Engineered air EngA M-TRAC1 Mounting instructions

A

IOM-55 May 2019

USER OPERATION

MANUAL

FOR

M-TRAC1

DIRECT FIRED HEATING CONTROLLER

UNIT MODEL NO. _________________

UNIT SERIAL NO. _________________

SERVICED BY: ___________________

TEL. NO: ________________________

CANADIAN

HEAD OFFICE

AND FACTORY

USA

HEAD OFFICE

AND FACTORY

CANADIAN

EASTERN FACTORY

1401 HASTINGS CRES. SE

CALGARY, ALBERTA

T2G 4C8

Ph: (403) 287-2590

Fax: 888-364-2727

32050 W. 83rd STREET

DESOTO, KANSAS

66018

Ph: (913) 583-3181

Fax: (913) 583-1406

1175 TWINNEY DRIVE

NEWMARKET, ONTARIO

L3Y 5V7

Ph: (905) 898-1114

Fax: (905) 898-7244

SALES OFFICES ACROSS CANADA AND USA

Retain instructions with unit and maintain in a legible condition.

Please give model number and serial number when contacting

factory for information and/or parts.

www.engineeredair.com

A M-TRAC1

IOM-55 May 2019

2

M-TRAC1

The M-TRAC1 has been certified by Intertek (ETL) for use with Engineered Air appliances only.

It has been evaluated to CSA C22.2 No. 24 Temperature-Indicating and Regulating Equipment

and UL 873 UL Standard for Safety Temperature-Indicating and Regulating Equipment. This is a

User Operation Manual and therefore not subject to evaluation.

If any errors or omissions are noted please contact the nearest Engineered Air Technical Service

Department.

To ensure warranty is honored, only qualified personnel should be employed for service and

troubleshooting. If further information is required please contact the nearest Engineered Air

office.

There are two sets of electrical drawings and unit function sheets provided with the appliance.

One set is in an envelope which also contains the Operation, Installation and Maintenance

manual(s). This package is for copying, then should either be returned to the appliance or

stored in a safe place. The other set is attached to the control panel door and should never be

removed.

Please report any omissions to the national service manager.

Warning:

Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury or death. Read the installation, operating and

maintenance instructions thoroughly before installing or servicing this equipment.

Warning:

This unit is connected to high voltages. Electrical shock or death could occur if

instructions are not followed. This equipment contains moving parts that can start

unexpectedly. Injury or death could occur if instructions are not followed. All

work should be performed by a qualified technician. Always disconnect and lock

out power before servicing. DO NOT bypass any interlock or safety switches under

any circumstances.

A M-TRAC1

IOM-55 May 2019

3

A M-TRAC1

IOM-55 May 2019

4

TABLE OF CONTENTS

INTRODUCTION .............................................................................................................................. 5

CONTROLLER RATINGS................................................................................................................... 5

CONTROLLER DESCRIPTION ........................................................................................................... 6

TERMINALS................................................................................................................. 6

DIP SWITCHES ........................................................................................................... 7

INDICATION AND DIAGNOSTIC LIGHTS................................................................... 7

ADJUSTMENT POTS .................................................................................................. 8

MULTIMETER TEST POINTS............................................................................................................ 8

MAXIMUM DISCHARGE SET POINT LIMIT SETUP (SP LMT)................................... 8

CALCULATED SETPOINT (SPC) ................................................................................ 8

DISCHARGE TEMPERATURE (DTEMP) .................................................................... 9

PROFILE PLATE VELOCITY....................................................................................... 9

LOCKOUT RESET ....................................................................................................... 9

CONTROL ...................................................................................................................................... 10

SYSTEM TIMING ....................................................................................................... 10

DISCHARGE AIR SETPOINT .................................................................................... 10

DISCHARGE AIR SENSOR....................................................................................... 10

LOW LIMIT................................................................................................................. 10

DAMPER CONTROL ................................................................................................. 11

BLOWER CONTROL ................................................................................................. 11

BURNER CONTROL.................................................................................................. 11

PROFILE PLATE VELOCITY SENSING SYSTEM .................................................... 12

TEMPERATURE RESET................................................................................................................... 12

MAKE / BREAK THERMOSTAT ................................................................................ 12

2 –10 Vdc SIGNAL .................................................................................................... 12

OPERATION................................................................................................................................... 13

EXHAUST FAN INTERLOCKING .............................................................................. 13

MODULATING VALVE LIGHT OFF POSITION ......................................................... 13

LOW FIRE.................................................................................................................. 13

CALIBRATION................................................................................................................................ 13

SETPOINT (SPC)....................................................................................................... 14

DISCHARGE AIR TEMPERATURE (DTEMP) ........................................................... 14

PROFILE VELOCITY ................................................................................................. 15

2-10 VDC RESET SET UP......................................................................................... 15

SERVICE......................................................................................................................................... 15

SERVICE MODE........................................................................................................ 15

SETPOINT REMOTE WIRING................................................................................... 15

AIR PRESSURE SENSOR ........................................................................................ 15

INPUT CONTACTS BY OTHERS .............................................................................. 16

BMS SENSOR LOCATION ........................................................................................ 16

M-TRAC1 LOCK OUT DESCRIPTION....................................................................... 17

SENSOR TABLE........................................................................................................ 17

FAN OPERATION FLOWCHART..................................................................................................... 18

HEAT OPERATION FLOWCHART................................................................................................... 19

A M-TRAC1

IOM-55 May 2019

5

INTRODUCTION

The M-TRAC1 is a discharge air temperature controller of large (BTUH) single volume direct-

fired Engineered Air equipment, using 120 Vac safety shut off valves, and operating a

modulating ball valve actuator.

The information used in this manual should be used in conjunction with the unit function

sheet(s) and the HE series Installation, Operation, and Maintenance manual.

The M-TRAC1 is designed to control only Engineered Air equipment. Various upgrades and

improvements have been made over time. Always include any suffix letters and numbers for

troubleshooting and/or replacement. All M-TRAC1 models are backwards compatible, however

some additional wiring may be required. M-TRAC1 controllers with a ( - P ) designation are

designed for propane fuel.

Note: It is necessary that all of the remote wiring and controls be complete and operational

before starting the appliance.

CONTROLLER RATINGS

Power requirements: 24 Vac, 40 VA.

Contact Rating: 120V 3A inductive

0-10 Vdc input impedance: 2 k

Environment: -40 to 120°F (-40 to 50°C) non-condensing.

Fuse Rating: 1.25 GDC slow-blow

A M-TRAC1

IOM-55 May 2019

6

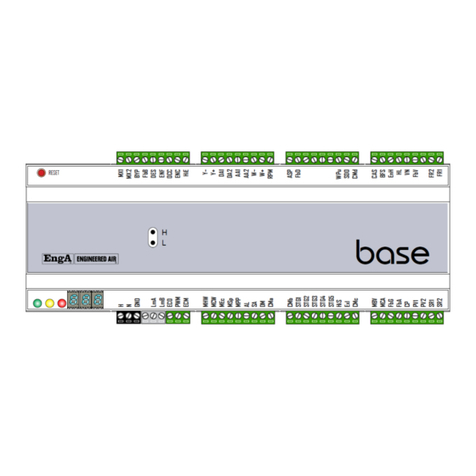

CONTROLLER DESCRIPTION

TERMINALS TABLE 1

Terminal

Description

HD

0-10 Vdc output to ball valve actuator

Q1

Input terminal for single discharge sensor

Q2

Input terminal for two discharge sensors wired in series

U

Sensor common

SP

Output from the built in set point POT.

RP

Positive supply for a remote set point POT.

RS

Return from the remote set point POT.

S

Setpoint enable

+ / -

2 to 10 Vdc input

PF

Not used

H

24 Vac hot

N

24 Vac neutral

FS

Fan switch input

HS

Heat switch input

LMT

Input from safety limit (high limit)

VN

Neutral for the 120 Vac Main gas valve feedback

VFB 120

Hot for the 120 Vac Main gas valve feedback

FR

Flame relay control

CFR

Flame relay control common

PV1 / PV2

Pilot Valve control contacts

C

Input power supply to feed DM, SA and AL outputs

DM

Damper enable output

SA

Supply blower output

AL

Alarm output or Reverse interlock control output

A M-TRAC1

IOM-55 May 2019

7

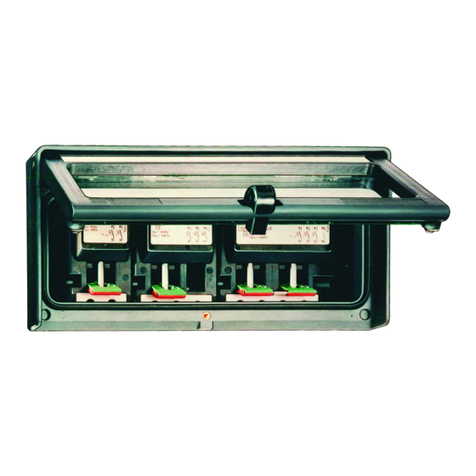

DIP SWITCHES

The M-TRAC1 options are configured by DIP switch selection and/or wiring connections. DIP

switch settings are noted on the internal wiring diagram, and should not be altered.

TABLE 2

DIP SW

Description

10

Disable Auto Heat Switch. If enabled the M-TRAC1 will monitor the discharge air

temperature and disable the heat if the temperature is constantly greater than

the Setpoint (> 3˚F).

9

Extended Profile Velocity Range. Allows the M-TRAC1 to be compatible with

older equipment.

8

Service Mode. Enable to manually control the firing rate.

7

Air Priority Program. See Blower Control.

6

16 Second Pre-purge. Heating will delay on after fan starts.

5

Slow Opening Valve. See Modulating Valve Light Off Position.

4

Disable Open Sensor Checking. See Discharge Air Setpoint.

3

Disable Low Limit. See Low Limit.

2

Alarm contact to be used for reverse interlock. See Reverse Interlock.

1

2-10 Vdc Set Point Reset. See Temperature Reset.

Note: Table based on model M-TRAC 1.4.3

INDICATION AND DIAGNOSTIC LIGHTS

There are 5 status lights on the M-TRAC1 labeled A to E. They operate in 4 patterns: an

irregular flash (.. __ .. __ ..), fast flash (…….), slow flash (. . .), or constantly on (_____).

TABLE 3

IRREGULAR

FAST

SLOW

ON

LIGHT

System Lockout

System Lockout

System

Problem

System

Ok

A –GREEN

Wiring Or Flame

Relay Problem

Prepurge Or Valve

Positioning Delay

Limit Open

Ignition

Attempt

B –RED

Air Flow Or M-TRAC

Problem

Air Velocity Very Low

Air Velocity Too

Low

Air Velocity Too

High

C –RED

Service Mode

Ignition Failure

Heat Switch Open

Burner On

D –RED

Open Discharge

Sensor

Discharge Temp Low

Fan Switch Open

Damper Open

Delay

E –RED

A M-TRAC1

IOM-55 May 2019

8

ADJUSTMENT POTS

There are a number of setting and calibration potentiometers (POT’s) located on the face of the

M-TRAC1. Modifications to these should only be performed by experienced and qualified

personnel.

TABLE 4

POT

Description

SP LMT

Limits the maximum discharge temperature set point.

CAL DTEMP

Discharge air sensor temperature calibration.

SP CAL

Setpoint dial calibration.

MIN FIRE

Adjusts the minimum valve output for low fire.

SERVICE POT

Manually sets burner firing rate for service. Located just above the centre.

When the service switch is on, this POT can be used to adjust the

modulating gas valve from low to high fire. When the service DIP switch is

on, light ‘D’ blinks irregularly.

2-10 Vdc

RESET RATIO

Sets the reset temperature range. This adjusts the amount of reset range

the 2-10 Vdc room thermostat will have. This allows an adjustment band

between 5°F and 50°F (3°C and 28°C).

PROFILE

VELOCITY

Allows a narrow adjustment for Profile pressure set point.

MULTIMETER TEST POINTS

The M-TRAC1 has readout test points for discharge air temperature, discharge set point and

profile plate velocity status. Temperature readings are indicated by Vdc referenced to ground.

MAXIMUM DISCHARGE SET POINT LIMIT SETUP (SP LMT)

Regulations, design or authorities having jurisdiction may limit the maximum discharge air

temperature the appliance is allowed to reach. This may be set by the potentiometer SP LMT,

which is located below and to the right of the M-TRAC1 discharge set point knob. Vdc readout

= °C / 10. See Table 5.

CALCULATED SETPOINT (SPC)

The SPC measurement point is located just below the M-TRAC1 set point knob. This

temperature is the current operating set point after all applicable temperature resets have

been applied to primary or base set point. Vdc readout = °C / 10. See Table 5.

A M-TRAC1

IOM-55 May 2019

9

DISCHARGE TEMPERATURE (DTEMP)

The DTEMP measurement point is located on the top left corner of the M-TRAC. The voltage

reading relates to the actual temperature of the discharge sensor.

Table 5

Voltage (Vdc)

˚C

˚F

1

10

50

1.5

15

59

2

20

68

2.5

25

77

3

30

86

3.5

35

95

4

40

104

NOTE: Sensor accuracy is diminished at temperatures greater than those noted in this table.

PROFILE PLATE VELOCITY

The profile plate has been factory set for the airflow shown in the submittal record.

The profile plate air velocity status can be determined by reading the DC volts measured

between the profile measurement point (located close to terminal S) and terminal N. When the

profile velocity is optimum, the reading is 6 Vdc. For other voltage readings see Table 6.

Note that if the airflow is reduced below safe operating conditions there are delays built into

the M-TRAC1 that will shut off the flame within 45 seconds.

TABLE 6

Test Point Reading

Status

Result

Below 0.8 volts

Very low or no

airflow

Unit lockout

Between 0.8 and 4.0

volts

Low airflow

If the burner is already off it is disabled. If the

burner is on, variable timed lockout.

Between 4.0 and 7.0

volts

Operating range

Normal

Over 7.0 volts

High airflow

If the burner is already off it is disabled. If the

burner is on, variable timed lockout.

M-TRAC models with a ( -P ) designation (propane) will operate with a slightly higher airflow.

LOCKOUT RESET

To reset the M-TRAC1 from a lockout condition push the “Reset Push Button” located just

above the DIP switch block. If the M-TRAC1 looses power while locked out, the status codes

A M-TRAC1

IOM-55 May 2019

10

(reason for the lockout) will be lost. When power is resumed the M-TRAC1 will remain locked

out, but only green LED flashing irregularly.

CONTROL

SYSTEM TIMING

Damper opening delay: Depends on type of damper actuator used.

Blower startup: 54 seconds after terminal FS is energized.

Low Limit bypass: 4.5 minutes from initial startup, 50 seconds nuisance timer.

Trial for ignition: 30 sec.

DISCHARGE AIR SETPOINT

The M-TRAC1 is a discharge air temperature controller with a built in face mounted set point

knob (that is activated by connecting terminal S to SP). Optionally, the M-TRAC1 is available

with a remote set point, with varying set point ranges. When a remote setpoint is provided, the

M-TRAC1 face mounted set point will have no effect.

Additional methods of resetting the discharge air temperature setpoint may be used. Refer to

the unit function and electrical drawing.

DISCHARGE AIR SENSOR

The M-TRAC1 is designed to use either a single or dual discharge sensors, wired in series. Dual

sensors are always used in equipment with temperature rise over 100˚F (55°C) or with dual

fans. In most applications the discharge air sensor(s) is located in the supply blower outlet.

The discharge air sensor also serves as a low limit (or freeze protection) sensor. The part

number of the sensor is noted on the electrical drawing.

The M-TRAC1 automatically checks the discharge air sensor(s). If the M-TRAC1 reads an open

sensor it will disable temperature control and reduce the firing rate to low fire, then shutdown

the appliance. Open sensor checking may be disabled by switching on DIP switch #4.

LOW LIMIT

The M-TRAC1 control is typically configured so that the discharge air temperature sensor also

performs the function of a low limit or freeze stat. If DIP switch 3 is ‘off’ the low limit function

is enabled. If the discharge temperature falls below 40˚F (4°C) the appliance will shut down and

the LED for low discharge temperature will begin flashing. On initial startup the M-TRAC1 will

internally bypass the low limit for 3 minutes. After this time, the low limit discharge

temperature must be below the low limit setpoint (40°F / 4°C) for 50 seconds before the

M-TRAC1 will shut the appliance off.

If DIP switch 3 is ‘on’, the low limit safety function is disabled.

A M-TRAC1

IOM-55 May 2019

11

DAMPER CONTROL

The inlet damper actuator(s) is enabled through output terminal DM. The M-TRAC1 allows time

for the dampers to open prior to starting the supply blower.

BLOWER CONTROL

The M-TRAC1 uses output terminal SA to control the supply air fan. There are, however, a

number of internal and/or external components that may be required to be functional prior to

starting the blower. Proof of air flow is confirmed by the profile pressure sensor.

In some applications continuous airflow is more important than temperature control. The

M-TRAC1 has two blower control program options. They are referred to as airflow priority, and

comfort priority. See Table 7 for the differences between the two priorities. Priority type is

selected by DIP switch 7.

For the comfort priority program, minimum airflow is defined as 60% of required airflow.

Airflow priority is defined as 40% of required airflow.

TABLE 7

Priority Level

Status

Comfort

Air Flow

Heat switch off.

Low airflow

Lock out in 50 seconds.

Blower will remain on until the

discharge air temperature falls

below 40˚F (4°C).

Flame failure, with

discharge temperature

greater than 40°F (4˚C).

Burner and blower off.

Burner off, blower continues to run.

Heat on, but sensing a high

air velocity condition.

Unit will shutdown after

60 seconds.

Burner will lockout after 60

seconds. Blower will remain on

until the discharge air temperature

falls below 40˚F (4°C).

Heat on, with the high limit

control open.

Unit will shutdown after 4

seconds.

Burner will lockout after 4 seconds.

Blower will remain on until the

discharge air temperature falls

below 40˚F (4°C).

BURNER CONTROL

The M-TRAC1 outputs a 0 to 10 Vdc signal to a modulating actuator / ball valve assembly to

control and maintain a defined discharge air temperature setpoint. 10Vdc is the maximum

firing rate (high fire).

A M-TRAC1

IOM-55 May 2019

12

PROFILE PLATE VELOCITY SENSING SYSTEM

The M-TRAC1 has a built in profile pressure sensor to prove and monitor air flow across the

burner. This allows the burner to operate safely and efficiently by proving the airflow is within

proper air velocity limits.

The profile pressure sensor has three non-adjustable air settings: 40, 60 and 120% of normal

airflow. These perform the equivalent function of the high (120%) and low (60%) velocity air

switches while providing an additional very low (40%) velocity for use in process applications,

when providing air is more crucial than temperature control.

The normal profile plate pressure drop is 0.48”w.c.

TEMPERATURE RESET

MAKE / BREAK THERMOSTAT

The set point can be configured for two-level discharge air temperature control, initiated by a

override contact or space mounted, single stage thermostat, with the second (upper) level

adjustable from 75˚(24°C) to 170˚F (77°C) by the SP LMT POT.

2 –10 Vdc SIGNAL

The set point can be adjusted linearly upwards from 5°F to 50 °F (3°C to 28°C) from a 2-10 Vdc

BMS input on terminals - and +. When equipped with a 2 to 10 Vdc room thermostat, this

option becomes a linear room reset. The discharge set point dial, either face mounted or

remote mounted, is the minimum set point. The maximum reset amount is adjusted by the 2-

10VDC RESET RATIO POT located beside terminals RS and RP.

RESET EXAMPLE

SP LMT set at 95˚F, Dial set point set at 50˚F.

2-10 Vdc reset ratio POT adjusted to give 30˚F reset at 10 Vdc.

The resulting control will be:

At 0-2 Vdc = 50˚F discharge

At 6 Vdc = is ½ of the reset authority. Half of 30˚F equals 15˚F, therefore the discharge setpoint

will be at 65˚F (50° + 15° = 65°). At 10 Vdc = full reset. Discharge will be at 50° + 30° = 80˚F.

This will not be limited by the SP LMT (at 95°F), unless the setpoint dial is turned up more than

15°F.

A M-TRAC1

IOM-55 May 2019

13

OPERATION

EXHAUST FAN INTERLOCKING

There are a number of different exhaust interlocking options available. Always refer to the

wiring diagram and unit function sheet to determine the exact type of interlocking used.

The AL output contact may be switched from an alarm output to a exhaust fan enable output

contact for control of reverse interlock control systems (DIP sw #2). In this mode terminal AL

will close on proof of supply air flow.

MODULATING VALVE LIGHT OFF POSITION

The appliance the M-TRAC1 is controlling may use either a fast opening (solenoid) safety shut

off valve, or a slow opening (hydraulic) valve. To ensure the modulating valve is positioned

correctly for initial ignition and avoid high fire ignition, DIP switch 5 is factory set depending on

the type of safety shut off valve.

The M-TRAC1 is designed to ignite the burner at approximately 40% of full fire (non-adjustable).

The positioning time delay allows the modulating valve actuator time to reach the correct light

off position before an ignition attempt is made.

Set DIP switch 5 to “on” when ever the main gas valve is a slow opening. For fast opening valve,

set DIP switch 5 to the “off” position.

LOW FIRE

The M-TRAC1 may control a broad range of burner sizes, all with unique minimum firing rates

(low fire). The ball valve actuator minimum position voltage to set low fire is adjusted using the

built in M-TRAC1 POT labeled “Min Fire”. The POT can be adjusted from 0 to 40% of full fire,

and is located immediately to the right of the discharge air setpoint knob.

CALIBRATION

While the heater and M-TRAC1 is factory tested and calibrated, field conditions may affect

airflow and sensor readings. After making any calibration adjustment, it may take a few

minutes for the M-TRAC1 to reflect the changes. After this time, turn the appliance off for a

few seconds, and then turn the appliance back on. Re-confirm the calibration.

A M-TRAC1

IOM-55 May 2019

14

SETPOINT (SPC)

Check the wiring diagram to determine if the M-TRAC1 is using the face mounted setpoint dial

or an optional remote mounted setpoint dial. The most commonly used remote control panel

includes fan and heat on/off switches and a setpoint dial. A jumper will be installed across

terminals S and SP if the M-TRAC1 is using its built in setpoint dial.

1. Disable any external temperature resets (DIP switch 1 off) or lower the room thermostat

settings so there is no call for additional heat.

2. Use a voltmeter to measure the Vdc output on the SPC measurement point.

3. Compare to the Setpoint dial and adjust the SP CAL POT (located near the face mounted

setpoint dial) so they match (1 Vdc = 10°C).

4. Turn DIP switch 1 on, or return the room thermostat to its normal position.

Note: If the adjustments have no effect on the discharge temperature, the set point may be

under the authority of the maximum set point limiting POT (SP LMT).

DISCHARGE AIR TEMPERATURE (DTEMP)

The discharge sensor must be located so that its temperature remains stable. Due to the

nature of direct fired appliance, the air temperature leaving the supply blower is often very

stratified. It is important to understand that the supply blower does not significantly mix the

air. As well, the stratification pattern will change with different firing rates, wind conditions,

ducting and blower configurations.

Field conditions may result in differences between the sensed temperature and the actual

temperature. Adjusting the location of the discharge sensor a few inches will often correct

temperature differences. If a section of duct is connected to the discharge opening, the sensor

may be moved downstream up to 10 ft. (3 meters). Moving the sensor too far downstream

may result in sensing lag, which could compound control error.

1. Accurately measure the temperature at the discharge air sensor.*

2. Compare the temperature to the DTEMP test point voltmeter reading.

3. Match the readings by adjusting the CAL DTEMP POT (located near terminal Q1,

1 Vdc = 10°C).

* The discharge sensor may be temporarily replaced with a resistor to confirm calibration.

Refer to the Sensor Table, or use a 1kΩ resistor for 21.1°C (70°F) or a 2 kΩ resistor is using dual

sensors (using terminal Q2). Do not leave the resistor in place for normal operation!

A M-TRAC1

IOM-55 May 2019

15

PROFILE VELOCITY

Profile velocity test point readings outside the 4.0 -7.0 Vdc range generally indicate improper

airflow through the heater, not a problem with the M-TRAC1. Before attempting to adjust the

profile velocity ensure the heater is operating at the required nameplate air volume.

The Profile Velocity POT is typically set to the ‘12’ o’clock position. Outside air temperature will

affect the pressure drop across the burner.

2-10 VDC RESET SET UP

1. The 2-10 VDC RESET RATIO POT is located beside terminal RP.

2. Turn off DIP switch 1 and turn the discharge set point knob (face mounted or remote) to

the minimum required set point.

3. Set the voltage across terminals + and –to maximum (10 volts).

4. Calculate the maximum required discharge temperature (°C) and divide by 10.

5. Turn on DIP switch 1 and adjust 2-10 Vdc reset POT ratio until the SPC voltage is equal to

the number calculated in the above step.

6. Adjust SP LMT until the voltage reading is the same as was recorded in step 5.

SERVICE

SERVICE MODE

Placing the M-TRAC1 into service mode allows for direct control of the burner firing rate. Once

the heater has started, the M-TRAC1 can be placed into the service mode by turning on DIP

switch 8. The service POT, located above the reset push button, will control the position of the

modulating valve to any position from low to high fire.

Note: The service mode does not bypass any safeties, heat or fan switches.

SETPOINT REMOTE WIRING

Impedance from long wiring runs may cause the setpoint to be out of calibration. Refer to the

setpoint calibration section if adjustment is required.

AIR PRESSURE SENSOR

The M-TRAC1 has an internally mounted air pressure sensor. Do not blow onto the pressure

ports –too much air pressure will damage it. The ports are fragile and can easily break.

During initial startup, the space the appliance is feeding may be under negative or positive

pressure. To accurately check the M-TRAC1 pressure sensor, remove the sensing tubes from

the M-TRAC1, while the fan is on, and the reading should be 0 Vdc.

A M-TRAC1

IOM-55 May 2019

16

Before making any modifications to the profile opening contact Engineered Air.

INPUT CONTACTS BY OTHERS

Mechanical relay (dry) input contacts must be used. The use of solid state relay’s (SSR’s) may

cause the M-TRAC1 to malfunction due to reverse leakage current when ‘open’.

BMS SENSOR LOCATION

The Engineered Air sensor must be calibrated to match its operation with the Engineered Air

control. Do not calibrate it to match BMS readout if one exists.

If there is a BMS sensor located in the discharge duct, that sensor must be mounted within ½

inch of the Engineered Air sensor.

Note: BMS (Building Management System) discharge air temperatures should never be used to

reset the temperature of the heater. Only use space or room mounted sensors.

A M-TRAC1

IOM-55 May 2019

17

M-TRAC1 LOCK OUT DESCRIPTION

Table 8

LED Code

Reasons

B Irregular

Faulty flame relay or wiring error. Ignition control and safety shut off valve

should be off (FR and CFR contact ‘open’, but receiving power to VFB120

indicating valve is still on.

Faulty flame relay or wiring error. FR and CFR contacts closes, but feedback

from safety shut off valve to VFB120 happening too fast.

B Slow

High limit open.

C Irregular

Air sensor self test. When the blower is off, the sensor reading should be below

0.7 Vdc.

Then the fan turns on, the air sensor reading should increase,

C Fast

Very low air flow. Sensed air flow is below 40%.

C Slow

Low air flow. Sensed air flow is below 60%.

C On

High air flow. Sensed air flow is over 120%.

D Fast

Ignition failure.

E Irregular

Open discharge air sensor. Sensor resistance should not exceed 1940, or 3450 Ω

for dual sensors.

E Fast

Low limit. Discharge temperature has fallen below 40°F (4°C).

SENSOR TABLE

Sensor Resistance Chart for TE 6100-960 and TE600EA3.

Table 9

˚C

˚F

Resistance Ω

˚C

˚F

Resistance Ω

˚C

˚F

Resistance Ω

-40

-40

597

4.4

40

877

48.9

120

1229

-34.4

-30

629

10

50

916

54.4

130

1279

-28.9

-20

661

15.6

60

958

60

140

1329

-23.3

-10

694

21.1

70

1000

65.6

150

1381

-17.8

0

728

26.7

80

1043

71.1

160

1433

-12.2

10

763

32.2

90

1088

76.7

170

1487

-6.6

20

800

37.8

100

1134

82.2

180

1542

-1.1

30

838

43.3

110

1181

87.8

190

1599

Note: Reference resistance is 1035 ohms at 77˚F. Resistance tolerances are ±0.05 to 0.15% at 77˚F.

A M-TRAC1

IOM-55 May 2019

18

FAN OPERATION FLOWCHART

- Main supply power ‘ON’.

- Service switch ‘ON’.

- Fire alarm contact ‘CLOSED’.

- Any additional contacts to terminal H ‘CLOSED’.

- 24Vac across terminals H and N.

Light C blinks

several times

very fast.

Fuse okay?

- Lights A and E slow blink.

Replace fuse.

No

Replace M-TRAC

Yes

No

- Enable fan switch and/or any

other interlocks to power terminal

FS (24Vac).

- Lights A and E ‘ON’.

- Flow control actuator moves to

ignition position.

- DM contact closes to enable damper

actuator.

Dampers

opening?

- Confirm output voltage at terminal DM.

- Check wiring connections to damper actuator.

- Confirm damper actuator is operational.

- Check damper assembly is free to move.

No

- Fan delays to allow dampers to open, then

starts.

Yes

Fan starts?

- Lights A and D slow blink (heat switch is still open).

- Light C will blink fast as fan speed increases, then off.

- Confirm output voltage on terminal SA.

- Check downstream wiring to motor starter.

Light C off?

End of fan section.

- Slow blink: air velocity too low.

- Fast blink: air velocity very low.

- Irregular blink: air flow or M-TRAC problem.

- Confirm air tubes are connected properly.

Yes

Yes

No

No

Yes

Check M-TRAC fuse.

A M-TRAC1

IOM-55 May 2019

19

HEAT OPERATION FLOWCHART

- Close heat switch and/or any other contacts or interlocks to power terminal

HS (24Vac).

- If system is reverse interlock the AL output will have closed when the supply

fan successfully started, and enabled the exhaust fan.

- Light D slow blink should now be Off.

Light B

irregular

blink?

Light B slow

blink?

Light B fast

blink?

Light B on?

- Wiring or flame relay problem. Check wiring into

terminals VFB120 and VN safety inputs.

- High limit safety contact is open. M-TRAC is

expecting 120Vac to terminal LMT.

- 16 second prepurge (DIP #6 on) or delay to set

modulating valve to ignition position.

No

Yes

Yes

Yes

Yes

No

No

No

- FR and CFR contacts close.

- PV1 and PV2 contacts close.

- Ignition control enabled.

Ignition sequence:

- Ignition control enables pilot valve and sparks at electrode.

- Pilot flame achieved and sensed.

- Ignition control outputs power to main valve control relay.

- Relay contact close to enable main valve(s) (SSOV).

- 120V feedback signal into terminals VFB120 and VN from main valve(s).

- Main burner lit from pilot flame.

- Ignition spark off.

- PV1 and PV2 contacts delay off to disable pilot valve. Ignition control is sensing

main burner only.

- Light D on (burner on).

End of heat section.

- Burner modulating valve enabled to

maintain discharge air temperature

setpoint, from 0-10Vdc output terminal

HD.

Table of contents

Other Engineered air Controllers manuals