Enigma Motus Powered User manual

Thank you for choosing Enigma

To ensure the installation process is simple and ecient,

we recommended you read this guide in full rst.

Specic tools are also required to complete the installation:

3

© 2019 by Selo. All rights reserved. Selo reserves the right to alter specication and designs without prior notice.

Laser Level

Pencil Tape Measure Knife Cordless Drill Driver

Powered

Chop Saw

Hex Keys

(Metric)

Cable Stripper

& Cutters

Flathead Screwdrivers

(Medium & Small)

Long-nose

Pliers

——————— Sync Unit Wiring Tools ———————

For Double Doors

Getting started

The Motus Enigma pocket door system will be delivered in three boxes:

1. Pocket Frame

2. Trim Surround

3. Track

If a door leaf has been ordered this will come separately.

Before you start installation ensure you

have read and understood the instructions.

POWER REQUIREMENTS

DELIVERY

The Motus Enigma pocket door system requires a low-voltage electrical

connection. Wiring for the system can vary based on the type of connection:

Hardwired (Optional)

1. 13 amp fused spur isolation switch

2. 1.5mm twin and earth cable feed to the

top of the pocket enclosure

‘Kettle-lead’ Wiring (Standard)

1. 13 amp single socket

IMPORTANT SAFETY INFORMATION

The unit should be installed and commissioned by a trained and qualied personnel.

The unit may only be opened and repaired by the manufacturer.

This unit may only be operated from a protective low-voltage with safe electrical isolation.

Always consider the safety functions of your application as a whole, never just in relation to one individual component of the system.

The installed is responsible for carrying out a risk assessment and installing correctly.

Avoid touching any electronic components.

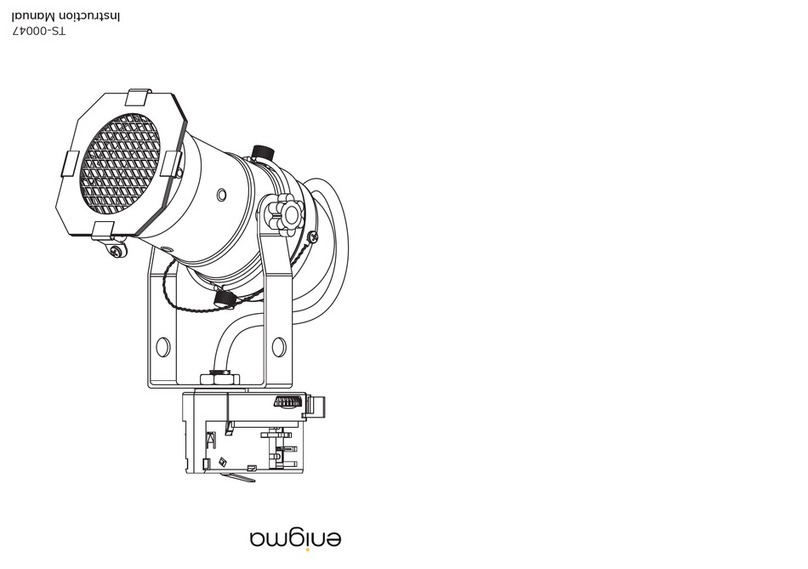

Motus Frame kit NFR V

MOTUS FRAME FIXINGS

MOTUS FRAME COMPONENTS

5

MOTUS NFR V › INSTALLATION GUIDE |FRAME KIT CONTENTS

Familiarise yourself with components included. All xings will

come pre-packaged to suit your specic project requirements.

Type-4

30mm screw

Type-5

25mm self drilling screw

Concrete Screws

7.5mm x 60mm

M6 Screws

6mm x 100mm

Timber Insert

Motus Sliding Track

Head Channel

Intermediate Jamb

Base Channel Leading Edge Jamb

Door Guide Pin & Channel

Type-2

40mm screw

Type-1

19mm self drilling pan head screw

Type-13

60mm screw

Type-3

50mm screw

Brush Strip

Base Channel Calculations

Please refer to Step 4 of the Frame Installation instructions shown on page 12.

Door sizes (mm)

Height = S/O -95mm

Clear

openings (mm)

Structural

openings (mm)

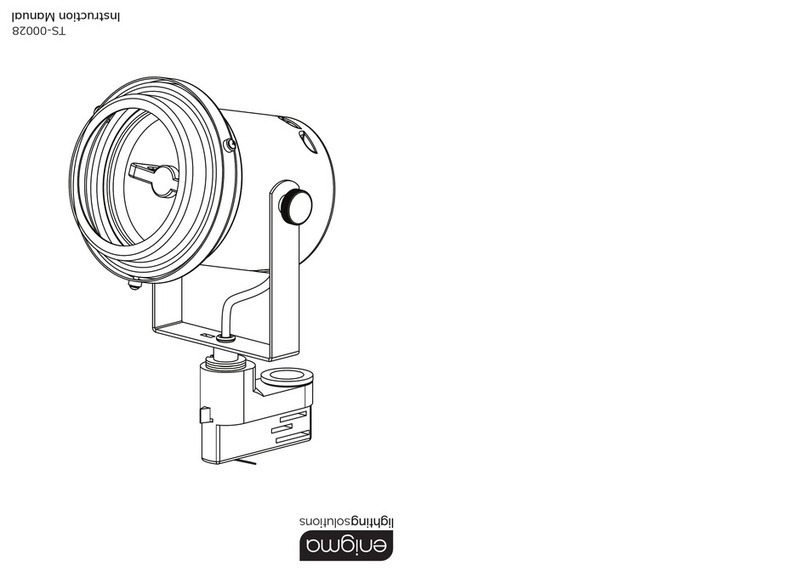

Wall construction preparation

The Motus Enigma system can be tted to steel or

timber studwork partitions. If using steel you must ensure

the head stud is strong enough to take the door weight.

IMPORTANT INSTALLATION NOTES

MOTUS NFR V › INSTALLATION GUIDE |WALL CONSTRUCTION PREPARATION

1. Studwork size

The studwork size required is 94mm.

If using steel studs a 94mm head and base track and

92mm uprights should be used.

2. Steel studs

If using steel studs, timber inserts are required within

the studs to provide additional strength and purchase

for 60mm track screws.

3. Doors above 2300mm

If the door height you are installing is above 2300mm

then using 2 layers of plasterboard is recommended.

To order kits to suite two layers of plasterboard add

the sux (145) to the product code.

4. Self-supporting Head

For situations in high rise buildings where you cannot

x to the ceiling or sot then use the Enigma Self-

supporting Head installation detail.

Follow standard Enigma instructions to calculate your

studwork structural opening and add the following

dimensions: Width +92mm and Height +44mm.

Refer to the specic Self-supporting Head installation

instructions for further details.

Width Single

Width Double

Height

1870

3700

Door +95mm

2120

4200

Door +95mm

2370

4700

Door +95mm

Width

Min. Height

Max. Height

Min. Single

Max. Single

Min. Double

Max. Double

875

1500

2815

600

844

1000

1710

845

969

1711

1960

970

1094

1961

2210

1000

1500

2815

1125

1500

2815

MOTUS TRACK SIZE

ITEM 1750mm 2000mm 2250mm

Dimensions

Motus NFR V

7

Bespoke requirements?

Enigma can be customised to suit bespoke projects.

In principle, the installation process remains the same,

however certain installation dimensions may dier.

Please contact the Selo team to discuss your bespoke

requirements.

020 3880 0339

SELF-SUPPORTING HEAD

Follow the standard Enigma instructions to calculate your studwork structural

opening and add the following dimensions: Width +92mm and Height +44mm

IMPORTANT

If installing Self-supporting Head please refer to the specic installation instructions for further details

.

When constructing your stud partition, please

ensure the head is strong enough to take the

weight of the sliding door that will hang from it.

IMPORTANT

If using a Self-supporting Head please refer to those

specic installation instructions.

CHECK SIZE WITH SCHEDULE

STRENGTHEN HEAD

B

A

When forming the structural opening, please

ensure you are working to the correct opening

size provided on the door schedule.

MOTUS NFR V › INSTALLATION GUIDE |WALL CONSTRUCTION PREPARATION 9

LEVEL-UP

C

Ensure the opening is square and plumb.

IMPORTANT

We strongly recommend using a laser level for setting out.

PREPARE HEAD CHANNEL & SLIDING TRACK

Single doors

Cut the head channel to S/O width.

Double doors

Cut the Head channels equally to take up the

whole S/O. It is important to ensure that where the

two channels meet is in the centre of the opening.

1b

PREPARE THE STRIKE JAMB

1a

IMPORTANT

If installing double doors skip this step.

Cut some C16 timber stud (70mm x 45mm)

to the height of the structural opening.

Cut noggins at 26mm thick. Space at a

maximum of 500mm centres and x to the

strike as per the drawing.

Using a laser level, t the head channel to the top

stud with Head Channel screws.

IMPORTANT

It is important to ensure the Head channel is level with no

bends or bows. If the top stud is not straight then pack the

head channel out with packers to maintain level.

Single doors

The 70mm gap and the kettle lead port should be

at the strike end of the pocket.

Double doors

For double ensure the kettle lead ports are facing

each other in the centre of the opening and with

100mm gap between the tracks.

FIT THE HEAD CHANNEL

3

11

MOTUS NFR V › INSTALLATION GUIDE |FRAME INSTALLATION

Single doors

2a Mark 50mm from the rear end of the Head

channel and 70mm from the strike/front end.

2b The kettle lead port is at the front of the track

and will be installed at the strike end of the pocket.

Place the Track on the Head channel and line-up

the kettle lead entry point with the 70mm mark.

Align the centre lines of the Track and the Head

channel together, pilot drill the screw holes.

Double doors

Mark 50mm from each end. The Tracks will be

installed with the kettle lead ports in the middle to

aid wiring. Place the two Head channels together

with the tracks inside lining up the centre lines.

Ensure there is 100mm gap between the tracks for

the wire box and then pilot drill the screw holes.

HEAD CHANNEL PREPARATION

2

2b

2a

70mm

Frame installation

IMPORTANT

If installing Self-supporting Head please refer to the specic installation instructions for further details

.

13

Cut the Leading edge jamb and

Intermediate jamb 15mm less than

the structural opening height.

FIT TOP TRACK

5

CUT LEADING EDGE & INTERMEDIATE JAMB

6

Cut the intermediate Timber insert 100mm

shorter than the aluminium jamb and slide the

insert into the Intermediate jamb so it sits

50mm from each end.

IMPORTANT

When using door leafs wider than 926mm the kit will

be supplied with extra intermediate jambs to be tted

equally space within the pocket width.

CUT & FIT INTERMEDIATE TIMBER INSERT

7

MOTUS NFR V › INSTALLATION GUIDE |FRAME INSTALLATION

The front of the track must be lined-up with the

70mm mark for single door, or 50mm mark for

double doors. (Detailed in Step 2)

Once in place, secure the Motus track to the

Head Channel using Type-13 screws provided.

Single/Double doors

To accurately determine the length of the Base

channel, refer to the calculations on the left.

Cut the Base channel to this dimension.

Do NOT cut-o the end with the notch. Image 4a

Base channel tting

Place the Base channel on the oor against the

rear stud.

If provided with a ‘cut-to-size’ system position the

notched end tight against the rear stud.

At this stage it is vital that to ensure that the

centre line of the Base channel is secured directly

underneath the centre line of the track above.

Any deviation will result in misaligned doors and

trims. Secure to the ground with Type-2 xings.

Cover-plate (Non- Sync)

If the Sync unit is not used, screw the cover-plate

provided between the tracks to cover the cable.

CALCULATE BASE CHANNEL & FIX

4

Structural opening examples*

1750mm wide

Single S/O 1820mm (Track +70mm)

Double S/O 3600mm (Track x2 +100mm)

Max. movement range 875mm

2000mm wide

Single S/O 2070mm (Track +70mm)

Double S/O 4100mm (Track x2 +100mm)

Max. movement range 1000mm

2250mm wide

Single S/O 2070mm (Track +70mm)

Double S/O 4100mm (Track x2 +100mm)

Max. movement range 1125mm

*S/O height Door leaf +95mm

Permitted door leaf sizes

Min. height 1500mm

Max. height 2815mm

Min. width 875mm

Max. width 1125mm

Travel for unit = The amount which goes into the strike jamb.

System calculations

Base channel length

Single doors NFR V

Structural Opening (minus) -Clear Opening (minus) -130mm

Double doors NFR V

Structural Opening (minus) -Clear Opening (minus) -64mm ÷2

4a

9a Slide the Intermediate jamb into the

Head channel and Base channel with the

Timber inserts facing out so it sits centrally

in the pocket. Fix using Type-1 screws.

9b Slide the Leading edge jamb into Base

channel with notched end at the top, so the

ange sits hard against the end of the Base

channel. Plumb the jamb and x into place

using one Type-1 screw top and bottom as

shown in the image. Must be posited furthest

from the opening.

FIT POCKET SIDES & FIX THE JAMB

9

9a

9b

‘

8

MOTUS NFR V › INSTALLATION GUIDE |FRAME INSTALLATION 15

Single doors

Push the kettle lead in the strike end of the

track. Run the excess cable behind the strike

trim packer to the plug. DO NOT power on at

this point.

Double doors

Remove the kettle lead ports on both tracks.

As standard; Motus Double doors utilise a

Sync unit to open both doors at the same time,

additional wiring is required - See p18.

For Hardwired power supply please see p28.

CONNECTING THE TRACK

Cut the Brush Strip to length and t to the

leading edge aluminium prole.

IMPORTANT

If using simultaneous opening ensure that the door leafs

and head trims have been tted. Refer to the simultaneous

opening instructions for more.

FIT BRUSH STRIP

10

MOTUS NFR V › INSTALLATION GUIDE |DOOR LEAF INSTALLATION 17

4a The bracket ts onto the bolt as shown.

4b Feed the rest of the door at least halfway

into the pocket and hang the front bracket

onto the trolley bolt.

4c With spanners provided, wind the bolts up

or down to plumb the leading edge of the door

and to achieve the required gap under the

door (door undercut).

Tighten the locking nuts to secure the door to

the brackets. They may need to be slacked-o

later, to true the door to the trims once they

are tted.

HANG THE DOOR

4

4b 4c

Adjust the bolts to achieve a gap

approximately 15mm between the underside

of the track and the top of the bolt.

ASSEMBLE GEAR

4a

3

The door leaf needs to be hung before the trim is tted.

FIT THE GUIDE CHANNEL

200mm

150mm

100mm

Apply a thin bead of adhesive into the groove in

the bottom of the door and then tap the plastic

channel into position.

Double Doors Fit brackets 100mm from the back edge and 200mm from the front so the two

doors meet in the centre over the 100mm sync unit. (Instead of hanging equally as per the singles.)

Single Door Position the brackets equally to the edges of the door, spaced to 150mm centres.

SINGLE

DOUBLE

1

2

FIT HEAD BRACKETS

150mm

Door leaf installation

MOTUS NFR V › INSTALLATION GUIDE |DOOR LEAF INSTALLATION 19

SYNC FOR DOUBLE DOORS ONLY

Slide the Door stop into the track, x into place

by tightening the grub screws. This can be nally

adjusted once the trims are installed. To set the

rear stop, slide the door back into the pocket

until the door will be ush with the leading edge

trims, then tighten the stop up against the

carriages.

IMPORTANT

It is important to set the rear stop at this point as once

plasterboard is installed there is no access to rear stop.

FIT THE DOOR STOPS

5

SYNC FOR DOUBLE DOORS ONLY

SYNC FOR DOUBLE DOORS ONLY

DRILL HEAD CHANNEL

REMOVE KETTLE-LEAD PORTS

A

B

IMPORTANT

The next steps A-E refer to the installation of a Sync unit

and is used with Double doors ONLY. For Single door

installation please skip the following steps.

Work out in relation to your current internal

wall cabling as to the route to the centre of the

tracks, then drill a hole no smaller than 8mm in

the Head Channel as shown.

Remove the fascias on both tracks to expose

the kettle lead port and connection terminals.

Ports need to be removed from both tracks.

Cut the Kettle-lead plug o the power cable

supplied and thread through the Head Channel

hole drilled previously.

Strip the cable approximately 30mm from the ends.

CONNECT TRACKS

WIRE POWER CABLE

PREPARE CABLE

D

SYNC FOR DOUBLE DOORS ONLY

E

SYNC FOR DOUBLE DOORS ONLY

C

Wire the block to the Tracks as shown.

Connect the two Tracks together with the

Sync-cable provided in the plugs shown.

Wire the power cable to the connector block as

shown then ‘power-up’ the track.

Prior to conguration ensure doorstops are

correctly tted to avoid any potential damage.

Power-up the Motus. Press-and-hold the

‘reset’ button (both tracks if installing a

Double door)

for 3 seconds - The LED light

will ash, let go and

stand clear of the door(s)

while it self calibrates. Usually the door will

open/close 2-3 times during the process.

Adjust the door levels so it closes straight

against the strike jamb.

IMPORTANT

The tracks must have the same Speed/Delay times to

sync correctly. These can be adjusted with the plastic

screwdriver (enclosed).

Do not over turn the adjustment screws; only turn

between Min and Max indicators.

SYNC FOR DOUBLE DOORS ONLY

CALIBRATE TRACKS

Test the doors to ensure correct movement/

function. Attached the Cover Plate to cover

the gap and screw into place.

6

Fit the door guide pin at the nished oor level

with Type-2 xings. The pin needs to be facing

the strike stud and aligned centrally with the

centre line on the base channel.

If your installation requires the door guide pin to

be raised up - use the 1mm stackable packers

IMPORTANT

1. The pin needs to be tted at FFL (nished oor level). If the

nished oor is not yet installed, tment of the oor pin can

be delayed until the ooring is completed.

FIT DOOR GUIDE PIN

7

Plasterboard over one side of the pocket along

with the rest of the wall using the Type-5 self

drilling screws provided. It is vital to ensure the

leading-edge jambs remain completely vertical

and plumb once boarded. It is essential to clear

any swarf or debris that may be in the top track

and bottom channel at this stage.

PLASTERBOARD ONE SIDE

8

MOTUS NFR V › INSTALLATION GUIDE |DOOR LEAF INSTALLATION 21

23

MOTUS NFR V › INSTALLATION GUIDE |TRIM INSTALLATION

SUPPLIED TOOLS

TRIM FIXINGS (cont.)

TRIM FIXINGS

Type-7

35mm self drilling

drywall screws

Type-5

25mm self-drilling screws

Strike Trim

Single door x1 / Double door n/a

Head Trim

Single door x1 / Double door x2

Type-8

42mm self drilling

drywall screws

Type-9

50mm gold screws

Panel Pins

30mm

Strike Jamb Seals

Leading Edge Trim

Single door x2 / Double door x4

VISIBLE TRIM COMPONENTS

Spanner

Visible trim kit

All xings will come pre-packaged to suit

your specic project requirements.

Adjust the metal clip, so the door leaf closes

and is held in place, against the strike jamb.

Cut the Leading Edge Trims to the height of the

opening and slot them over the ange on the

leading-edge aluminium jamb, with the grooves for

the intumescent seal facing in towards the door.

They must be secured into position with the

Type-5 screws at 300mm intervals. Please note

that the timber will need to be pilot-holed rst.

INSTALL LEADING EDGE TRIM

1

Cut the Head trim the distance between the

two timber side jambs. Slot into place in the

head and x using Type-5 screws.

INSTALL THE HEAD TRIM

5

Cut the Strike trim as per the drawing measuring

from the notch to the end that is not notch. Cut

the end that is not notched.

Then t the notched end centrally in the Head

channel. Plumb the strike trim using a level so it

is aligned centrally with the Head channel and x

into place using the Type-9 screws.

IMPORTANT

When installing double doors the strike jamb is not used.

INSTALL STRIKE TRIM

3

Dimension =

Underside of head

prole

to oor

SET CLOSER STOP

4

Now the door leaf is hung you are ready to install the trim.

Visible trim installation

25

MOTUS NFR V › INSTALLATION GUIDE |TRIM INSTALLATION

LINE THE DOOR UP

2

If required, the door can now be trued into

alignment with the leading-edge trims by adjusting

the hanger bolts up or down as necessary.

When you’re happy that everything is aligned and

the gaps between the door and trims are equal,

lock the bolts rmly into position by winding

down the locknuts.

IMPORTANT

Maximum undercut must not exceed 8mm.

FIT STRIKE SEALS

7

Fit the rubber seals to the corners of the

strike trim as shown in the illustration.

You have now

completed the

installation of your

Enigma Motus sliding

pocket door with

visible trim.

27

MOTUS NFR V › INSTALLATION GUIDE |TRIM INSTALLATION

6

Now the wall can be tape and jointed and wall

and trims painted.

IMPORTANT

We recommend tape and jointing not plastering.

TAPE & JOINT / PAINT

Cut the leads to length, dismantle them and

connect L1 and N to the connection terminals

of the power supply as shown.

IMPORTANT

Before starting with the installation, make sure that the

power supply line is dead (de-energized).

L1

N

35 mm

6 mm

6 mm

150 mm

L1

N

Loosen the screw in the cover of the power

supply housing and remove the cover (on the

side where the connections are located).

IMPORTANT

Keep the cover and the screw in a safe place as you

will require it later.

REMOVE POWER SUPPLY COVER

1.

B

A

When the system is installed with permanent

power supply, the internal power supply socket

has to be removed.

Loosen the screws at the end stop and move

the end stop to the centre of the system.

IMPORTANT

Do not remove or screw down the end stop.

MOVE END STOP

B

A

1

2

Lay the grounding line through the housing

of the operator as shown in the picture and

connect it to the grounding terminal (PE).

EARTH CONNECTION

5

Carefully open the cover of the control unit

housing by levering it out with the tip of a at-

bladed screwdriver.

Relax the screws of the connection terminals

and remove the internal shockproof socket.

REMOVE INTERNAL SOCKET

B

A

3

LIVE & NEUTRAL CONNECTIONS

4

How to hard-wire a permanent power supply to your Motus powered

Enigma pocket door system.

Hardwired power supply

29

MOTUS NFR V › INSTALLATION GUIDE | HARDWIRED POWER SUPPLY

MOTUS NFR V › INSTALLATION GUIDE | HARDWIRED POWER SUPPLY

Close the cover of the control unit housing.

Fix and screw down the cover of the power

supply housing.

A

C

B

Move the end stop to the end of the channel

and screw it down thoroughly.

IMPORTANT

The end stop must not overlap.

RETURN END STOP

A

B

8

Connect all external accessories, except safety

sensors. The cables for Sensors, Push-buttons

etc have to be laid inside a cable channel as

indicated in the picture.

If additional Accessories are not required move

to next Step.

CONNECT EXTERNAL ACCESSORIES

6

CLOSE AND SCREW-DOWN COVERS

7

50mm

6mm

B

C

A

Commissioning

and inspection

These checks should be carried out on a routine

basis to be determined based on risk assessment.

Low energy movement of the doorset is generally not protected with

additional protective devices because the kinetic energy levels are

not considered to be hazardous. However, use of low energy doorset

movement should only be considered when the risk assessment has

taken account of elderly, frail and disabled users and indicates that the

risk to these users is low.

The result of the nal verication and operational tests should

be recorded in a log book. The log book shall refer to applicable

instruction for use and shall have space available to record:

1. All maintenance and repairs carried out, including

recommendations (Improvements, replacements etc)

2. All signicant changes or upgrading carried out

3. Any work undertaken to the doorset

4. Name, date, signature of designated responsible person

5. Include copies of the ‘Check Details’ table below,

lled out at periods dened in the risk assessment

Risk assessment carried out

within the last 12 months.

Check door and pocket condition ensuring

no sharp edges* or other hazards. Check

all essential components are tted and in

serviceable condition.

*If flush handles are fitted then the doors stop should be set so the

handle remains out of the pocket when open to mitigate risk of injury.

Isolate the power to the doorset and check to

ensure manual operation is achievable.

Restore power and check door cycles twice

whilst initiating, led lamp should remain green

when nished.

✓or ✗

RISK ASSESSMENT GUIDANCE

INSPECTION RECORD

Test door closing time (see Table F.2

Min Time for 90% Travel Distance).

Test auto reverse function works when

the door contacts an obstruction.

If auto close is enabled ensure

users are aware of this function.

If switches are present,

check condition and function.

If additional sensors have been tted

following risk assessment check

condition and function.

Initials

Signed Date / /

✓or ✗Initials

80kg 70kg 60kg 50kg 40kg 30kg 20kg 10kg

0.21mps 0.22mps 0.24mps 0.26mps 0.29mps 0.34mps 0.41mps 0.58mps

3.5s 3.2s 3.0s 2.7s 2.5s 2.1s 1.8s 1.3s

3.9s 3.7s 3.4s 3.1s 2.8s 2.4s 2.0s 1.4s

4.4s 4.1s 3.8s 3.5s 3.1s 2.7s 2.2s 1.6s

4.9s 4.6s 4.3s 3.9s 3.5s 3.0s 2.5s 1.8s

5.4s 5.1s 4.7s 4.3s 3.8s 3.3s 2.7s 1.9s

0.7m

0.8m

0.9m

1.0m

1.1m

Mass of Door Leaf (Kilogram)

Max. Travelling Speed (Meters/Sec)

Min. Travelling Time (Seconds)

90% Travel

Distance Per Leaf

(Meters)

Table F.2 - Minimum Travelling Time per Doorset vs. Mass of Door Leaf

31

Table of contents

Other Enigma Spotlight manuals

Popular Spotlight manuals by other brands

Larson Electronics

Larson Electronics HL-85-LED-CPR instruction manual

Home Zone Security

Home Zone Security ELI0857V installation instructions

Brother, Brother & Sons

Brother, Brother & Sons K7 Twist manual

Stairville

Stairville BEL1 Battery Event Light 15W user manual

Conrad

Conrad 432303 operating instructions

Phottix

Phottix Indra500 TTL instruction manual

Dorcy

Dorcy 41-1080 owner's manual

Lumascape

Lumascape Quadralux Q2 LS9140 installation instructions

Chauvet

Chauvet Intimidator Spot 375Z IRC Quick reference guide

Vision & Control

Vision & Control SLB-500-R625-P-SL Instructions for use

Sea-Dog

Sea-Dog 405626-3 Installation & operation instructions

HAMPTON BAY

HAMPTON BAY 91950 Use and care guide