The ESC will not provide any power to the motor, if the throttle

stick is anywhere higher then zero throttle when the main battery

is plugged in. To arm the esc ready for use you, You must move

the throttle stick to zero then disconnect and re connected the

battery.

Always power your radio transmitter before powering up the

receiver and/or the ESC. Some receivers with failsafe features or

Spektrum receiver units that are not bound on receiver power up

are entirely capable of causing the arming sequence to occur and

command the ESC to drive the motor. Always keep the aircraft

restrained and clear of body parts when the ESC is powered.

If your ESC cannot sense any radio signal it will beep the motor

and flash orange on the LED continuously

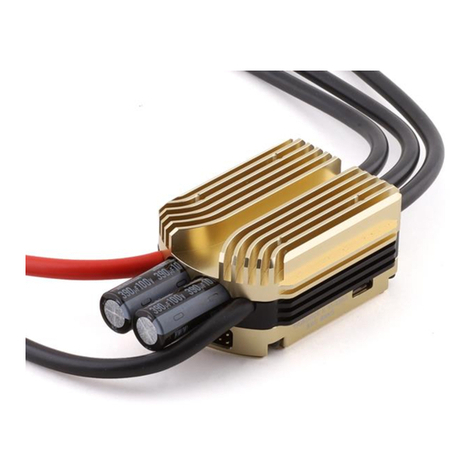

3.0 Scorpion SBEC features

ALL of the Scorpion 26V SBEC programming features are

available though the use of the ESC programming card

included with your ESC. So there is NO need to purchase any

other cables or cards to allow you to program your ESC

properly

Scorpion ESC’s come with default or factory settings which

are recommended for most applications. Programming

options can be changed at the discretion of the user. See

section 6.0 for programming instructions

Features:

Safe Power up To arm the controller, the throttle must be

held in the “Brake/Zero” position (all the way

down). If throttle is not at zero at startup, the ESC

will not provide any power to the motor regardless

of where the throttle stick is positioned when first

powered up.

Loss of signal

(fail safe) The Scorpion will stop the motor as a safety

feature when the throttle signal is lost or

corrupt for 3 seconds. If a signal is regained the

user will have instant control again.

LED The LED is used for programming/startup

confirmation of your scorpion esc. Once armed

the LED can be set to give an indication of low

battery conditions

Low Voltage Cutoff You can choose for your ESC to stop or reduce

power when the input battery voltage drops to a

preset/programmed cutoff voltage.

Current Limiting Amp output limit, the output is rated at 10% over

the rated Amp. At approximately 10% over the

rated Amps it will automatically limit the output to

the motor, as long as the motor is not rated too

much over the ESC spec limits, this safety

mechanism will prevent a over load to the ESC but

if you install a motor for example rated at 100

amp on a ESC that are rated for only 60Amp, this

mechanism will not work properly due to the

instant surge of power demand from the motor, it

may shutdown too early or simply fry the ESC, the

only solution to this is to never use a Motor that

has a rating bigger then the ESC, don’t even think

you can use it if you run the motor at a slower

RPM or load, it will not work!!

Thermal Protection At 95 degree C, the ESC will slowdown the power

output to the motor by 50% ( the on board LED

will flash red), to re initiate full throttle you need

to move the throttle stick to idle position and then

the ESC will resume normal output once you

throttle up again. If your ESC is over 60deg on

startup it will not arm red LED will flash and a DI

DI DI sound will be played.

Brake Stops rotation of the motor when the

throttle signal is moved to the lowest

position.

Throttle Airplane, Car and Heli modes come pre

programmed and can be selected by the user

Electronic timing Manual settings that may improve the efficiency of

the system for some motors are available. The

standard Scorpion setting is to automatically

detect and adjust for the motor it is driving.

4.0 Initial setup

You MUST perform throttle range setup before the first use of

the ESC. Remove propeller/pinion from motor while

performing initial throttle range setup.

4.1 Throttle range setup (full throttle and stop)

4.2 Turn on transmitter and set throttle to maximum

position

4.3 Connect battery to ESC. After approximately 2

seconds, the LED flashes rapidly, then 1 second after

you will hear 2 beeps from the motor confirming the

maximum throttle position has been set. (If at this

time, you leave the throttle stick at maximum

position for over 10 seconds, the ESC will reset itself

to Factory default throttle setting)

4.4 Move throttle to minimum position within 10 seconds

and hold throttle at minimum position, the LED

flashes slowly for 1 second. Then you will hear 2

beeps (1 KHZ tone) indicating minimum throttle

position is set and confirmed. You only need to do

this once as throttle range will be stored in the

memory of the speed controller. You can reset the

throttle range by performing steps 1.1 to 1.3 again

5.0 Connecting your Scorpion

SBEC to the programming card

Your Scorpion SBEC is programmed using the Infrared (IR)

Program card and Receiver included with this ESC.

First you must connect your IR Receiver to your ESC

Ensure the brown wire from your esc is facing outwards

5.1 Once you have plugged in the IR Receiver push the

switch across to IRS.

5.2 Now connect a battery to the ESC. Your motor will emit 3

beeps and the LED will flash 3 times red.

5.3 Your IR Receiver is now ready to receive a signal from

the program card.

please note that IR will be interfered in direct sunlight so to

program your model we suggest doing it indoors in the shade out

of direct sunlight

before flying you will need to place the switch back to PPM mode