Enginko MCF-LW06424 User manual

m2m Germany GmbH | Am Kappengraben 18-20 | 61273 Wehrheim | 06081 5873860

Table

of

Contents

MCF-LW06424

Operating

Manual

Important

safety

information

Read

this

manual

before

attempting

to

install

the

device!

Failure

to

observe

recommendations

included

in

this

manual

may

be

dangerous

or

cause

a

violation

of

the

law.

The

manufacturer

will

not

be

held

responsible

for

any

loss

or

damage

resulting

from

not

following

the

instructions

of

this

operating

manual.

Do

not

dismantle

or

modify

in

any

way.

Avoid

mechanical

stress

Do

not

use

any

detergent

or

alcohol

to

clean

the

device.

Disposal

information

for

users

Pursuant

to

and

in

accordance

with

Article

14

of

the

Directive

2012/19/EU

of

the

European

Parliament

on

waste

electrical

and

electronic

equipment

(WEEE),

and

pursuant

to

and

in

accordance

with

Article

20

of

the

Directive

2013/56/EU

of

the

European

Parliament

on

batteries

and

accumulators

and

waste

batteries.

The

barred

symbol

of

the

rubbish

bin

shown

on

the

equipment

indicates

that,

at

the

end

of

its

useful

life,

the

product

must

be

collected

separately

from

other

waste.

Please

note

that

the

lithium

batteries

must

be

removed

from

the

equipment

before

it

is

given

as

waste

and

disposed

separately.

To

remove

the

batteries

refer

to

the

specifications

in

the

user

manual.

For

additional

information

and

how

to

carry

out

disposal,

please

contact

the

certified

disposal

service

providers.

1.

Description

MCF-LW06424

is

able

to

read

4

analog

inputs

4-20mA

with

a

resolution

of

12

bit.

The

inputs

have

an

insulation

of

1000Vdc

with

respect

to

the

power

supply,

and

are

protected

against

polarity

inversion.

m2m Germany GmbH | Am Kappengraben 18-20 | 61273 Wehrheim | 06081 5873860

MCF-LW06424

is

available

with

DIN

rail

option

(MCF-DIN105):

2.

Overview

2.1

Technical

data

CPU

Cortex

M4

RTC

EEProm

32KB

Flash

1MB

Encryption

AES

128

bit

LiPo

800mAh

rechargeable

battery

Class

C

LoRaWAN®

stack

EU868,

AS923,

AU915,

US915

1000Vdc

isolated

analog

inputs

4

analog

current

inputs

4-20mA

12bits

and

disconnect

alarm

4

programable

thresholds

for

each

channel

USB

On

The

Go

IoT

node

setup

ad

firmware

upgrade

via

USB

interface

Power

supply

10÷36Vdc

Storage

temperature

range

-20°C

÷

+80°C

Working

temperature

range

-10°C

÷

+70°C

Dimensions

L

x

H

X

P:

81

x

60

x

50mm

3

Installation

3.1

Connection

3.1.1

Power

connection

as

stand-alone

device

Please

refer

to

following

connections:

m2m Germany GmbH | Am Kappengraben 18-20 | 61273 Wehrheim | 06081 5873860

pin

Name

Description

J3.9

GND

Negative

power

supply

(BLACK)

J3.10

VDD

Positive

power

supply

range

[10-36Vdc]

(RED)

Power

can

also

be

supplied

by

USB.

3.1.2

Power

connection

with

DIN

rail

option

Please

refer

to

following

connections:

Power

supply:

Pin

Name

Description

J2.1

Vdc

Positive

power

supply

range

[10-36Vdc]

J2.2

GND

Negative

power

supply

Power

can

also

be

supplied

by

USB.

3.1.3

Antenna

The

magnetic

antenna

must

be

positioned

on

ametal

body.

It

should

preferably

be

vertical

and

at

least

30

cm

away

from

other

metal

bodies.

The

installation

must

take

place

in

a

place

where

the

LoRaWAN®

signal

coverage

is

good

(SF=7

optimal,

SF=12

weak).

Use

the

provided

clip

to

hold

the

antenna

connector

in

place,

as

in

the

picture:

3.2

Analog

inputs

m2m Germany GmbH | Am Kappengraben 18-20 | 61273 Wehrheim | 06081 5873860

125Ω

1000Vdc

Pin

Name

Description

Range

Resolution

J1.1

AI1

Analog

input

1

4-20mA

12

bit

J1.2

GA

Common

J1.3

AI2

Analog

input

2

4-20mA

12

bit

J1.4

GA

Common

J1.5

AI3

Analog

input

3

4-20mA

12

bit

J1.6

GA

Common

J1.7

AI4

Analog

input

4

4-20mA

12

bit

J1.8

GA

Common

Current

Loop

(4-20mA)

Input

resistance

Absolute

maximum

value

24mA

Max

error

±0.1%

Insulation

Current

values

less

than

3mA

generate

a

“disconnected

sensor”

condition.

Caution:

inputs

are

not

galvanically

isolated

from

each

other.

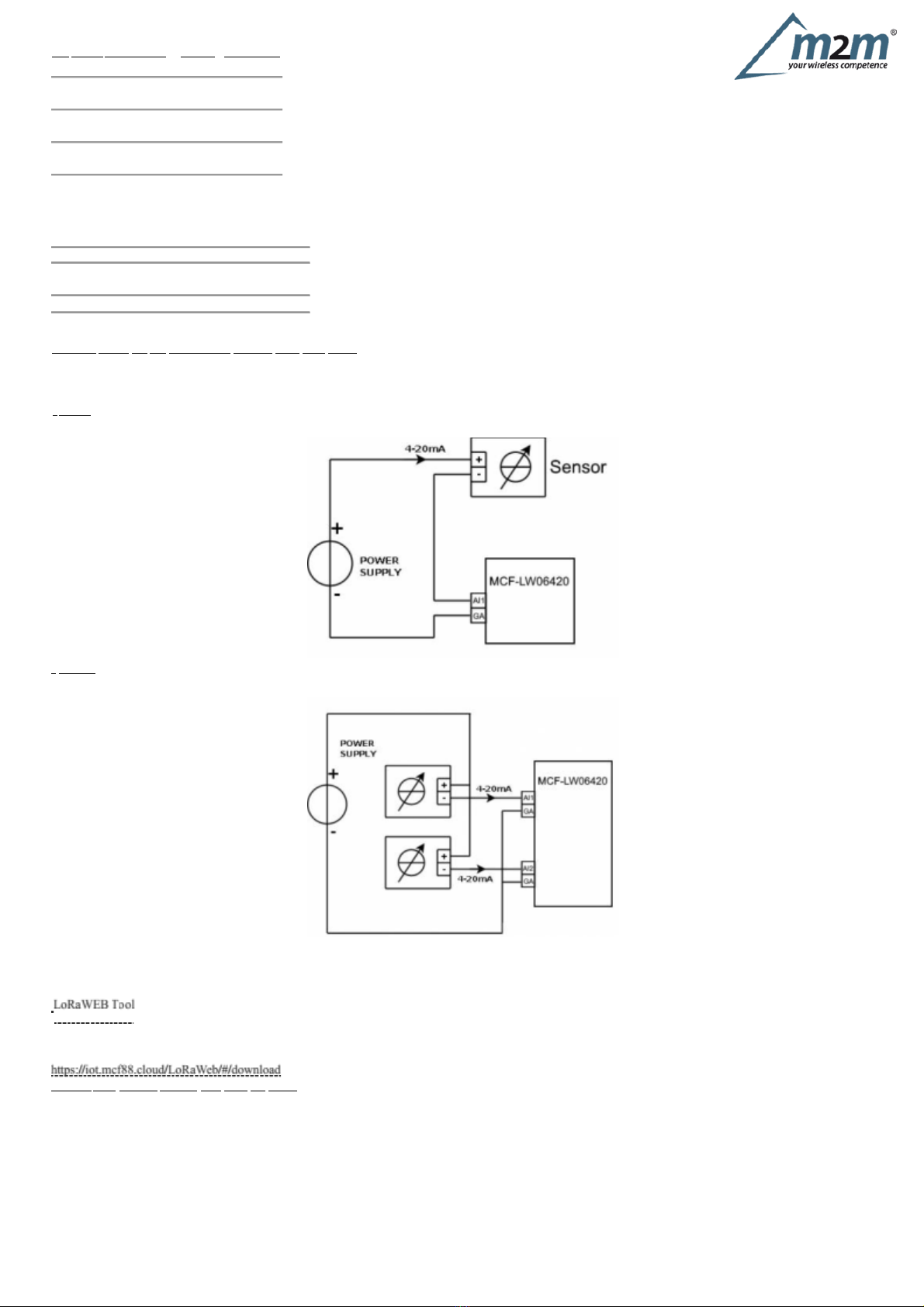

3.2.1

Connection

examples

1

sensor

2

sensors

3.3

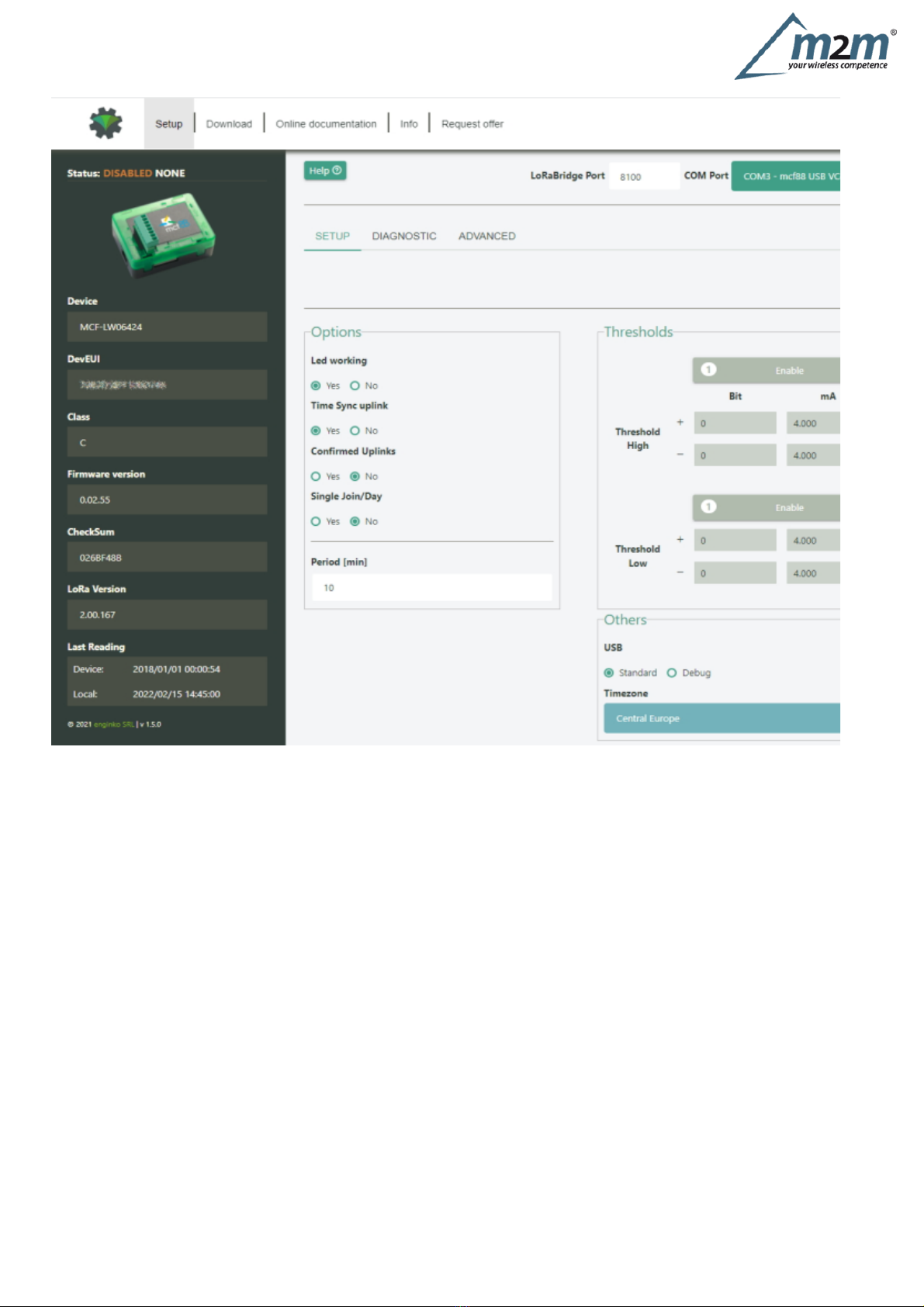

Configuration

To

deploy

the

sensor,

use

LoRaWEB

online

tool,

to

setup

LoRaWAN®

credentials

and

other

preferences

(only

available

for

Windows®)

:

(iot.mcf88.cloud/LoRaWeb)

Before

connect

the

device

the

first

time,

please

install

LoRaBridge

applications

and

drivers:

Validate

your

settings

reading

data

after

the

write.

enginko

provides,

upon

free

registration,

user

manuals,

javascript

examples,

downlink

generator,

uplink

decoder,

firmware

updates

and

different

tools

:

m2m Germany GmbH | Am Kappengraben 18-20 | 61273 Wehrheim | 06081 5873860

Quick

flashing

Quick

flashing

Quick

flashing

Fixed

Flashing

2

seconds

Flashing

1

second

3.4

System

led

LoRaWAN®

not

configured Slow

flashing

Joining

Sending

Receiving

Steady

state

Data

error

Connection

error

3.5

Firmware

update

Save

the

new

firmware

file

(.exe)

on

the

PC,

run

the

file,

select

the

USB

FW

port

and

start

the

update:

and

waiting

for

the

end

message.

4.

Setup

m2m Germany GmbH | Am Kappengraben 18-20 | 61273 Wehrheim | 06081 5873860

4.1

Period

Period

is

the

interval

(in

minutes)

between

one

measure

and

the

next

one.

The

sensor

sends

one

measures

for

every

transmission.

Value

can

be

between

15

and

65535

minutes

(default:

30

minutes).

Period

interval

can

be

set

with

LoRaWEB

or

with

downlink

command.

4.2

Thresholds

m2m Germany GmbH | Am Kappengraben 18-20 | 61273 Wehrheim | 06081 5873860

On

the

MCF-LW06424

is

possible

to

set

4

thresholds

for

each

channel:

Th+

=

Threshold

High

Rising

Th-

=

Threshold

High

Falling

Tl+

=

Threshold

Low

Rising

Tl-

=

Threshold

Low

Falling

When

target

values

are

rising

and

exceed

the

positive

thesholds,

the

device

sends

an

uplink

with

the

the

latest

measure.

Whenvalues

are

falling

below

the

negative

thresholds,

the

device

sends

a

new

uplink

with

the

latest

measure.

Thresholds

can

be

enabled,

disabled

and

changed

va

USB

with

LoRaWEB

or

with

downlinks:

m2m Germany GmbH | Am Kappengraben 18-20 | 61273 Wehrheim | 06081 5873860

4.3

Other

settings

DST:

set

to

change

DST

(default:

none).

Time

sync

uplink:

set

to

disable

time

synchronization

request

(default:

enabled).

Normally

sensor

asks

for

a

time

sync

at

every

power

on

(uplink

starting

with

01)

or

once

a

week.

If

no

or

wrong

reply

received,

it

will

retry

after

1

week.

If

not

handled

in

the

right

way

can

generate

unnecessary

traffic

on

the

network.

Please

check

chapter

2.1

.

Confirmed

Uplinks:

set

for

unconfirmed

uplinks

(default:

confirmed

uplink).

Single

join/day:

set

for

to

allow

only

one

join

per

day

(default:

multiple

join

allowed).

LED

working:

Set

OFF

to

turn

off

the

diagnostic

led.

USB:

Internal

use.

5.

Diagnostic

m2m Germany GmbH | Am Kappengraben 18-20 | 61273 Wehrheim | 06081 5873860

Press

Check

to

see

the

analog

values.

6

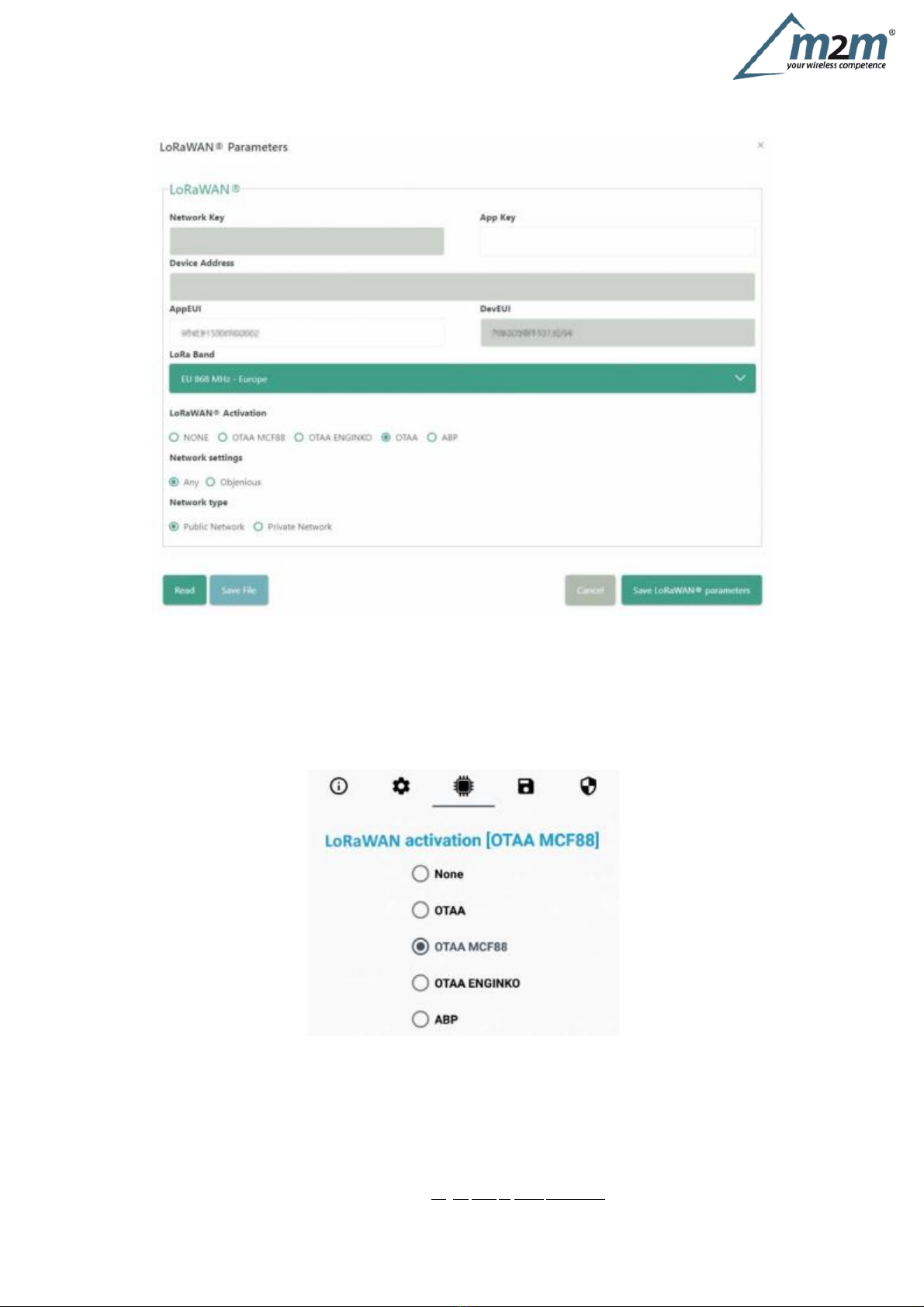

LoRaWAN

network

The

sensor

is

compliant

with

LoRaWAN®

specification

1.0.2,

regional

1.0.2b.

6.1

Activation

The

device

supports

the

following

activations

on

a

LoRaWAN®

network:

1.

NONE:

sensor

not

activated

2.

OTAA:

the

JoinEUI

and

the

AppKey

not

setted,

must

be

written

to

the

device;

3.

OTAA

MCF88:

Over

the

air

activation,

fixed

keys:

JoinEUI

=

904e915000000002,

AppKey

on

request;

4.

OTAA

ENGINKO:

Over

the

air

activation,

fixed

keys:

JoinEUI

=

904e915000000002,

AppKey

on

request;

5.

ABP:

requires

writing

to

the

device

of

NwkSkey,

AppSkey,

DevAddr.

The

device

exits

factory

activated

with

NONE

mode.

On

request

devices

can

be

shipped

already

activated.

Note:

in

OTAA

AppKey

is

write

only,

in

reading

the

field

will

always

be

empty,

even

if

set.

6.2

Other

settings

Network

settings:

please

keep

“Any”

settings.

Change

it

only

if

Objenious

network

is

used

(default_

any).

Network

type:

LoRa

syncword

can

be

setted

as

“private”(0x12)

instead

“public”

(0x34),

butthe

NS

must

be

setted

accordingly(default:

public).

Band:

select

the

right

LoRaWAN

®

band

settings

accodingly

to

country

requirements.

m2m Germany GmbH | Am Kappengraben 18-20 | 61273 Wehrheim | 06081 5873860

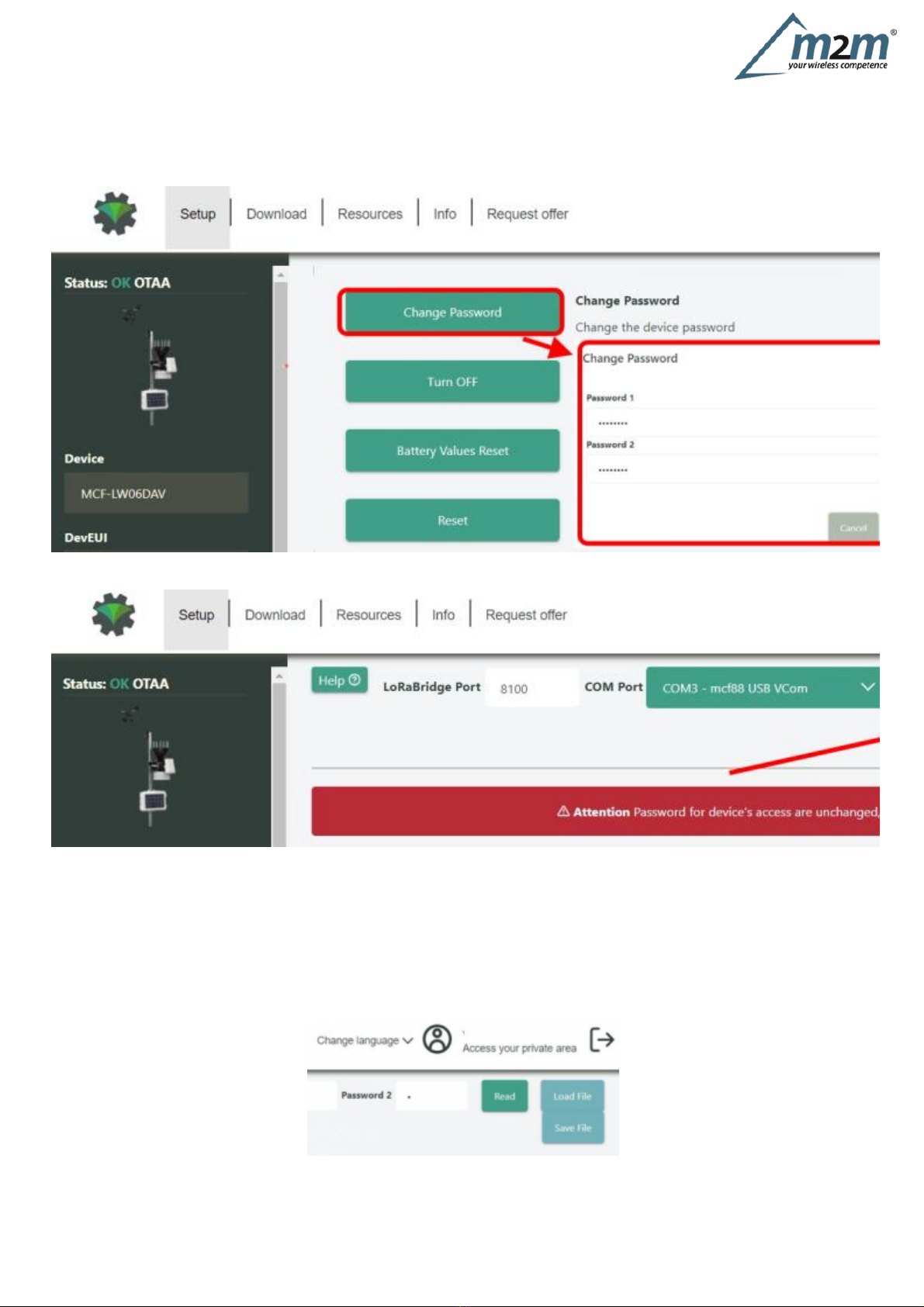

7

Passwords

The

device

can

be

protected

by

passwords,

to

avoid

unauthorized

persons

to

read

data

or

modify

parameters.

As

default

passwords

are

equal

to

0.

Allowedvalues

range

from

0

to

999999999

(only

numbers).

To

change

the

passwords,

set

the

new

values

with

LoRaWEB:

Once

the

passwords

are

setted,

to

gain

access

from

LoRaWEB

to

the

sensor,

set

the

right

values

before

reading

from

the

device:

To

bring

back

the

sensor

to

factory

default

and

reset

the

passwords,

a

reset

code

must

be

requested

to

enginko

(please

provide

the

DevEUI

of

the

sensor

when

you

ask

for

that

code).

8

General

configuration

file

WIth

LoRaWEB

is

possible

to

configure

the

device

using

an

XML

file,

instead

to

manually

adjust

the

parameters

(for

details

about

the

file

format

please

ask

to

enginko).

This

is

very

useful

especially

in

case

of

multiple

devices

configuration.

With

“Save”

button

an

XML

file

with

the

actual

configuration

of

the

sensor

will

be

generated.

This

is

useful

to

store

or

clone

the

configuration,

or

to

send

it

to

enginko's

support

if

needed.

8.1

Multi

devices

configuration

WIth

LoRaWEB

is

possible

to

configure

many

devices

in

an

easy

way.

For

multi-configuration

is

needed

at

least

one

XML

file

with

the

parameters

to

set.

m2m Germany GmbH | Am Kappengraben 18-20 | 61273 Wehrheim | 06081 5873860

4-20mA

to

LoRaWAN®

interface

EU863-870

Settings

on

this

file

will

be

applied

to

all

the

sensors.

With

an

additional

XLS

file

is

possible

to

load

different

LoRa

configuration

parameters

(Activation

Type,

AppKey,

AppEUI,

NetKey,

DevAddress,

Band,

Private

option)

for

each

sensor,

based

on

DevEUI.

XLS

is

prevailing

on

the

XML,

so

if

both

files

are

enabled,

if

the

DevEUI

of

the

device

matches

one

of

the

DevEUIs

in

the

XLS

file,

LoRa

parameters

will

be

setted

from

this

one.

These

configuration

can

be

done

in

the

in

the

Settings:

Use

of

the

general

configuration

by

file;

Use

of

the

specific

configuration

by

file.

For

details

on

files

format

please

ask

to

enginko.

9

Payload

For

payload

descriptions,

uplinks

and

downlinks

format

and

available

commands

please

refer

to

this

document:

10

Ordering

code

Code

MCF-LW06424

Description

MCF-LW06424-AS

4-20mA

to

LoRaWAN®

interface

AS920-925

MCF-LW06424-US

4-20mA

to

LoRaWAN®

interface

US902-928

MCF-LW06424-AU

4-20mA

to

LoRaWAN®

interface

AU915-928

For

payload

descriptions,

uplinks

and

downlinks

format

and

available

commands

please

refer

to

this

document:

m2m Germany GmbH | Am Kappengraben 18-20 | 61273 Wehrheim | 06081 5873860

11

Declaration

of

conformity

Hereby,

enginko

Srl

declares

that

MCF-LW06424

complies

with

the

essential

requirements

and

other

relevant

provisions

of

Directive

2014/53/EU.

12

FCC

compliance

for

MCF-LW06424-US

This

device

complies

with

part

15

of

the

FCC

Rules.

Operation

is

subject

to

the

following

two

conditions:

(1)

This

device

may

not

cause

harmful

interference,

and

(2)

this

device

must

accept

any

interference

received,

including

interference

that

may

cause

undesired

operation.

This

equipment

has

been

tested

and

found

to

comply

with

the

limits

for

a

Class

B

digital

device,

pursuant

to

part

15

of

the

FCC

Rules.

These

limits

are

designed

to

provide

reasonable

protection

against

harmful

interference

in

a

residential

installation.

This

equipment

generates,

uses

and

can

radiate

radio

frequency

energy

and,

if

not

installed

and

used

in

accordance

with

the

instructions,

may

cause

harmful

interference

to

radio

communications.

However,

there

is

no

guarantee

that

interference

will

not

occur

in

a

particular

installation.

If

this

equipment

does

cause

harmful

interference

to

radio

or

television

reception,

which

can

be

determined

by

turning

the

equipment

off

and

on,

the

user

is

encouraged

to

try

to

correct

the

interference

by

one

or

more

of

the

following

measures:

m2m Germany GmbH | Am Kappengraben 18-20 | 61273 Wehrheim | 06081 5873860

Reorient

or

relocate

the

receiving

antenna.

Increase

the

separation

between

the

equipment

and

receiver.

Connect

the

equipment

into

an

outlet

on

a

circuit

different

from

that

to

which

the

receiver

is

connected.

Consult

the

dealer

or

an

experienced

radio/TV

technician

for

help.

Any

changes

or

modifications

not

expressly

approved

by

the

party

responsible

for

compliance

could

void

the

user’s

authority

to

operate

this

equipment.

Contains

FCC

ID:

2AWAL409810

13

Contacts

enginko

Srl

Via

Roma

3

I-28060

Sozzago

(NO)

T

:

+39

0321

15

93

088

E

:info@enginko.com

PEC:enginkosrl@legalmail.it

W:enginko.com

rev.0

Other manuals for MCF-LW06424

1

Table of contents

Other Enginko Recording Equipment manuals