SMT MONILOG MicroShockDetector plus User manual

MicroShockDetector plus

Edition 11/2020

INSTRUCTION MANUAL

MONILOG®MicroShockDetector plus

(Transport data logger)

MicroShockDetector plus

- 1 -

P R O D U C T C E R T I F I C A T I O N

This device complies with part 15 of the FCC Rules. Operation is subject to the

following two conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that

may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment

off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

—Reorient or relocate the receiving antenna.

—Increase the separation between the equipment and receiver.

—Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

—Consult the dealer or an experienced radio/TV technician for help.

FCC ID: 2AELT-04MONILOG

This Class [B] digital device complies with Canadian ICES-003.

Cet appareil numérique de la classe [B] est conforme à la norme NMB-003 du

Canada

.

The product complies at intended use with the essential requirements of the

following EC-directives (www.monilog.de)

2014/30/EC (EMC –directive)

2011/65/EC (RoHS directive)

2012/19/EC (WEEE –directive)

MicroShockDetector plus

- 2 -

T A B L E O F C O N T E N T S

PRODUCT CERTIFICATION.................................................................................. 1

TABLE OF CONTENTS ........................................................................................ 2

1. INTRODUCTION ...................................................................................... 4

1.1 SCOPE OF DELIVERY.................................................................................................... 4

1.2 BRIEF INSTRUCTIONS FOR THE INSTALLER .......................................................................... 4

1.3 FUNCTIONALITY......................................................................................................... 5

1.4 ENVIRONMENTAL AND SAFETY INSTRUCTIONS .................................................................. 6

2. TECHNICAL PARAMETERS......................................................................... 7

3. DEVICE DESCRIPTION .............................................................................. 9

3.1 DEVICE SETUP /DEVICE VIEW................................................................................. 9

3.2 OPERATION OF MONILOG®MICROSHOCKDETECTOR PLUS ............................................. 10

3.3 DEVICE RUNTIME AND BATTERY CELL CHANGE....................................................... 13

3.4 MOUNTING INFORMATION................................................................................. 15

4. PC SOFTWARE –MONILOG®ANALYZER ................................................. 16

4.1 INSTALLATION ......................................................................................................... 16

4.1.1 General software installation ....................................................................................... 16

4.1.2 USB driver ................................................................................................................ 16

4.2 GENERAL USE OF THE PC SOFTWARE.................................................................... 17

4.2.1 Establishing the device connection................................................................................ 17

4.2.2 File area ................................................................................................................... 18

4.2.3 Message window (Log) ............................................................................................... 18

4.2.4 View of the measurement data ..................................................................................... 18

4.3 MONILOG®MICROSHOCKDETECTOR PLUS .................................................................. 20

4.3.1 Reading out status, configuration and measurement data................................................. 20

4.3.2 Measurement data, status and thresholds ...................................................................... 21

4.3.3 System events: ........................................................................................................... 22

4.3.4 Acquisition periods .................................................................................................... 23

4.3.5 Synchronous data ...................................................................................................... 23

4.3.6 Alarm events ............................................................................................................. 24

4.3.7 Evaluation of shock events........................................................................................... 25

4.3.8 Configuration of the MicroShockDetectors plus............................................................... 28

MicroShockDetector plus

- 3 -

4.3.9 Service information on the device ................................................................................. 33

5. ANDROID APP –MONILOG®CONNECT...................................................34

5.1 INSTALLATION..........................................................................................................34

5.2 GENERAL USE OF THE APP...........................................................................................34

5.2.1 Initial setup................................................................................................................ 34

5.2.2 Start-up menu............................................................................................................. 36

5.2.3 Read device via NFC.................................................................................................. 37

5.3 CONFIGURATION MONILOG®CONNECT ....................................................................39

5.3.1 Password .................................................................................................................. 39

5.3.2 Email ........................................................................................................................ 39

5.3.3 Further ...................................................................................................................... 39

6. FIRMWARE UPDATE...............................................................................40

6.1 PREPARATION.......................................................................................................40

6.2 CARRYING OUT UPDATE .......................................................................................41

WARRANTY CERTIFICATE.................................................................................42

MicroShockDetector plus

- 4 -

1. I N T R OD U C T IO N

1.1 S C O P E O F D E L I V E R Y

Thank you

for having chosen the MONILOG®MicroShockDetector plus.

Scope of delivery1(standard):

•MONILOGMicroShockDetector plus, incl. 1 replaceable lithium cell of type LR06 (AA,

Mignon) 3.6 V / 2500 mAh, lithium content ~ 0.7g

•USB stick

▪Configuration software „MONILOG Analyzer“ with integrated software help

▪Driver for USB interface

▪Operating instruction in electronic form (PDF)

▪Application examples, transport monitoring manual

•USB 2.0 interface cable (type A ↔type Mini AB)

In order to be able to further optimise our products for the respective applications, we are always

open to suggestions and change requests on your part.

1) The scope of delivery can deviate from the standard due to special contract agreements!

1.2 B R I E F I N S T R U C T I O N S F O R T H E I N S T A L L E R

Assuming the MONILOGMicroShockDetector plus is pre-programmed for the application and the

battery cell capacity sufficiently, the device only needs to be attached to the cargo and turned on.

The mounting is preferably with 2 mounting screws or optionally with magnetic bases (see Section

3.4).

Briefly (<3 sec) press the CONTROL-button. If the STATUS LED is green, the device is ready for

use and you do not have to do anything else. Otherwise, press the CONTROL-button for at least 3

seconds to switch on the device until STATUS LED light up in green and then release the button.

In all other states, the device can only be operated using the analyzer software MONILOG®(see

Section 3.2). If the STATUS LED lights up red, there is an error. Follow the instructions in the

MONILOG®analyzer or ask your administrator or the manufacturer.

To switch off the device, press the CONTROL-button for at least 5 seconds until the STATUS LED

lights up red.

MicroShockDetector plus

- 5 -

1.3 F U N C T I O N A L I T Y

MONILOG®MicroShockDetector plus is a small, universal and cost-effective data logger.

Developed for long-term measurement applications, it is perfectly suited for the monitoring of

transport goods and critical environments.

The integrated sensor system for the detection of shock events and for the measurement of

temperature, humidity, air pressure and light enables a wide range of different measurement

applications. Configured alarm thresholds ensure the reliable detection of exceedances of limit

values. Shock loads are recorded and evaluated in real time, the temperature, humidity, air pressure

and light also in an adjustable interval.

The compact and network-independent design enables

simple fixing on or in transport goods or transport devices with

screws, magnetic feet or adhesive pads.

The case of the device protects against dust and splash water

(degree of protection IP 67) and thus is also suitable for the

exterior use. Thanks to this, the MONILOG®MicroShockDetector

plus can be universally used as an almost invisible goods

companion in the international transport of goods, in storage rooms,

at reloading points and during transport by rail, by roads as well as

by water and by air.

The power supply is realised by customary, exchangeable lithium battery cells Thanks to very

low current consumption and associated very long, maintenance-free operating time, the

MONILOG®MicroShockDetector plus is perfectly suited for self-sufficient long-term

applications. Energy-optimised operating settings render possible a self-sufficient operational time

of up to 3 years under rough ambient conditions (depending on settings).

The licence-free configuration software MONILOG®Analyzer enables a simple and intuitive

configuration of the devices. It offers a comprehensive adjustment of the device functions to your

application-specific requirements. Besides the detailed evaluation of the device data in measured

value tables and graphs, the programme also provides export functions for external applications

(e.g. Microsoft Excel). Communication takes place via a USB interface.

With the status report function, an overview of the measurement data, including the division of all

impacts into acceleration classes and activities of the device, is created immediately without any

necessary settings. The license-free Android app MONILOG®Connect enables the device to be

conveniently read out via NFC with a smartphone. When reading out, an overview of all relevant

measurement data and activities of the device is created immediately in the form of a status report

without any necessary settings.

MicroShockDetector plus

- 6 -

1.4 E N V I R O N M E N T A L A N D S A F E T Y I N S T R U C T I O N S

Intended use

The MONILOG®MicroShockDetector plus is intended for the verification of transport and storage

conditions and may only be used under the operating conditions mentioned in the Section 2. No

safety-relevant functions may be derived from it.

Changes or modifications to the device could void the user's authority to operate the device.

The following information on handling lithium battery cells must be observed.

Environment & disposal

Der MONILOG®MicroShockDetector plus contains, excluding the lithium battery cells, no corrosive

or environmentally damaging substances.

Used lithium battery cells must be immediately removed from the device and be disposed of in an

environmentally friendly manner, according to the applicable legislation. Lithium battery cells are

hazardous waste.

Battery cell operation

The power supply in the MONILOG®MicroShockDetector plus is realized by one exchangeable

lithium battery cell (type AA|LR6) 3,6 V 2500 mAh. This can be bought in specialised stores or

from equipment suppliers. Due to the lithium cell used, the transport regulation UN3091-PI970 must

be observed during transport.

Operation with 1.5 V battery cells is not possible.

ATTENTION!

Risk of explosion if the battery cell is replaced with the wrong type.

Only use battery cells that conform to UN 38.3, IEC 60086-4 and

IEC 60079-11 (intrinsically safe).

In case of non-compliance with the national regulations/laws applicable in the handling of

lithium battery cells, any liability and warranty claims become void!

ATTENTION!

When transporting several devices or lithium battery cells in one package, this must be marked in

accordance with the transport regulation UN3091-PI970.

Decommissioning

In case of decommissioning the devices must be properly switched off and all battery cells must be

removed from the cases and be disposed of in an environmentally friendly manner.

MicroShockDetector plus

- 7 -

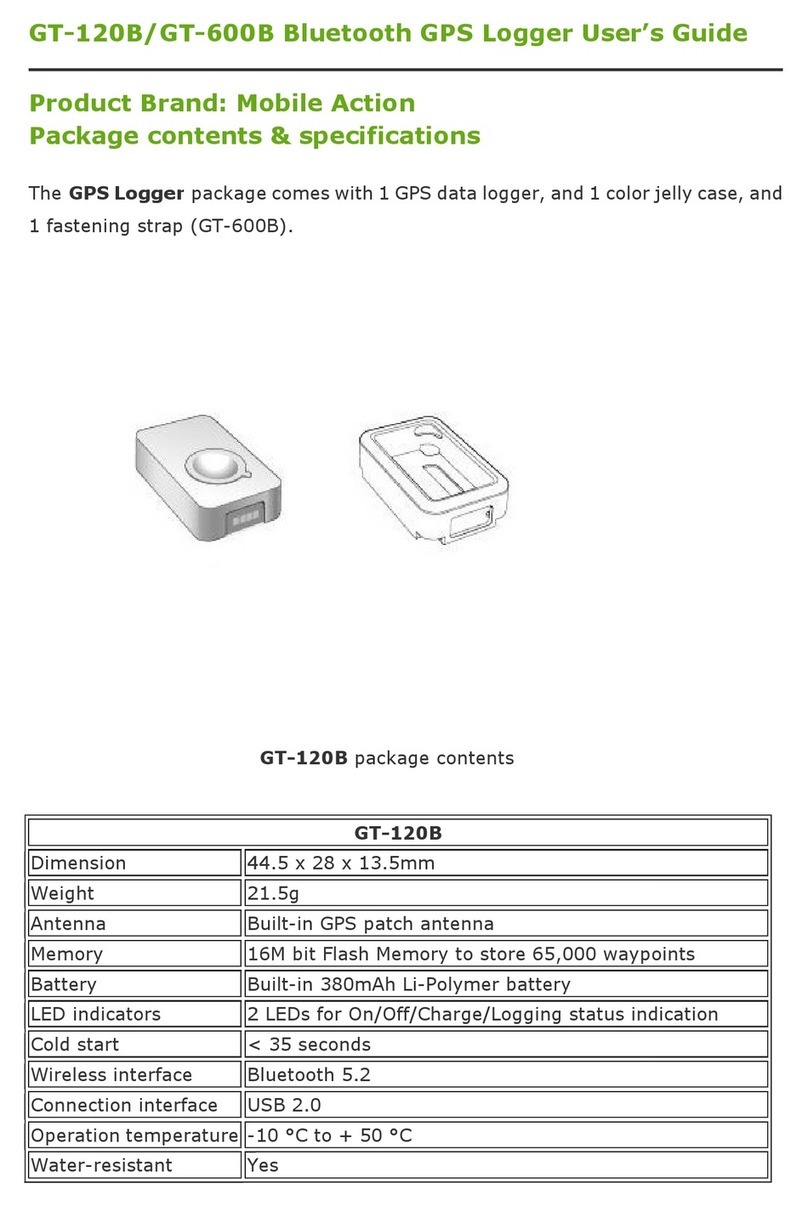

2. T E C H N I C A L P A R A M E TE R S

Shock parameters

200 data records with the highest space vector amplitude, of which

the 10 highest values with a curve-plots over 4 s, resolution 2 ms

Acceleration sensor

3D-MEMS, measuring range ±14 g, 1mg resolution, accuracy:

±(2% measuring range and 5% measurement value) at 13Hz/20°C;

±(3% measuring range and 6% measurement value) at 13Hz/+60°C

Registration threshold from 0.25 g

Lower limit frequency 1 Hz

Upper filter cut-off frequency set up fixed at 25 Hz

Shock classification

Subdivision of shocks according to space vector amplitude into

classes, number of shocks not limited;

>0,25; >0,5g; >1g; >1,5g; >2g; >3g; >4g; >5g

Temperature

measurement

-40°C to +65°C ±1 K;100,000 measurement values

Relative humidity

0 %RH - 100 %RH ±3 %RH, 100,000 measurement values

Air pressure

260 –1260 mbar ±2 mbar, 100,000 measurement values

Light

0 lx –65000 lx ±10 %, 100,000 measurement values

Indication

2 LED‘s, for status and alarm limit-value overshooting

Operating elements

1 button for status indicator, ON/OFF switching with password

protection

Connections:

Mini USB 2.0

Interfaces

NFC;

Status report can be read out via NFC with a smartphone and the

free “Monilog Connect” app;

Save and/or send the PDF report via email

Operation and

storage conditions:

-40°C to +65°C; max. 98% rel. air humidity

Power supply

1 exchangeable lithium battery cell, 3,6 V type LR06 (AA, Mignon),

lithium content ~0,7g

Duration of up to 3 years in the switch-on period (depending on the

device configuration)

Data storage

Receipt of measuring data independent of battery cell status for a

minimum of 10 years

Dimensions

106mm x 48mm x 33mm (LxWxH)

126mm x 48mm x 40mm (LxWxH with magnetic feet)

Housing

Plastic housing with stainless steel base

Weight

approx. 172 g, (258g total if mounted on magnetic feet)

Protection type

IP67

Calibration

Manufacturer’s calibration valid for 2 years, unless otherwise agreed.

MicroShockDetector plus

- 8 -

Programmable

parameters

X, Y, Z registration thresholds, X, Y, Z alarm thresholds, minimum

shock duration, measurement interval for temperature, humidity, air

pressure, light

Start-Stop time (switch-on time period), password protection by means

of license-free Windows software

Data evaluation

Using license-free Windows software, the following can be

displayed:

Measurement value tables, curve graphics, active periods of the

device, export functions, reports, statistical evaluation, battery

monitoring

Using license-free Android software:

Status report can be read out via NFC; save and/or send the PDF

report via email

Software update

Updates are provided by the manufacturer for both the Windows and

Android software and the firmware of the device.

MicroShockDetector plus

- 9 -

3. D E V I C E D E S C R I P T I O N

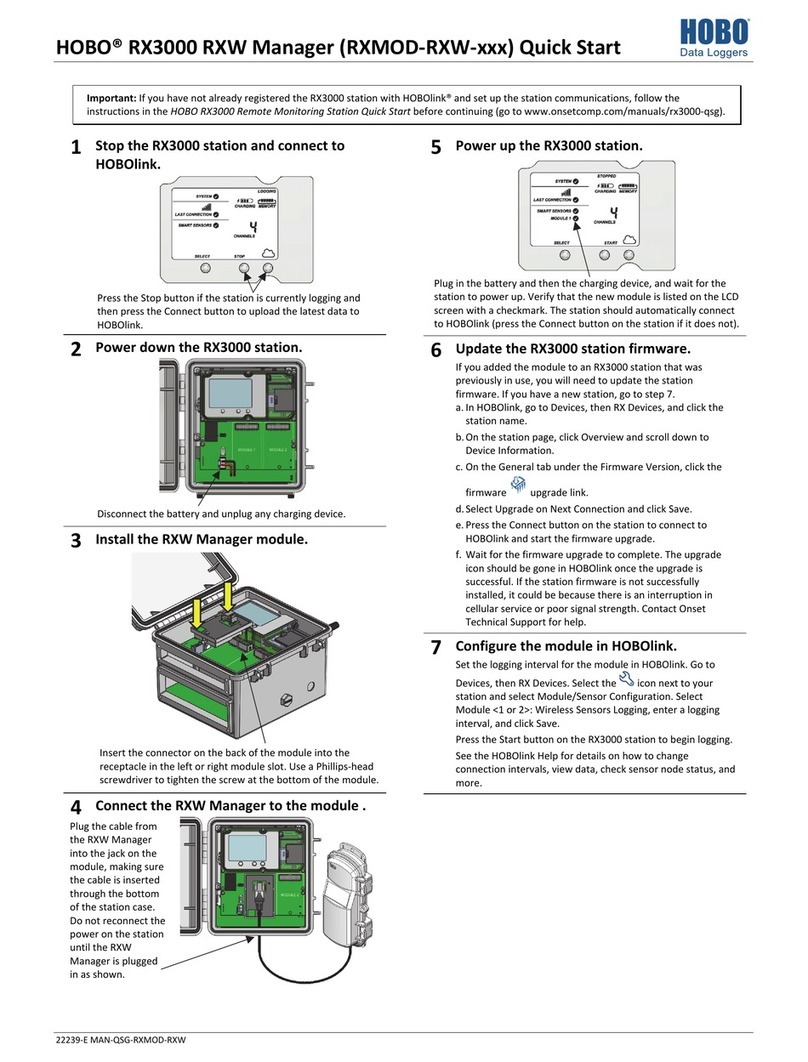

3.1 D E V I C E S E T U P / D E V I C E V I E W

1CONTROL button

6Battery cover

2STATUS LED, green/red display

7 Temperature/humidity sensor

3ALARM LED, red display

8Light sensor

4NFC chip

9Name plate

5USB port with cap

9

8

4

6

7

1

5

2

3

MicroShockDetector plus

- 10 -

3.2 O P E R AT I O N O F M O N I L O G ®M i c r o S h o c k D e t e c t o r

p l u s

The CONTROL button is available for operating the device, which can have different functions

depending on the current status and the duration of the button press. The current status is indicated

by the 2 LEDs.

Checking the on-state of the device

In order to determine whether the device is switched on or off, briefly press (<3 s) the

CONTROL-button:

STATUS LED does not light up →the device is OFF

STATUS LED briefly lights up →the device is ON

Switching on the device

To turn on the device, press the CONTROL-button for at least 3 seconds until STATUS LED lights up.

After that, release the button. Once the green STATUS LED stops lighting up the device is ready for

operation. If the device is provided with an On/Of password, it can only be activated via the

software. This is indicated by the STATUS LED flashing for 60 s. If the software is not activated, the

device switches off again after 60 seconds. To activate the device, connect the device to a PC while

the LED is flashing and start the MONILOG®Analyzer. When reading out the device, it is

recognized that the device is password-protected. At this point you will be asked to enter the device

password. Follow the instructions in the software to switch on the device. Explanations on the

configuration of the switch on/off password can be found in the chapter 4.3.8 in the section

„Configure password“.

If no password is required, the device starts recording data immediately.

Switching off the device

To switch off the MicroShockDetector plus, keep the CONTROL-button pressed for at least 2 seconds

until the ALARM LED flashes red. If you continue to keep it pressed, the STATUS LED lights up red

for 1 s. Now it can be released. Then the device switches off. This can be verified by briefly pressing

the button. If the button is released while flashing, the device remains switched on.

If the device is provided with an On/Of password, it can only be deactivated via the software.

In order to signal this, the STATUS LED starts to flash rapidly red when the button is pressed for a

long time (> 3 s). To switch off the device, connect the device to a PC and start the MONILOG®

Analyzer. When reading out the device, it is recognized that the device is password-protected. At

this point you will be asked to enter the device password. You can now switch off the device using

MicroShockDetector plus

- 12 -

Display of the functional statuses

Status

Device status

Condition

Auxiliary

condition

Subsequent

status device

LED status

green

LED status

red

LED alarm

red

A0

Device

on

Idle process

Ready for operation

A0

10ms

every 2s1

Off

Off

A1

System error

A1

Off

10ms

every

2s1

Off

A2

Critical battery status

A2

Off

10ms

every

2s1

Off

A3

Exceeding an alarm

threshold

A3

Off

Off

10ms

every

2s1

B1

Device

on

Pressing Control

button

t < 3 s

Measurement active

A0 or A3

1 s

Off

-

B2

Measurement inactive

A0 or A3

100ms

every

200ms

Off

-

B3

Alarm event present

A3

-

-

1 s

B4

System error

A1

Off

1 s

-

Critical battery status

A2

Off

1 s

-

B5

Pressing Control

button

3 s ≤ t < 5 s

Without active

switch-off protection by

password

Ax or B6

Off

Off

100ms

every

200ms

B6

Pressing Control

button

t ≥ 5 s

C0

Off

1 s

Off

B7

Pressing Control

button

t ≥ 3 s

With active

switch-off protection by

password

Ax (switch-off

prevention

through a

password)

Off

Off

Off

C0

Device

off

C0

Off

Off

Off

C1

Pressing Control

button t < 3 s

C0

Off

Off

Off

C2

Pressing Control

button

t ≥ 3 s

Battery cell empty

C0

Off

Off

Off

C3

Without active

switch-on protection by

password

Ax

2 s

Off

Off

C4

With active

switch-on protection by

password

Ax after valid PW

entry via software

in 60s;

C0 without PW

entry after 60s

1 s every

2 s

Off

Off

C5

Clock not set after

changing the battery

A1

Off

2 s

-

C6

Battery cell low

C0

Off

7 x 1 s

flash

-

D0

Device

on

Measurement

data recording

Ax

On

Off

Off

1 The cyclic device flashing can be switched on/off via the MONILOG®Analyzer software (see section 4.3.8).

MicroShockDetector plus

- 13 -

3.3 D E V I C E R U N T I M E A N D B A T T E R Y C E L L C H A N G E

Device runtime

The device runtime of the MONILOG®MicroShockDetector plus depends on the set measurement

parameters, the battery cell type and the conditions of use. The number of impacts above the

registration threshold of the device and the cyclical status flashing are decisive. Assuming that the

device has been activated 100,000 times by impacts and the cyclical status flashing is active, the

typical runtime of a battery cell is around 1 year (see also the trigger counter section 4.3.2). The

actually still available battery cell charge is monitored by the device itself and displayed when

reading out with the MONILOG®Analyzer software. If the device displays low battery while data

is being transferred, insert a new battery cell and reconfigure the time before using the device again

(see Setting the device time in section 4.3.8).

Battery cell change

ATTENTION!

Risk of explosion if the battery cell is replaced with the wrong type.

The MONILOG®MicroShockDetector plus may only be operated with lithium battery cells (type

AA|LR6) 3,6 V.

Only use battery cells that conform to UN 38.3, IEC 60086-4 and

IEC 60079-11 (intrinsically safe).

Before changing the battery cell, MONILOG®MicroShockDetector plus must be switched off

properly. Otherwise data loss from the device cannot be excluded.

For the change of the battery cell proceed as follows:

1) Remove the battery cover by loosening the fastening screws by means of a screw driver (cross

recess, H size 1).

You can then simply remove the battery.

2) Now insert the new battery cell according to the specified polarity into the device.

3) Screw the battery cover back on. Please take into account the maximum tightening torque of

0.3 Nm and the correct position of the seal.

4) Switch on the device and read it out with the MONILOG®Analyzer software.

5) Press the “Setup new battery” button in the “Configuration” tab and, if necessary, adjust the

capacity of the newly inserted battery cell (see section 4.3.8).

MicroShockDetector plus

- 15 -

3.4 M O U N T I N G I N F O R M A T I O N

The device can be attached by means of 2 fastening screws (see Figure 1) on the transported goods

according to the marked mounting holes. Optionally, the device can also be mounted on magnetic

surfaces with the aid of magnetic bases. Lashing strap mounting is also conceivable as long as they

do not have a shock-absorbing foam layer.

Figure 1: Dimensions and mounting information of the MicroShockDetector plus

Mounting holes

MicroShockDetector plus

- 16 -

4. P C S O F T W A R E –M O N I L O G®A N A L Y Z E R

The software MONILOG®Analyzer can be used both for the readout and configuration of the

MONILOG®MicroShockDetector plus and other MONILOG®devices. It is intended for the display

and analysis of the recorded data in tabular and graphic form. Furthermore, data sets can be saved

locally on your PC or loaded from your PC.

4.1 I N S T AL L A T I O N

4 . 1 . 1 G e n e r a l s o f t w a r e i n s t a l l a t i o n

The supplied USB stick contains the installation of the MONILOG®Analyzer software, the driver for

the USB interface and documentation. Please start the installation by double-clicking on the file

„setup.exe“, and follow the instructions.

Note:

To install the software and the USB driver you need administrator rights on the PC.

4 . 1 . 2 U S B d r i v e r

When connecting a MONILOG®MicroShockDetector plus for the first time, it may be necessary to

install a USB driver on the PC. The “FTDI CDM Driver” is located on the supplied USB stick and is

set up with the software installation if it is not already available on the PC.

Now connect the MONILOG®MicroShockDetector plus to your PC using the USB cable supplied.

When the device is connected, the green STATUS LED lights up. After the LED has gone out, USB

is ready for operation and you can read out the device with the MONILOG®Analyzer software.

MicroShockDetector plus

- 17 -

4.2 G E N E R A L U S E O F T H E P C S O F T W A R E

4 . 2 . 1 E s t a b l i s h i n g t h e d e v i c e c o n n e c t i o n

When the device driver is installed and a device is connected via USB, the connection will be

established automatically as a rule upon start of the evaluation software.

If the evaluation programme has already been active before plugging the device or if you want to

connect a device to a different COM port, select the device via the USB menu at the top right.

In case of connection problems:

If no connection can be established to the device, select the

Refresh button (blue double arrow) and disconnect the USB cable from the device. Afterwards,

reconnect it with the USB cable.

Figure 2: USB connection window: currently connected to COM23

After a successful USB connection, the measurement data is read and then the status data of the

connected device is displayed:

Figure 3 Status view

MicroShockDetector plus

- 18 -

4 . 2 . 2 F i l e a r e a

The data read from the device via USB can be saved on a data carrier using the icon or “Save

file” menu. Please note that the measurement data is only contained in the file if it was previously

read out via . Otherwise only the status data are included.

Figure 4: File area

Likewise, saved data can be fed again into the PC programme. The button “Open file” opens

the corresponding dialogue for the selection of the file.

4 . 2 . 3 M e s s a g e w i n d o w ( L o g )

The message window, which can be found as a programme tab “Log”, renders possible an

overview on the actions performed by means of the programme or the status changes of the device

during the established USB connection. Error messages and notes, e.g. for executing configuration

commands, connection establishment to devices, saving of data etc. are listed here.

Figure 5: Log-window

4 . 2 . 4 V i e w o f t h e m e a s u r e m e n t d a t a

As described above, the measurement data must either be read out from a connected device or be

available in an open file. The data can be displayed as a chart or a table.

Graphs

Table of contents