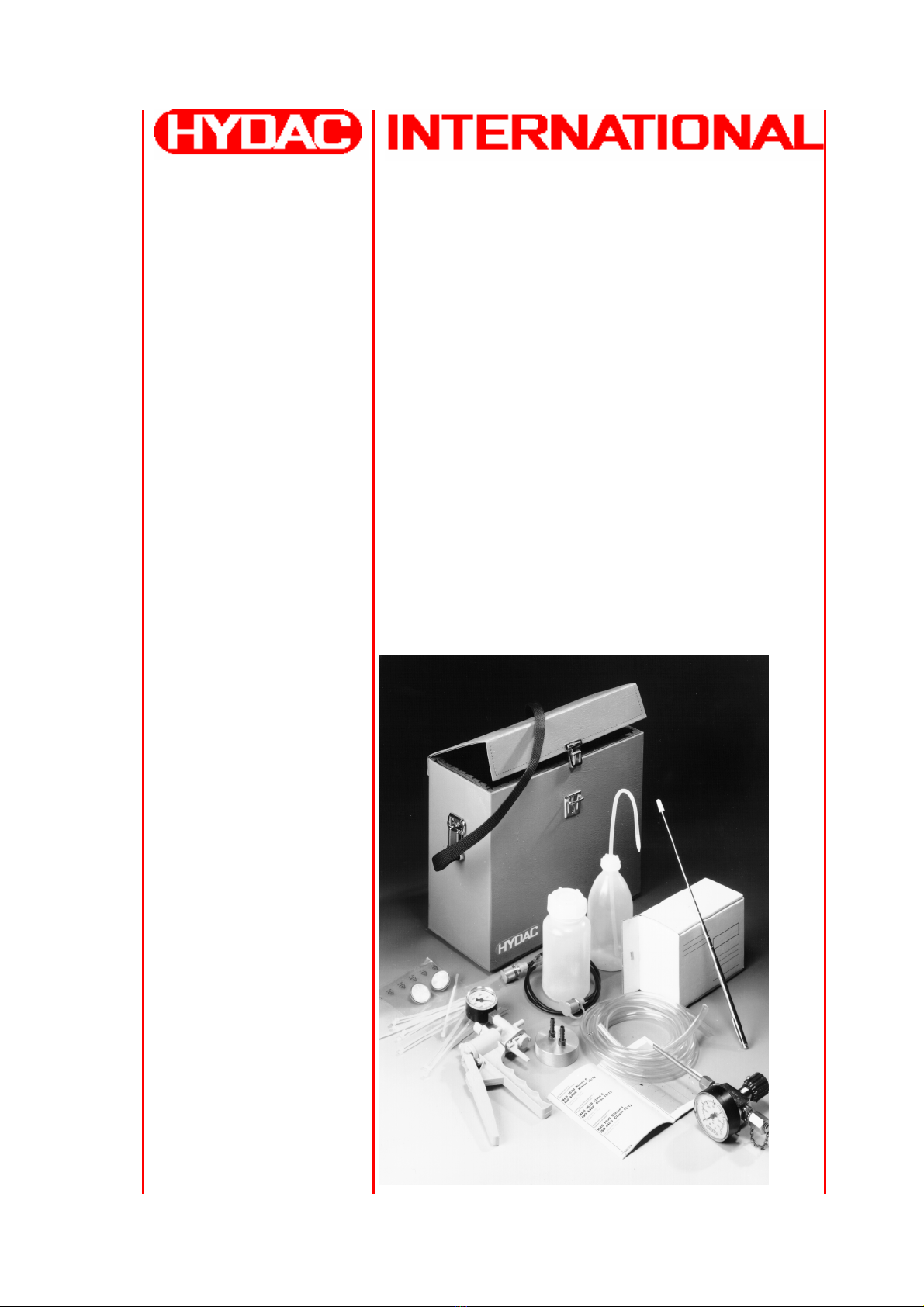

Fluid Sampling Set - FES Contents

HYDAC Filtertechnik GmbH en Page 3

Bewa FES 3160266a en.doc 2008-05-29

Contents

Trademarks ............................................................................................................................. 2

Contents..................................................................................................................................3

Preface ....................................................................................................................................4

Customer Service .................................................................................................................5

Modifications to the Product .................................................................................................5

Warranty ...............................................................................................................................5

Using the documentation ...................................................................................................... 6

Safety Information and Instructions..................................................................................... 7

Explanation of Symbols and Warnings ................................................................................. 7

Please observe the instructions in this manual..................................................................... 7

Responsibility of the owner...................................................................................................7

Hazards Posed by Using the FES ........................................................................................8

Proper/Designated Use ........................................................................................................8

Informal Safety Precautions.................................................................................................. 8

Modifications on the FES......................................................................................................8

Cleaning the FES..................................................................................................................8

Checking the scope of delivery ............................................................................................ 9

Fluid Sampling Set properties ............................................................................................10

Source of oil contamination.............................................................................................10

Oil contaminations influence the ageing of the oil...........................................................11

Sampling ...............................................................................................................................12

Static sampling ...................................................................................................................12

Dynamic sampling ..............................................................................................................12

Labelling samples...............................................................................................................14

Performing maintenance .....................................................................................................14

Disposing of the FES ...........................................................................................................14

Spare Parts List ....................................................................................................................15