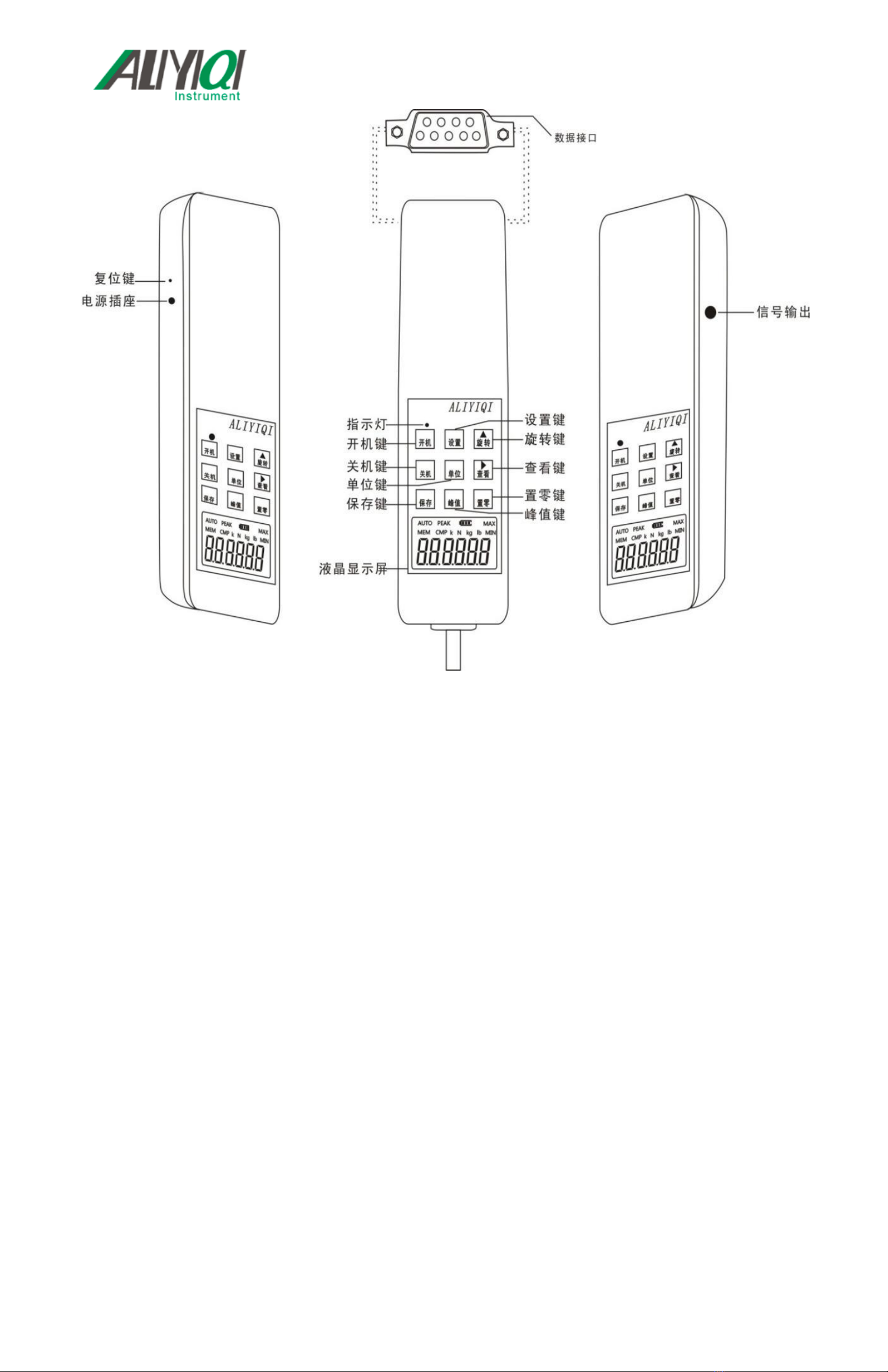

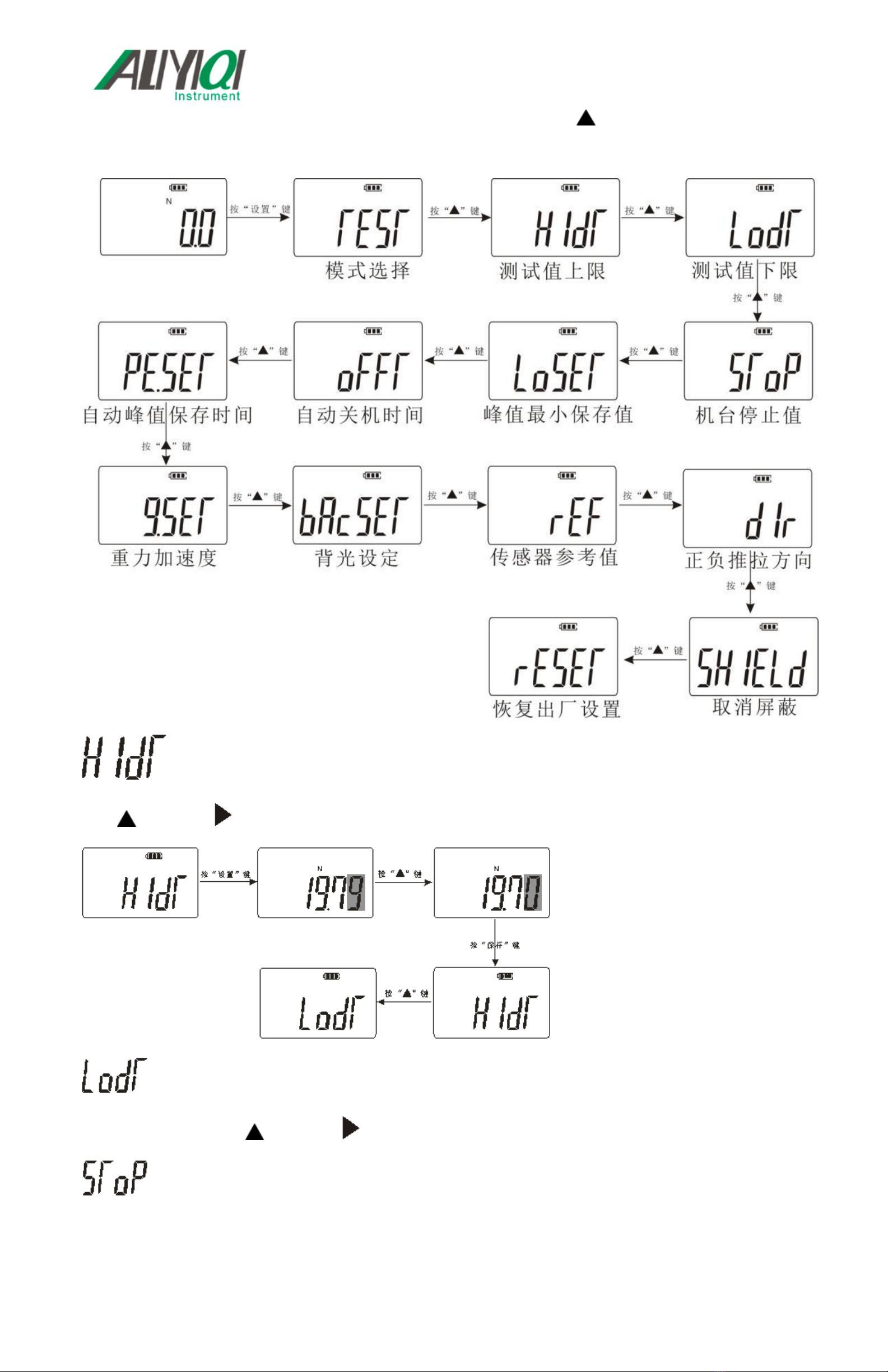

①, three kinds of display: after booting, when there is no character display, it means \"track mode \" (real-time

load measurement mode), the value on the screen changes with the change of load; press \"peak \" key here

When \"PEAK \" is displayed, it indicates Peak mode (peak hold measurement mode), and the display shows the

peak value until it is manually cleared; press \"Peak \" key here, when \"AUTO PEAK \" is displayed, it means

\"autopeak \" (Peak hold automatic release measurement mode), automatically save and clear the peak value

after displaying the peak value for 10 seconds, the peak time of 10 seconds can be freely set. For details, please

refer to the (PE.SET) Explanation}.

②With or without data storage display: when there is no \"MEM \" displayed, it means that no data is saved in

the instrument; when there is \"MEM \" displayed, it means that there is data saved in the instrument; When you

press \"View \" on the measurement interface to view the saved data, \"MEM \" is flashing.

③Push and pull instructions: In this machine, the thrust (pressure) is displayed as a negative value (\"-\"), and

the pulling force is a positive value (\"+ \" is not displayed).

④Comparison function. When setting the comparison value via STOP (for details, please refer to the

(STOP) Machine stop value description), this function is activated. \"CMP \" is displayed. It can be set separately

according to need when using.

⑤, measurement force value display.

⑥Display of upper and lower limit values reached: When \"MIN \" is displayed here, it indicates that the

measured data reaches and is below the lower limit; when \"MAX \" is displayed here, it indicates that the

measured data reaches and The upper limit is exceeded.

⑦, three units display: N (cow), kg (kilogram), lb (pound) three units are displayed separately, converted by

pressing the unit key. When HF10K and above specifications, K N (kilo-newton), K Kg (ton), \"K lb (kilo-pound) \"

are displayed here.

⑧, power display: when the battery voltage drops below 7.0V, it indicates that the voltage is insufficient and

needs to be recharged (it can still be tested during charging). There is a power indicator light above the power

button. When the charger is plugged in for charging, the indicator first changes from red to green. This process

is repeated twice, indicating that the charging is normal, then the indicator light is red, and the indicator light

changes when fully charged Into green. If the instrument is not used for a long time, and the battery power is too

low, the indicator light may not light up when the charger is plugged in. After about half an hour, after the battery

is woken up, the indicator light will turn red and the charging time will be 4 ~ 6 hours.

6. Key introduction