Enpaix EPX300 User manual

Tim e

Impact Re bound

Vimpact

Vrebound

HL=1000*

Vimpact

Vrebound

POLYGON Instrument Ltd.

1 Introduction

1.1 Principle

1.2 Structure

1.3 Specifications

2 Test

2.1 Instrument Preparation

2.2 Specimen

2.3 Test Procedure

2.4 Browse

2.5 Printing

3 Setup

3.1 Material

3.2 Direction

3.3 Scale

3.4 Clock

Preparation

EPX300

Portable Hardness Tester

CONTENTS

4 Maintenance

4.1 Routine Maintenance

4.2 Calibration

4.3 System Reset

Appendix

A-1 Hardness Conversion

A-2 Tensile StrenghConversion

1 Introduction

1.1 Principle

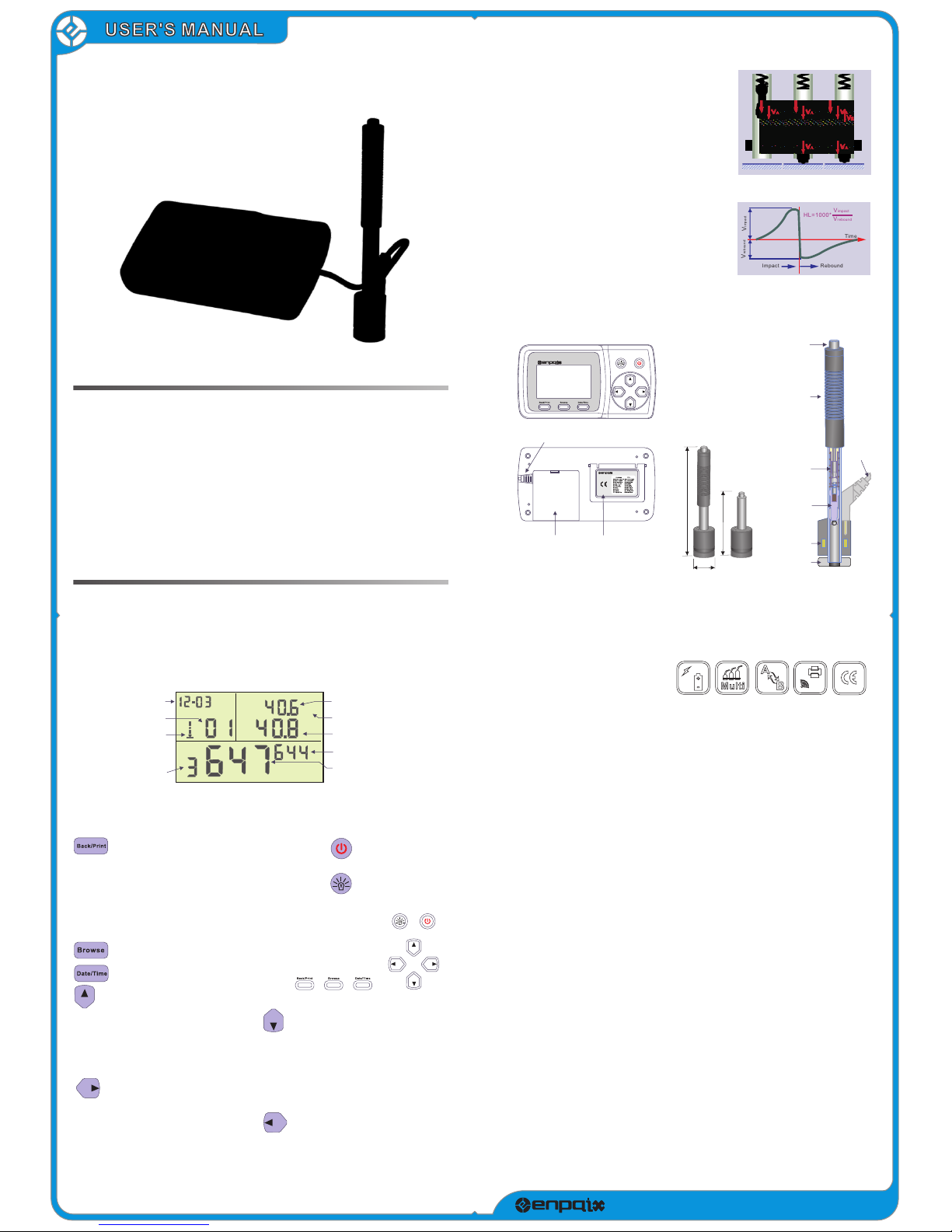

The tester measuring principle is physically a

rather simple, dynamic hardness tester.

An impact body with a hard metal test tip is

propelled by spring force against the surface of

the test piece. Surface deformation takes place

when the impact body hits the test surface,

which will result in loss of kinetic energy.

The energy loss is calculated by velocity

measurements when the impact body is at a

precise distance from the surface for both the

impact and rebound phase of the test. The permanent magnet in the

impact body generates an induction voltage in

the single coil of the impact device. The

voltage of the signal is proportional to the

velocity of the impact body, and signal

processing by the electronics provides the

hardness reading for display and storage.

1.2 Structure

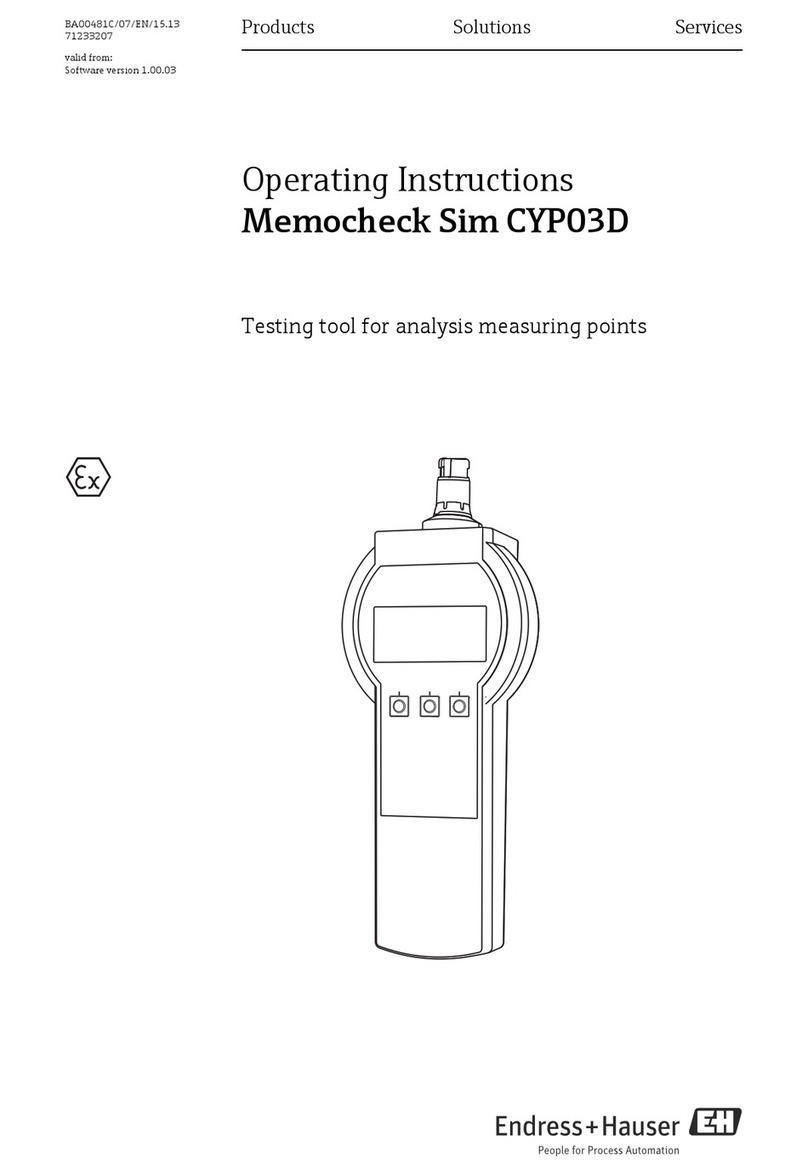

1) Display Unit 2) Impact Device

. 1 .

Portable Hardness Tester

Standardized

according to

ASTM A956

SCALE

MAT

DEL

DIR

EPX300

D

147

86

Φ20

DC

Release Button

Loading Tube

Coil

Catch Chuck

Cable

Impact Body

Support Ring

LCD

Signal Cable

Cell Cover Material Code

SCALE

MAT

DEL

DIR

Mat'L

Avg.

HRC

Avg.

HL

Clock

Material Code

Impact Direction

Impact Times

Conversion Average

Conversion Scale

Conversion

HL Average

HL Value

SCALE

DIR

DEL

MAT

❶In measurement mode, press and hold it to erase

the measured data. Or if the mini-printer is linked

with the display unit, it will print out those data.

❷In other mode, press it to complete setup and

save the parameters and return to the

measurement mode.

Browse data in memory

Adjust date and time.

Pressing and holding to

turn on/off power.

Turn on/off the LCD

backlight

❶ In measurement mode, press it to

setup the impact direction.

❷In Date/Time setup mode and

calibration mode, press it to increase

the flickering bit.

❸In browse mode, press it to display

the previous data.

❶In measurement mode, press it to

setup the conversion scale.

❷In Date/Time setup mode and

calibration mode, press it to decrease

the flickering bit.

❸In browse mode, press it to display

the next data. measurement mode or

browse mode.

Press and hold it to delete current data

in measurement mode or browse mode.

❶In measurement mode, press it to

select the material.

❷In Date/Time setup mode and

calibration mode, press it to select

the next bit.

3) Display

4) Keypad

1.3 Specifications

● Display Range 0~999HLD

● Accuracy: ±6 HL(at 800HLD)

● Resolution: 1 (HL,HV,HB, HSD , MPa ); 0.1(HRC,HRB)

● Impact Energy: 11 Nmm

● Mass of Impact Body: 5.5g

● Test Tip: Φ3mm tungsten carbide ball

● Power: 3 *1.5V AAA Batteries

●Operating Temperature:0°C~+50°C (32°F~122°F)

●Storage Temperature: -10°C~+60°C (14°F~140°F)

●Dimensions: 150*80*24mm(Display unit), Impact length

●Weight: Approx.200g(display unit)

Impact device 75g(Type D), 50g (Type DC)

●Conforms to Standard: ASTM A956 & DIN50156

:

. 2 .

3.3 Scale

In measurement mode, press to convert to the

other hardness scales or tensile strength (MPa).

Notes:

A) The conversion value is “---” indicated the conversion is out of range.

B) When you set the conversion from hardness scale to tensile strength or from

tensile strength to hardness scale, you must be reset the material group.

C) Conversion value only supplies the general reference, which may result in

some offset. Precisely conversion generally needs related comparative tests.

3.2 Impact Direction

In measurement mode, press button to select the

impact direction.

The tester can do some correction for test directions

automatically.

2.4 Browse

The tester can save 9 hardness values, you can browse them after testing.

Press button to browse stored data and display the first data in last

nine test data, including hardness value HLD, material code, conversion,

impact direction, date and time etc.

Press or button to browse the next or previous data group.

Press button back to the measurement mode.

3.4 Clock

The Hardness Tester has built-in real-time

clock system.

It must be adjusted when you reinstall the

batteries or other necessary case.

Press to enter the clock adjustment

mode.

Press or to change the value and press

or to move item.

Press to confirm the set and back to measurement mode.

Mat'L

Avg.

HRC

Avg.

HL

Month

Day

Year Hour Minute

Ra 1.6

2 Test

2.1 Instrument preparation

Install the battery

Connect impact device

Turn on the power

To confirm the accuracy: Use the standard test block to check the tester

and make sure it work well.

2.2 Specimen preparation

Inappropriate specimen will bring the error measured results. It should be

the necessary processing and preparation according to the original

conditions of specimen. The preparation of specimen shall be annexed the

basic requirements for the following:

In the test surface preparation, should be avoided

cold, heat processing on the specimen surface.

Test surface should be flat with metallic luster, and

no oxide skin and other dirt.

The roughness of test surface should be Ra ≤ 1.6.

The specimen must be of

sufficient mass and rigidity to

avoid the displacement or move in

test.

Generally, the mass of the

specimen is greater than or equal

to 5kg can be carried out the test

directly.

The specimen of 2 ~ 5kg need to

be clamped to fix, the specimen of

0.05 ~ 2kg should be coupled . If the mass is lighter than 0.05kg, it is

unfavorable to Leeb test type D.

The thickness of specimen shall be not less than 5mm, and thickness

of homogeneous layer (or surface hardening layer) is not less than

0.8mm.

If the test surface is not flat, the radius of test area should be larger

than 30mm. And should mount a appropriate support ring.

The specimen should not be with magnetic.

❶

❷

❸

❹

❶

❷

❸

❹

❺

❻

❼

2.3 Test Procedure

1) Loading

Simply load the impact device by sliding the loading

tube forward.

2) Locating

Then place and hold the impact device on the surface

of the test piece at the desired test point. Impact

indirection should be vertical with the test of surface.

3) Impacting (Measuring)

Trigger the impact by pressing the release button. The

hardness value will be instantaneously displayed.

4) Read test result

Read out the test result from LCD.

Note:

Generally, each measurement location of sample is conducted for the five tests.

The distance between any two impact point should be ≥3 mm ; the distance

between impact position and the edge of the sample should be≥3 mm.

Direct Clamping Coupling

>5kg 2~5kg 0.05~2kg

Mat'L

Avg.

HRC

Avg.

HL

Hardness value: 786HLD;

The 3rd measurement point;

Mean value: 785HLD

Material Code:"01"(Steel & Casting Steel)

Conversions to HRC: 58.6HRC

Mean value of HRC: 58.5HRC

SCALE

2.5 Print Test Report

The tester can be linked to a wireless printer to print a

report.

Place the printer near the tester(within 2 m), and turn it

power on.

Press for about 2 seconds, a report will be printed.

NOTE:

The original data in memory will be erased automatically when

the print completed.

Te s t R e po r t

Impact Unit Type: D

Material: Steel & Cast steel

1 7 8 2 H L D 5 8 .3 H R C

2 0 15 - 1 2 - 0 3 1 5 : 2 1

2 7 8 7 H L D 5 8 .7 H R C

2 0 15 - 1 2 - 0 3 1 5 : 2 1

3 7 8 6 H L D 5 8 .6 H R C

2 0 15 - 1 2 - 0 3 1 5 : 2 2

4 7 8 5 H L D 5 8 .5 H R C

2 0 15 - 1 2 - 0 3 1 5 : 2 2

5 7 8 4 H L D 5 8 .4 H R C

2 0 15 - 1 2 - 0 3 1 5 : 2 3

S = 5 H L D 0 . 4 H R C

X = 78 5 H L D 5 8 . 5 H R C

2 0 15 - 1 2 - 3 1 5: 2 5

3 Setup

3.1 Material Code

In measurement mode, press button

to select the material code you will test.

The material code is listed on the back

label

Note:

It is necessary to select the material

classification. When you did not know the

material type, you should reference the

related material handbook.

MAT

DIR

DIR

HRC HRB HB

HV

HSD

MPa

SCALE

SCALE

DIR

MAT

DEL

. 4 . . 5 .

. 6 . . 7 .

4 Maintenance

4.1 Routine maintenance

1) General considerations

Impact device should avoid collision, the weight stack in the use and

storage. Put into the case after use. The impact body should is in release

state when storage.

Should avoid close to the strong magnetic. Any of the components can't

stick any kinds of oil or lubricant.

2) Clean the impact body

General every 1~2 thousands of times after test, the impact device tube and

impact should be cleaned up.

Method: Rotate off the support ring, release and remove the impact body.

use the nylon brush to clean up the tube and impact body.

3) Replacement impact ball

For long-term use, the impact ball may be worn, it should be replaced when

affect the test precision.

4.3 System Reset

If the display unit isn't working properly or halt, you should reset system.

Replace the batteries and remount them , then turn on the power.

4.2 Calibration

The calibration can be done in any scale (HLD, HRC,

HRB, HB, HV, HSD), so as to farthest decrease the

measuring error.

Before calibration, the scale should be converted into

the scale needed. Such as to calibrate in HB, "HB"

should be selected by press button.

Press button for about 2 seconds until the

number of impact times flicker that the impact time

become to “0”.

Test 5 times on test block to obtain the average

value (can delete some error data in operation).

Press and hold button about 2 seconds to

display the calibration mode.

Enter the standard value of test block.

Press or to change the value and press

or to move digit.

❶

❷

❸

❹

Mat'L

Avg .

HRC

Avg .

HL

Mat'L

Avg .

Avg .

HL

Mat'L

Avg .

HRC

Avg .

HL

SCALE

DIR SCALE DEL

MAT

Note:

A) If calibration in the other scale(HRC, HRB, HB, HV or HSD), the scale must be

adjusted in measurement mode first.

B) In the other scale (HRC, HRB, HB, HV, HSD) calibration mode, the standard

values input is different from calibration in Leeb hardness(HL).

25.0HRC, should be entered into "250" (HRB is the same).

85HB, should be entered into "085"(HV, HSD are the same).

If the input data exceeds the range, the calibration will not be performed.

Steel & Cast Steel

Alloy Tool Steel

Stainless Steel

Grey Cast Iron

Ductile Iron

Cast Aluminum Alloy

Brass

Bronze

Copper

Forging Steel

Materials HV HB HRC HRB HSD

81-955

80-898

85-802

83-976

20.0-68.4

20.4-67.1

19.6-62.4

19.8-68.5

81-654

85-655

63-336

140-387

19-164

40-173

60-290

45-315

142-651

38.4-99.5

46.5-101.7

23.8-84.6

13.5-95.3

59.6-99.6

32.5-99.5

26.4-99.5

Low Carbon Steel

Hi-Carbon Steel

Chrome Steel

Cr-V Steel

Cr-Ni Steel

Cr-Mo Steel

Cr-Ni-Mo Steel

Cr-Mn-Si Steel

Hi-Strength Steel

Stainless Steel

Materials Tensile Strengh

(MPa)

375-788

774-1710

742-1845

736-2026

782-2058

747-1888

850-1947

781-2045

1170-2693

740-1725

Appendix

A-1 Hardness Scale Conversion Range

A-2 Tensile Strengh Conversion Range

. 8 . . 9 .

DUM111-00-0000EN1511

Popular Test Equipment manuals by other brands

Agilent Technologies

Agilent Technologies BERT N4901A Getting started

Endress+Hauser

Endress+Hauser Memocheck Sim CYP03D operating instructions

Tektronix

Tektronix Keithley 2302 Quick results guide

Tektronix

Tektronix 5110 instruction manual

Rigol

Rigol DS1000B Series quick guide

Bartec

Bartec Tech500 user guide