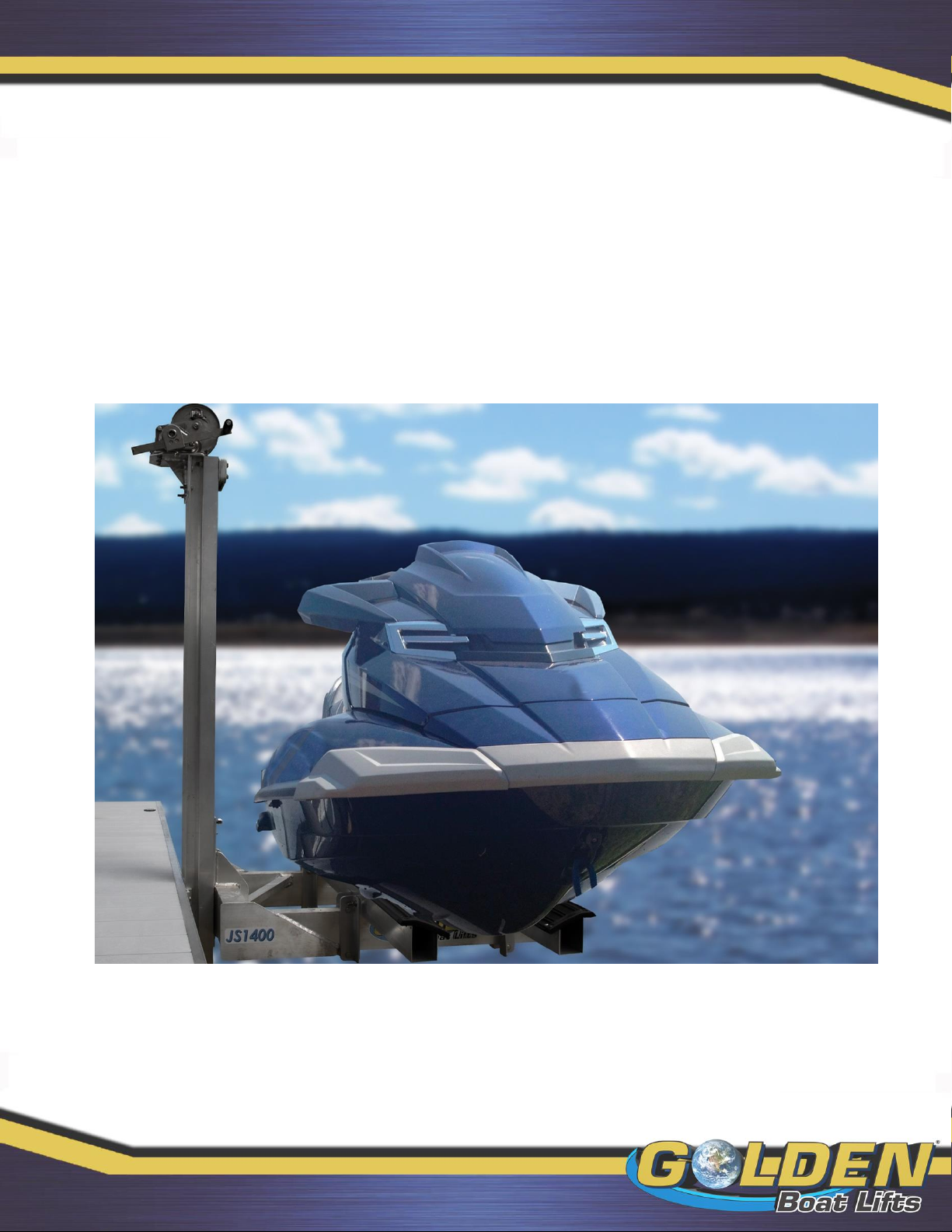

Golden JS-1400 User manual

Other Golden Boating Equipment manuals

Popular Boating Equipment manuals by other brands

Dowco

Dowco V322 CC - 2019 installation instructions

Humphree

Humphree HCS-5 installation manual

Vetus

Vetus BOW4512D Operation manual and installation instructions

Dock Doctors

Dock Doctors SLIDING BOARDING STEP Assembly instructions

Mastervolt

Mastervolt Mass Combi 12/2000-100 Quick installation

Zattini Group

Zattini Group bamar BOXTRON E14S Use and maintenance instruction manual