7

EFA COMPONENT DESCRIPTION

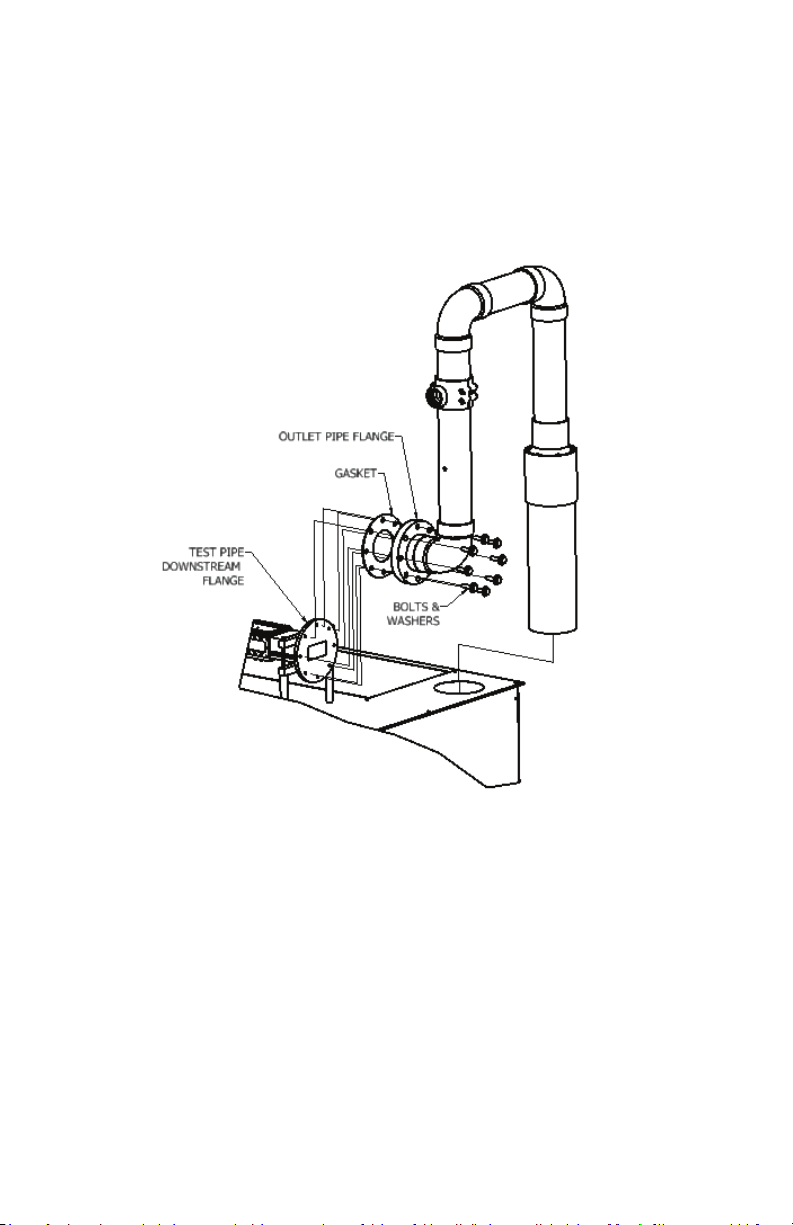

1. Flowmeter

a. The hardware monitors the speed of the water using the owmeter

downstream of the sample. The dimensions of the PVC up-pipe are

used to determine a ow rate which is then used to determine the

ow speed across the sample.

2. Temperature Probe

a. The resistance of the thermistor is monitored in order to display and

record temperature.

3. Water Level Sensor

a. Two water level sensors are used to ensure the tank is not under-

or over-lled.

4. Water Control

a. If fresh water is not cycled through the machine the pump will slowly

heat up the water over time. As such, during testing we recommend

turning on all three buttons (Sump, Flow, and Fill) to keep

temperatures relatively constant. The water will sump to the bottom

sensor, ll to the top sensor, then repeat. When the Flow Pump is

turned off, if the Sump Pump button is on, the machine will continue to

sump all water out of the tank.

b. A complete description of the possible states of the system are as

follows:

i. Fill OFF, Flow OFF, Sump OFF

1. System will do nothing.

ii. Fill OFF, Flow OFF, Sump ON

2. System will sump all water out of the tank.

WARNING: There is no automatic shut off of the sump pump.

User must manually turn off the sump pump when water level

gets lower than sump pump intake.

iii. Fill OFF, Flow ON, Sump OFF

1. System will ow water through the machine only.

iv. Fill OFF, Flow ON, Sump ON

1. System will ow water through the machine and will sump water

out until no water is seen at the lower water level sensor. Once

water is no longer detected the sump pump will stop but the

water ow will continue.

v. Fill ON, Flow OFF, Sump OFF

1. System will ll water tank until water is detected at upper water

level sensor.