ENG Vista PS-1 User manual

P

PS

S-

-1

1

U

Un

ni

iv

ve

er

rs

sa

al

l

P

Po

ow

we

er

r

S

Su

up

pp

pl

ly

y

B

Bo

oa

ar

rd

d

U

Us

se

er

r’

’s

s

M

Ma

an

nu

ua

al

l

500-0002MR2

http://audio.engineeringvista.com Rev. 2

Dear Customer

We at ENG Vista want to take this opportunity to thank you for purchasing the PS-1 Universal

Power Supply Board. The people that stand behind your Power Supply draw on more than a

decade of professional electronics design and manufacturing experience. We are committed to

providing our customers with the high quality equipment at an affordable price. We have achieved

this goal through modern design, quality parts, expert components sourcing and efficient

manufacturing.

Before using this power supply, please take the time to carefully read and understand the safety

instructions and operating procedures. Becoming familiar with all details about your unit will

ensure safe usage and reliable operation. Take special care when operating with high voltages

and making adjustments.

The effort you invest now will be well rewarded as the time goes by.

THANK YOU!

ENG Vista, Inc.

YOUR SAFETY IS VERY IMPORTANT TO US. PLEASE READ CAREFULLY THE

FOLLOWING NOTES AND SAFETY PRECAUTIONS. THANK YOU.

This kit is not intended for beginners. It requires familiarity with safe

procedures for tests, measurements and modifications of high voltage

equipment.

Exercise extreme caution when working with high voltages and always unplug

the power before making any changes or adjustments.

NOTE: Please make sure to check our website at http://audio.engineeringvista.com for updates,

test results and latest news. On our website you can also order spare parts. Feel free to contact

us with any questions or comments. We are looking forward to hearing from you.

2

SAFETY PRECAUTIONS

IMPORTANT SAFEGUARDS

PLEASE READ CAREFULLY ALL THE FOLLOWING

IMPORTANT SAFEGUARDS THAT ARE APPLICABLE

TO YOUR EQUIPMENT

SAFETY

1. Read the User’s Manual and refer to it frequently during your experimenting.

2. Retain the User’s Manual for future reference.

3. All warnings should be strictly adhered to.

4. Follow instructions to the last detail.

5. This product should be operated using only the type of power source indicated in this

manual.

6. Always use an electrical outlet that is grounded. If you do not know whether the outlet is

grounded, consult your electrician or local power company.

7. For continued protection against fire hazard, replace fuses with the same type and rating of

the fuses specified. When changing fuses, completely remove power from the circuit.

8. Power supply cords and all connecting cables or wires should be routed so that they are

not likely to be walked on or pinched. Pay particular attention to cords and cables at plugs,

receptacles and terminal blocks. Always use wires with adequate ratings and safety

certifications (CE, UL, etc.)

9. During operation the tubes get very hot. Do not touch the tubes since this may result in a

severe burn. Allow several minutes after removing power for tubes to cool down before

touching them.

10.Turn off the unit as soon as you stop actively using it. Unplug the power supply from the

wall during a lightning storm or when the product is to be left unattended and unused for

longer periods of time.

11. Do not use this product near water or in wet areas. Damp basements should be avoided.

12.The product should be placed away from heat sources such as radiators, heaters, stoves

or other appliances that produce heat. Also avoid putting the unit in the direct rays of the

Sun.

13.Proper ventilation is crucial for safe and reliable operation. Never place anything on top of

your amplifier that could obstruct airflow and cause the parts to overheat and damage the

amplifier. Do not place your amplifier in a rack or bookcase unless proper ventilation is

provided.

14.Care should be taken to prevent objects from falling and liquids from spilling into the unit.

Do not subject the unit to excessive smoke, dust, vibration or shock.

15.During experimenting, make sure that all jumpers are properly seated in the correct

position, that there are no foreign objects or solder bridges.

16.Always wear protective glasses and exercise caution when powering unit after any change

is made. If possible, gradually rise input voltage and look for any abnormalities – smell or

smoke, tubes overheating (excessive glow), etc.

3

17.Unplug this product from the wall outlet before making any changes. Wait until tubes have

cooled down.

18.When using replacement parts, be sure to use parts with sufficient voltage and power

rating and adequate current carrying capability.

19.Should it become necessary to replace your tubes, remove the AC power plug from the

wall and allow thirty minutes for the high voltage capacitors to discharge.

20.If you have any questions regarding safe and reliable operation of your amplifier, please

4

GETTING STARTED

The PS-1 Power Supply kit was designed to provide you with a universal power supply suitable for

tube equipment (amplifiers, preamplifiers, etc.) and other equipment requiring clean filtered DC

power.

The PS-1 is built on a two sided printed circuit board (PCB) and has two separate outputs for

powering two separate DC loads:

1. Output voltage of up to 400VDC and 500mA, for anode power supply;

2. Output voltage of up to 40V and 2Amp, for heaters.

The printed cisrcuit board will accept many standard leaded (lead spacing 10mm) and snap-in

capacitors. For higher power amplifiers this will enable adding extra filtering. The filte employed ic

a C-R-C and it is very easy to modify it to a C-L-C if the use of a filter inductor is desired. Please

refer to the Connections section for detailed explanation.

If you bought an assembled kit rest assured that all power supplies go through rigorous testing

and extended burn-in before being shipped, so you are guaranteed to receive high quality

product.

The PS-1 kit does not include power transformer, unless it is specifically listed that it does. Power

transformers are sold separately.

With our power transformer 250-0002, the PS-1 will generate anode (plate) voltage of 220-250V

and maximum of 200mA, and heater voltage of 31-33V and maximum of 0.7A output current.

5

ASSEMBLING THE KIT

If you purchased an unassembled kit, you will have all the parts, including printed circuit board.

Parts are in marked bags, with reference numbers and value written on a bag. Reference

numbers are the ones printed on the PCB, so locating parts positions should be very easy. PCB

layout printout is also part of this document and you can use it to locate parts. Power transformer

is purchased separately, and not included in the kit.

First step is to review all the materials received, compare to the part list and prepare all tools and

a well lit work area. Tools that you need are very basic – soldering iron, tweezers or flat pliers, and

cutters. You will also need solder wire and a digital multimeter.

- Start assembly with jumpers, grounding negative end of plate and heater power supply. In some

specific (and very rare) situations it is not required to ground the power supplyand you will not

install the jumpers.

- Follow with resistors and fuses, keeping in mind that both, resistors and fuses should be slightly

elevated off the PCB (1/32” is sufficient). Main reason is that power resistors get warm and this

will help air circulation and prevent overheating. Also, some resistors have circuit connections

underneath and there is a possibility of malfunction if the resistor body touches exposed trace.

This is not very likely, since the PCB connections are protected by a solder mask and resistors

have durable coating. However, this could be a matter of safety and, also, troubleshooting of such

problems is really difficult, so it is better to spend some extra time up front to come up with great

assembly.

- Next step is assembly of all capacitors. Make sure to follow polarity directions for electrolytic

capacitors. All electrolytics have markings designating leads to be connected to the negative

voltage. PS-1 printed circuit board has a plus sign for the positive terminal of an electrolytic

capacitor. Positive terminal on the PCB also has a square pad around the hole, for easier

identification on the bottom of the board.

- After capacitors are installed you can proceed with connectors.

Once everything is installed, take a short break and then come back and carefully inspect your

work. Check component locations and proper orientation of electrolytic capacitors. Inspect all

solder joints and make sure there are no solder bridges or splashes on the board. All joints should

look clean and shiny. If you are not sure that a solder joint look right, touch it with a hot soldering

iron again, until it looks right. Cold solder joints may create problems few hours (days, months)

down the road and are extremely difficult to troubleshoot.

Then, connect the power transformer and proceed with slowly powering the unit. Variable

autotransformer (a.k.a. variac) is a very helpful tool during this initial phase.

Measure voltage on the primary and all secondaries, as well as output voltages for plates and

filaments. Keep in mind that during this test there is no load and measured voltages may be up to

25% higher than expected. Transformer secondary voltages and output DC voltages are specified

for the maximum load and will be significantly lower once you connect your equipment.

After the test is done, shut down the power, wait 5 minutes for capacitors to discharge and then

connect your equipment and repeat the process. After reaching the steady state, your voltages

should be very close to the nominal ones.

6

CONNECTIONS

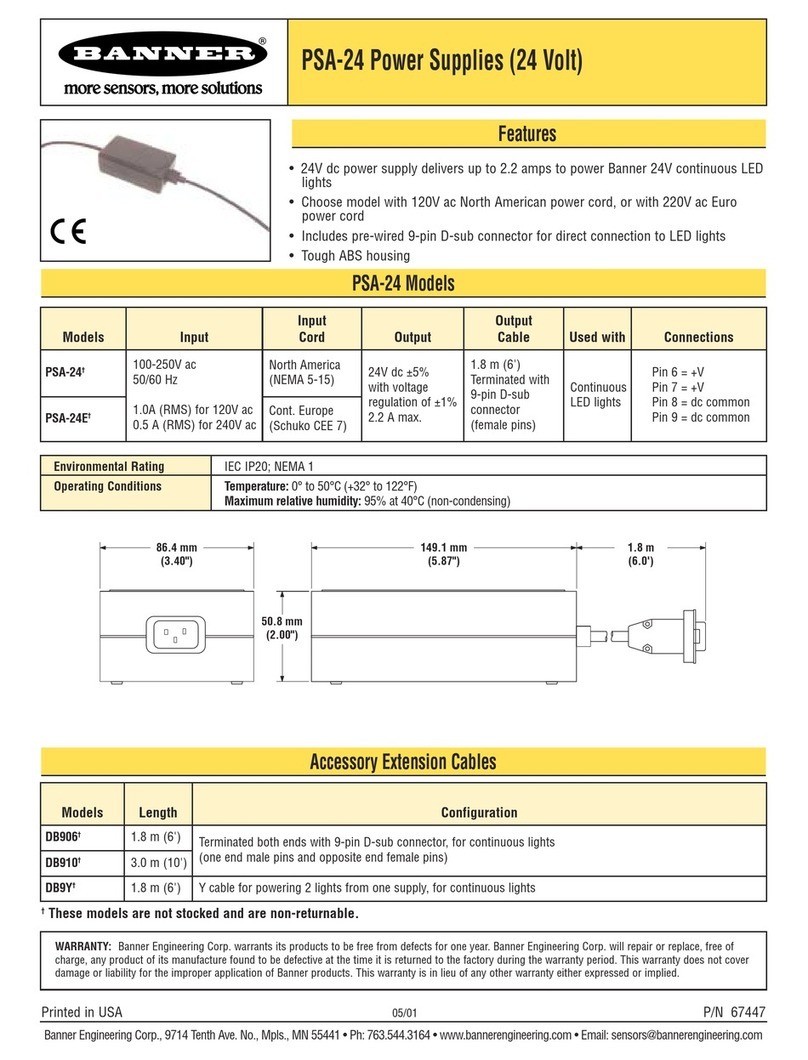

ELECTRICAL SCHEMATICS:

The complete electrical schematics with component values is given to assist you in your

experiments. Please note that the schematics is considered a copyrighted work and a trade

secret. However, as a purchaser of our product you are granted a license for unlimited

modifications. The only thing we ask for is that this schematics is not reprinted for public use or

commercially used without getting appropriate license from ENG Vista, Inc.

Depending on your particular kit, some of the parts may have different values or not be used.

7

R5

1k/2W

206-0003

R7

1k/2W

206-0003 C6

100n/400V

100-0012

C8

1000u/50V

100-0008

F3

3A

170-0002

J6

CONN PCB 2

160-0004

1

2

F1

3A

170-0002

-+

D2

2KBP10M

220-0001

2

1

3

4

J4

CONN PCB 2

160-0004

1

2

R6

270k/2W

206-0004

R3

1k/2W

206-0003

C11

*100n/400V*

100-0012

R11

0R/2W

206-NONE

C9

1000u/50V

100-0008

XFMR_PRI

SW1

SW DPDT

180-0001

2

1

3

5

4

6

J7

CONN PCB 2

160-0004

1

2

R9

0R

PLATE

F2

500mA

170-0001

-+

D1

2KBP10M

220-0001

2

1

3

4

PLATE

R2

1k/2W

206-0003

R10

0R/2W

206-NONE

XFMR_SEC_1

R13

2k7/2W

206-0005

XFMR_SEC_2

J1

IEC CONN

160-0006

1

3

2

C5

120u/450V

100-0011

C2

47u/450V

100-0010

C7

*100n/400V*

100-0012

FILAMENT

D3

LED

220-0002

R8

0R

FILAMENT

R4

1k/2W

206-0003

J2

CONN PCB 3

160-0003

1

2

3

C10

1000u/50V

100-0008

CHOKE

C3

47u/450V

100-0010

C1

*100n/400V*

100-0012

R1

1k/2W

206-0003

J5

CONN PCB 2

160-0004

1

2

J3

CONN PCB 2

160-0004

1

2

C4

47u/450V

100-0010

8

BOARD LAYOUT AND DIMENSIONS:

The following Figure shows the component layout, dimensions of the board (in mils –

1mil=0.001inch), mounting holes and locations of all components. This should help builder with

designing a fitting enclosure. Please always verify dimensions by measuring the actual printed

circuit board.

9

10

POWER TRANSFORMER CONNECTIONS:

Power transformer connects to the terminal blocks J2, J3 and J4.

Transformer primary winding connects to the two end terminals of the terminal block J2. The

center terminal of J2 is ground conection. It can be used to ground transformer core or for the

electrostatic screen, if available.

High voltage secondary for the plate power supply connects to the terminal block J3. Maximum

secondary voltage for the plate supply in the PS-1 kit should not exceed 260VAC. This will allow

sufficient margin for the filter capacitors used in the PS-1.

Transformer secondary for the filament power supply connects to the terminal block J4. Maximum

secondary voltage for the filament supply in the PS-1 kit should not exceed 32VAC. This will allow

sufficient margin for the filter capacitors used in the PS-1.

AMPLIFIER CONNECTIONS:

PS-1 outputs two voltages – Va (plate supply) and Vf (filament supply).

Plate voltage is present at the terminal J6 and filament voltage is present at J7. Positive and

negative power supply terminals are marked on the PC Board, as shown in the picture above.

OPTIONAL FILTER CHOKE:

The PS-1 Printed Circuit Board allows use of the filter inductor.

11

Resistors R1 to R5 should be removed from the PCB and external choke can be connected to the

terminal J5. This modification transforms the original C-R-C filter into the C-L-C and is best suited

for higher power applications.

FINAL WORDS

Once again, thank you for your purchase. We hope that the PS-1 will give you hours and hours of

fun and have you experience a multitude of different qualities of the “tube sound”. Robust design

should provide you with years of safe and reliable use.

Finally, we want to remind you once again to take extreme caution while working with high

voltages. If you are not thoroughly familiar with the safety procedures, feel free to enlist help of a

relative or friend. There are many very knowledgeable people in this field and they all share

passion for spreading the art and science of high quality sound reproduction.

Copyright, ENG Vista, Inc. 2006

12

PARTS LIST

Parts with asterisks in the VALUE column are not used. They have the place on the PCB, so you

can add them if you feel that they will improve the sound of your amplifier.

Item Qty Reference EPN Value

11R13 206-0005 2k7/2W

23R8,R9,R11 206-NONE 0R

31R6 206-0004 270k/2W

46R1,R2,R3,R4,R5,R7 206-0003 1k/2W

51J1 160-0006 IEC CONN

65J3,J4,J5,J6, J7 160-0004 CONN PCB 2

71J2 160-0003 CONN PCB 3

81F2 170-0001 500mA

92F1,F3 170-0002 3A

10 1D3 220-0002 LED

11 2D2,D1 220-0001 2KBP10M

12 3C8,C9,C10 100-0008 1000u/50V

13 1C6 100-0012 100nF/400V

14 3C1, C7, C11 100-0012 *100nF/400V

15 4 C2,C3,C4 100-0010 47uF/450V

16 1C5 100-0011 120uF/450V

17 1SW1 180-0001 SW DPDT

18 1PCB 500-0002

19 1User's 500-

13

Table of contents