application of mechanical products. Reaching the end of a product’s

expected life does not indicate any defect in material or workmanship and is not covered by this

warranty.

Costs for shipment of units returned to the factory for warranty repairs are the responsibility of the

owner of the product. Exlar will return ship all warranty repairs or replacements via UPS Ground at no

cost to the customer.

For international customers, Exlar will return ship warranty repairs or replacements via UPS

Expedited Service and cover the associated shipping costs. Any VAT or local country taxes are the

responsibility of the owner of the product.

The foregoing warranty is in lieu of all other warranties (except as Title), whether expressed or

implied, including without limitation, any warranty of merchantability, or of fitness for any particular

purpose, other than as expressly set forth and to the extent specified herein, and is in lieu of all other

obligations or liabilities on the part of Exlar.

Seller's maximum liability with respect to these terms and conditions and any resulting sale, arising

from any cause whatsoever, including without limitation, breach of contract or negligence, shall not

exceed the price specified herein of the product(s) giving rise to the claim, and in no event shall Exlar

be liable under this warranty otherwise for special, incidental or consequential damages, whether

similar or dissimilar, of any nature arising or resulting from the purchase, installation, removal, repair,

operation, use or breakdown of the product(s) or any other cause whatsoever, including negligence.

The foregoing warranty shall also apply to products or parts which have been repaired or replaced

pursuant to such warranty, and within the period of time, in accordance with Seller's stated warranty.

NO PERSON INCLUDING ANY AGENT OR REPRESENTATIVE OF EXLAR IS AUTHORIZED

TO MAKE ANY REPRESENTATION OR WARRANTY ON BEHALF OF EXLAR CONCERNING ANY

PRODUCTS MANUFACTURED BY EXLAR, EXCEPT TO REFER PURCHASERS TO THIS

WARRANTY.

Curtiss-Wright | FTX Series Rev. C PN71855 5/26/17

4

1.2 Safety Considerations

As with any electro-mechanical device, safety should be considered

during installation and operation of your FTX Series actuator. Throughout

this manual you will see paragraphs marked with WARNING or

CAUTION signs as shown below.

CAUTION WARNING

Pay particular attention to these paragraphs. They are intended to

provide you with helpful information to ensure a safe and trouble free

installation and operation.

Care should be taken not to exceed the physical travel

limits of FTX Series actuators. Doing so will cause the

actuator to end-crash internally. End crashes can physically

damage the roller screw and the internal components of the

actuator.

Care should be taken to avoid high speed impact with objects of

high rigidity that immediately stop the travel of the actuator with no

deceleration or energy absorption. An example would be a high

speed impact of two solid steel parts. The resulting impact will

create a very short effective deceleration time. Kinetic energy

contained in the rotating inertia of the actuator and motor can

possibly generate extremely high impact forces that exceed the

mechanical capacities of the actuator and cause physical damage

to the actuator. For applications requiring this type of impact,

contact Exlar application engineering to insure that the actuator is

properly sized or provisions are made to absorb the induced

energy.

Curtiss-Wright | FTX Series Rev. C PN71855 5/26/17

5

1.3 FTX Series Roller Screw Based Linear

Actuators Overview

Exlar FTX Series actuators utilize a satellite roller screw mechanism

that converts rotary motion to linear motion and is mounted within a

sealed tube assembly. The roller screw follower (nut) is attached to the

moveable output rod, which extends or retracts as the screw shaft is

rotated. The general operating principle is illustrated below.

Figure 1: Actuator Operating Principle

The FTX Series force tube design provides the contamination isolating

advantages of hydraulic cylinders without the limitations of load, life, and

speed which are inherent in ball screw and acme screw actuators. All

rotary to linear conversion components are mounted within a sealed

housing, preventing abrasive particles and other forms of contamination

to enter the actuator’s critical mechanisms. This assures trouble-free

operation in even the most severe environments.

1.4 Basic Actuator Construction

All FTX Series actuators are completely sealed from the outside

environment by the use of O-Rings on both ends of the extruded

aluminum case. The output rod runs through a wiper and seal, which are

captured within a gland insert.

Output Rod

Linear Motion

Screw Shaft

Internal Rollers

Roller Screw Nut

Rotational Motion

Curtiss-Wright | FTX Series Rev. C PN71855 5/26/17

6

The extruded aluminum case is epoxy coated (powder coated) on all

external surfaces. In cases where a motor is mounted in a parallel

configuration (see section 1.5) the pulley cover is also epoxy coated. All

other aluminum parts (faceplate, end plate, inline adapters etc.) are

anodized. All steel mounting parts (flange plates, trunnion components,

etc.) are finished with QPQ.

In applications where corrosive chemicals are to come in

contact with the actuator, it may be necessary to employ

non-standard coatings or materials. Contact Exlar for more details.

Unless otherwise specified, the output rod on a standard FTX Series

actuator is manufactured from case hardened and chrome plated carbon

steel. The case hardened chrome plated rod provides a very tough and

wear resistant surface for the rod seal to operate against.

If the surface of the output rod gets dinged or severally

scratched, the wiper and or rod seal may be compromised,

causing contamination of the internal components in the

actuator.

The base metal used in the standard output rod does not

resist corrosive environments. Custom materials or plating

may need to be used if the output rod is to come in contact

with a corrosively aggressive environment. Contact Exlar for more

details.

The standard tie rods on all FTX Series actuators are manufactured

out of 17-4 PH stainless steel and are corrosion resistant to most non-

chlorine based chemicals.

Curtiss-Wright | FTX Series Rev. C PN71855 5/26/17

7

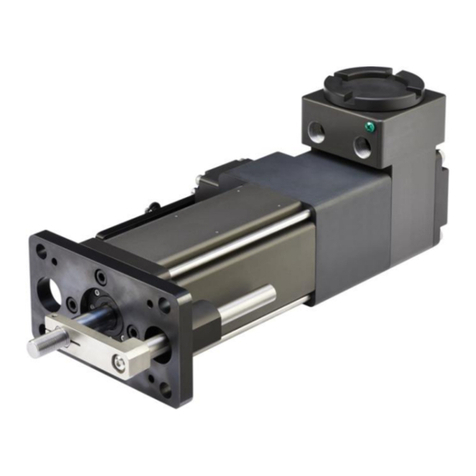

Figure 2: FTX Actuator with Parallel Motor Mount

1.5 Actuator Drive Train Configurations

Exlar offers a base FTX Series actuator model for the greatest

flexibility in application. The base actuator includes: a high performance

satellite roller screw assembly, pre-loaded angular contact bearings, an

epoxy powder coated aluminum housing, stainless steel tie-rods, internal

anti-rotation mechanism, a sealed output rod, and a keyed input shaft

for attachment to a drive system. A typical base FTX Series actuator is

shown below.

Figure 3: Base FTX Actuator

Curtiss-Wright | FTX Series Rev. C PN71855 5/26/17

8

Exlar also offers an FTX Series actuator, which is the base actuator

along with one of a variety motor mounting configurations, combined in

one product package. Parallel and in-line mounting options are offered

as standard configurations. The parallel motor mounting configuration

utilizes a high performance synchronous belt drive system and the inline

motor mounting configuration uses a zero backlash coupling to transmit

power from the motor to the input shaft of the actuator.

Typically a drive ratio of 1:1 is used, but a 2:1 reduction ratio is also

available as standard on the parallel motor mounting configuration.

FTX series actuators will also mate up with a wide variety of standard

planetary gearboxes to attain higher input torque.

Figure 4: Motor-Mounting Configurations

Parallel Motor Mount

Inline Motor Mount

Curtiss-Wright | FTX Series Rev. C PN71855 5/26/17

9

2.0 Installation

2.1 Mounting Configurations

The actuators come with a variety of mounting configurations as well.

Refer to the Exlar catalog to review what options are available on the

desired frame size.

2.2 Mounting Considerations

As with any linear actuator product, misalignment of the FTX Series

actuator with respect to the load the actuator is being used to move is of

great concern. Any misalignment will decrease the life of the components

within the actuator and also may create problems within the application

associated with misalignment. Therefore, every effort should be made to

minimize misalignment as much as is possible.

Excessive side load on the output rod of the actuator will

dramatically reduce the life of the actuator and should be

avoided completely.

Curtiss-Wright | FTX Series Rev. C PN71855 5/26/17

10

2.3 Motor Installation

1. Remove parallel drive cover screws, washers, cover and gasket.

The screws are hand tightened from the factory for shipment.

2. Attach motor or gearbox to motor plate using supplied mounting

screws, washers and gasket.

Curtiss-Wright | FTX Series Rev. C PN71855 5/26/17

11

3. Attach bushing and pulley to motor or gearbox output shaft and

actuator input shaft. Refer to belt tensioning procedure for the

approximate distance between the pulley and motor plate.

Torque the Taper-Lock screws to specification. The Taper-Lock

bushings can be used with or without a key.

Figure 5: Motor and Pulley with Taper-Lock Bushing

Curtiss-Wright | FTX Series Rev. C PN71855 5/26/17

12

4. If the parallel drive assembly is supplied with a keyless style

bushing, a key cannot be used. The bushing may have to be

reversed to attain proper pulley distance. In some instances the

bushing and pulley may have to be installed before the motor is

attached to the motor plate to allow clearance for tightening the

bushing. Torque the bushing using the large hex and refer to the

torque specification for bushing torque.

Figure 6: Motor Pulley with keyless Style Bushing

Curtiss-Wright | FTX Series Rev. C PN71855 5/26/17

13

5. Refer to section 3.3 for belt installation, belt tension and cover

assembly.

6. For inline motor mounting, an elastomer jaw coupling is used.

The coupling must be fitted flush to the end of the motor shaft.

Figure 7: Inline Motor Mounting

Figure 8: Coupling Alignment

Curtiss-Wright | FTX Series Rev. C PN71855 5/26/17

14

7. Torque coupling mounting screw to specification

Figure 9: Coupling-Mounting Screw

8. Insert motor or gearbox as assembled into inline housing

assembly. This is a blind assembly and may require reposition of

motor coupling to match actuator coupling. Do not force

installation or use motor mount screws to join pieces. If any

resistance is felt, reposition motor coupling to aid alignment.

A light film of oil will aid in the assembly process.

Figure 10: Inline Mount Final Assembly

Curtiss-Wright | FTX Series Rev. C PN71855 5/26/17

15

2.4 Lubrication

Grease Specification

FTX Series actuators are shipped from the factory fully

lubricated with high temperature grease. Exlar uses Mobilith SHC 220, a

high performance, extreme-pressure grease. The unique physical

properties of the synthetic base oil provide outstanding protection against

wear, rust, corrosion and high or low-temperature degradation. Mobilith

SHC allows for very low starting and running torque values. Its operating

range is -40 degrees C to 177 degrees C

(-40 degrees F to 350 degrees F).

Periodic inspection and renewal of the bearing and roller screw grease

is recommended. Re-greasing and maintenance schedules are largely

based upon customer applications. Contact the factory for general

recommendations on re-greasing schedules.

Follow the procedure in section 3.6 for renewing the lubrication.

Upon initial startup of your FTX Series actuator, cold

grease may cause increased motor torque to operate

actuator. Once grease has warmed up required motor torque should

decrease. Elevated operating temperatures may result in shorter

lubrication renewal periods.

Grease Zerk Access Plug

Curtiss-Wright | FTX Series Rev. C PN71855 5/26/17

16

Oil Specification

The FTX and FTP Series use Mobil SHC 626 for oil fill. The actuator is

shipped empty and only receives a light oil coating from the factory for

initial test. The actuator must be filled by the customer for their specific

application. The case features integrated sight glasses and sight tubing

to ensure a proper oil fill level depending upon the orientation of the

actuator. Slight foaming of the oil in operation is normal and is a result of

the initial coating of grease from the bearings.

Figure 11a: Horizontal Oil Fill Sight Glasses

Figure 11b: Vertical Oil Fill Sight Tube and Fill Ports

For lubrication of seals see section 3.1.

For inspection and lubrication procedure see section 3.6.

Curtiss-Wright | FTX Series Rev. C PN71855 5/26/17

17

Horizontal Oil Fill

If the actuator is to be used primarily in the horizontal orientation, the

side sight glass will indicate a proper oil fill level. Either port can be used

to fill the actuator depending upon the final orientation of the actuator.

The correct fill is achieved when the oil level covers the lower sight glass

completely. For reference, this table shows the approximate oil quantity

in correlation with stroke.

**Fill the Actuator with the Main Rod Retracted ONLY**

Approximate Horizontal Oil Fill Level

Actuator

L qt.

FTX095-0150 0.36 0.38

FTX095-0300 0.57 0.60

FTX095-0600 1.00 1.05

FTX095-0900 1.42 1.50

FTX095 - Oil

Qty. Per 25mm

of Stroke

0.035 0.037

Approximate Horizontal Oil Fill Level

Actuator

L qt.

FTX125-0150 0.57 0.60

FTX125-0300 0.87 0.92

FTX125-0600 1.50 1.58

FTX125-0900 2.12 2.24

FTX125 - Oil

Qty. Per 25mm

of Stroke

0.052 0.055

Approximate Horizontal Oil Fill Level

Actuator

L qt.

FTX/P215-0150 2.63 2.78

FTX/P215-0300 3.69 3.90

FTX/P215-0600 5.81 6.14

FTX/P215-0900 7.93 8.38

FTX/P215 - Oil

Qty. Per 25mm

of Stroke

0.177 0.187

Curtiss-Wright | FTX Series Rev. C PN71855 5/26/17

18

Horizontal Oil Fill

Vertical Oil Fill

If the actuator is to be used primarily in the vertical orientation, the

sight tube running the length of the actuator will be used to measure the

oil fill level. Two magnetic plug ports are provided for fill and drain.

Proper oil quantity will vary with the stroke of the actuator as well as the

motion profile. Correct fill level should be decided by where the most

work is done by the roller screw nut. The nut should be submerged in oil

or allowed to dip back into the standing oil in a cycle. The tables below

are an approximation for half oil fill. This should be used as a starting

point; final level is decided by end user application.

Curtiss-Wright | FTX Series Rev. C PN71855 5/26/17

19

**Fill the Actuator with the Main Rod Retracted ONLY**

Approximate Rod End Down Level

Actuator

L qt.

FTX095-0150 0.25 0.26

FTX095-0300 0.80 0.84

FTX095-0600 1.90 2.00

FTX095-0900 2.99 3.16

FTX095 - Oil

Qty. Per 25mm

of Stroke

0.091 0.096

Approximate Rod End Down Level

Actuator

L qt.

FTX125-0150 0.57 0.60

FTX125-0300 1.44 1.52

FTX125-0600 3.17 3.35

FTX125-0900 4.90 5.18

FTX125 - Oil

Qty. Per 25mm

of Stroke

0.144 0.153

Approximate Rod End Up Level

Actuator

L qt.

FTX095-0150 0.12 0.12

FTX095-0300 0.67 0.70

FTX095-0600 1.77 1.86

FTX1095-0900 2.86 3.02

FTX095 - Oil

Qty. Per 25mm

of Stroke

0.091 0.096

Approximate Rod End Up Level

Actuator

L qt.

FTX125-0150 0.30 0.31

FTX125-0300 1.16 1.23

FTX125-0600 2.90 3.06

FTX125-0900 4.63 4.89

FTX125 - Oil

Qty. Per 25mm

of Stroke

0.144 0.153

Curtiss-Wright | FTX Series Rev. C PN71855 5/26/17

20

Approximate Rod End Down Level

Actuator

L qt.

FTX/P215-0150 2.11 2.23

FTX/P215-0300 4.68 4.95

FTX/P215-0600 9.83 10.39

FTX/P215-0900 14.98 15.83

FTX/P215 - Oil

Qty. Per 25mm of

Stroke

0.429 0.453

Vertical Oil Fill Ports and Sight Tube

Approximate Rod End Up Level

Actuator

L qt.

FTX/P215-0150 1.75 1.84

FTX/P215-0300 4.32 4.56

FTX/P215-0600 9.47 10.00

FTX/P215-0900 14.62 15.44

FTX/P215 - Oil

Qty. Per 25mm

of Stroke

0.429 0.453

This manual suits for next models

16

Table of contents

Other Exlar Controllers manuals

Popular Controllers manuals by other brands

SMC Networks

SMC Networks ITV2000 series Easy Programming Guide

Agilent Technologies

Agilent Technologies TwisTorr 74 FS user manual

EHEIM

EHEIM LEDcontol+ manual

McCain

McCain ATC eX2 NEMA user manual

Hydrofarm

Hydrofarm autopilot APC8400 user manual

Spirax Sarco

Spirax Sarco LC2250 Installation and maintenance instructions