10

Operation Manual

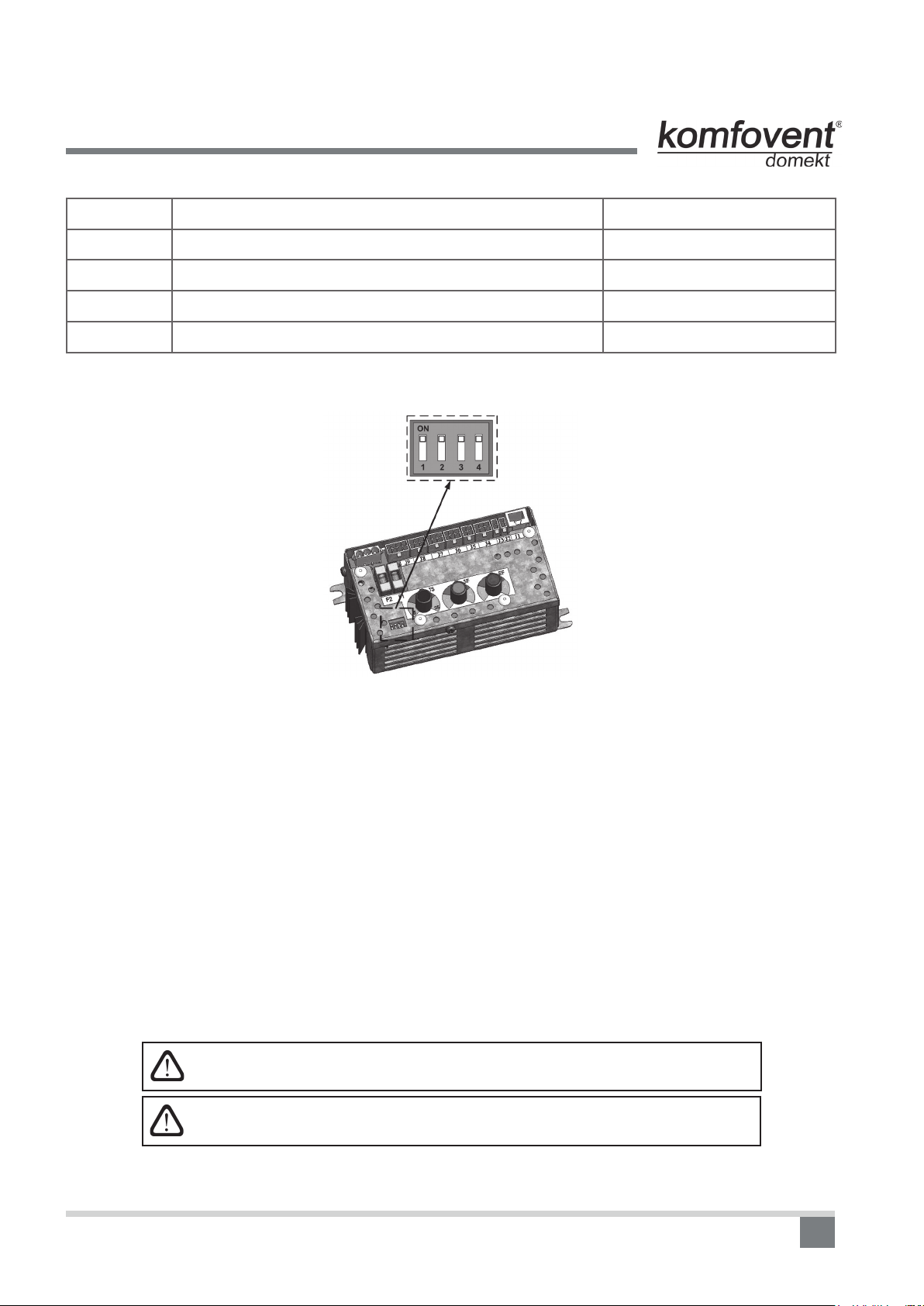

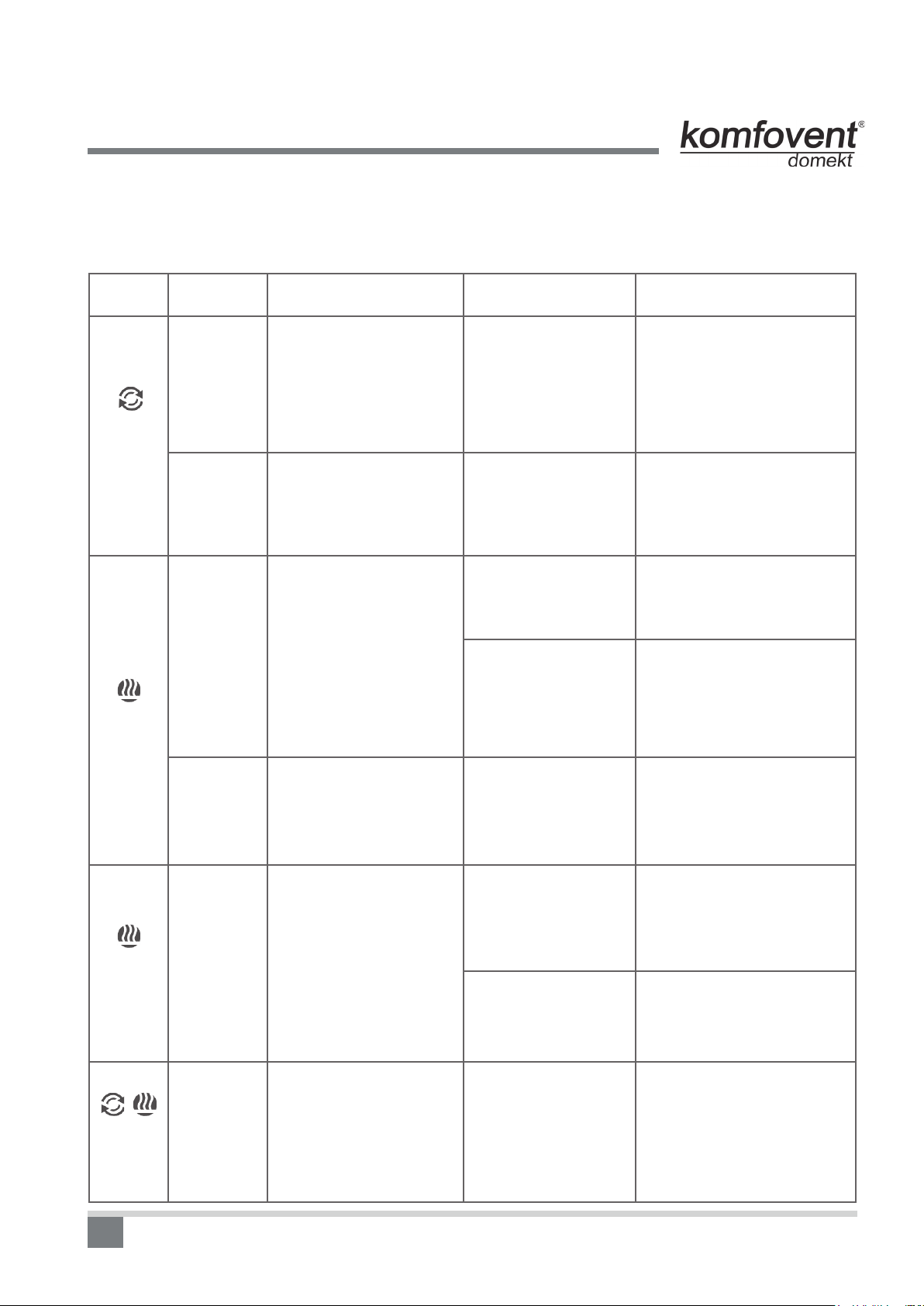

2.9 Table

Failures indicated on the control panel, possible reasons and it elimination

Failure

indication Unit type Protection tripping

description Possible failure cause Failure elimination

Blinks 3

times per

second

Unit with

rotary heat

exchanger

When there is no signal from

the rotor’s rotation sensor, if

the “Winter” season is set,

the unit will stop operating in

2 min. And if “Summer” sea-

son is set, unit will continue

operating.

The belt is broken, fai-

lure of the rotor motor

or rotor sensor.

Check rotor drive and rotation

sensor condition.

Unit with

plate heat

exchanger

If the freezing protection

of the heat exchanger is

activated and is not re-

stored in 10 min, the unit

will stop operating.

Temperature of the

air passing through

plate heat exchanger,

dropped lower allow-

able level.

Check by-pass damper con-

dition and actuator perfor-

mance. It is recommended to

decrease ventilation level.

Blinks 3

times per

second

Unit with

electric

heater

Unit with electric heater

has emergency protection

from overheating at 90°C

with automatic reset and at

120°C with manual reset.

Heater is disconnected

duetolowairow.

When heater cools down, pro-

tection restores automatically.

It is recommended to increase

ventilation intensity level.

Electric heater over-

heating protection is

on.

It is possible to restore emer-

gency overheating protection

with button “RESET” (located

on the heater), only if before

heater overheating cause has

beenclariedandeliminated.

Unit with

water heater

In the unit with water heat-

er, when the water tem-

perature falls below the

permitted value of +9°C,

the unit will stop operating.

Failure of the hot water

preparation and supply

function in the heating

system.

Check circulation pump and

heating system condition,

heating valve actuator per-

formance.

Blinks 8

times per

second

Independent

of unit type

If the supply air tempera-

ture is not of the permit-

ted values: +5°C …-+45°C,

unit will stop operating

with 10 min. delay. When

temperature exceeds the

maximum permitted lim-

its: -30°C...+75°C, the unit

stops operating immedi-

ately.

The supplied air is too

cold or too hot.

Check temperature and sea-

son settings. Check the heat

exchanger and heater opera-

tion.

Supply air temperature

sensor is not connected

or broken down.

It is necessary to check sensor

connections or change the sen-

sor.

+

Blinks

every

second

Independent

of unit type

Depending on the intensity

of unit operation, at a cer-

tain time a periodic inspec-

tion message appears on

the control panel.

---

After disconnecting the

unit from power supply, it

is necessary to carry out

periodic inspection of the unit,

i.e.tochecktheairlterclogging

and the condition of the heat ex-

changer, the heater and fans.