Engbo MAXI 31 Operating manual

ENGBO AS –et selskap i Engbo-gruppen

BESØKSADRESSE: Wirgenesvei 7, 3157 Barkåker POSTADR: Postboks 2288 Postterminalen, 3103 Tønsberg

E-MAIL: suppo[email protected]o WEB: www.engbo.no TLF: +47 33 00 31 50 FAKS: +47 33 00 31 60

USER AND INSTALLATION

MANUAL

ENGBO ANCHOR WINCH

MAXI 31

MAXI 32

MAXI 34-series

MAXI 38

MAXI 40

Engbo MAXI products fit most boat models

Rev. 7-2010-01-04

According to NS-EN ISO 9001:2000

FCC ID: R78-RC-01

Part no. 117-00036 R78-MCU-01

ENGBO AS –et selskap i Engbo-gruppen

BESØKSADRESSE: Wirgenesvei 7, 3157 Barkåker POSTADR: Postboks 2288 Postterminalen, 3103 Tønsberg

E-MAIL: suppo[email protected] WEB: www.engbo.no TLF: +47 33 00 31 50 FAKS: +47 33 00 31 60

2

INNHOLD

INTRODUCTION......................................................................................................................................................... 3

GENERAL PROCEDURES FOR USING ENGBO MAXI WINDLASSES................................................................................ 4

OPERATING INSTRUCTIONS....................................................................................................................................... 5

Anchor down............................................................................................................................................................ 7

Anchor up................................................................................................................................................................. 7

The “Power” indicator information: ........................................................................................................................ 7

Forced operation of the windlass ............................................................................................................................ 7

A BRIEF DESCRIPTION OF THE ENGBO ANCHOR SYSTEM ........................................................................................... 8

ELECTRONIC CONTROL UNIT................................................................................................................................................. 8

SWITCH PANELS ................................................................................................................................................................ 9

Standard touch panel .............................................................................................................................................. 9

Wireless remote control .......................................................................................................................................... 9

Holder for wireless remote control ........................................................................................................................ 10

INSTALLATION –GENERAL....................................................................................................................................... 10

The anchor bracket................................................................................................................................................ 10

Hull conduit / Line guide ........................................................................................................................................ 11

Anchor rope ........................................................................................................................................................... 11

Safety line .............................................................................................................................................................. 12

Auto stop ............................................................................................................................................................... 12

WIRELESS REMOTE.................................................................................................................................................. 12

FITTING ANTENNA ........................................................................................................................................................... 12

CODING OF THE WIRELESS REMOTE CONTROL ........................................................................................................ 13

Procedure for wireless remote controls with serial no. above 8600...................................................................... 13

How to put the wireless control unit in code mode: .............................................................................................. 13

How to put the receiver unit in code mode:........................................................................................................... 13

DIMENSIONAL SKETCHES ........................................................................................................................................ 14

MAXI 31/40 –SERIES...................................................................................................................................................... 14

MAXI 32 –SERIES ........................................................................................................................................................... 14

MAXI 33 –SERIES ........................................................................................................................................................... 15

MAXI 34-SERIES ............................................................................................................................................................. 15

MAXI 38-SERIES ............................................................................................................................................................. 15

TECHNICAL SPECIFICATIONS.................................................................................................................................... 16

ELECTRICAL WIRING ................................................................................................................................................ 17

SWITCH PANEL................................................................................................................................................................ 17

Standard touch panel (Item no. 12-79000) ................................................................................................. 17

Connecting the switch panel.................................................................................................................................. 17

Connecting the auto stop switch ........................................................................................................................... 18

Connecting the motor and battery cables ............................................................................................................. 18

BATTERY CONNECTION ..................................................................................................................................................... 19

Main power switch ................................................................................................................................................ 19

Fuse and fuse holder.............................................................................................................................................. 19

ELECTRICAL WIRING DIAGRAM ............................................................................................................................... 20

FITTING INSTRUCTIONS ........................................................................................................................................... 21

GENERAL INFORMATION............................................................................................................................................ 21

Hinged platform roller ........................................................................................................................................... 21

Line guide in the stern........................................................................................................................................... 21

FITTING MAXI 31............................................................................................................................................................ 23

ENGBO AS –et selskap i Engbo-gruppen

BESØKSADRESSE: Wirgenesvei 7, 3157 Barkåker POSTADR: Postboks 2288 Postterminalen, 3103 Tønsberg

E-MAIL: suppo[email protected] WEB: www.engbo.no TLF: +47 33 00 31 50 FAKS: +47 33 00 31 60

3

FITTING MAXI 32............................................................................................................................................................ 23

Maxi 32 box ........................................................................................................................................................... 24

FITTING MAXI 33............................................................................................................................................................ 25

FITTING MAXI 40............................................................................................................................................................ 26

FITTING MAXI 34-V ........................................................................................................................................................ 27

FITTING MAXI 34-D ........................................................................................................................................................ 28

FITTING MAXI 34-G ........................................................................................................................................................ 29

Drawing - Maxi 34-G –line wheel, rope guide, rope guard and fixing plate ......................................................... 30

FITTING MAXI 34-S ......................................................................................................................................................... 31

FITTING MAXI 34-H ........................................................................................................................................................ 32

FITTING MAXI 38............................................................................................................................................................ 33

AUTO STOP FUNCTION...................................................................................................................................................... 34

Adjust the auto stop switch ................................................................................................................................... 34

Auto stop –fitting the stop indicator/brass wire................................................................................................... 34

MAINTENANCE........................................................................................................................................................ 36

Replacing the batteries in the wireless remote control ......................................................................................... 36

Replacing the line wheels ...................................................................................................................................... 37

Line guide –adjusting the tension spring .............................................................................................................. 38

Winter storage....................................................................................................................................................... 38

Troubleshooting..................................................................................................................................................... 39

INSTALLATION OF EQUIPMENT WITH HIGH CURRENTS - SPECIAL CONSIDERATIONS............................................... 40

Preface/introduction.............................................................................................................................................. 40

Battery ................................................................................................................................................................... 40

Battery-cables/lugs................................................................................................................................................ 41

Battery connection ................................................................................................................................................ 41

Fuse connection ..................................................................................................................................................... 41

Main switch connection......................................................................................................................................... 42

Control box connections ........................................................................................................................................ 42

Motor terminal connections .................................................................................................................................. 43

Introduction

Thank you for buying an Engbo anchor windlass. We hope you will find it useful and simple to

work with. To ensure that you do, it is essential that you fit and use it in accordance with the

instructions in this manual to ensure the best possible conditions for optimal windlass

operation. For example, the windlass motor must receive sufficient power, and the windlass,

rope and anchor bracket must all be positioned correctly.

Engbo has been active in the boat industry for more than 30 years, and are well aware of the

requirements made on the equipment on board. To meet the challenges posed by a boat

operating in wet conditions –often with limited power capacity –Engbo has invested heavily

in developing new, modern electronic control systems.

Most Engbo MAXI windlasses can be supplied for use with rope or chain. The descriptions for

rope or chain operation in this manual are therefore suitable for both.

IMPORTANT! This manual contains information you need to know before installing

the windlass. Therefore, please read it carefully.

ENGBO AS –et selskap i Engbo-gruppen

BESØKSADRESSE: Wirgenesvei 7, 3157 Barkåker POSTADR: Postboks 2288 Postterminalen, 3103 Tønsberg

E-MAIL: suppo[email protected] WEB: www.engbo.no TLF: +47 33 00 31 50 FAKS: +47 33 00 31 60

4

General procedures for using Engbo Maxi windlasses

Read the operating manual carefully before installing and using the windlass.

Please note that strong forces are involved, so please use the windlass carefully and make

sure, for example, that:

You do not get your fingers caught up in the rope, chain, anchor, rollers or gypsies.

The rope/chain is always under observation when the anchor is being raised.

Everyone on board has been informed of how the windlass functions.

You always operate the winch from a place that provides an unobstructed view of the

anchor while it is being raised. This will help prevent “unpleasant surprises” that may

damage the boat.

You release the switch for a little while if the windlass is straining to raise the anchor.

When the boat has started moving backwards, you can start the windlass again. This

will make it easier for the windlass to operate, and it will use less power.

If the anchor is stuck on the seabed: Release some rope and make it fast to a cleat on

the boat. Then use the boat engine to free the anchor. Once the anchor has been freed,

use the windlass in the usual manner.

The windlass can run for max. 3 minutes at normal load.

The anchor must always be secured to the boat while the boat is travelling. Use the

securing lines supplied.

Disconnect the power to the windlass once the boat is underway.

Children must not operate the windlass.

Negligent use can result in unnecessary damage.

Always make sure the battery is well charged when using the windlass. Always have

the motor running when the windlass is in use.

The windlass features electronic overload protection. If necessary, let the winch cool

down for 15–20 min. and then try again. In the event of an emergency, you can

override the overload protection by disconnecting and then reconnecting the main

power switch for the windlass.

Engbo AS accepts no liability for injuries or damage resulting from the use of the

windlass.

IMPORTANT!

Always have the boat engine running while the windlass is in use.

Always disconnect the power from the windlass when it is not in use.

Make sure to fit and use the windlass and its accessories in such a way as to

prevent injuries to people and damage to the boat and/or its surroundings.

Installation must be done or checked by trained personel with special

knowledge regarding high current and low voltage.

Faulty installations or connections of any components to the windlass will

render all warranty given by Engbo void.

To avoid overload when anchoring, the anchor line/chain must be secured

properly.

If the anchor has got stuck at the seabed, if possible, pull the anchor from

different directions by moving the boat in different positions.

When doing this, it is recommended to fix the anchor line in the cleat to avoid

overload.

ENGBO AS –et selskap i Engbo-gruppen

BESØKSADRESSE: Wirgenesvei 7, 3157 Barkåker POSTADR: Postboks 2288 Postterminalen, 3103 Tønsberg

E-MAIL: suppo[email protected] WEB: www.engbo.no TLF: +47 33 00 31 50 FAKS: +47 33 00 31 60

5

Operating instructions

Preparation before anchoring.

Landing.

Make sure the boat engine is running during anchoring.

Decide where you want to drop anchor.

Check that the safety line on the anchor has been

loosened.

Turn on the main switch of the windlass.

When the main switch of the anchor windlass has been

switched off, you must press the down button first.

Keep this button depressed for at least 1 second to drop

the anchor.

The windlass motor will run out for 1.5 seconds to

ensure the correct release function.

Fixed switch panel

Press the down button for at least 1 sec.

The anchor will drop.

The windlass is now released and the rope will run out

in step with the progress of the boat towards land.

Tie up the boat on land.

NB If you are using a free-fall chain windlass, the high

weight of the chain may result in the full length of the chain

being pulled out. If so, make sure to take up the slack once

you have tied the boat up.

Tighten up the slack of the anchor rope (or chain) by

pressing the up button so that the anchor settles firmly

on the seabed and pulls the boat away from land.

NB The windlass will always wind in slowly for 1.5 sec

before it switches to full speed. If you release the button

within 1.5 sec and press it again and then repeat the

process, the windlass will continue to wind in at low speed.

Setting off

Start the boat engine to charge the battery.

Check that the main switch of the windlass is

turned on.

Cast off from land.

Activate the windlass.

Keep the up button depressed, and the windlass will pull

the boat away from land. The windlass will pull the anchor

up at full speed until the first auto stop is activated.

NB This ONLY applies for rope windlasses and requires the

anchor rope to be correctly fitted with brass wire markers.

NB Keep an eye on the anchor when it leaves the

water and seats in the anchor bracket. This will

allow you to stop the windlass and prevent

damage if the anchor pulls up foreign objects

from the seabed.

ENGBO AS –et selskap i Engbo-gruppen

BESØKSADRESSE: Wirgenesvei 7, 3157 Barkåker POSTADR: Postboks 2288 Postterminalen, 3103 Tønsberg

E-MAIL: suppo[email protected] WEB: www.engbo.no TLF: +47 33 00 31 50 FAKS: +47 33 00 31 60

6

NB If the windlass is straining while raising the anchor, it

would be a good idea (and save power) to run the windlass

in periods. Once the boat has begun to move backwards,

you can release the up button and then run the windlass in

periods.

Release the up button, press again and keep

depressed.

The windlass will continue to raise the anchor slowly

until the second auto stop is activated, stopping the

windlass completely.

The anchor will then be correctly seated in the anchor

bracket.

Attach the safety line to the anchor.

Turn off the main switch of the windlass.

Have pleasant sailing!

Wireless remote control

To switch on the remote control, keep one of the

buttons depressed for 1.5 sec. The green “power”

indicator will light up, and you will hear a brief audio

signal.

Every time you subsequently press a button, the

associated indicator will light up, and the remote will

emit an audio signal.

To ensure a long lifetime, the remote control switches

off automatically 5 min. after the last button was

pressed. Automatic shut-off is preceded by two short

audio signals and the “Power” indicator flashing.

ENGBO AS –et selskap i Engbo-gruppen

BESØKSADRESSE: Wirgenesvei 7, 3157 Barkåker POSTADR: Postboks 2288 Postterminalen, 3103 Tønsberg

E-MAIL: suppo[email protected] WEB: www.engbo.no TLF: +47 33 00 31 50 FAKS: +47 33 00 31 60

7

Anchor down

When the remote control is switched on, you can drop

the anchor by pressing the “down” button in. Keep this

button depressed for at least 1 second to drop the

anchor.

The windlass will then run out for 1.5 seconds to

ensure the correct release function.

Anchor up

When the anchor has dropped to the seabed, press the

“up” button to take up the slack. The windlass will

continue to winch in as long as you keep the “up”

button depressed. If the remote control has switched

off automatically (i.e. if you have not pressed a button

for more than 5 min) it will first switch on and then

immediately start to wind in the anchor rope/chain. The

windlass always starts to operate for 1.5 sec at reduced

speed before increasing to full speed.

This means that you can keep the windlass operating at

low speed by releasing and pressing the “up” button

repeatedly as required.

The “Power” indicator information:

Green light indicates that the remote control is ready

for use.

Orange light indicates that the power supply to the

windlass is not optimal, or that the windlass is

overloaded and needs time to cool down.

Red light indicates a system error or that the battery

charge is too low for the windlass to operate.

Red light flashing slowly accompanied by short

audio signals indicates that contact with the electronic

unit (receiver) cannot be established.

NB These error notifications will continue for as long as a

button is depressed.

Forced operation of the windlass

If you need to raise the anchor a little further than the

second “auto stop”mark, you can do so by keeping the

“up” button depressed for more than 10 seconds. The

windlass will then operate at low speed for as long as you

hold the button in.

NB. The use of this function must be closely

controlled to prevent damage.

ENGBO AS –et selskap i Engbo-gruppen

BESØKSADRESSE: Wirgenesvei 7, 3157 Barkåker POSTADR: Postboks 2288 Postterminalen, 3103 Tønsberg

E-MAIL: suppo[email protected] WEB: www.engbo.no TLF: +47 33 00 31 50 FAKS: +47 33 00 31 60

8

A brief description of the Engbo anchor system

Engbo MAXI windlasses is a common designation for

1000/1500 W, 12/24V Engbo windlasses. Some of the

models are most suitable for fitting aft, some fore, and

others both fore and aft. Engbo MAXI windlasses are

designed for boats larger than around 25 feet. These

windlasses –with the exception of type 33 –are

authentic free-fall windlasses, which means that a

neutral position in the windlass gears allows the anchor

to drop directly to the seabed immediately after the

“anchor down” (arrow down) button has been pressed.

The system is based on allowing the weight of the

anchor on the outside of the anchor bracket to define

how quickly the anchor drops. Therefore, it is

important to avoid unnecessary friction between rope

and hull, rollers and/or guides.

Example: If you fit the windlass with a Bruce anchor,

you will need to use the jointed anchor bracket and

ensure that the angle between horizontal and the rope

is at least 15–20º. If the angle is too narrow, the

anchor will “balance” and need “assistance” to tip out.

Electronic control unit

Engbo MAXI windlasses are fitted with modern

electronics that consist of:

Transistor-controlled power electronics that

replace the conventional cut-in relay. The new

electronic unit contains no open contacts and is very

flexible as regards voltage.

The control electronics are software-based and

feature an integrated radio receiver that

communicates with the wireless remote control, and

a built-in system to protect the windlass motor and

electronic components. Other functions controlled

electronically are two “up” speeds and two automatic

stop indicators for seating the anchor.

ENGBO AS –et selskap i Engbo-gruppen

BESØKSADRESSE: Wirgenesvei 7, 3157 Barkåker POSTADR: Postboks 2288 Postterminalen, 3103 Tønsberg

E-MAIL: suppo[email protected] WEB: www.engbo.no TLF: +47 33 00 31 50 FAKS: +47 33 00 31 60

9

Switch panels

12-79000

Standard touch panel

The windlasses are supplied as standard with 1 x

watertight (IP 68) touch panel (12-79000) for

installing in a readily accessible place in the cockpit.

If only this touch panel is to be fitted, it must, for

safety reasons, be positioned so as to allow the

operator a clear view of the anchor as it is raised and

seated in the anchor bracket.

The panel comes with a self-adhesive surface, but if

you prefer, it can be seated more firmly using the

screws supplied.

12-47020

12-47021

Wireless remote control

Three different wireless controls are available;

12-47020 designed for controlling two separate anchor

winches, 12-47021 two winches and two thrusters and

12-47022 for controlling up to six different

anchor/mooring winches.

The remote control is splash proof and features a

modern, compact design with strips of “anti-slip

material” on the rear surface. It will also float if

dropped over board.

Two-way narrow-band radio communication

guarantees the transmission of unique code to ensure

that the signal controls only your windlass.

An indicator light shows the voltage level or overload.

Range of more than 30 m in normal conditions.

The remote control uses three standard AAA (LR03)

batteries –included. For normal operation, the

batteries have a service life of more than two seasons.

A wrist/neck strap is supplied as standard.

12-47022

ENGBO AS –et selskap i Engbo-gruppen

BESØKSADRESSE: Wirgenesvei 7, 3157 Barkåker POSTADR: Postboks 2288 Postterminalen, 3103 Tønsberg

E-MAIL: suppo[email protected] WEB: www.engbo.no TLF: +47 33 00 31 50 FAKS: +47 33 00 31 60

10

Holder for wireless remote control

The enclosed, handy holder (12-47030), keeps the

wireless remote located in the right place when not in

use.

The holder kit consists of two single parts, and the holder

to and the bracket.

Slide the holder into the bracket by the slots.

Fix the bracket to the base with the adhesive tape.

By turning the backside of the remote forward and

fit it in the holder, the buttons will be protected

from unwanted activating of the winch or thruster

when kept in the pocket.

Installation –general

The windlass should be positioned as high as possible to allow maximum space for the rope

that will be stored below the windlass. The height from the bottom of the well where the rope

is stored to the bottom edge of the line wheel should be at least 50 cm, and the area

should be at least 40 x 40 cm to allow room for 50 m x 15 mm anchor rope. This will

prevent the rope from bunching under the windlass, and assure sufficient friction between the

line wheel and the rope.

See the specific descriptions for the separate windlass models.

The anchor bracket

Fit the windlass so that the rope is wound up in line with the anchor bracket (see pictures 1

and 2) –numerous different models are available –positioned on the exterior of the boat. The

anchor bracket functions as a guide for the rope when the anchor is on the seabed and as a

“seating point” for the anchor once it has been raised.

ENGBO AS –et selskap i Engbo-gruppen

BESØKSADRESSE: Wirgenesvei 7, 3157 Barkåker POSTADR: Postboks 2288 Postterminalen, 3103 Tønsberg

E-MAIL: suppo[email protected] WEB: www.engbo.no TLF: +47 33 00 31 50 FAKS: +47 33 00 31 60

11

Picture 1

.

Picture 2

Hull conduit / Line guide

It will often be necessary to install a hull conduit with a

pulley that guides the rope with low friction through the

hull.

The hull conduit will also prevent large volumes of water

from leaking in. (When fitting the MAXI 34V or MAXI 40 on

the inside of the stern, it will often be possible to adjust

the hull conduit so as to prevent friction between the hull

and the rope.)

Anchor rope

Engbo supplies original woven anchor rope with a lead

core in the whole length of the rope along with a fine

special thimble that will not snag on the pulley or bracket

when the anchor is dropped. This rope has been specially

designed for Engbo anchor windlasses and is a

precondition for problem-free operation of the system.

Supplied in various lengths and dimensions. The Engbo

Maxi range generally uses 16 mm line. If the available

space for storing the line is limited, 14mm line could be an

alternative.

ENGBO AS –et selskap i Engbo-gruppen

BESØKSADRESSE: Wirgenesvei 7, 3157 Barkåker POSTADR: Postboks 2288 Postterminalen, 3103 Tønsberg

E-MAIL: suppo[email protected] WEB: www.engbo.no TLF: +47 33 00 31 50 FAKS: +47 33 00 31 60

12

Safety line

Once the anchor is seated in the anchor bracket, it must

be secured with the safety line supplied. This prevents the

anchor from dropping unintentionally.

Auto stop

Engbo MAXI winches for anchor lines feature an advanced

electronic auto stop switch that stops the windlass

automatically, twice. The first stop comes just before the

anchor reaches the anchor bracket. The windlass can then

only be operated at low speed until it stops for the second

time once the anchor is seated correctly in its bracket –

ready to be dropped next time.

NB The fitting procedures for the different models are described in separate

chapters.

Wireless remote

Fitting antenna

Before starting to operate the wireless remote, the

electronic unit must be fitted with an aerial. In addition, the

remote control and electronic unit must be coded/

electronically instructed to communicate with one another.

Remove the left-hand rubber plug on the electronic unit

(the one closest to the Engbo logo).

Pierce the plug (to one side) with the aerial.

Depress the female socket of the aerial holder and press

the aerial fully into the clip.

Release the female socket and the aerial will be secured in

position.

Replace the rubber plug. Start by pressing the part of the

rubber plug through which the aerial has been inserted,

and continue around the edge until the plug is firmly

seated.

Make sure not to twist the plug and deform the aerial.

NB The remote control will function at short distances even if the

aerial is not fitted.

ENGBO AS –et selskap i Engbo-gruppen

BESØKSADRESSE: Wirgenesvei 7, 3157 Barkåker POSTADR: Postboks 2288 Postterminalen, 3103 Tønsberg

E-MAIL: suppo[email protected] WEB: www.engbo.no TLF: +47 33 00 31 50 FAKS: +47 33 00 31 60

13

Coding of the wireless remote control

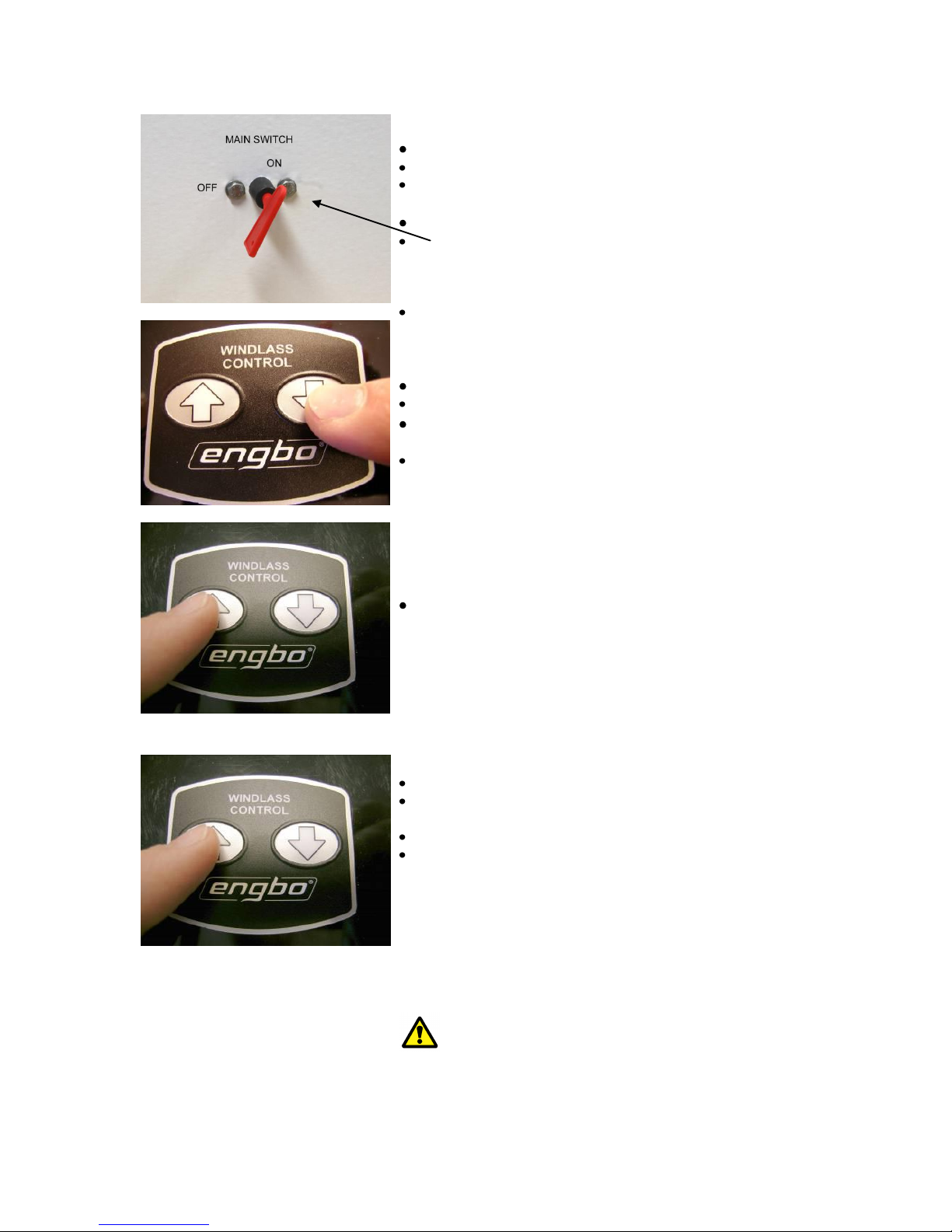

Image A

Image B

Image C

Image D

Image E

Procedure for wireless remote controls with serial

no. above 8600

Important!

If your wireless control has serial no. lower than 8600,

use the procedure enclosed your remote.

If coding a wireless control with serial no. above 8600 is

to be coded to a receiver with Soft Ware of previous version be

aware that the remote will be ready for operation after 10 sec.

How to put the wireless control unit in code mode:

Select the pair of switches on the remote control to be

coded.

Press down both switches simultaneously for

approximately 12 seconds. When you hear a short

sound signal and the green power light starts to flash,

the remote control is prepared for coding and will stay

in coding mode for 5 minutes or until the coding has

been finished.

(Image A)

How to put the receiver unit in code mode:

Alt. 1. Touch panel installed.

Press and keep both switches on the touch panel down

while simultaneously switching on the power to the

receiver unit.(Image B and C)

The receiver will now understand that coding is

requested and automatically connect to your wireless

control and the wireless remote control will immediately

be ready for use.

This will be confirmed by a short sound signal and the

green power light will turn from flashing to permanent.

Check that the wireless control is functioning.

Alt. 2. Joystick installed.

Turn the thruster main switch off.

Disconnect the cables to the joystick connected to 1, 2

and 3 on the green plug on the remote control unit

(RCU).

Prepare two short wires (5 cm). Remove the insulation

in both ends and connect these between 1 and 2 as well

as between 2 and 3 on the green plug. (Image D).

Turn the power on.

The receiver will now understand that coding is

requested and automatically connect to your wireless

control and will immediately be ready for use.

This will be confirmed by a short sound signal and the

green power light will turn from flashing to permanent.

Turn the thruster main switch off.

Disconnect the short wires and connect the joystick

cables.

Turn the power on and check that the wireless control is

functioning.

ENGBO AS –et selskap i Engbo-gruppen

BESØKSADRESSE: Wirgenesvei 7, 3157 Barkåker POSTADR: Postboks 2288 Postterminalen, 3103 Tønsberg

E-MAIL: suppo[email protected] WEB: www.engbo.no TLF: +47 33 00 31 50 FAKS: +47 33 00 31 60

14

Dimensional sketches

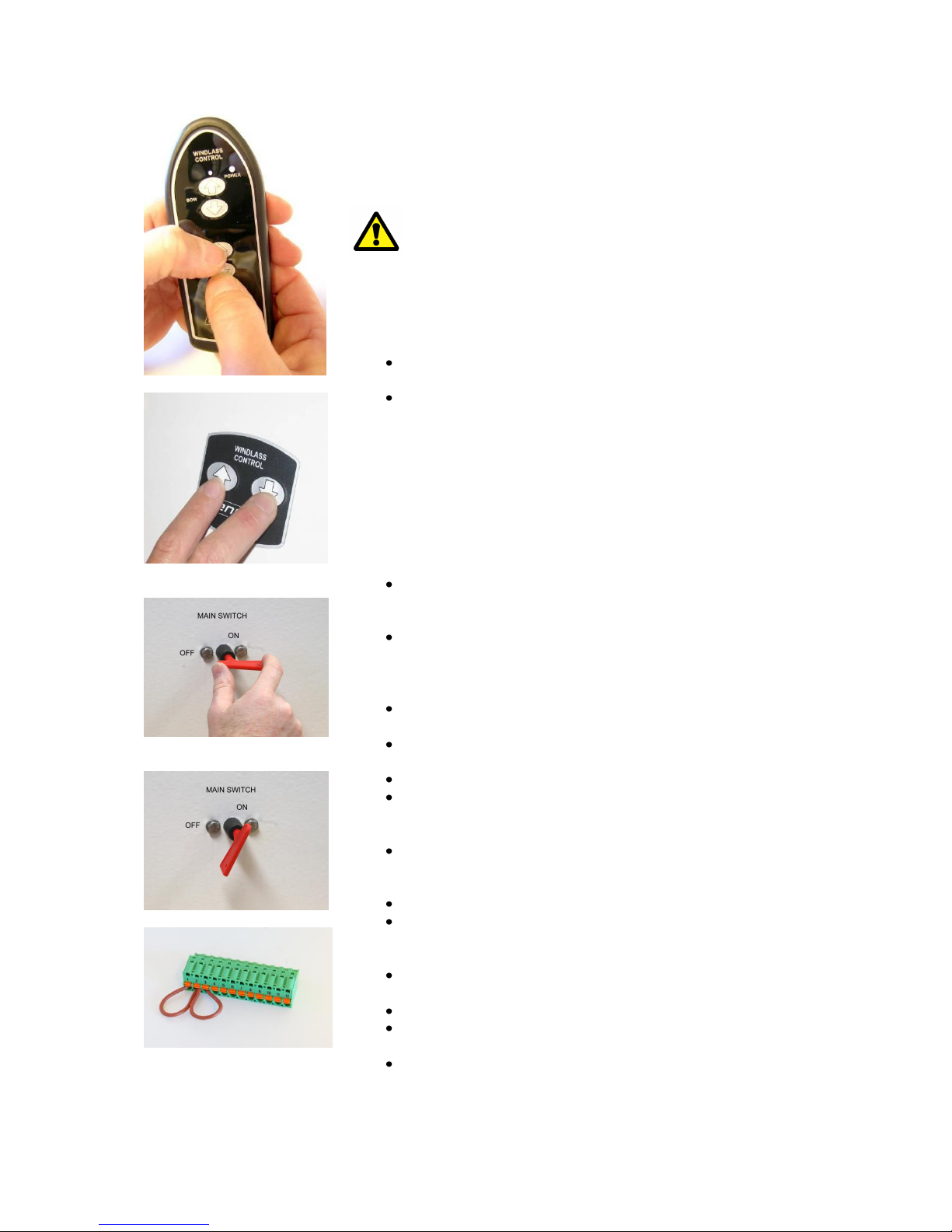

Maxi 31/40 –series

A: Height

B: Length

C: Width incl. line wheel

D: Width excl. line wheel

200 mm

370 mm

230 mm

160 mm

Maxi 32 –series

A: Height above deck

B: Length above deck

C: Width above deck, incl. line wheel

D: Width excl. line wheel

E: Height below deck

200 mm

255 mm

230 mm

160 mm

150 mm

ENGBO AS –et selskap i Engbo-gruppen

BESØKSADRESSE: Wirgenesvei 7, 3157 Barkåker POSTADR: Postboks 2288 Postterminalen, 3103 Tønsberg

E-MAIL: suppo[email protected] WEB: www.engbo.no TLF: +47 33 00 31 50 FAKS: +47 33 00 31 60

15

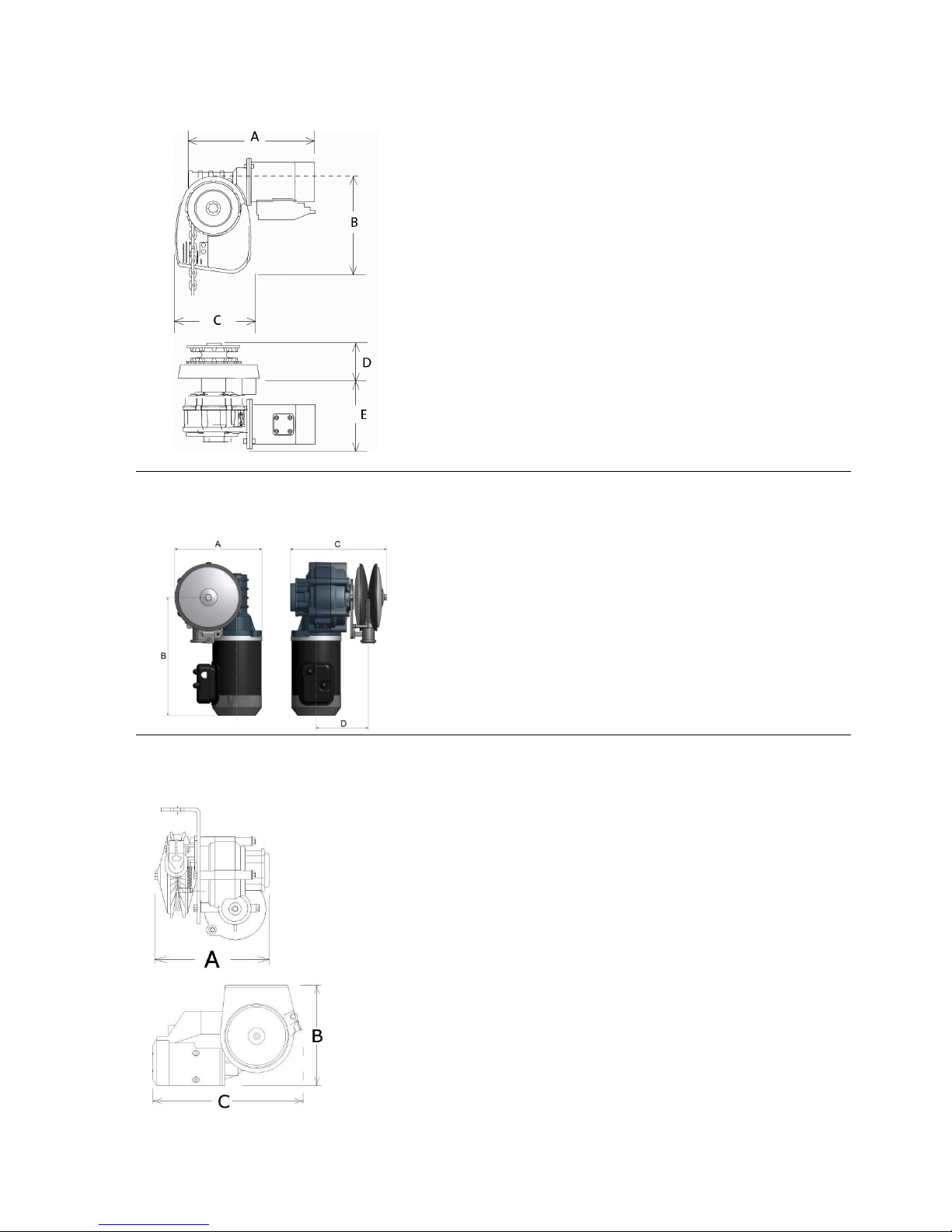

Maxi 33 –series

A: Total width below deck

B: Total length above deck (cover)

C: Total width above deck (cover)

D: Height above deck

E: Height below deck

350 mm

220 mm

160 mm

90 mm

160 mm

Maxi 34-series

A:

B:

C:

D:

200 mm

271 mm

220 mm

120 mm

Maxi 38-series

A: Total width

B: Total height

D: Total length

220 mm

230 mm

370 mm

ENGBO AS –et selskap i Engbo-gruppen

BESØKSADRESSE: Wirgenesvei 7, 3157 Barkåker POSTADR: Postboks 2288 Postterminalen, 3103 Tønsberg

E-MAIL: suppo[email protected] WEB: www.engbo.no TLF: +47 33 00 31 50 FAKS: +47 33 00 31 60

16

Technical

specifications

ENGBO MAXI 31, 32, 33, 34, 38 and 40

Motor output, nom.

-12V DC / 1000 W

-24V DC / 1500 W

Rope

(for rope windlasses)

Woven lead rope: dia. 16 mm. Breaking strain: 4000 kg

Woven lead rope: dia. 14 mm. Breaking strain: 3300 kg

Length:

50 m, weight, 21.7 kg

75 m, weight, 32.0 kg

100 m, weight, 43.0 kg

Chain (for chain

windlasses)

6.5 mm, short link Norwegian std. Breaking strain: 2300 kg

8 mm DIN 766 std. Breaking strain: 4000 kg

Pulling power

(Electronically governed)

Rope windlasses:

1000 W, up to approx. 500 kg

1500 W, up to approx. 650 kg

Chain windlasses: up to approx. 850 kg

Pulling speed

20–25 m/min with a load of approx. 40 kg

Power consumption

80–200 A during normal operation

Recommended fuses

1000 W/12V and 1500 W/24V, 250 A

Recommended min.

battery capacity

12V/100Ah

24V/75 Ah

Weight: windlass with

motor and cables

Approx. 20 kg

Weight: electronic unit

2.3 kg

Auto stop function

Yes (NB Only for rope windlasses)

Recommended anchor/

weight

Engbo / Bruce / Spade /10–30 kg

Recommended boat size

Over 25-foot

Fitting

See the separate descriptions for the individual models

Standard equipment

Windlass incl. cables for electronic module, electronic

module, switch panel and main power switch

Supplementary

equipment

Anchor (Multiple types)

Anchor bracket (Multiple types)

Battery cable

Lead rope or chain

Fuse w/holder

Hull conduit for rope or chain

Wireless remote control

ENGBO AS –et selskap i Engbo-gruppen

BESØKSADRESSE: Wirgenesvei 7, 3157 Barkåker POSTADR: Postboks 2288 Postterminalen, 3103 Tønsberg

E-MAIL: suppo[email protected] WEB: www.engbo.no TLF: +47 33 00 31 50 FAKS: +47 33 00 31 60

17

Electrical wiring

The label on the cover of the electronic unit also shows a diagram for connecting the electrical

cables, - but always verify correct connections with wiring diagram.

IMPORTANT

Always switch off the power at the main switch and/or disconnect the battery

before working on the wiring connections.

Switch panel

Standard touch panel (Item no. 12-79000)

The windlasses are supplied as standard with 1 x

watertight touch panel for installing in a readily accessible

place in the cockpit.

If only this touch panel is to be fitted, it must, for safety

reasons, be positioned so as to allow the operator a clear

view of the anchor as it is raised and seated in the anchor

bracket.

The panel comes with a self-adhesive surface, but if you

prefer, you can use the corner holes to screw it firmly in

position.

Drill an hole (dia. 18 mm) in the place where the panel

is to be fitted.

Run the panel cable through the hole.

Remove the protection tape from the rear surface of

the panel and affix the panel firmly to the surface.

Run the cable to the electronic control box.

Cut off any surplus cable and strip the ends of the

three wires that are to be connected to the terminal

clips as described in the connection diagram. (Picture

of control box).

Connecting the switch panel

The windlasses are supplied as standard with one switch

panel and 10 m of cable. Cut the wires to the required

length and strip approx. 10 mm from their ends. Twist

the wires in the separate cables and attach the cables to

the green terminal box by pressing in the orange button

above the appropriate hole and keeping it depressed

while you insert the cable. Release the button once the

cable is in place. Check that the cable is seated firmly

and that the insulation is inside the terminal clip so that

no loose wires are sticking out.

Connect the cables as follows:

1: White

2: Brown

3: Green

If you wish to connect additional panels, connect the

cables in parallel to 1, 2 and 3. (2 is the common 0 V).

(Spring-lock terminal clips have been chosen rather than

screw clips to prevent problems linked to vibrations

and/or changes in temperature causing the clips to

loosen).

ENGBO AS –et selskap i Engbo-gruppen

BESØKSADRESSE: Wirgenesvei 7, 3157 Barkåker POSTADR: Postboks 2288 Postterminalen, 3103 Tønsberg

E-MAIL: suppo[email protected] WEB: www.engbo.no TLF: +47 33 00 31 50 FAKS: +47 33 00 31 60

18

Connecting the auto stop switch

NB Only applies to rope windlasses.

Auto stop switch

Connect the cables from the auto stop switch in the same

way as described above.

Connect the cables as follows:

4: Brown (BN) = +V

5: Black (BK) = Signal

6: Blue (BU) = Gnd

Connecting the motor and battery cables

It is best to connect the cables from the battery and

motor to the electronic unit first, before fastening the

unit upright against the bulkhead with the cables bent

down over it.

Start by connecting the motor cable marked (A1) to the

left. NB The lock nuts are on the left-hand side.

Then connect motor cable (D2) and then the black (-)

battery cable. Then connect the red (+) battery cable to

(D1) from the motor. Finally, connect (A2) from the

motor. (If necessary, remove in the reverse order). It is

best to use a pair of pliers, as shown in the picture.

The picture shows the correct connection and the

direction of the bolts and cables.

NB The cable shoes must be connected directly to the

copper bars without washers or anything else between.

Use flat washers between the bolt heads and the top

sides of the cable shoes, and between the plastic side of

the end panel and the locking nuts.

The M8 x 25 mm bolt is for the positive battery cable.

Please note that on this terminal, there are two cable

shoes that have to be connected.

NB Connect the cable shoes as shown in the picture to

ensure best possible contact.

NB When the cable length (one way) between the battery

and electronic unit is up to 5 m, use 35 mm2cable. For

longer distances, use 50 mm2cable.

ENGBO AS –et selskap i Engbo-gruppen

BESØKSADRESSE: Wirgenesvei 7, 3157 Barkåker POSTADR: Postboks 2288 Postterminalen, 3103 Tønsberg

E-MAIL: suppo[email protected] WEB: www.engbo.no TLF: +47 33 00 31 50 FAKS: +47 33 00 31 60

19

IMPORTANT

The anchor winch shall not be installed in areas which may contain

flammable or explosive gasses.

In cases where this is not possible, the winch can be built into closed

space, but with ventilation to open air.

The MCU must be installed in dry place in such in a way that no cables

with current may be short circuited.

Battery connection

WARNING!

Check that none of the cables is short-circuited or damaged before

connecting the battery.

Check that all power cables and connection points are tightly secured –

post-tighten if necessary.

NEVER use washers between cable shoes and connection points in places

where high voltage currents pass.

A fuse and main power switch must be fitted to the positive battery cable, as close to

the battery as possible. (See the connection diagram).

The windlass must always be connected to the start battery.

Remember to turn off the main power switch when the windlass is not in use.

Main power switch

The picture shows the battery cable correctly

connected to the main power switch, with

rubber caps insulating the connection points.

Fuse and fuse holder

The fuse holder and fuse are to be fitted to the

(+) cable between the battery and the

electronic control unit of the windlass. See the

electrical connection diagram.

This picture shows correct connection of the

battery cable to the fuse-holder terminal.

NB The fuse must be fitted directly above the

cable shoe. There must NOT be any washers or

nuts between them.

Fit washers on both sides. Recommended

torque: 13–15 NM. Fit plastic caps on the top of

the cover.

Washer

Fuse

Cable shoe

Washer

ENGBO AS –et selskap i Engbo-gruppen

BESØKSADRESSE: Wirgenesvei 7, 3157 Barkåker POSTADR: Postboks 2288 Postterminalen, 3103 Tønsberg

E-MAIL: suppo[email protected] WEB: www.engbo.no TLF: +47 33 00 31 50 FAKS: +47 33 00 31 60

20

Electrical wiring diagram

This manual suits for next models

4

Table of contents

Other Engbo Boating Equipment manuals