SAV-Uc/0650

ATEQ, THE ASSURANCE OF A COMPETENT AFTER SALES

SERVICE

THE ATEQ AFTER SALES SERVICE IS :

•a team of qualified technicians,

•a permanent telephone assistance,

•agencies close to you for faster reaction,

•a stock of spare parts available immediately,

•a car fleet for rapid intervention,

•a commitment to quality ...

THE OVERHAUL

ATEQ carries out the overhaul of your instruments at interesting prices.

The overhaul corresponds to the maintenance of the instrument (checking, cleaning, replacing of used

parts) as part of preventive maintenance.

Preventive maintenance is the best way to guarantee reliability and efficiency. It allows the

maintenance of a group of instruments in good operational order and prevent eventual break-downs.

MAINTENANCE KITS

The ATEQ After Sales Service proposes, two kits destined for the preventive maintenance of the

pneumatic circuits of instruments.

CALIBRATION

This may be carried out on site or in our offices.

ATEQ is attached to the COFRAC and delivers a certificate following a calibration.

TRAINING COURSES

In the framework of partnership with our customers, ATEQ offers two types of training in order to

optimise the usage and knowledge of our instruments. They are aimed at different levels of technician:

•method / control training,

•maintenance / upkeep training.

A TARGETED TECHNICAL DOCUMENTATION

A number of technical documents are at your disposal to allow you to intervene rapidly in the event

minor breakdowns:

•problem sheets describing and offering solutions to the main pneumatic and electronic

problems,

•several maintenance manuals.

A QUALITY GUARANTEE

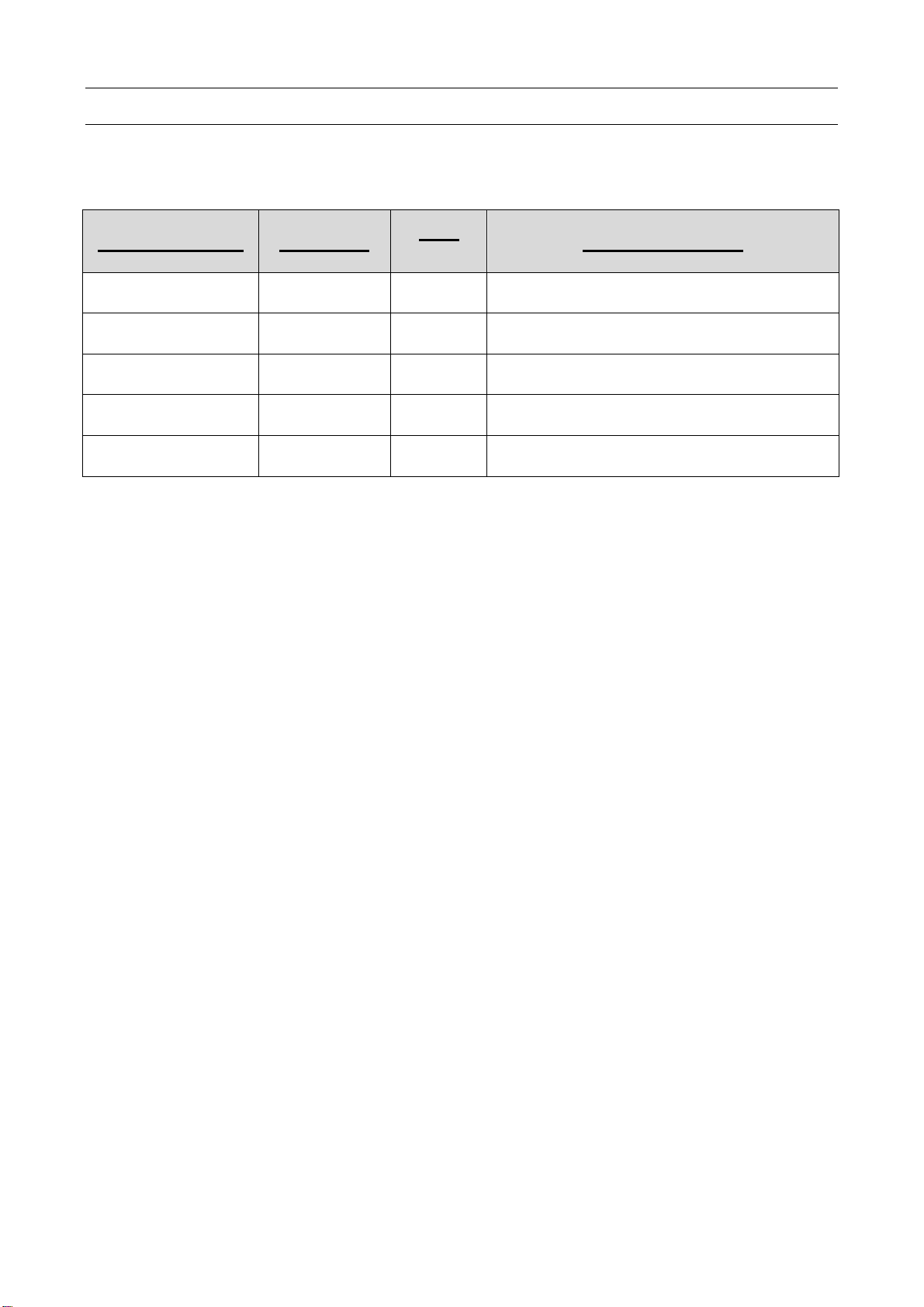

The instruments are guaranteed for parts and labour in our offices:

•2 years for leak detection equipment,

•1 year for electrical tests to norms instruments,

•1 year for the accessories.

Our After Sales Service is capable of rapidly answering all your needs and queries.

We strongly recommend to send the instrument

back to ATEQ once a year for re-calibration