Engineered air EngA W-TRAC User manual

IOM‐49 Mar99R4

INSTALLATION, OPERATION

AND MAINTENANCE MANUAL

FOR

W-TRAC

HEAT WHEEL CONTROLLER

UNIT MODEL NO. _________________

UNIT SERIAL NO. _________________

SERVICED BY: ___________________

TEL. NO: ________________________

CANADIAN

HEAD OFFICE

AND FACTORY

USA

HEAD OFFICE

AND FACTORY

CANADIAN

EASTERN FACTORY

1401 HASTINGS CRES.

SE

CALGARY, ALBERTA

T2G 4C8

Ph: (403) 287-4774

Fx: 888-364-2727

32050 W. 83r

d

STREET

DESOTO, KANSAS

66018

Ph: (913) 583-3181

Fx: (913) 583-1406

1175 TWINNEY DRIVE

NEWMARKET,

ONTARIO

L3Y 5V7

Ph: (905) 898-1114

Fx: (905) 898-7244

SALES OFFICES ACROSS CANADA AND USA

Retain instructions with unit and maintain in a legible condition.

Please give model number and serial number when contacting

Engineered Air for information and/or parts.

www.engineeredair.com

A

IOM‐49 2of12 Mar99R4

W‐TRAC

IfanyerrorsoromissionsarenotedpleasecontactthenearestEngineeredAirTechnicalService

Department.

Toensurewarrantyishonored,onlyqualifiedpersonnelshouldbeemployedforserviceand

troubleshooting.IffurtherinformationisrequiredpleasecontactthenearestEngineeredAiroffice.

Therearetwosetsofelectricaldrawingandunitfunctionsheetsprovidedwiththeappliance.Onesetisin

anenvelopewhichalsocontainstheOperation,InstallationandMaintenancemanual(s).Thispackageis

forcopying,thenshouldeitherbereturnedtotheapplianceorstoredinasafeplace.Theothersetis

attachedtothecontrolpaneldoorandshouldneverberemoved.

Pleasereportanyomissionstothenationalservicemanager.

Warning:

Improperinstallation,adjustment,alteration,serviceormaintenancecancause

propertydamage,injuryordeath.Readtheinstallation,operatingand

maintenanceinstructionsthoroughlybeforeinstallingorservicingthisequipment.

Warning: Thisunitisconnectedtohighvoltages.Electricalshockordeathcouldoccurif

instructionsarenotfollowed.Thisequipmentcontainsmovingpartsthatcanstart

unexpectedly.Injuryordeathcouldoccurifinstructionsarenotfollowed.All

workshouldbeperformedbyaqualifiedtechnician.Alwaysdisconnectandlock

outpowerbeforeservicing.DONOTbypassanyinterlockorsafetyswitchesunder

anycircumstances.

AW-TRAC

IOM‐49 3of12 Mar99R4

AW-TRAC

IOM‐49 4of12 Mar99R4

TableofContents

INTRODUCTION..................................................................................................................................................5

CONTROLLERRATINGS......................................................................................................................................5

CONTROLLERDESCRIPTION...............................................................................................................................6

TERMINALLIST...................................................................................................................................................6

DIPSWITCHES....................................................................................................................................................6

INDICATIONANDDIAGNOSTICLIGHTS..............................................................................................................7

ADJUSTMENTPOTS............................................................................................................................................7

TEMPERATURECONTROL..................................................................................................................................7

BASESETPOINT..................................................................................................................................................8

SETPOINTRESET.................................................................................................................................................8

FROSTCONTROL................................................................................................................................................8

EXHAUSTAIRRH%SENSOR...............................................................................................................................8

RETURNAIRRH%SENSOR.................................................................................................................................9

BDRHPREDICTEDRETURNAIRRELATIVEHUMIDITY........................................................................................9

WIRING...............................................................................................................................................................9

SENSORTABLE.................................................................................................................................................12

SERVICENOTES................................................................................................................................................10

ROTATION........................................................................................................................................................10

MOTORSPEEDCONTROL.................................................................................................................................10

KBVF/SIVF(R)..................................................................................................................................................10

WHEELROTATIONSPEED................................................................................................................................11

SENSORCALIBRATION.....................................................................................................................................11

DISCHARGETEMPERATURECALIBRATION......................................................................................................11

EXHAUSTTEMPERATURECALIBRATION..........................................................................................................11

HUMIDITYSENSORS.........................................................................................................................................12

AW-TRAC

IOM‐49 5of12 Mar99R4

INTRODUCTION

TheW‐TRACisasupervisorycontrollerforEngineeredAirHRWheatwheels,withbuiltindischargeair

temperaturecontrolandoptionalexhaustfrostcontrol.

Theinformationusedinthismanualshouldbeusedinconjunctionwiththeunitfunctionsheet(s)andthe

HRWseriesInstallation,Operation,andMaintenancemanual.

TheW‐TRACisdesignedtocontrolonlyEngineeredAirequipment.Variousupgradesandimprovements

havebeenmadeovertime.Alwaysincludeanysuffixlettersandnumbersfortroubleshootingand/or

replacement.AllW‐TRACmodelsarebackwardscompatible;howeversomeadditionalwiringmaybe

required.

Note:Itisnecessarythatalloftheremotewiringandcontrolsbecompleteandoperationalbeforestarting

theappliance.

CONTROLLERRATINGS

Powerrequirements:24VAC,40VA.

ContactRating:120V3Ainductive

0‐10Vdcinputimpedance:5k

Environment:‐40to120°F(‐40to50°C)non‐condensing.

AW-TRAC

IOM‐49 6of12 Mar99R4

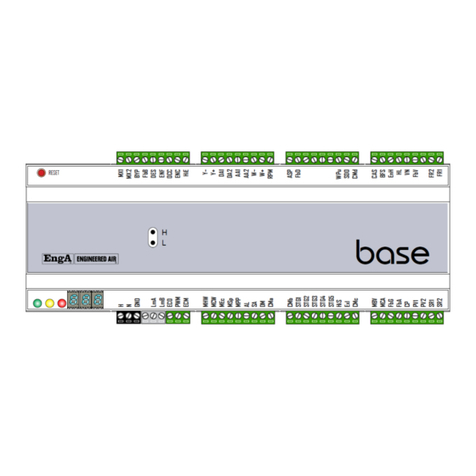

CONTROLLERDESCRIPTION

TERMINALLIST

Terminal Description

C1 Sensorcommon,and0‐10Vdcresetcommon(‐).

S 0‐10Vdctemperatureresetinput(+).

D Supplyairtemperaturesensorinput.

E Exhaustairtemperaturesensorinput.

A Outsideairtemperaturesensorinput.

RMH 0‐10VdcreturnairRH%input.

EXH 0‐10VdcexhaustairRH%input.

MOD 0‐10Vdcheatwheelcontroloutput(+).

C2 0‐10Vdcheatwheelcontroloutput(‐).

+12 12Vdcoutputpower

+32 32Vdcoutputpower(RH%sensorhot)

T2(N) 24VacNeutralpowerinput.

T1 24VacHotpowerinput.

6 Outputcontactcommon

5 Outputcontactnormallyclosed(N.C.)

4 Outputcontactnormallyopen(N.O.).Startcontact.

P1 Lowoutputpotentiometer(legacy,foroldstyleDCdrivemotors).

P2 Wiperoutputpotentiometer(legacy,foroldstyleDCdrivemotors).

P3 Highoutputpotentiometer(legacy,foroldstyleDCdrivemotors).

DIPSWITCHES

W‐TRACconfigurationoptionsareconfiguredbyDIPswitchselection and/or wiring connections. These

arefactorysetandshouldnotnormallyneedtobealtered.

DIPSW Description

BDRHSPEN ‘ON’whenRH%sensingofthereturnairisnotused.W‐TRACwillcontrolbasedon

pre‐definedRH%values.Switchwillbe‘OFF’whensensingactualRH%.

EXRHCTRL ‘ON’whenusingexhaustairRH%sensing.

BDRHCTRL ‘ON’whenRH%sensingofthereturnairisnotused.Switchmustbeinthesame

positionasBDRHSPEN(above).

MANHISPEED* ‘ON’todrivetheoutputtomaximumwheelrotationspeed.

MANLOSPEED* ‘ON’todrivetheoutputtominimumwheelrotationspeed.

*Donotenablebothswitchesatthesametime,orleaveeitherswitch‘on’innormaloperation.

AW-TRAC

IOM‐49 7of12 Mar99R4

INDICATIONANDDIAGNOSTICLIGHTS

OnthefaceoftheW‐TRACare5redLEDindicationlights.

Light Description

LowExhaust

Temp

Indicatestheexhausttemperatureisbelowthecalculatedminimumallowable

temperature,whichisbasedontheamountofmoistureinthereturnair(measured

orestimated)andtheambienttemperature.

BadSensor Shortedoropensensorindication.

VentMode Wheelwillbestopped.Nocallforheatingorcooling.

DischargeTooHot Wheelisslowingdownduetoexcessiverecoveryofheat.

FrostMode Heatwheelrotationspeedisreducingtopreventfrostaccumulation.

ADJUSTMENTPOTS

Thereareanumberofsettingandcalibrationpotentiometers(POT’s)locatedonthefaceoftheW‐TRAC.

Modificationstotheseshouldonlybedonebyexperiencedandqualifiedpersonnel.

POT Description

DISCAL Dischargetemperaturesensorcalibration.

EXCAL Exhausttemperaturesensorcalibration.

AMBCAL Ambient/outdoortemperaturesensorcalibration.

BDRH PredicteddesignreturnairRH%scale(1‐4).

TEMPERATURECONTROL

TheW‐TRAChas4modesofoperation;Heat,Defrost,VentandCool,thatcontrolsthewheelrotational

speedtoachievethedesiredtemperaturesetpointofsupplyairleavingthewheel.

Whentheoutsideairiscolderthantheexhaustair,theheatwheelwillrotatetocaptureheatfromthe

exhaustairsideandtransferittothesupplyairstream.Increasingtherotationspeedwillincreasethe

amountofheattransferred.

Iftoomuchheatisbeingremovedfromtheexhaustairstreamitispossibleforfrosttoaccumulateonthe

faceoftheheatwheel.TheW‐TRACwillautomaticallyreducetherotationspeedtopreventfrosting.

Ifnoheatingisrequired,theW‐TRACwillstopthewheelrotationandenter‘ventmode’.

AW-TRAC

IOM‐49 8of12 Mar99R4

IftheoutsideairtemperatureiswarmerthantheexhaustairtheW‐TRACwillenter‘coolmode’and

rotatetheheatwheeltotransferheatfromtheoutsideairtotheexhaust.

BASESETPOINT

TheW‐TRACisdesignedtobeadischargeairtemperaturecontroller.Thebasedischargeairtemperature

issetfromthesetpointcontrolknoblocatedonthefaceoftheW‐TRAC.

SETPOINTRESET

Thebasedischargeairtemperatureisoftenmodifiedfromaremotesignaltomaintainthedesired

temperatureofthesuppliedspace.Thisiscalledreset.TheW‐TRACdischargetemperaturecanbereset

fromavarietyofsourcesusinga0‐10VDCsignal.

AnoffsettotheBMSinputrangecanbeimplementedbyaddinga7.5kresistorinserieswithterminalS.

Thefollowingtabledescribesthechangeofdischargesetpointfromtheinputvoltage(toterminalsS+and

C1‐),withasetpointfixedat66°F.Refertotheequipmentfunctionpageforthedesignresetrange.

InputVoltage

0.0 2.0 4.0 6.0 8.0 10.0

Discharge

Setpoint(°F/°C)

NoResistor 30/‐1 40/4 45/7 52/11 60/15 66/19

7.5kResistor 48/9 53/12 56/13 59/15 63/17 66/19

FROSTCONTROL

Frostshouldnotbeallowedtobuilduponthewheel.Itisnecessarytoreducetheamountofheat

recoveredwhentheoutsidetemperatureisbelowthefreezingpoint(0°C/32°F)andtheexhaustleaving

temperaturefallstoapointthatfrostcanbegintoform.Frostmaydamagethewheelandreduceairflow.

Operatingtheheatwheelclosetothefrostthresholdtemperaturewillprovidemaximumenergyrecovery.

Thereare3differentmethodsofprovidingfrostcontrol,allofwhichreducetheheatwheelrotation

speed.

EXHAUSTAIRRH%SENSOR

ThismethodofcontrolrequiresahumiditysensorconnectedacrossterminalsEXHandC2.DIP1and3

mustbeOFF,DIP2mustbeON.Thesensorisinstalledintheexhaustairsection,justaftertheheat

wheel.

AW-TRAC

IOM‐49 9of12 Mar99R4

Whentheoutdoorambienttemperatureisbelow15°F(‐10°C)thespeedoftheheatwheelwillbereduced

tomaintaintheleavingexhaustairhumiditybetween80–90%.Thisapplicationrequireshighaccuracy

humiditysensors.

RETURNAIRRH%SENSOR

ThismethodoffrostcontrolrequiresaRHsensorinstalledintheequipmentreturnairsection,justbefore

theheatwheel,wiredintoterminalsRMHandC2.DIP3mustbeON,DIP1and2mustbeOFF.

UsingthevaluesoftheRHandambient(outsideair)sensor,theW‐TRACcalculatestheminimum

allowableexhaustairtemperaturethatwillkeepfrostfromformingonthewheel.

BDRHPREDICTEDRETURNAIRRELATIVEHUMIDITY

RH%sensingisnotusedinthismethodoffrostcontrol.DIP1and3mustbeON,whileDIP2isOFF.

TheW‐TRACmayoperatewithouttheuseofhumiditysensinginsituationswheretheRH%valuesare

expectedtobereasonablyconstant.Inthesecases,theW‐TRACoperatesbysensibletemperatureonly.

Whenenabled,theBDRHpot(BuildingDesignRelativeHumidity)issetaccordingtotheexpecteddesign

returnairconditions.RefertothetablebelowtosettheexpectedvaluesbasedontemperatureandRH%.

Table1

BDRHsetting ReturnAirConditions

70°F(21°C) 75°F(24°C) 80°F(27°C)

1 <25% <21% <18%

2 26–32% 22–27% 19–23%

3 33–39% 28–33% 24–27%

4 40–49% 34–42% 28–35%

Tousethistable,firstselectthereturnairtemperature,thenselecttheRH%rangeinthecolumnbelow,

thenselecttheBDRHsettingtotheleft.

WIRING

TheW‐TRACterminalsHandNrequireaminimum24VAC,40VAclass2powersupplythatdoesnotneed

tobeisolatedfromtherestofthesystemscomponents.

TerminalNshouldbewiredtothecommonofthesamesourcesupplyingpowertoterminalsE,A,andK.

Allremotewiringshouldbeinstalledinaclean(noelectricalnoise)environment.Wiresizeshouldbea

minimumof24ga.twistedpairtoreduceelectricalnoise(shieldedwireisrecommended).Forlongerruns

AW-TRAC

IOM‐49 10of12 Mar99R4

(over50ft.eq.length),theuseofaminimum20gauge‐shieldedwireisrecommended.Theshieldshould

begroundedatthecontrollerendonly,withtheotherendtaped.

Itisimportanttoensurecorrectpolaritywhenwiringintothesystem.

NOTE:Fieldanalogcontrolinputsrequiresignalisolationtopreventgroundloop

signalcorruptionand/ordamagetothecontroller(s).

SERVICENOTES

ROTATION

Mostheatwheelshaveapurgesectiontopurgeexhaustairtrappedinthewheelflutesbeforetheyrotate

tothesupplyairside.Thecorrectwheelrotationdirectionisnotedonthefaceoftheheatwheel.Drive

motorrotationmaybechangedatthemotorwireconnectionsorontheinverterdrivefeedingthemotor

(ifused).

MOTORSPEEDCONTROL

Themodulating0‐10Vdcmotorspeedoutputmaybeconnectedtoavarietyofcontrollersand/or

inverters.Refertotheequipmentwiringdiagramforconnectiondetails.Thefollowingsetupparameters

aretypical.Alwaysrefertotheequipmentfunctionsheetforanychanges.Toensurepropersetup

operation,donothaveDIP4andDIP5onatthesametime.

KBVF/SIVF(R)

TheKBVFinverterdriveandSIVFsignalisolatoraremanufacturedbyKBElectronicsInc.Theinverterand

isolatorinstallationandoperationmanualsareincludedintheinformationpackage,originallylocatedin

themainequipmentelectricalpanel.The0‐10VdcW‐TRACcontroloutputfeedsintotheSIVFsignal

isolatorwhich,inturn,feedsanisolated0‐5VdcsignaltotheKBVFinverterdrive.

HighSpeed

TurnonW‐TRACDIP4toforcetheW‐TRACtomaximumoutput(near10Vdc).Notethatifthe

W‐TRACisoperatinginfrostmodeDIP4willnotallowthedrivetogotofullspeed.Measurethemotor

ampsandconfirmthereadingsarelessthanthemaximummotorampacity.Ifpossible,measureand

confirmtheoutputfrequencyis60Hz.

TheKBVFisfactorysetto100%ofratedfrequency(60Hz)andshouldnotbeadjusted.

AW-TRAC

IOM‐49 11of12 Mar99R4

LowSpeed

TurnonDIP5todrivetheoutputtominimum(0Vdc).AdjusttheminimumspeedpotontheKBVF

inverterdriveuntiltheheatwheeljustbeginstoturn,usuallybetween0.5and2rpm.Turnthepoweroff,

andthenrestartthesystemtoconfirmthemotorhasenoughstartingtorquetoreliablystartrotatingthe

heatwheel.

ReturnallDIPswitchestotheiroriginalposition.

WHEELROTATIONSPEED

Maximumwheelrotationspeedwillbefactorysetintherangeof30‐40rpm,at60Hz,dependingonthe

sizeoftheheatwheel.

Minimumwheelspeedisdependentonthestartingtorqueofthemotorandheatwheel,usuallybetween

0.5and2rpm.

SENSORCALIBRATION

DischargeTemperatureCalibration

Removethesupplyairtemperaturesensorandmeasureboththesensorresistanceandthetemperature

atthesensingelement.Comparethesereadingstothesensortablevalues.Iftheresistanceisoutby

morethan16ohms,replacethesensor.

Measuringasensortemperaturebetween60–70°F,slowlyrotatethetemperaturesetpointdial

counterclockwiseuntilthe‘DischargeTooHot’lightjustcomeson.

Slowlyincreasethetemperaturesetpointdialuntilthelightgoesoff.

Thesetpointshouldmatchthesensedtemperaturemeasurement.Ifnot,adjustthecalibrationpot

andrepeattest.

ExhaustTemperatureCalibration

Removetheexhaustairtemperaturesensorandmeasureboththesensorresistanceandthetemperature

atthesensingelement.Comparethesereadingstothesensortablevalues.Iftheresistanceisoutby

morethan16ohms,replacethesensor.The‘badsensor’LEDmayturnonandoffduringthisprocedure.

PlaceajumperwireacrossterminalsAandC1.

Removetheexhausttemperaturesensorandreplacewitha909Ωresistor.

NotethepositionoftheBDRHpot,andthenadjusttoposition2.

AW-TRAC

IOM‐49 12of12 Mar99R4

Slowlyrotatepot#2counterclockwise(EXCAL))untilthelowexhausttemperaturelightcomeson.

Slowlyrotatepot#2clockwiseuntilthelowexhausttemperaturelightjustturnsoff.

ReconnectallsensorsandsetpotBDRHbacktoitsoriginalposition.

Humiditysensors

AccuratelymeasuretherelativehumidityatthesensorlocationandcomparetothesensorVdcoutput.

The0‐10Vdcoutputisproportionalto0‐100%RH.

SENSORTABLE

SensorResistanceChartforTE6000EA3

Table2

°C °F Resistance°C °F Resistance°C °F Resistance

‐40 ‐40 602 18.3 65 983 48.9 120 1234

‐34.4 ‐30 633 20 68 996 54.4 130 1269

‐28.9 ‐20 665 20.6 69 1000.7 60 140 1333

‐23.3 ‐10 698 21.1 70 1005 65.5 150 1365

‐17.8 0 732 23.9 75 1026.5 71.1 160 1437

‐12.2 10 768 26.7 80 1048 76.7 170 1491

‐8.7 20 804 29.4 85 1070 82.2 180 1546

‐1.1 30 842 32.2 90 1092 87.7 190 1602

4.4 40 881 35.6 95 1116 93.3 200 1659

10 50 921 37.8 100 1139 98.8 210 1718

12.8 55 942 43.3 110 1186 100 212 1778

Referenceresistanceis1035ohmsat77°F.Resistancetolerancesare±0.05to0.15%at77°F.Temperature

range+32to+104°F.

Table of contents

Other Engineered air Controllers manuals

Popular Controllers manuals by other brands

Siemens

Siemens RVD230 Basic documentation

Joy-it

Joy-it LINKERKIT OLED manual

Afag

Afag IRG 1-MS Translation of original operating instructions

Emerson

Emerson Dixell XR70CHC Installing and operating instructions

dixell

dixell XC660D Installing and operating instructions

Asco

Asco Froment SIGMA IHT Version 4 quick start guide