Enovation Controls Murphy EMS PRO LITE User manual

2015-03-23 00-02-0787

Section 40

EMSPROLITE

EngineMonitoringSystemController

Installation and Operations Manual

In order to consistently bring you the highest quality, full-featured

products, we reserve the right to change our specifications and designs

at any time.

Enovation Controls has made efforts to ensure the

reliability of the EMS PRO LITE and to

recommend safe use practices in system

applications. Please note that in any application,

operation and controller failures can occur. These

failures might result in full control outputs or other

outputs that might cause damage to or unsafe

conditions in the equipment or process connected

to the EMS PRO LITE.

To follow good engineering practices, electrical

codes, and insurance regulations requires that you

use independent external protective devices to

prevent potentially dangerous or unsafe

conditions. Assume that the EMS PRO LITE can

fail with outputs full ON, outputs full OFF, or that

other unexpected conditions can occur.

NOTES

BEFORE BEGINNING INSTALLATION OF

THIS MURPHY PRODUCT:

•This installation information is intended for all EMS

PRO LITE Series models. A visual inspection of

this product before installation for any damage

during shipping is recommended.

•Disconnect all electrical power to the machine.

Failure to disconnect all electrical power

connections before welding can result in damage

to the panel and/or its components.

•It is your responsibility to have a qualified

technician install the unit and make sure

installation conforms to local codes.

•Observe all Warnings and Cautions in each

section of these instructions.

•The EMS PRO LITE is designed for use in

industrial environments. There might be potential

difficulties in ensuring electromagnetic

compatibility in other environments due to

conducted as well as radiated disturbances.

•Please contact Enovation Controls immediately if

you have any questions.

IMPORTANT! Improper use and

operation of electronic products can be

dangerous. It is required that point-of-

operation guarding devices be installed and

maintained. All such devices must meet

OSHA and ANSI Machine safety standards.

The manufacturer shall not accept any

responsibility for installation, application, or

safety of systems.

CONTENTS

Introduction...................................................................................1

User Interface and Navigation...................................................1

Membrane Keypad..........................................................1

Key Switch.......................................................................2

Stop Switch .....................................................................3

Screens Displayed ..........................................................3

Quick Set Up................................................................................7

Setting the Date/Time Clock......................................................7

EMS PRO LITE on electronically-governed Engine..................8

EMS PRO LITE on mechanically-governed Engine..................8

Start/Stop Settings.....................................................................8

Transducer Start/Stop Types..........................................8

Pressure Start/Stop Type................................................9

Level Start/Stop Type......................................................9

2-Float Start/Stop Type.................................................10

Throttle Type............................................................................10

Throttle to Pressure.......................................................10

Throttle to Level ............................................................11

Tier 4 Emissions*.....................................................................11

Unit System – Metric or English ..............................................13

Operating Instructions................................................................15

AUTO Start/Stop Sequence ....................................................15

Start Sequence........................................................................15

Stop Sequence........................................................................18

Manual Start/Stop Sequence...................................................19

Start Sequence .............................................................19

Stop Sequence..............................................................20

Special Features......................................................................21

Shutdown History..........................................................21

Float Backup .................................................................21

Standby Mode...............................................................21

Menus......................................................................................22

S-Number Description and Listing ................................22

P-Number Description and Listing ................................33

M-Number Description and Listing................................35

Inputs and Outputs ..................................................................38

Digital Inputs .................................................................38

Analog Inputs ................................................................39

Digital Outputs...............................................................40

PCBA Shunts ................................................................41

General Information ...................................................................42

LCD Contrast Adjustment on Startup......................................42

General Wiring Precautions.....................................................42

Diodes...........................................................................42

Wire power leads directly to battery post......................42

Pilot excessive loads.....................................................42

Use stranded wire for hookup.......................................43

Separate AC and DC wiring..........................................42

Wire standby battery charger directly to battery...........42

Special precautions for spark ignition engines..............42

Use shielded cable on magnetic pickup........................42

Fuses.............................................................................42

Communications......................................................................43

CAN...............................................................................43

RS-485..........................................................................43

RS-232..........................................................................43

CPU PCB Wiring Interface (J2) DB9 Connector .....................43

Description ....................................................................44

Protocol.........................................................................44

Registers.......................................................................44

Entry Code Supplement.............................................................48

WARNING.....................................................................48

P-NUMBERS.................................................................48

S-NUMBERS.................................................................48

M-Numbers....................................................................48

Loading a Program..................................................................48

Installation..................................................................................49

EMS PRO LITE Dimensions....................................................49

EMS PRO LITE Wiring Diagram..............................................50

Specifications.............................................................................51

NOTES

Section 40 00-02-0787

2015-03-23 ~ 1 ~

Introduction

The EMS PRO LITE is a customizable pump-controller designed with

dewatering and irrigation applications in mind.

EMS PRO LITE offers field-adjustable operating parameters without the

need for a laptop computer. It can support both mechanical and J1939

electronic engines.

This unit offers selectable auto start/stop with auto-throttling options:

Floats, and Transducer. A backlit operator-interface offers many easy-to-

use performance-enhancing features. The display is readable day or

night.

The EMS PRO LITE is ideal for use with a remote modem or in a

SCADA system offering Modbus® RTU protocol on either the RS232 or

RS485 port.

NOTE: Your EMS PRO LITE must be modified to use these

ports – changes include additional wiring and enclosure

modifications.

User Interface and Navigation

This section defines how to navigate through the EMS PRO LITE user

interface. It explains the screens and keys used to modify settings and

how each works.

Membrane Keypad

The membrane keypad is made up of eight buttons. All of the functions

for the EMS PRO LITE can be set using these eight buttons.

Section 40 00-02-0787

2015-03-23 ~ 2 ~

ICON Description

START = In the “MAN” (manual) mode this initiates a start sequence.

STOP = In the “MAN” (manual) mode this initiates a stop sequence.

THROTTLE INCREASE = In the “MAN” (manual) mode this increases

engine speed.

THROTTLE DECREASE = In the “MAN” (manual) mode this decreases

engine speed.

MENU = Toggles between the front display and the password window,

and allows user to exit menus.

UP arrow = Use the arrow keys to scroll through information on the front

display. Also, scroll through and increase values in the “S” & “P”

numbers.

DOWN arrow = Use the arrow keys to scroll through information on the

front display Also, scroll through and decrease values in the

ENTER = Scroll to the entry code and press Enter to get into or out of

the M, Sor Pnumbers group, or an individually selected M, Sor P

number, to make changes. If changes were made, press Enter to exit,

and your changes are saved.

Key Switch

The controller accepts inputs from a 3-position key switch. The three

positions are AUTO, OFF, and MAN:

Input

Description

AUTO

Functions described in the “Auto Start/Stop Sequence” of this

document.

OFF

Disconnects control power to prevent the engine from starting or

continuing to run through the control panel. The OFF position provides

an immediate shutdown whenever the key switch is placed in this

position while the engine is running in either the automatic or manual

modes.

MAN

Functions as described in the “MAN Start/Stop Sequence” in this

document.

Section 40 00-02-0787

2015-03-23 ~ 3 ~

Stop Switch

The Stop Switch is the large red push button on the front face of the

EMS PRO LITE. When it is pushed in, it latches closed. If the Stop

Switch is pushed in, power to the controller is OFF. The Stop Switch

must be pulled out to power the controller.

Screens Displayed

During normal operation, the controller allows you to scroll through a

number of informative screen displays by using the

membrane keys. Below are several example screens.

4-Up Screen

Entry Code

S-Number Screen

P-Number Screen

The EMS PRO LITE screens described below may appear in an order

that is different from listed.

Screens Displayed

Screen Name

Description

FW Murphy / Murphy

/ Enovation Controls

From the 4-Up screen default, depending where in the

screen scroll you are, when you press the down arrow,

the top line of the text page could be either FW

MURPHY, MURPHY, or ENOVATION CONTROLS.

BUILD XXXXX

The current BUILD is usually a 5-digit number. Make

note of the build number. You will need it if requesting

technical assistance.

PROGRAM

XXXXXXXX

The current PROGRAM is usually an 8-digit number.

Make note of the program number. You will need it if

requesting technical assistance.

Section 40 00-02-0787

2015-03-23 ~ 4 ~

Screens Displayed

Screen Name

Description

LEAD SPD XXXX

RPM

If the controller is in AUTO mode, the internally

generated lead/command speed is displayed in RPM. If

the controller is in MANUAL, this does not display.

SELECTOR XXXX

This displays the position of the key: AUTO, or MAN.

When a start signal is active, the display may include the

following state or start options in place of the Auto or

Manual states.

START DELAY PRESSURE START

STOP DELAY LEVEL START

FLOAT START SCADA START

CLOCK START

DAY OF THE WEEK

This line shows the present day of the week.

DD MMM YYYY

This line displays the present date

HH:MM:SS

This line shows the present time.

STATE:

XXXXXXXXXX

The following are the different states the controller can

execute during operation:

ST: (STATE XXXX)

This text line displays states the controller can execute

during operation:

•NOT READY occurs when the key switch is in the

OFF position. This is seen briefly while the controller

is powering ON. No sequence occurs in this state.

•PANEL READY occurs when the key switch is in

the AUTO position and no shutdowns have

occurred. The controller is waiting for an auto start

condition to occur.

•START DELAY occurs when a start signal is active

and the start delay is timing. The start signal must

remain active throughout this delay before the auto

sequence can continue.

•PRESTART occurs after the start delay expires.

During the Prestart state, the prestart output is

turned ON.

•WAIT FOR ECU occurs after the Prestart delay

expires if “ECU” is selected in the engine type.

During the WAIT state, the unit allows the ECU to

warm-up prior to cranking.

•CRANK ON occurs when cycle cranking begins.

During the crank-on state, the crank output is turned

ON.

Section 40 00-02-0787

2015-03-23 ~ 5 ~

Screens Displayed

Screen Name

Description

ST: (STATE XXXX),

continued

•CRANK OFF occurs when cycle cranking begins.

During this state, the crank output is turned OFF.

•RECRANK DELAY occurs if the engine speed

drops below the “crank stop” set point before the

“shutdown lockout delay” expires.

•WARMUP occurs after the engine starts. During this

state, the controller throttles the engine to the warm-

up RPM until this delay expires.

•AT LOAD occurs after the Warm-up delay expires.

The low discharge pressure shutdown is armed

when this delay expires.

•FILL MODE occurs after the Warm-up delay

expires. Auto throttling to the minimum RPM set

point occurs during this state.

•STOP DELAY occurs when a stop signal is active

and the stop delay is timing. The stop signal must

remain active throughout this delay before the auto

sequence can continue.

•COOLDOWN occurs after the Stop Delay has

expired. During the Cool down state, the controller

throttles the engine to an idle.

•SHUTDOWN occurs if a shutdown condition is

detected. Reasons for shutdown include low oil

pressure, high engine temperature, overspeed, etc.

During this state, the engine is signaled to shutdown

and all start signals are ignored until the state is

reset by moving the key switch to the OFF position

and then back to AUTO or MAN.

FUEL XXX%

This displays the current fuel level as sensed from a

sender.

SYS BAT XX.X VDC

This displays the current engine battery voltage.

SYS HRS or ECU

HRS XXXX.X

This displays the current total engine run time. The

prompt and data shown in this display is dependent on

S#38 - ENGINE TYPE and S#39 - ECU HOUR SELECT.

ENG XXXX RPM

This displays the current engine RPM sensed either

from a magnetic pickup or as broadcast from the ECU.

OIL PR XXX PSI

This displays the current engine oil pressure as sensed

from an electric gauge sender, or as broadcasted from

the ECU.

Section 40 00-02-0787

2015-03-23 ~ 6 ~

Screens Displayed

Screen Name

Description

LEVEL XX.X

(IF SELECTED)

This displays the current system level as sensed from a

transducer.

LOCAL THROT

(IF SELECTED)

This is only show if Local Throttle is selected in S-34.

SOOT LEVEL

(IF SELECTED)

This shows the soot level percentage from SPN 3719.

There are also 3 alarms associated with this Status

sent from the ECU. The Alarms will be displayed on the

Alarm line as “SOOT LEVEL LOW”, “SOOT LEVEL

MEDIUM”, or “SOOT LEVEL HIGH”.

UREA LEVEL

(IF SELECTED)

This shows the urea level percentage from SPN 1761.

FIRST FOUR-UP

SCREEN

(DEFAULT SCREEN)

The first four-up screen should display Engine Oil

Pressure, Engine Coolant Temp, Battery Voltage, &

Engine RPM. This is the default screen when powering

up the controller.

SECOND FOUR-UP

ELECTRONIC ONLY

SCREEN

The second four-up screen should display Run Hours,

Fuel Consumption, Engine Load %, & Engine RPM. This

screen can be viewed by pressing the arrow up key from

the default screen.

SHUTDOWN

SCREEN

This screen shows the last five shutdowns that have

occurred. This screen can be accessed by pressing the

arrow up key past the four-up screen(s).

Section 40 00-02-0787

2015-03-23 ~ 7 ~

Quick Set Up

This section gives information on setting up specific functions within the

controller such as time, date, engine type, Tier 4 activity, and Unit display

type (Metric or US Standard). Other menus, such as the S-menu, P-

menu, and M-menu must also be setup before placing the unit in service.

NOTE: This section is a reference guide. We recommend you

read this document completely, and ensure you understand it,

before placing the controller in service.

Setting the Date/Time Clock

Setting up the clock is critical to many of the functions of the EMS PRO

LITE. The clock includes the time (displayed in 24hr format), the date,

and the day of the week. Use the following steps to set the Clock.

1. Access the SMenu by pressing [Menu].

2. Use the [Up or Down Arrow] to increase or decrease

the value to reach the correct Entry Code (See Entry

Code Supplement for Entry Codes).

3. When the Entry Code displays, press [Enter] to

access the S menu.

NOTE: S1 through S6 are the S-Numbers used to set the

clock. A complete guide to all S-Numbers is found in the

Menus section, page 22.

1. Press [Up or Down Arrow] to scroll through the S-

Numbers on the unit.

2. Press [Enter] when the setting you want to modify

displays.

3. Use the [Up or Down Arrow] to scroll to increase or

decrease the value.

4. Press [Enter] when you are finished.

5. Repeat steps 3 through 6 for each clock and date

setting.

6. When setup is complete, exit the S Menu by pressing

[Menu].

NOTE: The user must be out of the Sor Pnumber Editing

Mode to exit the menu.

Section 40 00-02-0787

2015-03-23 ~ 8 ~

EMS PRO LITE on electronically-governed Engine

The EMS PRO LITE factory defaults are set to run on an electronically

governed engine. See the following section to use the controller on a

mechanically governed engine.

EMS PRO LITE on mechanically-governed Engine

To use the controller on a mechanically governed engine, follow the

steps below:

1. Access the S Menu by pressing [Menu].

2. Use the [Up or Down Arrow] to scroll to the correct

Entry Code (See the section, Entry Code Supplement

for Entry Codes, page 48).

3. When the Entry Code displays, press [Enter] to

access the S menu.

4. Press the [Up Arrow] until (S38) ENGINE TYPE is

displayed and press [Enter].

5. Press the [Up Arrow] until MECHANICAL is

highlighted, then press [Enter].

6. Press the [Up Arrow] until (S40) ENG THR TYPE

displays and press [Enter].

7. Press the [Up Arrow] until MECHANICAL is

highlighted, then press [Enter].

8. Press the [Down Arrow] until (S7) SPEED CALIB

displays and press [Enter].

9. Press the [Up or Down Arrow] to enter the number of

pulses per revolution (PULSES/REV) the magnetic

pickup supplies to the controller and press [Enter].

10. Exit the S Menu by pressing [Menu].

Start/Stop Settings

The auto/start/stop types are Transducer (pressure and level), Floats,

and Clock Start.

Transducer Start/Stop Types

Existing Transducer choices include None, Pressure Control, and

Level Control.

Use the following step-by-step instructions to set up the Pressure

Start/Stop Type and the Level Start/Stop Type.

Section 40 00-02-0787

2015-03-23 ~ 9 ~

Pressure Start/Stop Type

The Pressure Start/Stop Type allows you to automatically start and stop

the engine using a pressure transducer to measure low and high set

points. Follow the steps below to set this start/stop feature.

1. Access the S Menu by pressing [Menu].

2. Press the [Up or Down Arrow] to scroll to the correct

Entry Code (See Entry Code Supplement, page 48).

3. Press the [Up or Down Arrow] until (S35) SRT/STP

SEL is displayed and press [Enter].

4. Press the [Up Arrow] until TRANSDUCER is

highlighted and press [Enter].

5. Press the [Up Arrow] until (S37) XDUCER TYPE is

displayed and press [Enter].

6. Press the [Up Arrow] until PRESSURE CONTROL is

highlighted and press [Enter].

7. Review and modify the settings for S-numbers S45

through S56 for Pressure Start/Stop Type. To modify,

press [Enter] while the setting is highlighted. When

finished with the modification, press [Enter] again.

Refer to the S-Number table in Menus for a

description of the S-Numbers settings.

8. When finished with the S45 through S56 settings,

press [Menu] to exit.

Level Start/Stop Type

The Level Start/Stop Type allows you to automatically start and stop the

engine using a level transducer to measure low and high set points.

Follow the steps below to set this start/stop feature.

1. Access the S Menu by pressing [Menu].

2. Press the [Up or Down Arrow] to scroll to the correct

Entry Code (See Entry Code Supplement for Entry

Codes).

3. Press the [Up or Down Arrow] until (S35) SRT/STP

SEL is displayed and press [Enter].

4. Press the [Up Arrow] until TRANSDUCER is

highlighted and press [Enter].

5. Press the [Up Arrow] until (S37) XDUCER TYPE

displays and press [Enter].

6. Press the [Up Arrow] until LEVEL CONTROL is

highlighted and press [Enter].

Section 40 00-02-0787

2015-03-23 ~ 10 ~

7. Review and modify the settings for S57 through S71

for Level Start/Stop Type. To modify a setting, press

[Enter] when the setting is highlighted. When finished

with the modification press [Enter] again. Refer to the

S-Number table in Menus for a description of the S-

Numbers settings.

8. When finished with the (S57-S71) settings, press

[Menu] to exit.

2-Float Start/Stop Type

The 2-Float Start/Stop Type allows you to automatically start/stop the

engine by using two float contacts (see page 21 for a description of Float

Operation). Follow the steps below to set this start/stop feature.

1. Access the S Menu by pressing [Menu].

2. Use the [Up or Down Arrow] to scroll to the correct

Entry Code (See Entry Code Supplement for Entry

Codes).

3. Press the [Up or Down Arrow] until (S35) SRT/STP

SEL is displayed and press [Enter].

4. Press the [Up Arrow] until FLOATS is highlighted

then press [Enter].

5. Exit the S Menu by pressing [Menu].

Clock Start/Stop Type

Using the internal real time clock, the user can select up to (3) different

start times per day. The clock start/stop feature can be used in

conjunction with other start/stop types.

Throttle Type

This section outlines several different throttling methods from which to

choose and how to set these for operation in the controller. ). Follow the

steps below to set the type of throttling necessary for the application.

Throttle to Pressure

This type of throttling allows you to set a pressure you would like the

controller to maintain when a transducer is used for discharge pressure.

1. Access the S Menu by pressing [Menu].

2. Press the [Up or Down Arrow] to scroll to the correct

Entry Code (See Entry Code Supplement for Entry

Codes).

Section 40 00-02-0787

2015-03-23 ~ 11 ~

3. Press the [Up or Down Arrow] until (S47) MAINTAIN

PSI is displayed in the menu and press [Enter].

4. Press the [Up or Down Arrow] until the desired

pressure to maintain is highlighted and press [Enter].

5. Press the [Up or Down Arrow] until (S48)

DEADBAND PSI is shown in the menu and press

[Enter].

6. Press the [Up or Down Arrow] until the desired

deadband range is highlighted and press [Enter].

7. Press [Menu] to exit.

Throttle to Level

This type of throttling allows you to set a level you would like the

controller to maintain when a transducer is used for Level.

1. Access the S Menu by pressing [Menu].

2. Press the [Up or Down Arrow] to scroll to the correct

Entry Code (See Entry Code Supplement for Entry

Codes).

3. Press the [Up or Down Arrow] until (S59) MAINTAIN

LEVEL is displayed in the menu and press [Enter].

4. Press the [Up or Down Arrow] until the desired

pressure to maintain is highlighted and press [Enter].

5. Press the [Up or Down Arrow] until (S60)

DEADBAND LEVEL is shown in the menu and press

[Enter].

6. Press the [Up or Down Arrow] until the desired

deadband range is highlighted and press [Enter].

7. Press [Menu].to exit.

Tier 4 Emissions*

*Murphy products are compliant with requirements for U.S. EPA Emission

Standard ‒ Tier 4 Interim and EU Emissions Standard ‒ Stage IIIB for diesel

engines. These engines, when fitted with a DPF (Diesel Particulate Filter), can

self-clean the filter of particulates. The self-cleaning process is known as

Regeneration. EMS PRO LITE offers two tier levels: Tier 3 and Tier 4. The

following S-numbers are associated with emission control actions: S73 (Tier

Rating), S74 (Tier State), and S75 (Request DPF Regen) and can be seen in the

S-number table on page 22.

NOTICE: Enovation Controls does not control the

Emissions ECU, please consult with your engine

manufacturer for specific emissions operation.

Section 40 00-02-0787

2015-03-23 ~ 12 ~

If you are using the EMS PRO LITE on an Interim Tier 4 engine, please

read and understand the information for the following S-numbers: S73,

S74, and S75 in the S-number table, page 22. Also, read and understand

the following information and steps to set up Tier 4 Emission options.

The controller displays the SOOT level on the display when the engine

has been de-rated and/or when regeneration (regen) is required to return

to normal service. You must set S73 (Tier Rating) to Tier 4 for these

options to be available.

•If S74 (Tier State) is set to Auto DPF Regen, the ECU

performs a regen automatically. This only occurs if the

ECU conditions allow.

•If S75 (Request DPF Regen) is set to YES, the controller

commands the ECU to perform a regen. This only occurs

if ECU conditions allow.

•If S75 (Request DPF Regen) is set to NO, Inhibit Regen is

active and no regen occurs.

To use the controller on a Tier 4 engine, follow the steps below:

1. Access the S Menu by pressing [Menu].

2. Press the [Up or Down Arrow] to scroll to the correct

Entry Code (See Entry Code Supplement for Entry

Codes).

3. Press the [Up or Down Arrow] until S73 (Tier Rating)

is displayed in the menu and press [Enter].

4. Press the [Up or Down Arrow] until TIER 4 is

highlighted and press [Enter].

5. Press the [Up or Down Arrow] until S74 (Tier State)

is highlighted and press [Enter]. The default value is

set to INHIBIT. To select Auto DPF Regen use the

[Up or Down Arrow] to highlight the text and press

[Enter].

To use the Request DPF Regen feature, follow these steps (If all the

conditions for a regen to occur are not met, this request could be ignored

by the ECU):

1. Access the S Menu by pressing [Menu]

2. Press the [Up or Down Arrow] and scroll to the

correct Entry Code (See Entry Code Supplement for

Entry Codes).

3. Press the [Up or Down Arrow] until S75 (Request

DPF Regen) is displayed in the menu and press

[Enter].

4. Press the [Up Arrow] until YES is highlighted and

press [Enter].

Table of contents

Other Enovation Controls Controllers manuals

Popular Controllers manuals by other brands

Galcon

Galcon 9001 E-Z Installation and operation instructions

Alphatech

Alphatech GRL 4G Installation and programming manual

Hanna Instruments

Hanna Instruments HI 8001 installation manual

Sunricher

Sunricher SR-ZV9003T3-RGBW-US Installation

Yamaha

Yamaha MJC8 owner's manual

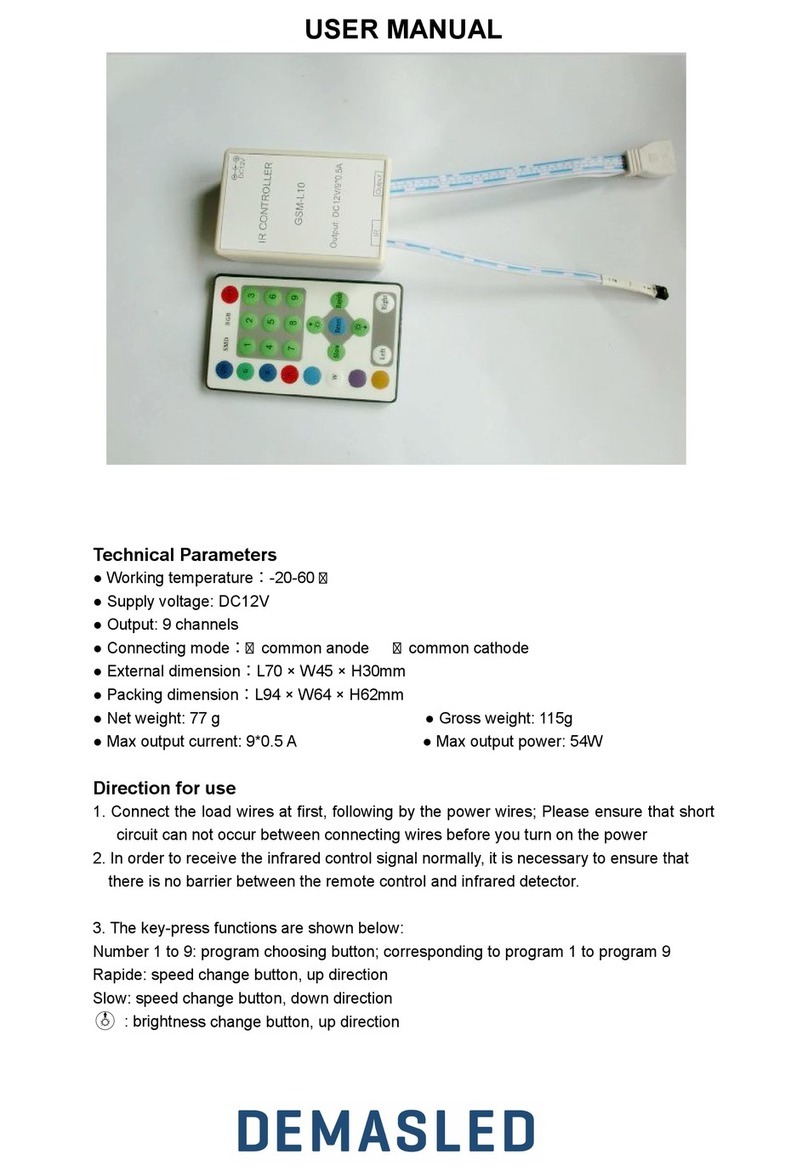

Demasled

Demasled GSM-L10 user manual