eNovates Single Wallbox User manual

Single Wallbox

Installation manual

SWB_4xx_22_T2

SWB_4xx_22_C7

SWB_4xx_22_T2S

SWB_4xx_22_T2SE

English

To access the Single Wallbox Installation Manual

please scan the QR code or use the link

https://www.enovates.com/manual-installation-manual/

To access the Pedestal Installation Manual

please scan the QR code or use the link

https://www.enovates.com/manual-pedestal-installation/

To access the Single Wallbox User Manual

please scan the QR code or use the link

https://www.enovates.com/manual-user-manual/

To access the Single Wallbox Acessories Manual

please scan the QR code or use the link

https://www.enovates.com/manual-accessoire-manuals/

CONTENTS

Contents1. Safety instructions................................................................. 5

1.1. Purpose..................................................................... 5

1.2. Safety terminology...................................................... 5

2. Technical specifications........................................................... 9

3. Installation supplies.............................................................. 11

3.1. Box content.............................................................. 11

3.2. Accessories...............................................................12

3.3. Required tools...........................................................13

4. Installation requirements.......................................................14

4.1. Installer specifications................................................14

4.2. General cable specifications........................................ 14

4.3. Power cord specifications............................................14

4.4. Grounding specifications.............................................15

4.5. Required nominal input voltage................................... 15

4.6. Electrical protection specifications................................16

5. Wall mounting......................................................................17

6. Check before configuration.................................................... 24

7. How to configure.................................................................. 25

8. Final note............................................................................ 26

9. Support...............................................................................26

10. Abbreviations..................................................................... 27

11. Software............................................................................29

3

1. SAFETY INSTRUCTIONS

1.1. Purpose

Safety instructions are provided below in order to ensure safe, long-

term use of the product. Failure to comply with the instructions

and general safety guidelines for electrical systems may lead to an

electric shock, fire hazard, damage, malfunction, injury and/or death.

Read the safety instructions in this document before installing and

using the product.

1.2. Safety terminology

Danger texts provide important

information to avoid situations with a

high chance to cause severe malfunction,

damage, injuries or death.

Warning texts provide important

information to avoid situations with a

significant chance to cause malfunction,

damage, injuries or death.

Caution texts provide important

information to avoid situations that

may cause some degree of malfunction,

damage or injuries.

5

• Do not let the product be used by children, or individuals who

cannot assess the risks associated with unintended product use.

Children in the vicinity must be supervised by adults while the

product is in use.

• Do not have the product serviced by non-qualified personnel in

order to avoid the risk of serious injury from electric shock or

damage to the product. None of the product’s parts are intended

to be serviced by users. Do not attempt to disassemble, tamper

with, or modify the product. If the product requires servicing,

repair or relocation, contact a qualified electrician to perform

these operations.

• If an accident has occurred or a hazardous situation has

developed with regard to the product, have a certified electrician

immediately disconnect the product’s electrical supply.

• Do not use the product if one or more of its components may

have become damaged or compromised.

• Always make sure the product is not submerged in water, and

is not located near water. Do not handle the product with wet

hands, and make sure no liquid is sprayed on it or comes into

contact with it. Store the charging cable in the socket to prevent

unnecessary exposure to contamination or moisture. Handling the

product or its components while conductive liquids are present

may cause an electric shock with the risk of serious injury or

death.

• Do not use or install the product in the vicinity of explosive,

volatile, combustible or highly flammable substances. Note that

some electric vehicles release hazardous or explosive gasses

when charging, which may cause an explosion with the risk of

serious injury or death. Refer to the vehicle’s manual to check

if this is the case, and follow the instructions it specifies before

choosing the location of the product.

6

• The product must be grounded through a permanent wiring

system or grounding conductor.

• Disconnect input power at the circuit breaker before installing,

cleaning, removing or relocating the product.

• The product should be used to charge Mode 3 compatible

electric vehicles only. Check the vehicle’s compatibility using the

information in the vehicle manual.

• Avoid using a private power generator, adapters, conversion

adapters or cord extensions with the product. The introduction of

accessories not prescribed for the product may create technical

incompatibilities that can cause malfunction or damage, and

result in injury or death.

• Do not let the product and charging cable come into contact with

heat sources. High temperatures may impair functionality, cause

damage or cause hazards.

• Damage to the product may cause injury or death. Respect the

product’s operating parameters and technical specifications, and

make sure damage is not inflicted or allowed to accumulate on

the product. Do not use the product if it fails to operate normally

or appears cracked, frayed, broken or otherwise damaged. If you

suspect the product may have been damaged, have it checked by

a qualified electrician as soon as possible.

• Take care not to apply force or pressure to any part of the product

or to damage it with sharp objects or impacts.

• Use of the product may interfere with the proper functioning

of medical or implantable electronic devices in the user, such

as a pacemaker or defibrillator. The user should check with the

manufacturer of such electronic devices whether electric charging

may affect such a device before using the product.

7

• Installing and/or testing the product incorrectly may result in

damage to the product and/or a connected vehicle’s battery.

Such damage is excluded from the vehicle and charging product’s

warranties.

• The charging cable must be completely unwound and overlapping

loops must be avoided before charging to prevent overheating,

which may damage the product.

• Do not put fingers or objects in the socket or any other exposed

part of the product, as doing this may cause injury or damage.

• Keep (electro)magnetic devices away from the product, as their

use in the vicinity of the product may negatively affect the

product’s functionality, even to the point of causing damage to the

product.

• Use the product only in temperatures within its operating range of

-30°C to 50°C.

• Only transport and store the product in its original packaging.

Do not subject the product to strong force, impact, pull, twist,

tangle or drag and do not step on any part of the product. If the

product is damaged in transport, while it was not transported in

its original packaging, no damage liability can be accepted.

• Store the product in a dry environment and within the

temperature range provided in the technical specifications.

8

2. TECHNICAL SPECIFICATIONS

Residential & Fleet Professional

Charging Mode Mode 3 (IEC 61851-1ed.

3) ISO-15118

Mode 3 (IEC 61851-1ed.

3) ISO 15118

Charge Control RFID (IEC 14443 A/

B, ISO 15693) Plug &

Charge (ISO-15118-2)

RFID (IEC 14443 A/

B, ISO 15693) Plug &

Charge (ISO-15118-2)

Connectivity BLE 5.X

Wifi Client Mode

Ethernet (2x LAN,

bridged)

BLE 5.Xw

Wifi (AP & Client)

Ethernet (WAN + LAN,

router)

2G / 4G / LTE

Multi-charge

(Parking Lot)

Satellite Main Charger/ Satellite*

Backend Protocol OCPP 1.6J

OCPP 2.0

OCPP 1.6J

OCPP 2.0

Metering MID meter MID meter

Load Balancing Supported via optional

hardware

Supported via optional

hardware

HMI BLE app BLE app

Options Broken PEN

Detection

BiDirectional Charging

(V2G AC)

HEMS Integration

(EEBus)

Broken PEN

Detection

BiDirectional Charging

(V2G AC)

HEMS Integration

(EEBus)

* A network with one main charger and one or multiple satellites acts as a charging hub. In

this setup, satellite charge points are dependent on a main charger. The main charging

station handles the loadbalancing in the charging hub.

Electrical Properties

Supply network system AC

Electric connection

method

Permanently connected

Protective class Class I equipment

Voltage Rating 1x230V+N (50Hz)

3x400V+N (50Hz)

3x230V (50Hz)

Current Rating 32A

Rated impulse voltage 4kV

9

Electrical Properties

Max Charging Power 7.4kW (single phase)

22kW (triphase)

Charging socket AC–Type2 socket

Optional: T2S, T2SE

Cable plug Cable (7m) with AC-Type2 plug

Installation wiring 0.75 .. 10mm²

Earth Leakage Detection DC 6mA (included)

Compliancy The products described above are in conformity with

the relevant Union harmonization legislation:

-Low Voltage Directive LVD (2014/35/EU and

changes)

-Electromagnetic Compatibility EMC Directive

(2014/30/EU and changes)

-Radio Equipment and repealing Directive (2014/53/

EU)

-Waste electrical and electronic equipment WEEE

directive (2012/19/EU)

-Registration, Evaluation, Authorization and

Restriction of Chemicals REACH directive (No

1907/2006)

-RoHS directive (2002/95/EC)

-RoHS 2 Directive (2011/65/EU)

and are compliant with the following standards:

-IEC 61851-1:2017

-IEC 61851-21-2:2018

-IEC 62196

-IEC 60529:1989 + A1: 1999 + A2:2013

-IEC 61439-7:2018

-OCPP1.6 Full incl. Security

-EV-Ready 1.4G1

-ZE-Ready 1.4G1

Physical Properties

Access Locations with non-restricted access

Dimensions (W x H x D) 248 x 426 x 120 (T2 or C7)

248 x 426 x 165 (T2S or T2SE)

Weight (kg) 3.5 - 5.0 kg

Enclosure rating IK10 (IEC 62262)

IP54 (IEC 60529)

Operating Temperature -30°C … +50°C

Humidity Max 95% (non condensing)

10

Physical Properties

Mounting Wall mount (included)

Single side pedestal (optional)

Double side pedestal (optional)

Warranty 2 years

3. INSTALLATION SUPPLIES

Not all the necessary tools for installation are delivered with the

product.

Before you start, please check that all tools and components,

required for an easy installation, are available.

3.1. Box content

12

3

4

56789

11

10

12

# Description Amount

1 Charger unit (T2 version or C7 version with fixed cable) x1

2 Cover (contains socket lid) x1

Cable block x1

3Cable bridge x1

11

# Description Amount

4 Wall bracket x1

5 Security screw M4x8 (Torque 1.2Nm) x1

6 Screws M5x14 (Torque 1.2Nm) x4

7 Screws M5x16 (Torque 1.2Nm) x2

8 Screws M6x14 (Torque 1.2Nm) x2

9 Screws 6x30 (Torx T25) x3

10 Plugs 8mm x3

11 Installation Manual x1

12 C sticker (hexagonal) x1

3.2. Accessories

#Can be additionally purchased Residential

& Fleet

Professional

1 eDSBI x x

2 eDSBIII x x

3 eDLB x

4 eDP1B: Dynamic P1 Balancer x x

5 External Coil set x x

6 Single Side Pedestal x x

7 Double Side Pedestal x x

8 Pedestal Anchor

(flat for solid soil)

x x

Compatible external tools Residential

& Fleet

Professional

Potential-free on/off peak contact x x

Shunt device x x

12

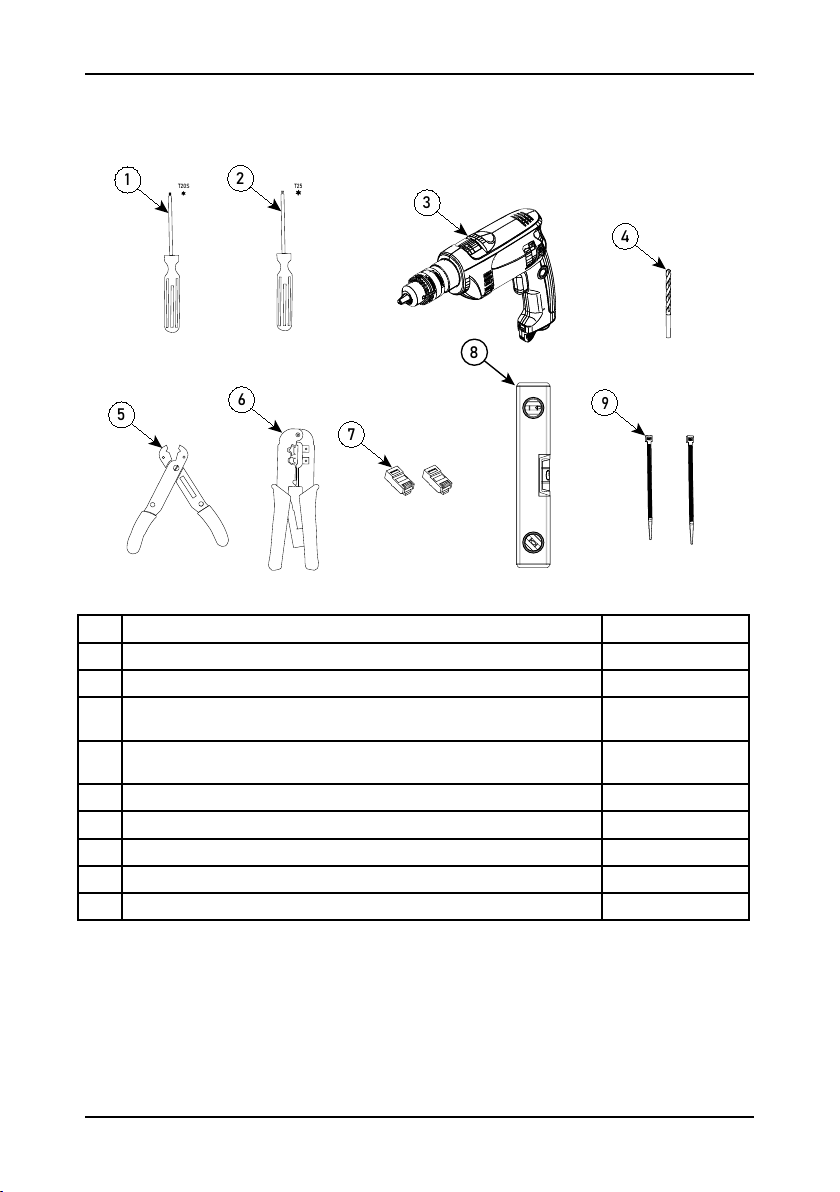

3.3. Required tools

T20S T25

12

3

4

5

6

7

9

8

# Description Amount

1 Torx screwdriver T20S x1

2 Torx screwdriver T25 x1

3 Drill for pedestal mounting

(suited to mounting surface) x1

4 Hand drill 8mm for wall mounting

(suited to mounting surface) x1

5 Cable stripper x1

6 Ethernet RJ45 cable crimper x1

7 Ethernet connector RJ45 for cable crimping x2*

8 Spirit level tool x1

9 Tie wraps x2

* When installing a charging hub, 1 or 2 ethernet connectors are used for each charge point.

This depends if charging hub is configured as a daisy chain or a star.

13

4. INSTALLATION REQUIREMENTS

4.1. Installer specifications

Only authorized technicians should install and maintain the product.

The technician should conform to the following qualifications:

• safety measures as well as the parts of this manual that relate to

the installation of the product;

• The technician should be aware of and comply with all applicable

local, national and international laws and regulations;

• The technician should be capable of acknowledging the potential

hazards of the product and take the necessary precautions to

protect people and property from hazard damage.

4.2. General cable specifications

The product requires a proper power cord. An ethernet cable is

recommended (not required) to connect the charge point with the

internet. Wifi and 4G (only professional) are also possible to connect

the charge point with the internet. The ethernet cable is not to be

used underground unless through a holding tube or reinforced (STP)

cable in order to prevent corrosion by moisture or rupture by ground

shifts.

Insofar as is possible, the cables should already be present and ready

to connect to the product at the start of the product installation

procedure. Use of sheathed cables is recommended when running

cables underground. Do note that the RJ45 connectors should be

connected only after feeding the cable through the grommet into the

product.

Always use shielded ethernet cable when installing.

4.3. Power cord specifications

The electrician should select the type and dimensions of the power

cord and safety components as appropriate for the installation

environment and situation, compliant with local regulations.

14

The power cord should be able to provide power continuously at

maximum load for the charging station.

• Power cord thickness: Ø 10 – 22.5 mm.

• Power cord cross-section: solid wires max 10 mm² | string wires

6 mm² .

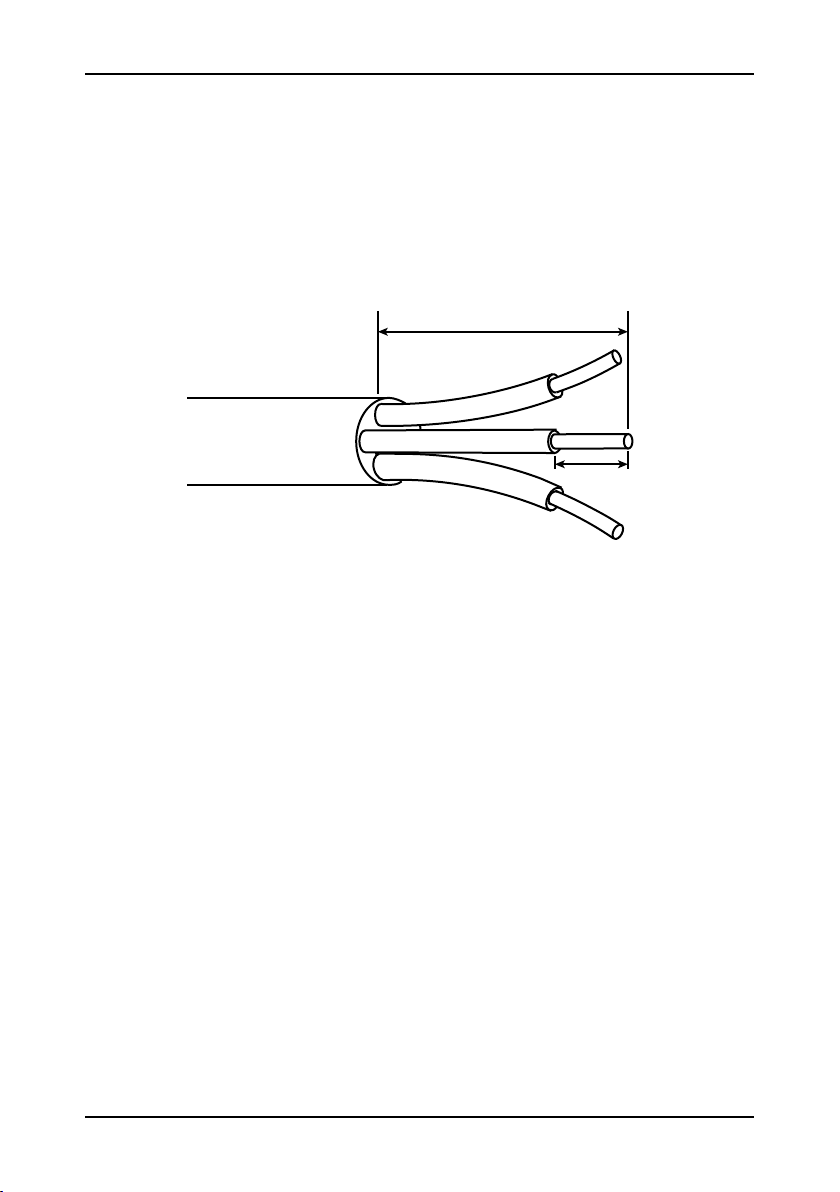

1,8cm

16cm

1. Strip ±16 cm from the exterior insulating coating of the power cord.

Consider shortening cable length if that makes installation easier.

2. Strip ±1,8 cm from the exterior insulating coating of the N, L3, L2, L1

and PE wires.

4.4. Grounding specifications

The charging station should be grounded in accordance with local

regulations.

4.5. Required nominal input voltage

• 1-phase: 230 V ± 10 % - 50 Hz.

• 3-phase: 400 V (3 × 400 V + N) ± 10 % - 50 Hz.

A 3-phase charging station can also be connected to a 1-phase setup.

Important note: when connecting only 1 phase, the charge point

MUST be connected to L1, NOT to L2 or L3. Make sure there is 230V

between L1 and N at the power input of the charge point.

15

Some electrical vehicles may have a more limited voltage tolerance

than 10%. If issues occur when charging, and the voltage is close to

the 10% voltage tolerance, check that the electrical vehicle type is

suitable for charging with this voltage.

4.6. Electrical protection specifications

Circuit breaker

The installer must select a suitable circuit breaker (type B or C, rated

40A) to match the charging limit of the charging station, taking

into account the specifications of the circuit breaker manufacturer,

selectivity regulations and EV-Ready guidelines.

Set a lower load limit on the charging station than the nominal current

of the charging station protection.

The overcurrent protection is built in

as part of other electrical components

in an existing consumer unit.

Set the load limit to 80%

of the rated current.

The overcurrent protection is built into

a special case with adequate cooling.

A simultaneity factor of 1 was used in

the design of the consumer unit.

Set the load limit to 90%

of the rated current.

Residual current protection

According to IEC 60364-7-722:2015, this charging station must be

installed with a minimum residual current protection type of A, rated

30mA. IEC 60364-7-722:2015, paragraph 722.531.2.101:

Excluding circuits that use electrical isolation as a safety measure,

each connection point shall be shielded using residual current

protection.

Note: When installing in accordance with EV-Ready guidelines,

each residual current protection system must be type A high

immunity: type HPI, SI, HI, KV... depending on the supplier.

RCBO

Has overcurrent and residual current protection as described above.

16

Note: The charging station comes with a DC fault current detection

device, certified in accordance with IEC 62955.

The electrician is responsible for selecting a suitable residual current

protection that complies with local rules and regulations.

5. WALL MOUNTING

Note: For mounting the charger on a pedestal, see the installation

booklet, which is accessible through the QR code or web link

on the first page of this manual.

The wall mounting procedure consists of a few steps.

1. Install the wall bracket.

2. Secure the cable block to the wall bracket.

3. Slide the charger onto the wall bracket.

4. Secure the charger to the wall bracket.

5. Connect the cables.

6. Attach and secure the cover.

7. Attach and secure the socket lid.

8. If necessary, attach a C sticker.

More detailed information about each step is available.

17

Install the wall bracket.

1) The standard installation height is 100 to 110 cm from the floor or

ground, measured from the center of the socket. The wall bracket

contains three pill-shaped clearance holes for installation. Use the

clearance holes to mark the positions on the wall where the holes

should be created, and then drill the three holes.

104-114 cm

Note: Use proper levelling tool to make sure that the wall bracket

is levelled.

Make sure the position of the bracket provides at least 30

centimeters of space around the charger when the charger is

attached to it.

Lead the cables through the circular holes at the bottom of the

bracket. Use either the holes in the back support, or the holes in

the bottom support, as is most convenient for your cable setup.

2) If the mounting surface consists of concrete or brick, fix the

bracket securely to the wall using the provided 3 8mm plugs and

3 M6x30 screws. If there is a different type of mounting surface,

another fixing method must be used.

Note: Make sure the bracket is level and sturdy.

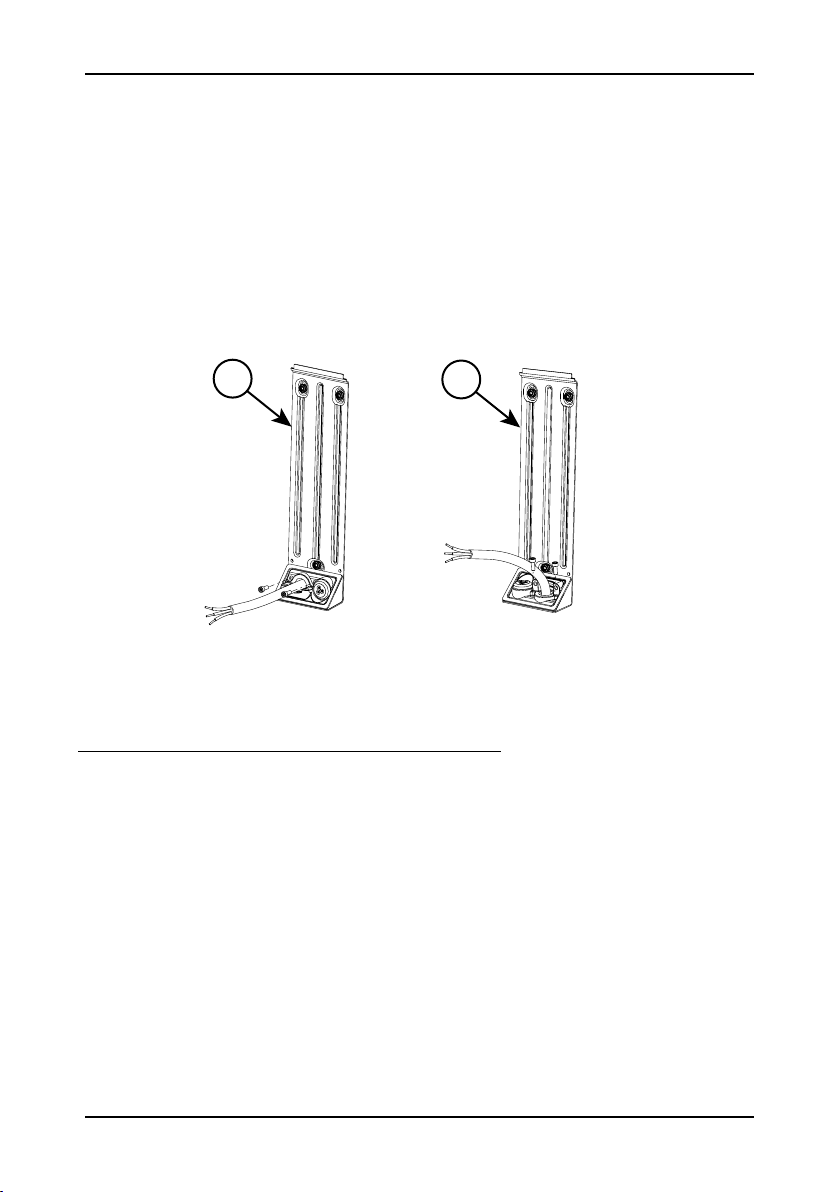

Secure the cable block to the wall bracket.

1) Position the cable block onto the bottom of the wall bracket using

18

your preferred orientation. There are circular holes in the bottom

and the back of the wall bracket, from which cables can pass

through the cable block into the charger unit. Remove the bridge

component from the cable block. Pull the cables through the

circular holes and through the cable block.

2) Use the provided 2 M5x16 (Torque 1.2Nm) screws to secure

the cable block to the wall bracket. Keep the bridge component

nearby.

12

1: cable from back (wall)

2: cable from below (ground)

Slide the charger onto the wall bracket.

1) Align the niche with the wall bracket.

19

Note: The back of the charger unit contains a niche, designed as

a connection slot for a wall bracket or pedestal bracket.

2) Carefully slide the charger unit onto the wall bracket so that the

wall bracket slots into the back of the charger unit. Lead the

cables into the charger unit through the hole at the bottom.

Secure the charger to the wall bracket.

Use the provided 2 M6x14 (Torque 1.2Nm) screws to secure the

charger unit to the wall bracket through the clearance holes and

tapped holes inside of the mounted charger.

20

Other manuals for Single Wallbox

1

Table of contents

Other eNovates Batteries Charger manuals