Warnings

•Keep the operation zone free. Consider it a security zone. This zone will

be free of persons and objects that could be an obstacle by shifting the

machine or moving any of its parts. Take care that the raising elements

do not encounter an obstacle in their way.

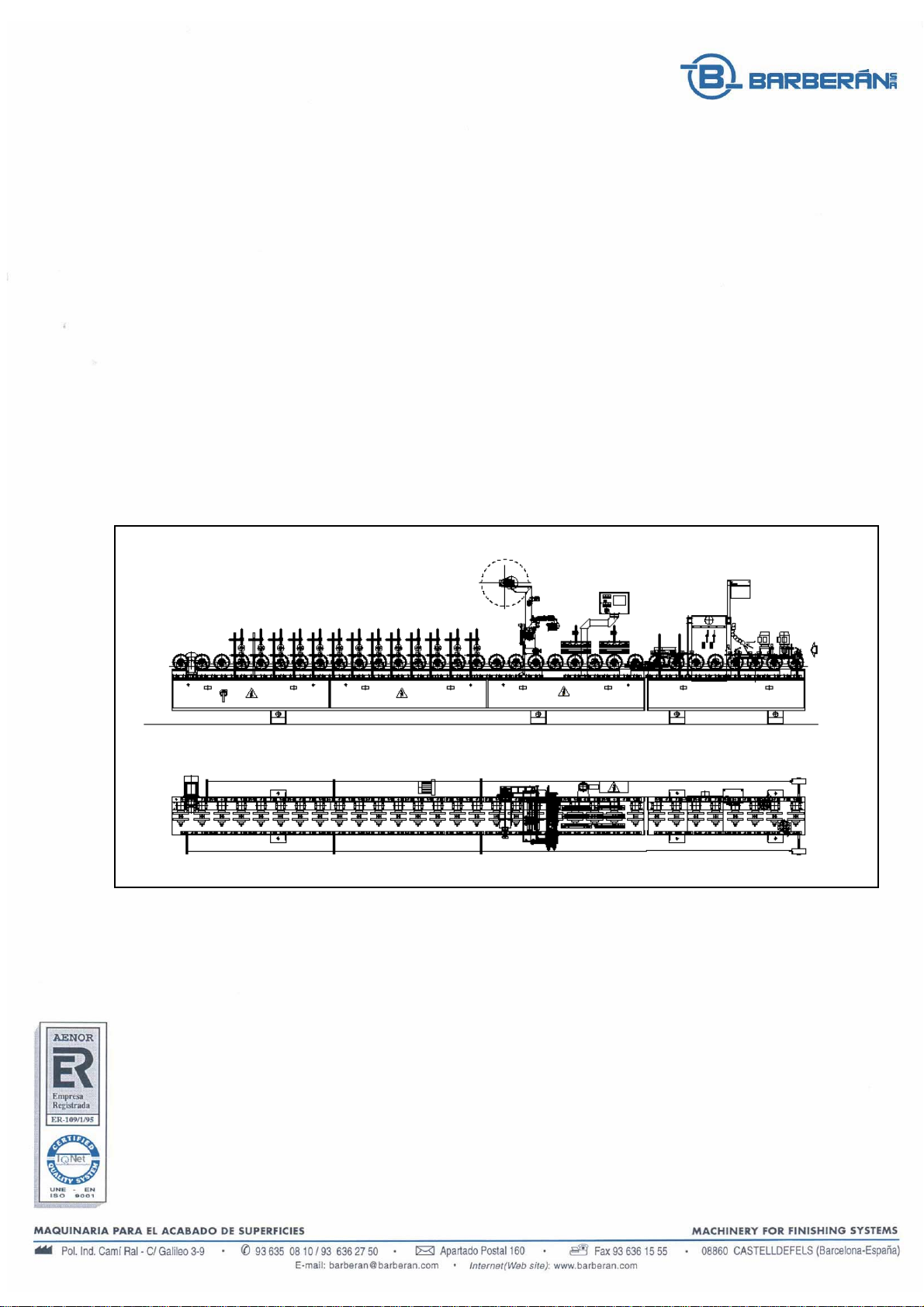

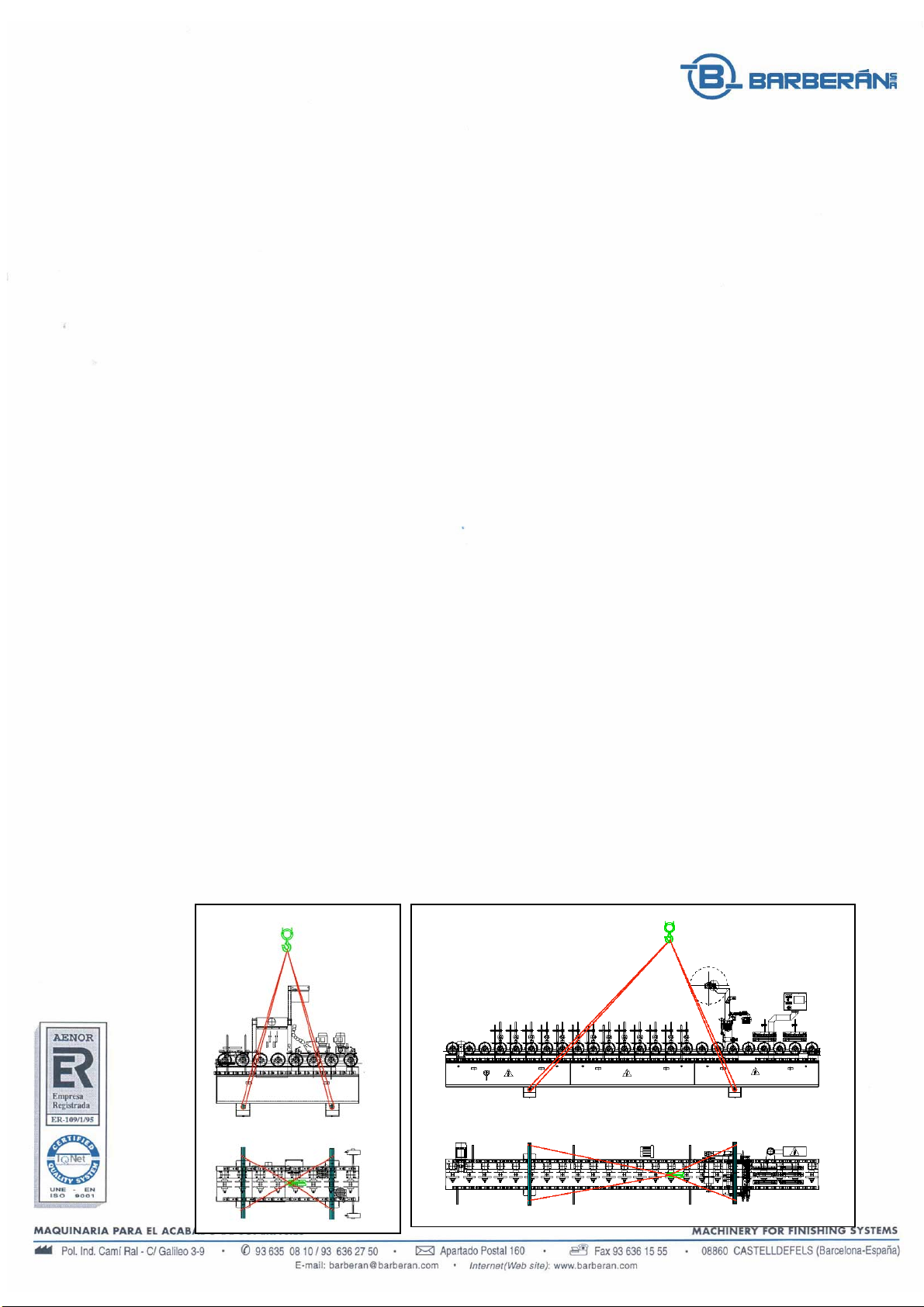

•Before lifting the machine you have to equilibrate its weight (see

technical feature sheet) and use the adequate equipment to raise it.

•All the operations that are mentioned in this section should be done by

personnel authorized for this tasks.

1.3.3 Positioning and installation

The positioning of the machine must be done in a place which has all

necessary conditions like status of the floor, leveling, good lighting, ventilation

and air exhaustion and weather protected.

The machine must have enough free space at both sides to allow an

easy access for operation. The minimum area to be considered should be 2

meters at the control side and 1 meter at the opposite side. Do not place any

material or obstacles in these areas.

Warning

•Consider to use protection cover for wirings and pipes on the floor to

avoid falls of the personnel.

1.3.3.1 Positioning conditions

The machine must be levelled in the perpendicular direction to the floor,

using the levelling screws placed at the bedframe base. If the machine is part of

a line, you have to level the machine according to the line level, that means so

that the working height coincides with the prior and next machine. As a

reference, please use the conveyor.

1.3.3.2 Electric connections

Before the machine is connected, you must verify that the network

connection complies with the present standards.

Verify that the tensión and frecuency are the ones indicated in the

identification plate of the machine. If this data does not coincide, please do not

proceed with the connection.