Enertronica Santerno BRIDGE MINI User manual

USER MANUAL

BRIDGE MINI

15P4600B100 REV 02

1/38

BRIDGE MINI

USER MANUAL

Installation, use and maintenance

English

15P4600B100

2021/04/12 R.02

USER MANUAL

BRIDGE MINI

15P4600B100 REV 02

2/38

USER MANUAL

BRIDGE MINI

15P4600B100 REV 02

3/38

INDEX OF REVISIONS:

In this Bridge Mini Manual R.02 the following topics have been added, changed or deleted compared to the

previous revision R.01.

TECHNICAL DATA, BENEFITS and TROUBLESHOOTING.

•This manual is integrant and essential to the product. Carefully read the instructions contained herein

as they provide important hints for use and maintenance safety.

•This device is to be used only for the purposes it has been designed to. Other uses should be considered

improper and dangerous. The Manufacturer is not responsible for possible damages caused by improper,

erroneous and irrational uses.

•Enertronica Santerno is responsible for the device in its original setting.

•Any changes to the structure or operating cycle of the device must be performed or authorized by

Enertronica Santerno.

•Enertronica Santerno shall hold no responsibilities for any consequences caused by use of non-original

spare-parts.

•Enertronica Santerno reserves the right to make any technical changes to this manual and to the device

without prior notice. If printing errors or similar are detected, the corrections will be included in the new

releases of the manual.

•The information contained herein is the property of Enertronica Santerno and cannot be reproduced.

Enertronica Santerno enforces its rights on the drawings and catalogues according to the law.

USER MANUAL

BRIDGE MINI

15P4600B100 REV 02

4/38

SOMMARIO

1. GENERAL DESCRIPTION .........................................................................................7

1.1. PRODUCT OVERVIEW ...........................................................................................................................9

1.2. CAUTION STATEMENT ........................................................................................................................10

1.2.1. Symbols and levels of warning message in the document..........................................................10

1.2.2. Intended use.................................................................................................................................10

1.2.3. Qualified technical personal.........................................................................................................10

2. INSTALLATION........................................................................................................11

2.1. BRIDGE MINI EMBEDDED....................................................................................................................11

2.2. BRIDGE MINI STAND ALONE (DIN-RAIL MOUNTING).......................................................................13

3. TECHNICAL DATA...................................................................................................14

3.1. NAMEPLATE..........................................................................................................................................14

3.2. ENVIRONMENTAL REQUIREMENT.....................................................................................................14

3.3. ELECTRICAL SPECIFICATION.............................................................................................................15

3.4. DIMENSION AND WEIGHT...................................................................................................................15

3.5. CONNECTION OF POWER PORT AND SIGNAL PORT......................................................................16

3.5.1. Power supply port ........................................................................................................................16

3.5.2. Signal port....................................................................................................................................16

4. BENEFITS.................................................................................................................24

4.1. DATALOGGING.....................................................................................................................................24

4.2. DATA CONCENTRATOR ......................................................................................................................24

4.3. DATA PROXYING..................................................................................................................................24

4.4. DOWNLOAD DEI LOG...........................................................................................................................25

4.5. INVERTER FIRMWARE UPGRADE......................................................................................................25

5. DATALOGGER CONFIGURATION: WEB INTERFACE..........................................25

5.1. LOGIN ....................................................................................................................................................25

5.2. HOME.....................................................................................................................................................26

5.3. SETTINGS..............................................................................................................................................26

5.3.1 Devices.........................................................................................................................................26

5.3.2 Measurements..............................................................................................................................29

5.3.3 Time Zone....................................................................................................................................30

5.3.4 Network........................................................................................................................................31

5.3.5 Serial Ports...................................................................................................................................32

USER MANUAL

BRIDGE MINI

15P4600B100 REV 02

5/38

5.3.6 Logging.........................................................................................................................................32

5.4 ALARMS.................................................................................................................................................32

5.5 DOWNLOADS........................................................................................................................................33

5.6 STATISTIC .............................................................................................................................................33

5.7 CONNECTION TO INTERNET ..............................................................................................................33

6. REMOTE MONITORING...........................................................................................34

6.1. SANTERNO.IO.......................................................................................................................................34

6.2. MOBILE APP..........................................................................................................................................34

7. SERVICES................................................................................................................35

7.1. PREREQUISITES FOR REMOTE COMMUNICATIONS ......................................................................35

7.2. REMOTE CONNECTION SECURITY....................................................................................................36

7.3. DATA REFRESH RATE AND EXTERNAL QUERIES...........................................................................36

8. TROUBLESHOOTING..............................................................................................36

8.1. CONNECTION TEST.............................................................................................................................36

8.2. DEVICES OFFLINE................................................................................................................................36

9. ANNEX......................................................................................................................37

9.1. PURCHASE CODES..............................................................................................................................37

Figure 1 - Plant Connection Example 1............................................................................................................. 7

Figure 2 - Plant Connection Example 2............................................................................................................. 8

Figure 3 - Plant Connection Example 3............................................................................................................. 8

Figure 4 - Bridge Mini Embedded (Top View) ................................................................................................... 9

Figure 5 - Bridge Mini Stand Alone.................................................................................................................... 9

Figure 6 - Embedded Installation (Top view)................................................................................................... 12

Figure 7 - Embedded installation (Bottom view).............................................................................................. 12

Figure 8 - Connection view 1........................................................................................................................... 13

Figure 9 - DIN-rail mounting ............................................................................................................................ 13

Figure 10 - Nameplate..................................................................................................................................... 14

Figure 11 - Recommended wiring diagram for the connection of 2-wire MODBUS devices .......................... 17

Figure 12 - RS485 COM 1 Serial port pin-out ................................................................................................. 19

Figure 13 -RS485 COM 2 Serial port pin-out .................................................................................................. 19

Figure 14 - Configuration of the dip switch CN6-COM1.................................................................................. 20

Figure 15 - Configuration of the dip switch CN2-COM2.................................................................................. 20

Figure 16 - Cable of Cat. 5 for Ethernet and standard color arrangement in the connector........................... 22

Figure 17 - Standard Eth Connector............................................................................................................... 22

Figure 18 - Login Page.................................................................................................................................... 25

USER MANUAL

BRIDGE MINI

15P4600B100 REV 02

6/38

Figure 19 - Home page Bridge Mini................................................................................................................. 26

Figure 20 - Device Page.................................................................................................................................. 27

Figure 21 - Device Configuration..................................................................................................................... 28

Figure 22 - Measurements Configuration........................................................................................................ 29

Figure 23 - Time Zone Configuration............................................................................................................... 30

Figure 24 - Networking Page........................................................................................................................... 31

Figure 25 - Serial Ports configuration.............................................................................................................. 32

Figure 26 - Setting Loggind period .................................................................................................................. 32

Figure 27 - Download Page............................................................................................................................. 33

Figure 28 - Home Page Santerno.io................................................................................................................ 34

Figure 29 - App................................................................................................................................................ 35

USER MANUAL

BRIDGE MINI

15P4600B100 REV 02

7/38

1. GENERAL DESCRIPTION

Bridge Mini is a datalogger, designed for remote monitoring and assistance purposes, offering features such

as the acquisition of measures and indicators, the representation of energy production patterns, the upgrade

of the connected inverter firmware and the log download, with a simple browser web interface.

Bridge Mini can manage devices of any brand and model, using standard IoT protocols and industrial protocols.

Compact and performing, it is available in two variants:

- Embedded: mounted inside a Santerno inverter and powered directly by the inverter itself, thus offering

maximum convenience and an easy installation.

- Stand-alone: with DIN support.

Bridge Mini may be interconnected with the plant devices through two serial connections (RS485 ports) with

Modbus RTU protocol, called COM1 (non isolated) and COM2 (isolated) and an Ethernet port (LAN) with

TCP/IP protocol.

Also, it allows to connect USB 2.0 flash drives to download the logs.

It is connected to the Santerno Cloud via secure and encrypted connections through the Internet, to allow

remote monitoring and remote assistance.

Figure 1 - Plant Connection Example 1

USER MANUAL

BRIDGE MINI

15P4600B100 REV 02

8/38

Figure 2 - Plant Connection Example 2

Figure 3 - Plant Connection Example 3

USER MANUAL

BRIDGE MINI

15P4600B100 REV 02

9/38

1.1. Product Overview

Figure 4 - Bridge Mini Embedded (Top View)

Position

Description

1

LAN

ETHERNET 10/100Base-TX IEEE 803 3 connection

2

COM 2

RS485 optically isolated connection

3

COM 1

RS485 non isolated connection

4

USB

USB 2.0 host interface

5

LED

LED board/communication status

6

Micro SD

Additional Micro SD Flash Memory reader - not implemented yet

7

RTC

Real Time Clock

Figure 5 - Bridge Mini Stand Alone

2: COM 2

3: COM 1

2: LAN

1: PWR

4: USB

3: COM 2

4: USB

1: LAN

5: LED STATUS

6: MICRO SD

7: RTC -back

USER MANUAL

BRIDGE MINI

15P4600B100 REV 02

10/38

Position

Description

1

PWR

9 –36 Vdc power supply

2

LAN

ETHERNET 10/100Base-TX IEEE 803 3 connection

3

COM 2

RS485 optically isolated connection

4

USB

USB 2.0 host interface

1.2. Caution statement

1.2.1. Symbols and levels of warning message in the document

The following levels of messages are used through the document:

DANGER

Indicates a hazardous situation which, if not avoided, will result in

death or serious injury due electric shock.

WARNING

Indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION

Indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTE

Indicates a situation which, if not avoided, can result in property

damage.

PROHIBITION

Indicates an operation must not be carried out

INFORMATIVE

Information that is important for a specific topic or goal, but is not

safety-relevant

1.2.2. Intended use

Bridge-Mini is a monitoring equipment designed for data collection and low-voltage connection to

inverters, power meters and other equipment.

PROHIBITIO

N

It is absolutely forbidden to modify the equipment.

Any modification, manipulation, or alteration not expressly agreed

with the manufacturer, concerning either hardware or software,

shall result in the immediate cancellation of the warranty.

1.2.3. Qualified technical personal

All work on Bridge Mini products must be carried out by skilled technical personnel only.

By skilled personnel it is intended persons who have been suitably trained to carry out the work in question.

USER MANUAL

BRIDGE MINI

15P4600B100 REV 02

11/38

2. INSTALLATION

2.1. Bridge Mini Embedded

Product-Accessory compatibility

Product

Bridge-Mini Embedded

Comments

Sinus Penta

√

Penta Marine

√

Iris Blue

√

Solardrive Plus

√

Sunway TG BT

√

Sunway TG TE

√

Table 1: Bridge-Mini product compatibility

DANGER

Before gaining access to the components inside the inverter, remove

voltage from the inverter and wait at least 20 minutes. Wait for a complete

discharge of the internal capacitors to avoid any electric shock hazard.

CAUTION

Electric shock hazard: do not connect/disconnect the signal terminals or

the power terminals when the inverter is on.

This also prevents the inverter from being damaged.

NOTE

All the screws used to fasten removable parts (terminals cover, serial

interface connector, cable plates, etc.) are black, round-head, cross-head

screws.

When wiring the inverter, remove only this type of screws.

If different screws or bolts are removed, the inverter warranty will be no

longer valid.

Bridge Mini Embedded can be directly installed onto a Santerno inverter.

The board is connected to the inverter control board (either a ES821 or a ES927) via the slot B, through the

strip connection and fixed on the dedicated support.

1. Remove voltage from the inverter and wait at least 20 minutes

2. The electronic components in the inverter and the communications board are sensitive to electrostatic

discharge.

Be careful when you reach the component parts inside the inverter and when you handle the communications

board. The board should be installed in a workstation equipped with proper grounding and provided with an

antistatic surface.

If this is not possible, the installer must wear a ground bracelet properly connected to the PE conductor.

USER MANUAL

BRIDGE MINI

15P4600B100 REV 02

12/38

3. Remove the cover allowing gaining access to the inverter control terminals. The fixing spacers and

the signal connector are located on the right

4. Fit Bridge-Mini Embedded board and make sure that all contacts enter the relevant housing in the

signal connector. Fasten the board to the fixing spacers using the screws supplied.

5. Connect the communications cables to the relevant ports based on the type of communications to be

established. Set DIP-switches accordingly (see sections below).

6. Close the inverter frame by reassembling the cover, allowing access to the inverter control terminals

Figure 6 - Embedded Installation (Top view)

Figure 7 - Embedded installation (Bottom view)

When the data logger is embedded it is located on slot B (ES821 and ES927) of the inverter and is directly

powered.

SCREW

DIP-SWITCH 1

LED COM2 Tx Status

LED Reset Board

SLOT B

LED COM2 Rx Status

LED USB Status

DIP-SWITCH 2

Micro SD Reader

RTC Li Battery

USER MANUAL

BRIDGE MINI

15P4600B100 REV 02

13/38

2.2. Bridge Mini Stand Alone (DIN-Rail Mounting)

WARNING

Ensure a proper electrical connection between the mounting rail contact

and the mounting rail in order to guarantee sufficient grounding and to

avoid electric shock in the event of an error. Observe the properties of the

mounting rail.

Bridge Mini can be inserted on a DIN-Rail, placed on its back, which allows an easy hooking in any position of

the cabinet.

To release Bridge Mini, push the tab and release the handle so that it clicks into place.

Figure 8 - Connection view 1

Figure 9 - DIN-rail mounting

USER MANUAL

BRIDGE MINI

15P4600B100 REV 02

14/38

3. TECHNICAL DATA

3.1. Nameplate

Bridge-Mini Standalone nameplate indicates the product’s technical data and identification details.

1) Name of the product.

2) Part number assigned to the product by Enertronica Santerno.

3) Technical data (input voltage and current range, rated power, etc.)

4) CE marking and indications of the relative reference Standards applied in the construction of the

equipment (CE is a registered collective trademark).

5) Product revision index.

6) Serial Number: identifies the product serial number.

The nameplate measures 100 x 70 mm and it is silver in color. Example of a nameplate on Bridge-Mini

Standalone:

Figure 10 - Nameplate

3.2. Environmental requirement

Operating

Operating ambient temperature

–25 to +55°C ambient temperature

(please contact Enertronica Santerno S.p.A. for higher ambient

temperatures)

Operating ambient humidity

5 to 95% (non-condensing)

Max. operating altitude

2000 m a.s.l.

1

2

3

5

4

6

USER MANUAL

BRIDGE MINI

15P4600B100 REV 02

15/38

(please contact Enertronica Santerno S.p.A. for installation above

2000 m and up to 4000 m)

Installation site

Indoor

Degree of protection

IP20

Pollution degree

2

Transport and storage

Ambient temperature for storage and transport

–25 to +60°C

Ambient humidity for storage

From 5% –95%, from 1 g/m3–25 g/m3, with no

condensation or ice formation

Ambient humidity for transport

Maximum 95% up to 60 g/m3.

Slight condensation may occur when the equipment is

not running

Atmospheric pressure for storage

86 –106 kPa

Atmospheric pressure for transport

70 –106 kPa

3.3. Electrical specification

Hardware

CPU

Colibri iMX6DL

DRAM

512 MB

Flash Memory

4 GB

Bridge-Mini Embedded

It is directly connected to the inverter, so it does not need an external power supply.

Bridge-Mini Standalone

Input Voltage Range

9 –36 Vdc

Max Input Current

0.232 –0.056 A

Max Input Power

2.1 W

3.4. Dimension and weight

Bridge-Mini Standalone

Dimension W x H x D [mm]

60.6 x 140 x 100

Weight [kg]

0.44

USER MANUAL

BRIDGE MINI

15P4600B100 REV 02

16/38

3.5. Connection of power port and signal port

3.5.1. Power supply port

Bridge-Mini Embedded

It is directly connected to the inverter, so it does not need any external power supply cables.

Bridge-Mini Standalone

Cables coming from an external power supply must be connected directly to the PWR connector:

Decisive voltage class A according to EN 61800-5-1

TERMINAL

N. of

connectable

cable

Rated

Insulation

Voltage

[V]

Max allowable cable

cross section

[mm2]

Tightening torque

[Nm]

PWR (+,-)

2

300

0.14 –1.5

0.22 –0.25

NOTE

Check the polarity of connection, miswiring could cause damage on Bridge-Mini

Standalone.

3.5.2. Signal port

CAUTION

Remove voltage from the inverter before wiring Bridge-Mini Embedded

board.

Take any safety measure required before touching the connectors and

handling the Bridge-Mini Embedded board.

Bridge-Mini is provided with the following serial communications ports:

Port

Description

Terminal Board

Link

COM1 RS485

Slave supervisor connection

ES1007B3 –CN6

DB9 –Male

COM2 RS485

Master supervisor connection

ES1007B3 –CN2

DB9 - Female

LAN

Ethernet connection

ES1007B3 –CN3

RJ45

USB

USB 2.0 connection

ES1007B3 –CN1

USB - Male

3.5.2.1. RS485 (COM1, COM 2)

RS485 links are needed for certain communication options required by Bridge-Mini:

USER MANUAL

BRIDGE MINI

15P4600B100 REV 02

17/38

- Direct connection to a computer with a properly wired cable and an RS485/USB converter

(MODBUS RTU protocol in slave mode or PPP protocol);

-Direct connection to the multidrop network of the plant’s devices (MODBUS RTU in master

mode).

The MODBUS-IDA (http://www.modbus.org) Association defines the type of connection for MODBUS

communications over serial link RS485, used by the drive, as a “2-wire cable”.

Specifications are:

Type of cable

Shielded cable made up of a balanced pair known as D1/D0 +

common conductor.

Recommended cable model

Belden 3106A Paired EIA Industrial RS485 PLTC/CM

AWG23 corresponding to 0.258 mm2.

For long lengths it is advisable to use a larger section, up to 0.75 mm2.

Maximum length

500 meters based on the max. distance measured between two

stations.

Characteristic impedance

Greater than 100 Ω (recommended), typically 120 Ω.

Standard colors

Yellow/brown for the D1/D0 pair, grey for the “Common” signal

The typicalwiring diagram recommended by the MODBUS-IDA Association for the connection of “2-wire”

devices is shown in the following figure.

Figure 11 - Recommended wiring diagram for the connection of 2-wire MODBUS devices

The network composed of the termination resistor and the polarization resistors is incorporated into the

inverter and can be activated via DIP-switches. The figure above shows the termination network for the

devices located at both ends of the network, where the terminator must be installed.

For multidrop connections, 1 to 128 devices may be connected.

NOTE

All the devices connected to the communication multidrop network should

be grounded to the same conductor (0V) to minimize any difference of

ground potentials between devices that can adversely affect

communications.

Provide a linear wiring (not a star wiring) for multidrop line RS485: the first device in the multidrop

connection will have only one outgoing line, while the last device will have only one incoming line. The

line terminator is to be installed on the first device and the last device.

The line master device (Bridge-Mini) is typically placed at the beginning or at the end of a multidrop

connection; in that case, the line terminator of the farthest inverter from the master computer shall be

“ON”.

USER MANUAL

BRIDGE MINI

15P4600B100 REV 02

18/38

NOT

E

Communication does not take place or is adversely affected if multidrop

terminators are not properly set up, especially in case of high baud rate. If

more than two terminators are fitted, some drivers can enter the protection

mode due to thermal overload, thus stopping dialoguing with some of the

connected devices.

RS485 Serial communication ratings:

Baud rate:

Configurable between 1200..115200 bps (default value: 38400 bps)

Data format:

8-bit

Start bit:

1

Parity: (1)

NO, EVEN, ODD (default: NO)

Stop bits:

2,1 (default: 2)

Protocol:

MODBUS RTU

Supported functions:

03h (Read Holding Registers)

10h (Preset Multiple Registers)

Device address:

Configurable between 1 and 247 (default value: 1)

Electric standard:

RS232, RS484

(1) Ignored when receiving communication messages.

USER MANUAL

BRIDGE MINI

15P4600B100 REV 02

19/38

COM1, COM2 Configuration and Wiring

Decisive voltage class A according to EN 61800-5-1

CN6 - DB9

Connector

Pin N.

Name

Description

-

Shield

Frame of the connector

connected to the PE

1

CD

Carrier Detect

2

RD

Received Data

3

TD

Transmitted Data

4

DTR

Data Terminal Ready

5

GND

Ground

6

DSR

Data Set Ready

7

RTS

Request To Send

8

CTS

Clear To Send

9

RI

Ring Indicator

Figure 12 - RS485 COM 1 Serial port pin-out

Decisive voltage class A according to EN 61800-5-1

DB9

Connector

Pin N.

Name

Description

1 –3

A-Line

(D+)

(TX/RX A) Differential input/output A

(bidirectional) according to RS485

standard. Positive polarity in respect to pins

2 –8 for one MARK.

2 –8

B-Line

(D-)

(TX/RX B) Differential input/output B

(bidirectional) according to RS485

standard. Negative polarity in respect to

pins 1 –3 for one MARK.

5

GND

(0V ISO) Control board zero volt.

6

+5V

+5 V ISO, max. 100mA for the power

supply of the external optional RS485

converter.

7-9

N.C.

Not connected.

Figure 13 -RS485 COM 2 Serial port pin-out

Terminators and polarizers can be configured for each serial port via dip switches.

- For the COM1, the dip switch SW2 is visible above the CN6 connector

- For the COM2, the dip switch SW1 is visible above the CN2 connector

USER MANUAL

BRIDGE MINI

15P4600B100 REV 02

20/38

Figure 14 - Configuration of the dip switch

CN6-COM1

Figure 15 - Configuration of the dip switch CN2-

COM2

The dip switches are:

DP switch

Function

1,2 [ON]

Terminator and polarizer active

1,2 [OFF]

Terminator and polarizer not active

NOTE

Variants of this configuration are not allowed.

NOTE

When the termination is active, a 120 Ω resistance is inserted between the

two signal lines of the RS485 port.

WARNING

When connect COM 2 to another inverter, other pins than 1/2/5 must not

be used and it is not possible to use a complete flat extension cable.

3.5.2.2. Ethernet Port (LAN)

The Ethernet port, or LAN port, is a communication port which may be configured to work with either a static

or a dynamic IP address. Integrated web interface is available through this port.

Default configuration is static, with IP 10.16.0.254, netmask 255.255.0.0.

LAN Configuration and Wiring

Bridge Mini is provided with a standard RJ-45 connector (IEEE 802) for Ethernet connection 10/100

(10Base-T, 100Base-T).

The yellow LED indicates the Link/Operation with 10Mbps baud rate, whereas the green LED indicates the

Table of contents

Popular Data Logger manuals by other brands

MadgeTech

MadgeTech Temp1000IS Product user guide

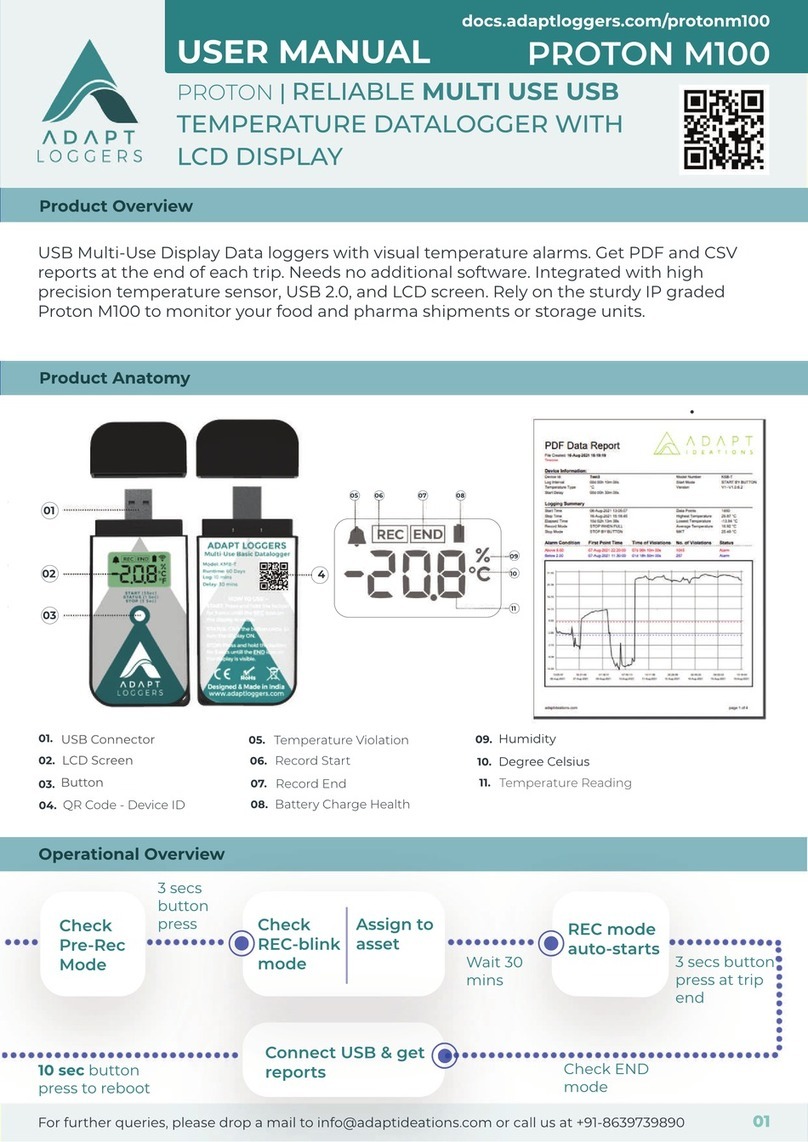

ADAPT LOGGERS

ADAPT LOGGERS PROTON M100 user manual

LogTag

LogTag UTREL30-WIFI Product user guide

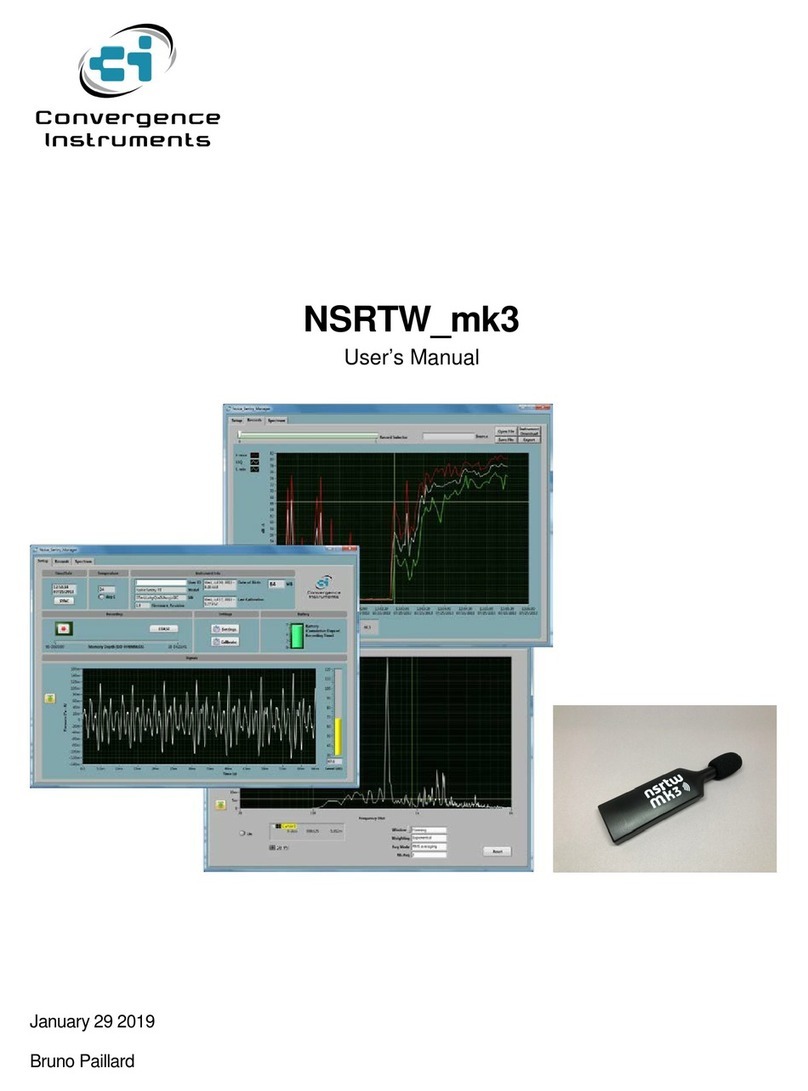

Convergence Instruments

Convergence Instruments NSRTW mk3 user manual

ELTEX

ELTEX Matman 12810 user manual

SMT

SMT MONILOG MicroShockDetector plus instruction manual