Enovative Technologies DC000A User manual

Enovative Group Inc. www.autohotusa.com Contact: 866-495-2734, [email protected]

DC000A - R9c Draft Installation and Operations Manual

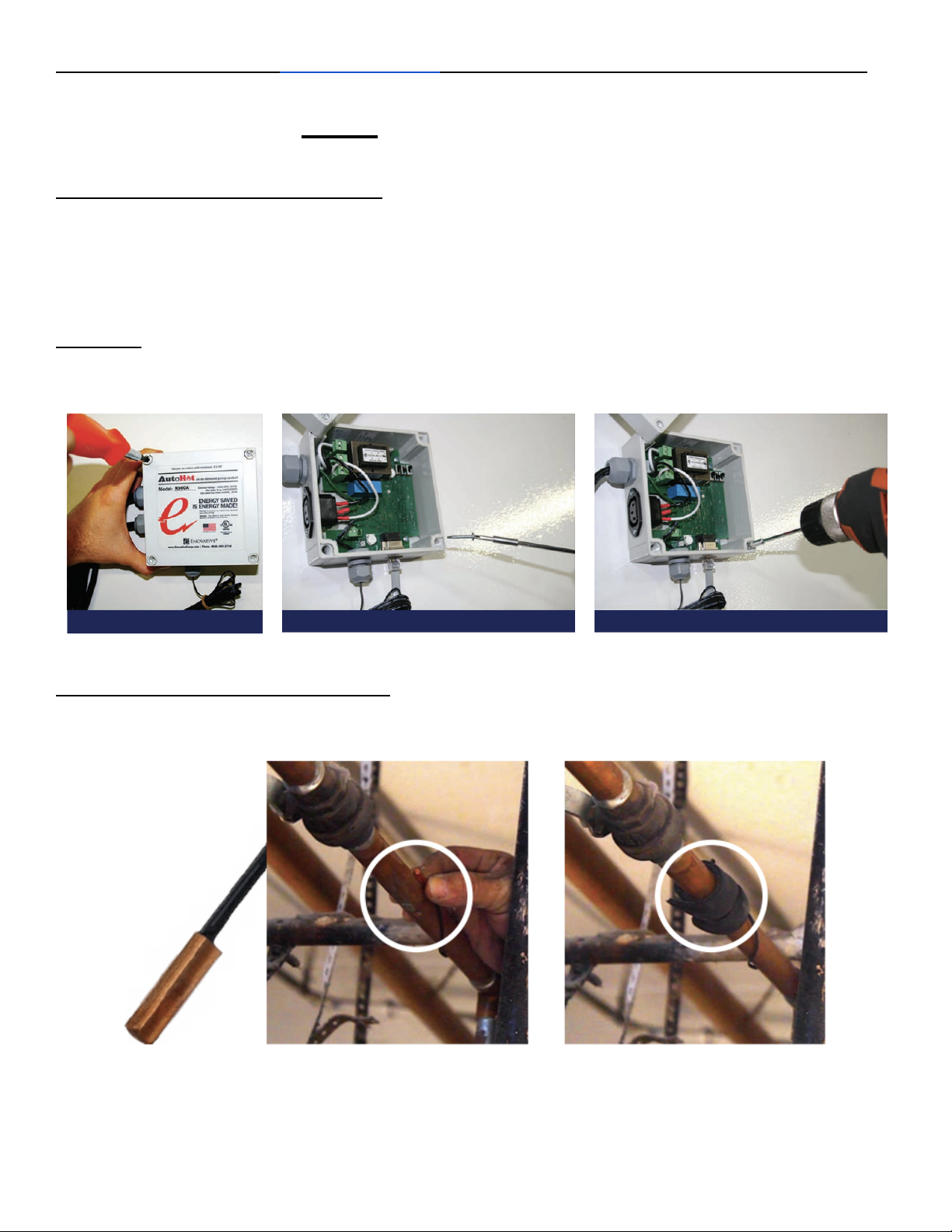

Mount the AutoHot Control Box

AutoHot® can be mounted to a nearby surface using screws. Unscrew lid (avoid power

tools as it may strip the screws). Use the same holes as the lid screws to mount the

box (make sure the wall screw head fits in the hole, and make sure you have a drill but

that is long and skinny enough to go all the way in. Drill into wall.

Important:Make sure the location where you mount the box is reachable for all the

sensors, cables, and power.

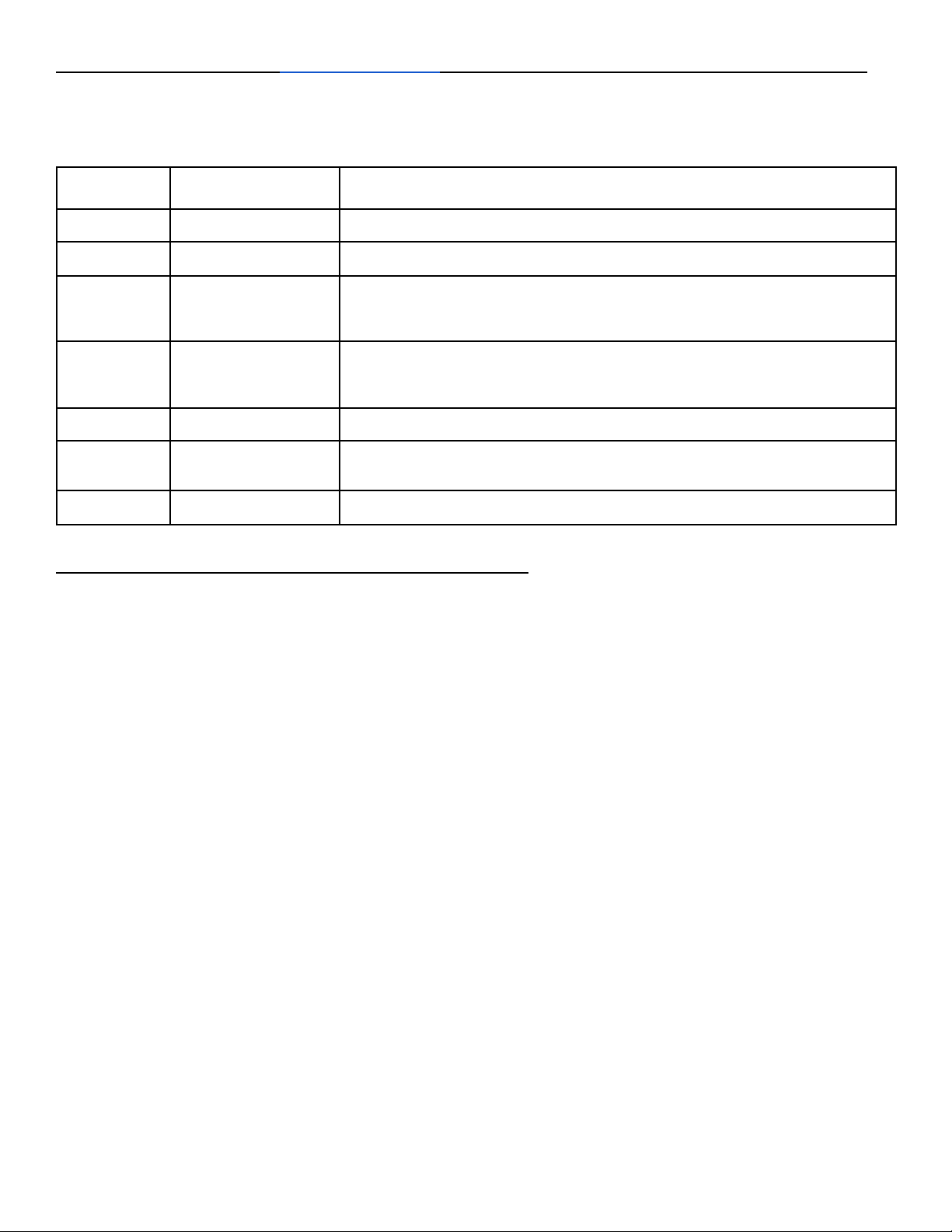

Attach the Temperature Sensors

Use the included insulation tape to attach the temperature sensor, concave side

towards the pipe. Zip ties will secure them into place.

R9c 101920 - draft

Enovative Group Inc. www.autohotusa.com Contact: 866-495-2734, [email protected]

The placement of the temperature sensors should be as follows:

T1 -On the return line as far

upstream of the pump as the wire

length and available return line

permit. If there are multiple loops

the sensor needs to be attached on

the side that takes longer to heat

up.

This sensor is important to the

operation of the pump control, as

the lockout temp determines when

the pump should and shouldn’t run.

T2 -This should go on the cold

water pipe, near the top of the tank.

If a boiler system, attach where the

cold water feed tees into the

system, and 6 inches upstream on

the cold pipe.

If a hot water return hits the cold

water inlet, place T2 downstream of

the tee where the return hits,

sensing the mixed temperature

water).

This sensor can send a demand

activation signal to the pump, when

the temperature drops below the

average of the past 10 seconds by

the setting for Temp Drop Trigger

(e.g. 2.5F).

T3 -This should go on the hot out

of the system, right above the

storage tank, but close to the tank.

You want to sense the temperature

of the stored water.

This sensor is used for boiler control

to turn on and off the water heater

based on the target temperature.

(e.g. at 2pm, we only want 112F, so

will keep the water heater off, if

above 112, and turn on if below).

Connect all the components & organize wires

Plug the Flow sensor (if included) into the bottom of the Control Box. Plug the pump into the female power outlet (if your

pump is hardwired, add a power cord). Plug in system to power and finish installation.

R9c 101920 - draft

Enovative Group Inc. www.autohotusa.com Contact: 866-495-2734, [email protected]

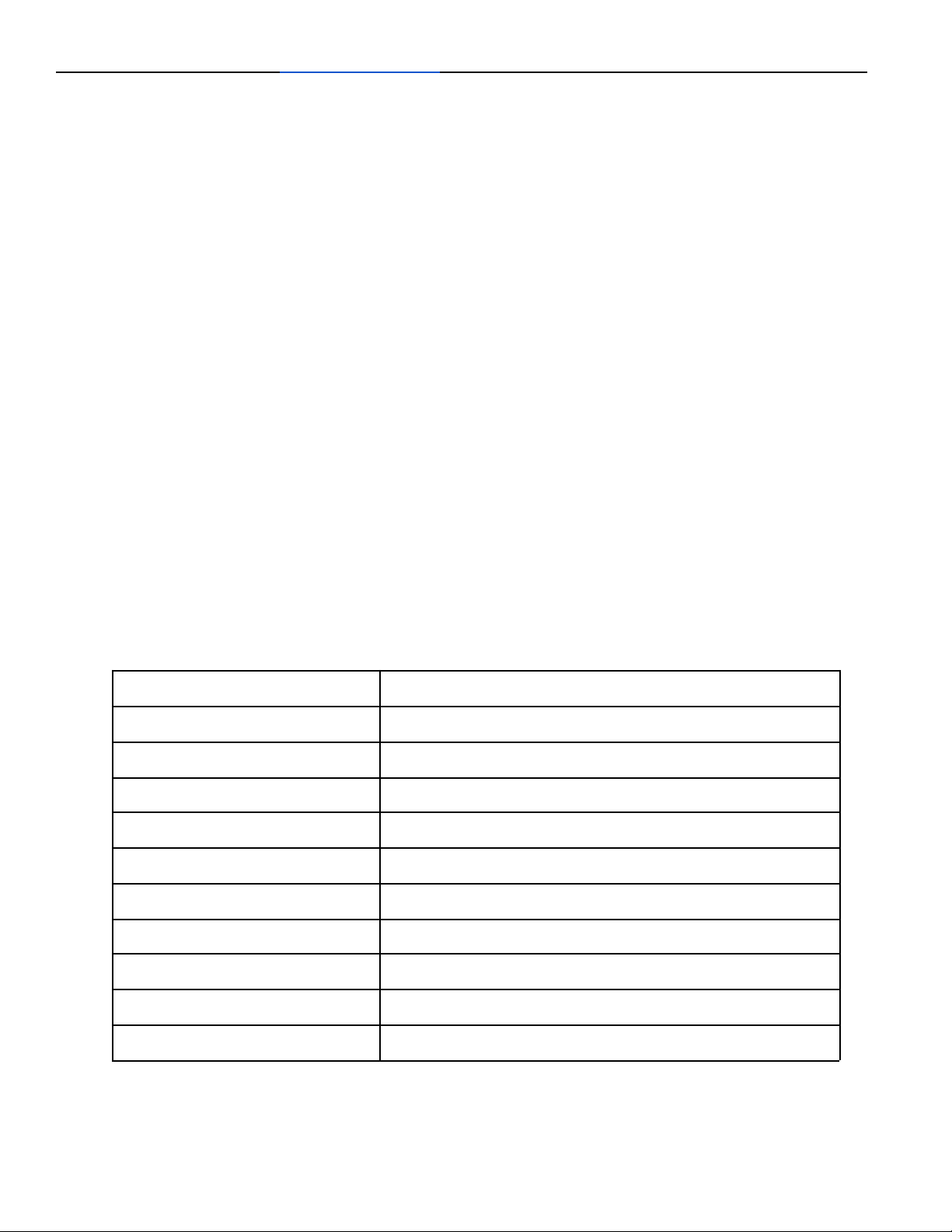

Onboard LED status lights -There are LED indicators on the board placed next to the relevant component

to indicate status. See table for list of LED indicators.

LED ID

Location

Description

D3

By Relay 1

On = relay 1 on, which controls pump, meaning pump should be on

D4

By Relay 2

On = relay 2 on, which can control a pump, meaning pump should be on

D14

By Solid State Relay

On = solid state relay on, used to control boiler, meaning the boiler temp sensor is

connected and should fire up to heat up (unless it has hit the boiler temp limit), Off =

the boiler cannot turn on, temp on boiler is disconnected

D12

T1 port

On = T1 is sensing the lockout temp (or within deadband (2-5F)), and it won’t allow

pump on (unless in Timer or constant mode), or will turn off pump. Off = below lockout

temp and can turn on if there is a activation signal or in Thermo mode

D20

T2 port

On = The temp drop activation is activated, therefore temp has fallen on T2 rapidly

D19

T3 port

On = T3 is sensing a temperature at or above the target temperature for this hour of

the day

D13

FLOWSW port

On = there is an activation signal coming from the attached sensor

Make Sure the System is functioning properly

See next page for how to read the LCD and set different settings.

Pump Control -Make sure the T1 led is off, create a activation signal (press BL button, activate flow switch, cause

a temperature drop in T2), and see that the pump turns on (Relay 1 LED turns on), and turns off once Lockout is met (T1

LED turns on).

Boiler Control - Make note of the Boiler setpoint, and turn it up temporarily during testing.

If T3 temperature shown on home screen is below the target temp for the hour of the day shown at the top of the LCD, the

SSR relay LED should be on, and the circle red on the R2 box of the LCD Home Screen and the boiler should be firing.

Within the Boiler Menu on the LCD, turn down the target temp for this hour (shown at top of LCD) to be 5 degrees below

the T3 reading, and the circle should turn black in the R2 box of the Home Screen, and the boiler should stop firing.

Turn the target temperature(Boiler Screen) back up above the T3 reading (Home screen), and the R2 circle should turn

red, and SSR LED turn on, and the boiler should starting firing again. You can turn the target temp up and down to both

turn on and off the boiler to confirm control by the controller. Once satisfied that controller is controlling, set the boiler

setpoint back to where it was.

R9c 101920 - draft

Enovative Group Inc. www.autohotusa.com Contact: 866-495-2734, [email protected]

CONTROLLER OPERATIONS, LCD SETTINGS

Home screen

Screen blinks every second, that's normal.

Large circle - Indicates the connection between the Mainboard and the LCD screen. Should be

green and may indicate an issue if it stays red.

Diamond - Indicates signal strength to a wifi connection, black/empty means no Wi-Fi connection,

and a full symbol (no black) indicates a strong Wi-Fi signal.

Snowman - indicates connection to server. 2 red dots indicate no connection and 2 green dots

indicate the controller is connected and reporting data to the server for display in the web portal.

Date/Time - Date and time

Menu icons

Setup - gives the id, firmware version, WiFi network name, mainboard model, ability to

send and fetch settings between controller and web portal

Pump - pump control settings such as, mode, lockout, Delta, autoprime, interval, tempdrop

trigger

Boiler - settings for boiler profile and boiler control override

T1/R1 - The top right shows the current temperature of T1. The yellow line is a graph of the lockout

temperature setting. The green line represents T1 temperature as a line graph over time. The bottom

red line indicates whether R1 (relay 1, used for return pump actuation) has been running as a line

graph over time. The circle is black if the R1 pump is not currently running and red if the controller is

actuating R1 to turn on the pump meaning the pump is or should be running.

T2/R2 - The top right shows the current temperature of T2. The green line represents T2 temperature

as a line graph over time. The bottom red line indicates whether R2 (relay 2, used for boiler control)

has been running as a line graph over time. The circle is black if the R2 boiler control is at target

temperature and doesn't need to fire up the boiler. The circle is red if the temperature of T3 is below

the target temperature for this hour of the day (or if overwritten) and the boiler should fire up to get to

target temperature.

T3 - The top right shows the current temperature of T3. The green line represents T3 temperature as

a line graph over time.

Note: T1 is for R1/Pump Control. T2 is used for temperature drop pump activation (so its may

activate R1), and T3 controls whether the R2 boiler control wants the boiler to fire up or not.

Setup Screen

Fetch Settings - Hold down the button for fetch settings until the black bar beneath is completely

blue and it will take any settings saved in the web portal, and save them to this controller. This

function also happens every 20 minutes automatically. Only applies to controllers connected to the

web portal.

Send Settings - Hold down the button for send settings until the black bar beneath is completely

blue and it will take the settings currently on the controller and send and save them to the web portal.

If you do not do this while changing settings at the controller, the settings will revert the next time the

controller automatically fetches settings from the server, every 20 minutes. Only applies to controllers

connected to the web portal.

Board model / firmware - displays the mainboard model and firmware version.

ID - displays the ID for this controller.

LCD firmware - displays the firmware version of the LCD

Net - displays the Wi-Fi network name that the controller is trying to connect to. Only applies to

controllers connected to the web portal. Only applies to controllers connected to the web portal.

Pump Settings Screen

To navigate this screen, the work colored in red, indicates the setting that is selected for modification.

Pressing the up and down buttons moves the setting up or down, or left or right. Press the next

button to highlight in red the next setting wished to be changed. The settings only are submitted upon

hitting the back button. If web portal connected, make sure to send the settings to the server so they

do not get automatically overwritten because a web connected controller reads settings from the web

portal every 20 minutes, so you need the local settings sent, in order to sync them up so it doesn't

change.

R9c 101920 - draft

Enovative Group Inc. www.autohotusa.com Contact: 866-495-2734, [email protected]

Mode (default: Demand) - the mode selected in yellow will be the mode select to run. Press the up and down buttons to cycle through the options. See

table below for the meaning of the different modes.

Pump Modes

Demand

This is full demand mode, and most energy efficient. Pump turns on with demand, if lockout temp is not met, and turns off with

lockout temp being met or based on interval time being met.

Thermo

This only looks at meeting the target temp of the lockout. It makes a constant demand signal, so that the pump turns on when T1

has fallen below lockout temp by the deadband (2 to 5 degrees), and turns off once lockout setpoint temperature is met.

Timer

This only looks at the demand (activation) signal, it turns on based on an activation signal, and only turns off after the demand

signal is gone, plus the interval time. Example: flow sensor sensing flow for 10 minutes, and interval set to 60 seconds, the pump

will run for 10 minutes, then an additional 60 seconds, and then turn off.

Constant

This runs the pump 24/7, does not save any energy, but is water efficient and minimizes hot water issues.

Lockout (Default: 115F) - is the target temperature for T1, at which point the the pump is unable to

turn on, or if running, stops running. This only applies to Demand, and Thermo modes, because

constant and timer modes ignore temperature in general.

Delta (Default 6F) - the temperature rise needed on a return line from T1 needed to turn off the

pump. (mostly ignored in commercial/multifamily/houses with return lines)

Autoprime (Default: 10 minutes for commercial, disabled for residential) - Time between

activation pulses, 5 minutes, means it will send a momentary demand signal (activation) every 5

minutes. If T1 is at or above the lockout, this does not mean the pump will turn on.

Interval (Default 5 min) - the amount of time before the pump turns off even if lockout is not met.

E.g. a 5 minute interval means even if T1 is not meeting the lockout, if its run for 5 minutes without an

activation signal it will turn off.

Temp drop trigger (Default 2.5F) - the amount the temperature must drop on T2, when compared to

the average temperature of T2 for the past 10 seconds, for it to send an activation signal which will

be there until the threshold is reached.

Boiler Screen

Screen shows the temperature profile over a 24 hours period, with a different target temperature for

each hour of the day for T3. The selected hour of the day shows as a red marker, and shows in the

bottom left of the screen, while the bottom right shows the target temperature for that hour of the day.

To navigate, press the next button, and it will move to the next hour of the day.

Boiler override - After the 23rd hour, it will show a 24-25th hours (which doesn’t exist), but highlight

the word “Override:” at the top right. Press the up or down buttons to toggle between override off or

on (to override this function).

Target Temperatures - To change any of the target temps, cycle through until the desired hour of the

day is reached (highlighted) and shown at the bottom, and press up and down to change the target

temp for T3.

Once all settings are as desired on this screen, press the back button to save and apply the settings,

at which point they go into affect. For web connected controllers, make sure to send the settings from

the setup menu, to the web portal in order for these settings to not get overwritten the next time it

checks and download the portal settings (every 20 minutes).

Default profile is shown in this table:

R9c 101920 - draft

Enovative Group Inc. www.autohotusa.com Contact: 866-495-2734, [email protected]

AUTOHOTⓇLIMITED WARRANTY

THIS WARRANTY IS APPLICABLE TO THE ORIGINAL OWNER ONLY in accordance with the warranty terms and

conditions specified below.

The warrantor will furnish the ORIGINAL OWNER, 1) a replacement AutoHot of identical model or current equivalent

model if a component inside the AutoHot control box fails and, 2) a replacement part for any external component part

which fails.

THE REPLACEMENT AUTOHOT OR PART WILL BE WARRANTED FOR ONLY THE UNEXPIRED PORTION OF THE

ORIGINAL WARRANTY. The warranty period will be determined by the original date of purchase of the AutoHot, or in the

absence of a Bill of Sale verifying said date, from the date of manufacture indicated on the rating plate affixed to the

AutoHot enclosure. This warranty is not transferable and applies to models listed below:

ITEM

WARRANTY PERIOD

Controller (the control box only, not anything attached to it)

5 years

Pumps (pumps included with the AutoHot)

18 months or OEM warranty

length, whichever is greater

Activators/Accessories (activators and accessories included with AutoHot, or sold by

Enovative Group, Inc.)

1 year

CONDITIONS AND EXCEPTIONS

This warranty shall apply only when the AutoHot is installed and

operated in accordance with 1) all local fire codes, electrical codes,

and plumbing codes, or other ordinances and regulations, 2) the

printed instructions provided with it, 3) good industry practices, and 4)

proper safety practices.

This warranty shall apply only when the AutoHot is:

● owned by the original purchaser;

● installed for indoor operation only, or if installed for outdoor

operation, installed correctly;

● used in a non-corrosive and non-contaminated atmosphere;

● used with factory approved accessories installed;

● in its original installation location;

● in the United States, its territories or possessions, and

Canada;

● Has relays sized in accordance with proper sizing techniques

for the controlled pump;

● bearing a rating plate which has not been altered, defaced or

removed except as required by the warrantor;

● installed with no attempted, nor actual modification or

alteration of the AutoHot’s design in any way, including but

not limited to, the attachment of non-company approved

appliances or equipment, including any additional

aftermarket equipment introduced into the control,

monitoring, or electrical pathways.

Any accident to the AutoHot or any part thereof (including

freezing, fire, floods, or lightning), any misuse, abuse or

alteration of it, any operation of it in a modified form, or any

damage caused by attempts to repair the AutoHot will void

this warranty.This warranty does not apply to a Commercial

AutoHot used in a residential setting, nor does it cover a

Residential AutoHot used in a Commercial Setting, without

prior written approval from warrantor.

This warranty gives you specific legal rights, and you may

have other rights which vary under the laws of each state. If

any provision of this warranty is prohibited or invalid under

applicable state law, that provision shall be ineffective to the

extent of the prohibition or invalidity without invalidating the

remainder of the affected provision or the other provisions of

this warranty.

SERVICE AND LABOR RESPONSIBILITY

UNDER THIS LIMITED WARRANTY, THE WARRANTOR WILL

PROVIDE ONLY A REPLACEMENT AUTOHOT OR PART THEREOF.

THE OWNER IS RESPONSIBLE FOR ALL OTHER COSTS. Such

costs may include but are not limited to:

A. Labor charges for service, removal, or reinstallation of

AutoHot or part thereof.

R9c 101920 - draft

Enovative Group Inc. www.autohotusa.com Contact: 866-495-2734, [email protected]

B. Shipping and delivery charges for forwarding the AutoHot or

replacement part from the nearest distributor and returning

the claimed defective AutoHot or part to such distributor.

C. All costs necessary or incidental for handling and

administrative charges, and for any materials and/or permits

required for installation of the replacement AutoHot or part.

LIMITATION ON IMPLIED WARRANTIES

Implied warranties, including any warranty of merchantability imposed

on the sale of this AutoHot under state law are limited to one year

duration for the heater or any of its parts. Some states do not allow

limitations on how long an implied warranty lasts, so the above

limitations may not apply to you.

CLAIM PROCEDURE

Any claim under this warranty should be initiated with the dealer who

sold the AutoHot, or with any other dealer handling the warrantor’s

products. If this is not practical, the owner should contact: Enovative

Group, Inc., 340 S Lemon Ave Suite 5425, Walnut, CA 91789. Phone:

1.866.495.2734 or visit our website: www.autohotusa.com.

Replacement Parts may be ordered through authorized servicers or

distributors. Refer to your local Yellow Pages for where to call or

contact AutoHot Parts Fulfillment, 340 S Lemon Ave Suite 5425,

Walnut, CA 91789. Phone: 1.866.495.2734 or visit our website:

www.autohotusa.com.

The warrantor will only honor replacement with identical or similar

AutoHot or parts thereof which are manufactured or distributed by the

warrantor.

Dealer replacements are made subject to in-warranty validation by

warrantor.

PROOF OF PURCHASE AND PROOF OF INSTALLATION DATE ARE

REQUIRED TO SUPPORT WARRANTY CLAIM FROM ORIGINAL

OWNER. THIS FORM DOES NOT CONSTITUTE PROOF OF

PURCHASE OR PROOF OF INSTALLATION.

DISCLAIMERS

NO EXPRESSED WARRANTY HAS BEEN OR WILL BE MADE ON

BEHALF OF THE WARRANTOR WITH RESPECT TO THE

MERCHANTABILITY OF THE HEATER OR THE INSTALLATION,

OPERATION, REPAIR OR REPLACEMENT OF THE HEATER OR

PARTS. THE WARRANTOR SHALL NOT BE RESPONSIBLE FOR

WATER DAMAGE, LOSS OF USE OF THE UNIT, INCONVENIENCE,

LOSS OR DAMAGE TO PERSONAL PROPERTY, OR OTHER

CONSEQUENTIAL DAMAGE. THE WARRANTOR SHALL NOT BE

LIABLE BY VIRTUE OF THIS WARRANTY OR OTHERWISE FOR

DAMAGE TO ANY PERSONS OR PROPERTY, WHETHER DIRECT

OR INDIRECT, AND WHETHER ARISING IN CONTRACT OR IN

TORT.

Should governmental regulations or industry standards prohibit the

Manufacturer from furnishing a comparable model replacement under

this warranty, the Owner will be furnished with the closest comparable

model meeting the then current governmental regulations and industry

standards. A supplementary fee may be assessed to cover the

additional cost associated with the changes made to meet applicable

regulations and standards.

IMPORTANT INFORMATION

Model Number

Serial Number

Date Installed

Installer Company Name

Installer Address

Installer Phone Number

Installer License Number

Recirculation Pump Model

Recirculation Pump Serial Number

Water Heater Model

Water Heater Serial Number

R9c 101920 - draft

Table of contents