Defro Home NG01 HYDRO User manual

operating manual

controller

NG01 HYDRO

with control panel K100

adapted for operation with HYDROPELL dry stoves fired with pellet

translation of original operating manual

issue 1

September 2019

www. .pl

Table of Contents

Introduction.......................................................................................................................................................................4

Controlpanel.....................................................................................................................................................................5

Keys...............................................................................................................................................................................5

Diodes...........................................................................................................................................................................5

Temperatureindicators..................................................................................................................................................6

Indicators.......................................................................................................................................................................6

Configurationmadebythefitter.........................................................................................................................................6

Configurationofoperationincentralheatingsystem......................................................................................................6

V2outputconfiguration.................................................................................................................................................7

Inputsconfiguration.......................................................................................................................................................7

Operationstatus.................................................................................................................................................................7

Alarms................................................................................................................................................................................8

Messages...........................................................................................................................................................................8

Usermenu.........................................................................................................................................................................9

MenuCustomization......................................................................................................................................................9

MenuCustomizationPower..................................................................................................................................9

MenuCustomizationThermostats..........................................................................................................................9

MenuCustomizationChrono.................................................................................................................................9

MenuSettings..............................................................................................................................................................11

MenuSettingsSettings........................................................................................................................................11

MenuSettingsKeyboardMenu............................................................................................................................12

Informationscreens..........................................................................................................................................................12

Controlofstoveoperation................................................................................................................................................13

Firststart‐upofthestove.............................................................................................................................................13

Stovestart‐up..............................................................................................................................................................13

Operatingpowersetting...............................................................................................................................................13

Workcycle...................................................................................................................................................................13

Stoveshutdown...........................................................................................................................................................13

Stoveemergencyshutdown.........................................................................................................................................13

Workingtimeprogramming.........................................................................................................................................13

4

Introduction

NG01isacontrolsystemforstovesfiredwithpelletandisavailableintwoversions:AirandHydro.

Itischaracterizedby:

easyinstallationanduser,

simpleandintuitiveuserfunctions,

reliableandflexibleoperationofthesoftwarewithproventechnologyfromTiEmmeelettronica,

advancedfunctionsavailablefordesignersallowingadaptationtothevariousstovesandsystems.

Productcomposition:

electronicboardwithdurableandsafe4‐pointfixing

removableconnections

fluegastemperaturesensor

ambientprobe

mainboard‐controlpanelconnectingcable

controlpanelwithantistaticcover

Safetynotice

Priortoinstallationusershouldacquireknowledgeof:

Environmentalandsafetystandards.

Followalllocalregulations,inclusiveofthesegiveninthenationalandEuropeanstandards.

Followallapplicablesafetystandards.

Thisinstructionisintendedonlyfortechnicalpersonnel

DECLARATIONOFCONFORMITY

Appliedregulations:EN60730‐150081‐1EN60730‐1A150081‐2.

Thismanualhasbeenpreparedwithduecare,butinformationmaynotbecomplete,exhaustiveormaycontainerrors.

Therefore,designandinformationmaybechangedwithoutpriornotice.

TiEmmeelettronicashallnotberesponsibleforincompleteorincorrectinformation.

TiEmmeelettronica06055Marsciano(PG)Italy

Tel.+39.075.874.3905;Fax.+39.075.874.2239info@tiemmeelettronica.it

5

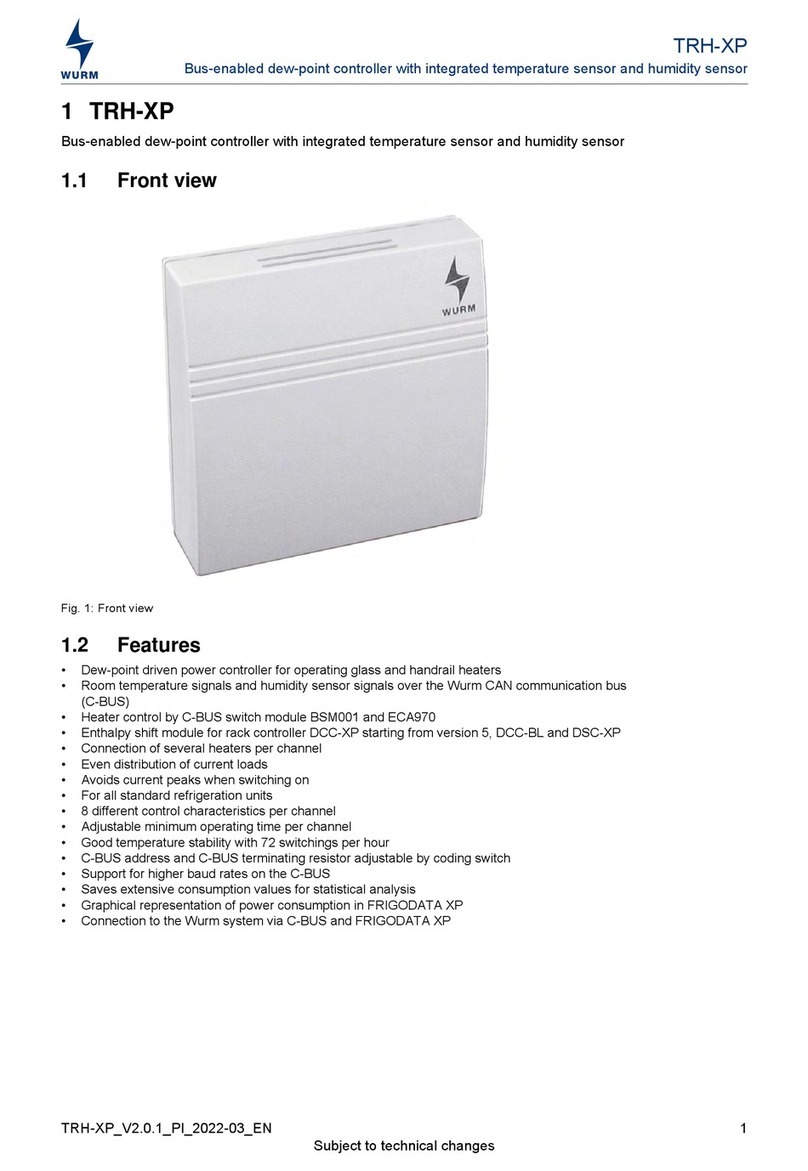

Control panel

Picture1ViewofcontrolpanelK100

Keys

KeyDescription

K1exitfrommenu/submenu

K2ignition/damping(pressfor3sec.)

errorsreset(pressfor3sec.)

activation/lockoftheclock(chrono)

K3entrytomenu/submenuoftheuser1

entrytousermenu2(pressfor3sec.)

saveofsettings

K4exittoinformationscreen,

valueincrease

K5exittoinformationscreen,

valuedecrease

Diodes

DesignationIconDescription

L1clock,currenttime

L2signallingofactivationofchronomode

L3signallingofemptypelletcontainer

L4signallingofreachingremotetemperature

L5signallingofhotwaterdemandinDHW(temperatureincontainerbelow55⁰C,while

thisvaluemaybechangedbythefitter).

L6signallingofreachinglocaltemperature

L

7

or operationmodes

‐summer

‐winter

30

20

15:21

Normalny

ESC

SET

K1

K4

K5

K2

K3

L7L5L3

L2 L4 L6

L1

P1

T1

T2

P2

15:21

6

Temperature indicators

DesignationViewDescription

T1

Localtemperatureset

T2

Currenttemperatureset

Indicators

DesignationViewDescription

P1

Combustionpowerlevel.Mletterstandsformanuallevelsetting,Aletter

standsforautomaticallyselectedlevel(usuallyitisamaximumlevel).

P2Normal Currentoperatingstate

Configuration made by the fitter

Thefitterisobligedtoconfigurethecontrollerafterinstallationofthepelletstoveinthecentralheatingsystem.The

configurationcomprisesofthreestages:

Selectionofhydraulicsystem,

SelectionofcontrolleddevicebyoutputV2(P44),

SelectionofdevicesconnectedtoinputsIN2(P77),IN3(P75),IN6(P78)andIN7(P82),

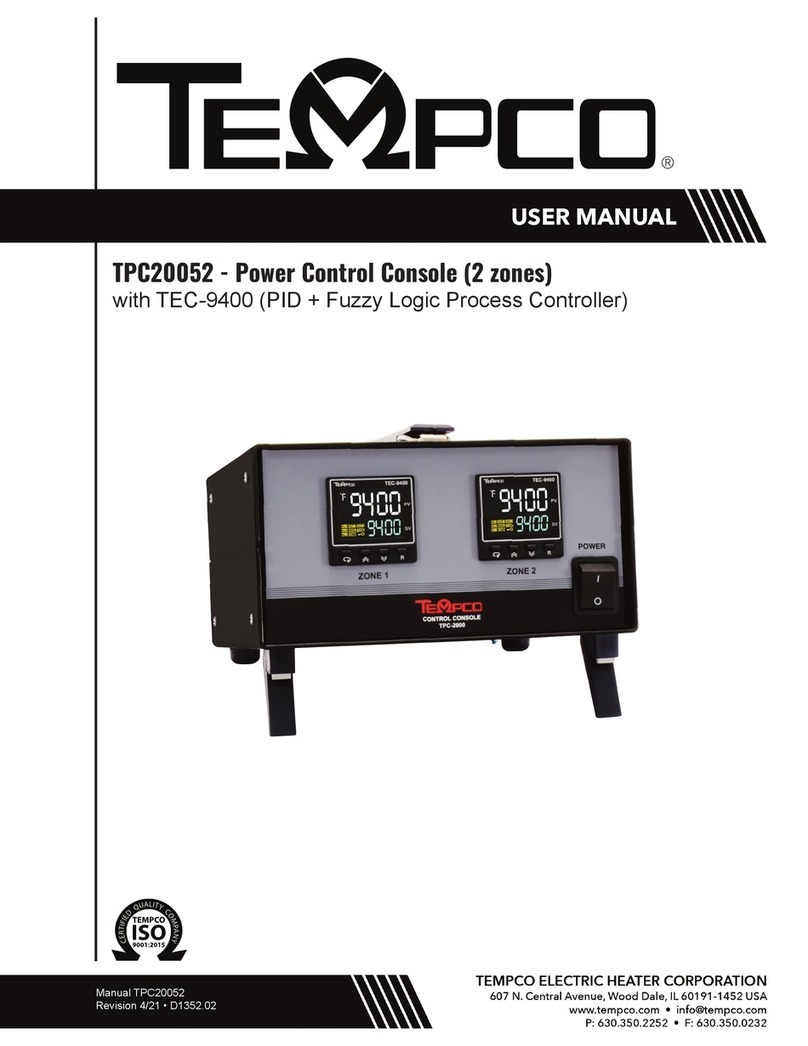

Configuration of operation in central heating system

AfirststepitselectionofhydraulicsystembyparameterP26inoptionKonfiguracja(Configuration)inMenuSystemu

(System)(accessfromMenuModyfikacje(Modifications)Menu).

ConfigurationSchemeofthesystem P26parametervalue

Configuration0

0

Configuration0

0

Configuration2

2

30

20

MA

P1

S1 P2

piec

wymiennik

ciepła

P1

S1 P2

FL

piec

wymiennik

ciepła

P1

S1 P2 S2

zbiornik

cwu

piec

wymiennik

ciepła

7

Configuration5

5

V2 output configuration

NextstepistheconfigurationofoutputV2(P44)specifyingtheequipment,whichshouldbecontrolledbythisoutput.

DeviceParameter OutputV2(P44)

None‐outputblocke

d

0

Pelletsafetyvalve1

Loadingmoto

r

2

Outputunderthermostat3

Fluegasfan25

Hotairfan6

Airvalve7

Errormessage11

S

olenoidvalvewith2wire

s

15

S

crewconveyor217

Cleaningmoto

r

25

Inputs configuration

ThelaststageofconfigurationisthedefinitionofequipmentconnectedtoIN2,IN3,IN6,IN7inputs.

DeviceParamete

r

Inputs

IN2(P77) IN3(P75)IN6(P78)IN7(P82)

None‐inputnotconnecte

d

0

Doorsenso

r

2

Pelletthermostat3

Ambientthermostat4

Flowswitch5

Pelletlevelsenso

r

6

Domestichotwaterprobe9

Limitswitchforcleaningthemoto

r

12

Ambientprobe15

Primaryairflowcontrolle

r

16

Externalclock(Chrono) 17

Inputofencoderofconveyingscrew 28

Waterpressuresenso

r

29

Operation status

Nameofoperatingstatesisdisplayedoncontrollerdisplayduringoperation.

StatusCode

S

witchedoff ‐

CheckingChEc

FiringupOn1

S

tabilization On

5

Normal ‐

Modulation Mo

d

S

tan

d

by

S

tby

DampingOFF

S

on

d

ChEc

Operation Alt

Firinguprepeat rEc

P1

S1

piec

wymiennik

ciepła

8

Alarms

CodeDescription

Er01InterventionofsafetypressureswitchHV1:signallingevenwhencombustionfanisWYŁ./OFF

Er02InterventionofsafetypressureswitchHV2:signallingwhencombustionfanisWŁ./ON

Er03Dampingduetodecreaseoffluegasestemperature

Er04Dampingduetotheexcessivetemperature ofwater

Er05Dampingduetoexcessivefluegasestemperature

Er06Pelletthermostatopened(returnofflamefrombrazier)

Er07Combustionfanencoder:lackofencodersignal(ifP25=1or2)

Er08Combustionfanencoder:failureoffanspeedadjustment(ifP25=1or2)

Er09Lowpressureofwater(issystemisWYŁ./OFForinmodeBlok(Block)andpumpP1isswitchedoff

thentheerrorisnotreported

Er1

0

Highpressureofwater

Er11Incorrectvaluesoftime/dataafterprolongedmainspowerfailure

Er12Ignitionfailed

Er15Mainssupplyinterruption

Er16RS485communicationerror

Er17Airflowadjustmentfailed

Er18Nofuel

Er23BoilerofDHWsensoropened

Er25Cleaningmotordamaged

Er3

9

Damagedsensorofflowmeter

Er41MinimumflowofairinControl/Checkingmodeshasnotbeenreached

Er42Maximumflowofairexceeded(FL40)

Er44Doorserror

Er47Conveyingscrewencoder:lackofencodersignal(ifP81=1or2)

Er48Conveyingscrewencodererror:speedadjustmentfailed(ifP81=1or2)

ServiceServiceerror.InformsthatthehoursplannedforMaintenance1function(parameterT66)have

beenreached.Contacttheauthorizedservicecenter.

Messages

CodeDescription

PRobFaultduringinspectionofsensorduringChecking/Inspectionstage

CleanInformsthatthehoursplannedforoperaiton(parameterT67)havebeenreached.

DoorDoorsareopen

IgnitionBlockMessageappearsifthesystemisswitchedoffduringignition(afterpreliminaryloading)by

externaldevice:systemstopsonlywhenitswitchestoPracy/Workmode.

LinkErrorLackofcommunicationoftheLCDpanelandcontrolboard

CleaningOnPeriodiccleaninginprogress

9

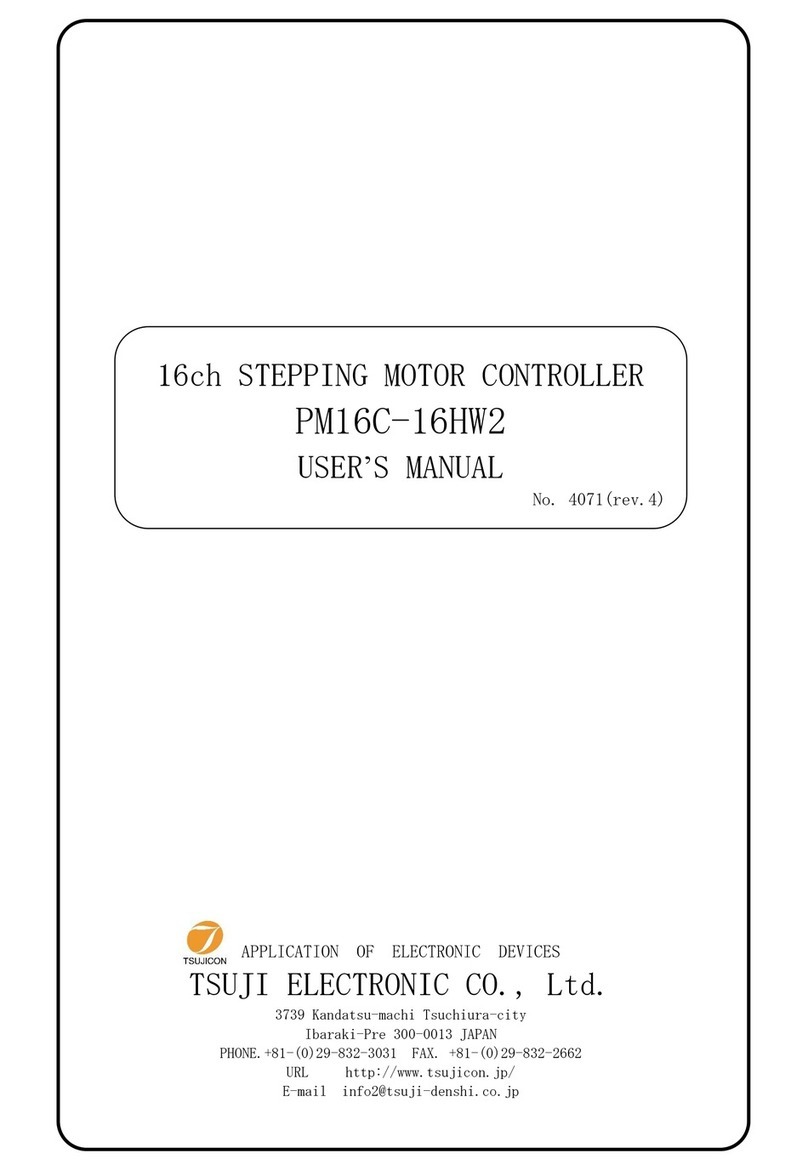

User menu

Menu Customization

MenuCustomizationisintendedforcontrolofcurrent

operationofthestoveby:

poweradjustment‐Power,

thermostatssettingsmenu‐Thermostats,

workingtimeprogramming‐Chrono,

forcingofendlessscrewloading–Manual

Load.

CustomizationMenuwillbedisplayedafterpressing

key.

Menu Customization Power

Contentofthisscreendependsonconfigurationofthe

hydraulicsystem.Forthesimplestconfigurationthereis

onlyanoptiontoadjustcombustionpower.

Combustionmenuisusedtoadjustpowerofthestove

intherangeofsixlevels(from1to6).Firststage

correspondstominimumpowerofthestove(approx.

40%ofnominalpower)andthelastonetothenominal

power.

Selectrequiredlevelwithakey.

Confirmtheselectionwithakey.

Menu CustomizationThermostats

Thismenuallowschangingvaluesoftemperatureof

stovethermostat.

Boiler‐setvalueiswithinthedeterminedlimits

betweenthegivenMaxandMinvalues:

Selectrequiredvalueofwatertemperaturein

boilerusingkeysand.

Confirmthesettingwithakey.

Menu Customization Chrono

Chrono,thatistimeprogrammerallowssettingand

activationofaprogrammecontrollingthedurationof

stoveoperation.

Modalitymenuisusedtoselectmodeof

programmeoperation,

Programmenuisusedtosetoperatingtimes

foreachmode.

Chrono Modality

Itallowsselectingoneofthemodesorlockingoperation

oftheprogram.

entertothemodewithakey,

selectrequiredmodeDaily,WeeklyorWeek‐

end)usingkeys,

SwitchingON/OFF(programswitchon/off)

optionbypressingbutton,

confirmnewsettingspressingthekey.

Menu Customization

Power

Thermostats

Chrono

Manual Load

Power

Combustion

Combustion

Pot 4

Thermostats

Boiler

Boiler

Max: 75

Set: 51

Min: 50

Chrono

Modality

Program

SET

SET

10

Chrono Program

Thismenucanbeusedtoprogrameachofprogram

modesbydeterminingtimesofswitchingonandoffof

thestove:

selectthemodewithakeys,

entertheprogrammingwithakey.

Chrono Program Daily

Dailymodeallowssettingstoveswitchingon/offtimes

individuallyforeachdayoftheweek.Theotherdaysof

theweek(Saturday,Sunday)willbedisplayedafter

pressingkeys,whenthecurrentlyselecteddayis

MondayorFriday,respectively,(firstorlastitemonthe

list).

selectdayusing

keys,forwhichyou

wanttospecifytimesofswitchingonand

switchingoff,

pressbutton

Screen,whereyoucansetmaximumthreeoperation

cyclesduringtheday,willbedisplayedafterselectionof

aday.

Chooseselectedfieldoftime(00:00)withkeys

.SwitchingontimeisenteredinON

column,whileswitchingofftimeinOFF

column

Presskey,toconfirmselectionofhoursor

minutesfield.

Selecthourandminutes(with15‐minutes

interval)withthekeys

Confirmselectedvaluewithakey.

Repeatoperationsfortheotherfields.

Eachcyclecanbeactivatedorblockedpressing

abutton.Activetimeintervalismarkedby

fillingabulletprecedingeachofthecycles(‐

active,‐inactive).

Chrono Program Weekly

Weeklymodeallowssettingonlyonesetoftimesfor

switchingonandoffthestove,whichwillbeapplicable

foreachdayoftheweek.

Intervalsaresetinthesamewayaspreviouslydescribed

forDaily(Codzienny)mode.

Chrono Program Week-end

Intervalsaresetinthesamewayaspreviouslydescribed

forDaily(Codzienny)mode.

MenuCustomization Manual Load

Theprocedureforcesloadofpellet.Loadingis

automaticallystoppedafter300seconds.Toactivatethis

functionitisrequiredtoselectpreviouslyOFFoption.

Onlyforlocalpanel.

Modality

Daily << <<

Weekly

Week End

OFF

SET

Program

Daily

Weekly

Week-end

SET

Daily

Monday

Tuesday

Wednesday

Thursday

Friday

SET

SET

Daily

Monday

ON OFF

o00:00 - OO:00

o 00:00 - 00:00

o 00:00 - 00:00

Weekly

Mon-Sun

ON OFF

o00:00 - OO:00

o 00:00 - 00:00

o 00:00 - 00:00

Week-end

Mon-Fri

Sat-Sun

Week-end

Mon-Fri

ON OFF

o00:00 - OO:00

o 00:00 - 00:00

o 00:00 - 00:00

11

Menu Settings

Thismenucontainsthreeoptions:

Settings–additionalconfigurationofstove

operation

KeyboardMenu–settingofdisplayoperation

parameters

SystemMenu–accessafterenteringthe

password;menucontainsoptionssetbythe

fitterorservicetechnician.

Menu Settings Settings

Configurationcontains:

TimeandDate

Language

Remotecontrol

AugerCalibration

FanCalibration

Summer‐Winter

AutomaticPower

Settings Time and Date

Settingofcurrentdataandtime.

Selectfieldwiththekeys,

Confirmselection,

Usingthekeyssetthevaluesfor:hour,

minute,day,monthoryear.

Settings Language

Selectionoflanguageforthemessagesfromthe

controller.

Settings Remote control

Switchingonorswitchingoffthecontrolbyremote

module.

Settings Auger Calibration

Calibrationofendlessscrewallowschangingspeedof

operationordurationofoperationofdriveofthe

conveyingscrew.Factorysettingis0,whilevaluesetby

theusershouldbebetween‐7to7.

Settings Fun Calibration

Fancalibrationisintendedforchangingoffluegasfan

speedfrom‐7to7inrelationtothefactorysettings

(value0).

SettingsSummer-Winter

Thissettingallowsselectingoperatingmodeofthe

hydraulicsystemdependingontheseason.

Manual Load

ON <<

OFF

Menu Settings

Settings

Keyboard Menu

System Menu

SET

Time and Date

17 :22

Wednesday

18 / 09 / 2019

Language

Latviesu

Lietuviu

Magyar

Nederlandse

Polski

Remote Control

ON <<

OFF

Auger Calibration

Max: 7

Set: 0

Min: -7

Fun Calibration

Max: 7

Set: 0

Min: -7

12

Settings Automatic Power

Thissettingallowsselectingmodeofpowermodulation.

SelectingoptionONthestovesystemwillchoosepower

(automaticmode).InthiscasedontappearMenu

Customization

Power

Combustion.SettingOFF

optionallowuserchoosethepowerlevelin

CustomizationLevel

Power

Combustion.

Menu SettingsKeyboard Menu

Displaymenucontainsfunctionsresponsibleforcontrol

ofitsoperations:

ListaAdresow(Addresslist)

Contrast

Backlight

TonePrzyciski(Buttonstone)

Modyfikacje (Modifications) Menu Menu

wyświetlacza (Display menu) Lista

Adresów (Address list)

Addresslistcontainslistofcooperatingdevices

connectedwiththecontroller.Eachitemofthelist

containsaddress,typeandversionofsoftware.

Designationoftypes:

MSTR –masterdevice

INP –input

KEYB –Keyboard

OUT–output

CMPS–complexequipment

SENS–sensor

COM–communicationlink

Keyboard Menu Contrast

Thisoptionisusedtoadjustcontrastofthedisplay

Keyboard Menu Min Light

Thisscreencanbeusedtosetadegreeofscreen

backlight.

Keyboard Menu Mute Keys

ButtonsTonemenuallowsswitchingonandoffasound

duringpressingofpanelcontrolbuttons

Information screens

Informationoncurrentparametersofboileroperation

aredisplayedontwoscreenstitledInformacja

(Information),whicharerecalledbybuttons.

Screendisplayedwithabutton:

ExhaustT.–temperatureoffluegas

BoilerT.–watertemperatureinheatexchanger

BufferT.–watertemperatureinbuffertank(DHW)

(ifinstalled)

Settings

Summer-Winter

Automatic Power

AUTOMATIC POWER

ON <<

OFF

Menu Wyswietlacza

Lista Adresow

Kontrast

Podswietlenie

Tone Przyciski

1. FSYSR02000002.

2. -MSTR - FW 1.5 0

2.FSYSF04000035

6 - KEYB - FW 1.4.0

Contrast

+

-

8

Min Light

+

-

8

Mute Keys

ON <<

OFF

13

Fan[rpm] –rotationalspeedoffluegasfan

Auger[s]–operationtimeofendlessscrew

Screendisplayedwithabutton:

Pressure[mbar]–waterpressureincentralheating

system

Worktime[h] –operatingtimeofstoveinNormal,

Modulationmodes.

Ignitions–numberoffiringupcycles

Prod.Code.–productcode

Control of stove operation

First start-up of the stove

Duringfirststart‐upofthestoveorwhenitisstated

afterrefuellingresultingfromcompletecombustionof

pellet.

Turnonthepower

SwitchonpelletendlessscrewMenu

CustomizationManualLoadusingoption

ON,whenyouhearasoundoffallingpellet,

switchoffusingOFFoption.

SwitchonRozpalanie/Firingupwith

button.

Thestovewillswitchtofiringupandwill

continueoperationinautomaticmode.

Stove start-up

Turnonthepower.

Pressbutton.

Thestovewillswitchtofiringupandwill

continueoperationinautomaticmode.

Operating power setting

InMenucustomization

Power

Combustionthereis

a7‐stagecontroller,whichcanbeusedforcontrolof

stovemaximumpower.Thestoveisoperatingonpower

6bydefault,thatisituseswholepowerforheatingof

water.ThisstatusisindicatedbyaletterAonP1

indicatorofcontrollerdisplay.Whenuserdecreases

powerinthemenuitwillbereflectedinP1index,letter

MwillappearinsteadofletterA.Decreasingcombustion

powerresultsinprolongationoftimeforreachingofset

watertemperature,decreasingatthesametime

portionsofsuppliedpellet.

Work cycle

Afterinitiationofthefiringthestoveswitches

successivelytothefollowingoperationmodes:

Checking

Probe

Firingup

Stabilization

Operation

Modulation

Standby

Damping

Presentedcycleisrepeatedautomaticallytomaintain

constantpowerofthestoveandtemperatureofwater

instove.Duringoperationtemperatureofwatermay

increaseordecrease,butitalwaysshouldoscillate

aroundthesetvalue.

Stove shutdown

Stove,inanyoperatingmode,canbeswitchedoffby

button,whatresultsinautomaticswitchingto

Dampingmode.Aftercompletionofthiscyclethestove

switchestoOffmodeandinthismodeyoucansafely

shutdownsupplyofthestove.

Stove emergency shutdown

Incaseofemergencythestovecanbeimmediately

switchedoffbydisconnectingpowersupply‐using

switchorpullingouttheplugfromasupplysocket.A

smallpartofpelletinburnerwillbecombustedduring

severalsecondsandflamewillbedamped.

Working time programming

Thestovecanbeprogrammedforscheduledoperation

usingMenuCustomization

Chrono

Modality.

Selectedmodecausesswitchingonandoffthestovein

accordancewiththeperiodssetinMenu

Customization

Chrono

Programwithaprogramme

correspondingtothegivenmode.Timeprogramming

detailsaredescribedinthechapterMenu

Customization,subsectionChrono.

Informations

Exhaust T. [

o

C] 101

Boiler T. [

o

C] 65

Buffer T. [

o

C] 36

Fan [rpm] 0

Auger [s] 0.0

Informations

Pressure [mbar] 0

Work time [h] 65

Ignitions 11

Prod. Code: 562 0

14

15

DEFRO Spółka z ograniczoną odpowiedzialnością Sp. k.,

00-403 Warszawa, ul. Solec 24/253,

Manufacturing plant:

Ruda Strawczyńska 103 A

26-067 Strawczyn, tel.: 41 303 80 85,

fax: 41 303 91 31, biuro@defro.pl,

Table of contents