EnPro EHR-S 250 User manual

Models:

EHR-S 250

EHR-S 500

EHR-S 1000

Technical Manual of Enpro

Energy Recovery Ventilator

Attention

Please read this manual carefully before using the equipment

Ening d.o.o.

Safety Considerations------------------------------------------------------------3,4

Unit Specifications--------------------------------------------------------------- 5

Dimensioned Drawings------------------------------------------------------------6

Installation Considerations----------------------------------------------------7,8,9

Electrical Installation--------------------------------------------------------------10

Wiring Diagrams------------------------------------------------------------------11

Commissioning Information------------------------------------------------------12

Controller Instruction-------------------------------------------------------13 to 21

Dial switch------------------------------------------------------------------------22

Maintenance ----------------------------------------------------------------------23

Contents

2

Please read the following safety instructions before installation. And ensure that the unit is installed

correctly.

Please observe all instruction in order to avoid any injury or damage to equipment or property.

Safety attentions

The following symbols indicate potential levels of caution.

Situations with a risk or death or

serious injure. Situations with a risk of injury or

equipment/property damage.

The following symbols indicate compliance which must be observed

Not allowed or Stop Must follow or obliged

Installation to be carried out by qualified

person, End Users must not install, move or

re-install this equipment by themselves

An anti-bird net or similar device should be

installed to outside vents. Ensure there are

no obstructions to or in the ducts

Installation engineers must follow this man-

ual strictly. Improper action can create a

health hazard and reduce efficiency of the

unit

Fresh air vent must be far enough away

from any flue gas discharge or areas where

hazardous vapors are present

Unit must be installed strictly following this

manual and mounted to a weight bearing

surface for the weight of the unit

Electric engineering must follow national

regulations and the manual, use special ca-

bles. Less capacity cables and improper en-

gineering can cause electric shock or fire.

During maintenance or repair, the unit and

circuit breaker must be switched off. Other-

wise electric shock could occur.

Ground wire cannot be connected to gas

pipe, water pipe, lighting rod or telephone

line etc. Incorrect grounding can cause

electric shock.

Power cable and wires must be installed by

a qualified electrical engineer. Improper

connection can cause over heating. Fire and

loss of efficiency.

To avoid condensation, insulation should be

fitted to fresh air ducts. Other ducting may

also require insulation depending on dew

point conditions.

Insulation between the metal ducting and

wall penetration must be installed if the

ducting penetrates metal wall cladding, to

avoid risk of electric shock or current leak-

age.

The cover of wiring box must be pressed

down and closed to avoid dust and dirt en-

tering. Excess dust and dirt can cause over-

heating of terminals and result in fire or

electric shock.

Use only approved installation hardware

and accessories. Failure to observe can re-

sult in fire risk, electric shock and equip-

ment failure

Where the unit is positioned, at high level in

a hot humid situation. Please ensure suffi-

cient ventilation is available

The outdoor ducts must be installed facing

downwards to avoid rain water entering.

Improper installation can cause water leak-

age.

Correctly sized MCB must be fitted to the

unit suitable earth leakage protection

should also be installed to avoid risk of elec-

tric shock or fire.

3

Safety Considerations

Safety Considerations

Do not install the unit in an extremely hu-

mid conditions, as it may result in electric

shock and pose a fire risk.

Do not use the units as the primary kitchen

extract grease and fatty deposits can block

the heat exchanger, filter and pose a fire

risk.

Don not install the unit in areas there any

poisonous or caustic gases are present.

Do not install the unit near open flame as it

may result in over heating and pose a fire

risk

Acidic or alkali environments can cause

poisoning or a fire

Rated supply voltage must be maintained,

otherwise this may cause fire.

4

Safety Considerations

This appliance can be used by children aged from 8 years and above and persons with reduced

physical, sensory or mental capabilities or lack of experience and knowledge if they have been

given supervision or instruction concerning use of the appliance in a safe way and understand

the hazards involved.

Children shall not play with the appliance. Cleaning and user maintenance shall not be

made by children without supervision.

Means for disconnection must be incorpo-

rated in the fixed wiring in accordance with

the wiring rules.

Prior to cleaning or other maintenance, the

appliance must be disconnected from the

supply mains.

5

Specifications

Model EHR-S 250 EHR-S 500 EHR-S 1000

Performance

Airflow (m3/h) 200/250/250 400/500/500 840/1000/1000

Airflow (l/s) 55/69/69 111/138/138 233/277/277

Enth. Eff (%) Heating 73/65/65 75/67/67 72/62/62

Cooling 71/62/62 72/63/63 68/60/60

Temp. Eff (%) 81/73/73 81/76/76 80/76/76

Noise Db(A) 27/34/34.5 29/35/39 36/42/44

Power Supply 220V/1Ph/50Hz

Input Power (W) 117 200 690

Power Cable 2x1.5mm2

Control Cable 2x0.5mm2

Control

Standard Yes (7-Day Time-clock)

(BMS)

Modbus Yes

Fan Type AC Fan Motors

Fan Speeds (Supply) 3 Speeds Individual Control

Fan Speeds (Exhaust) 3 Speeds Individual Control

Summer Bypass Yes (Automatic with adjustable range)

Defrost Yes (Automatic with adjustable range)

CO2 Control Optional controller available (On / Off control with adjustable range)

Fan Boost Contacts Yes (3x available connections to Volt-Free Contacts: Closed = Boost to High Speed)

Fire Shutdown Yes (1x available connection to Volt-Free Contact: Closed = Shutdown)

Weight (Kg) 25 36 79

Size (LxWxH) 744x599x270 824x904x270 1129x1216x388

Duct Size 150 200 250

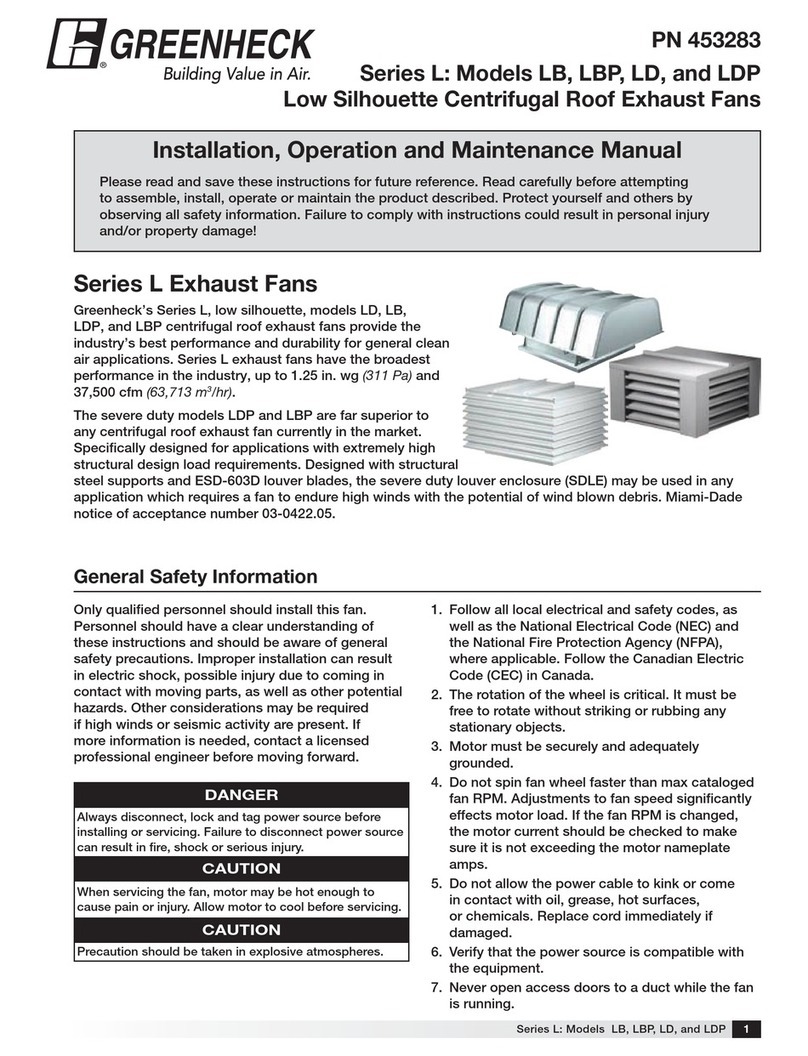

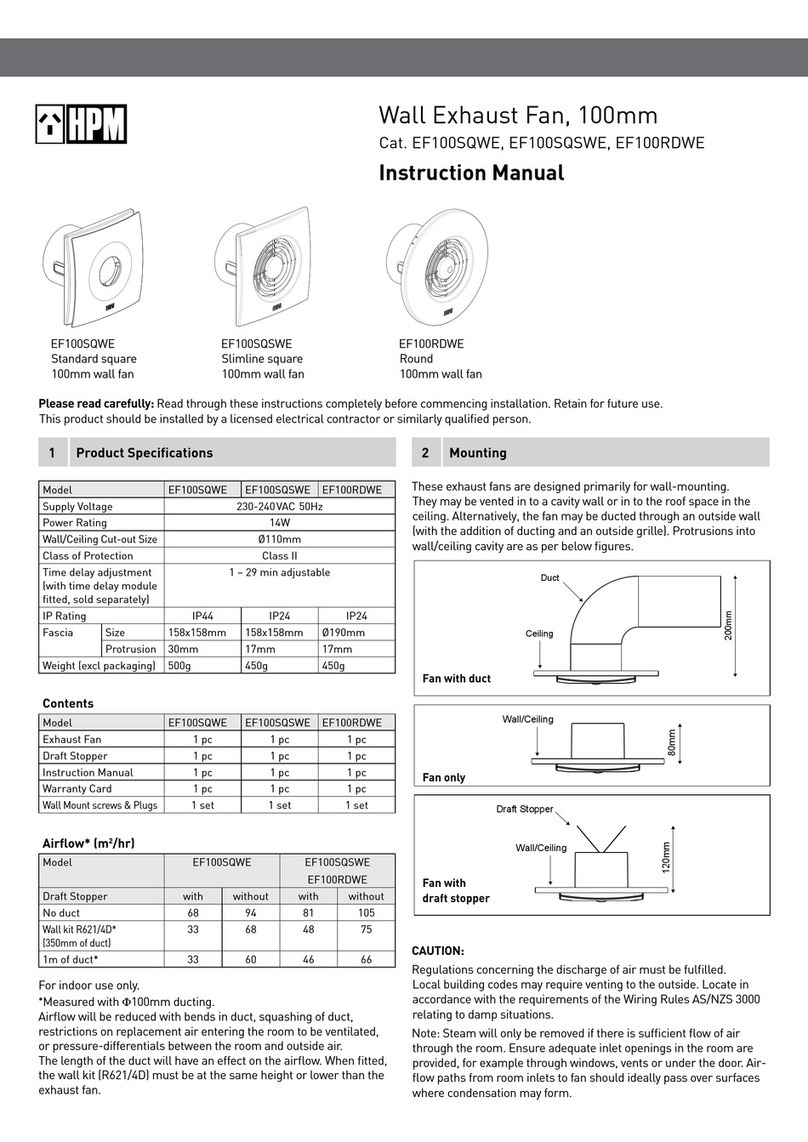

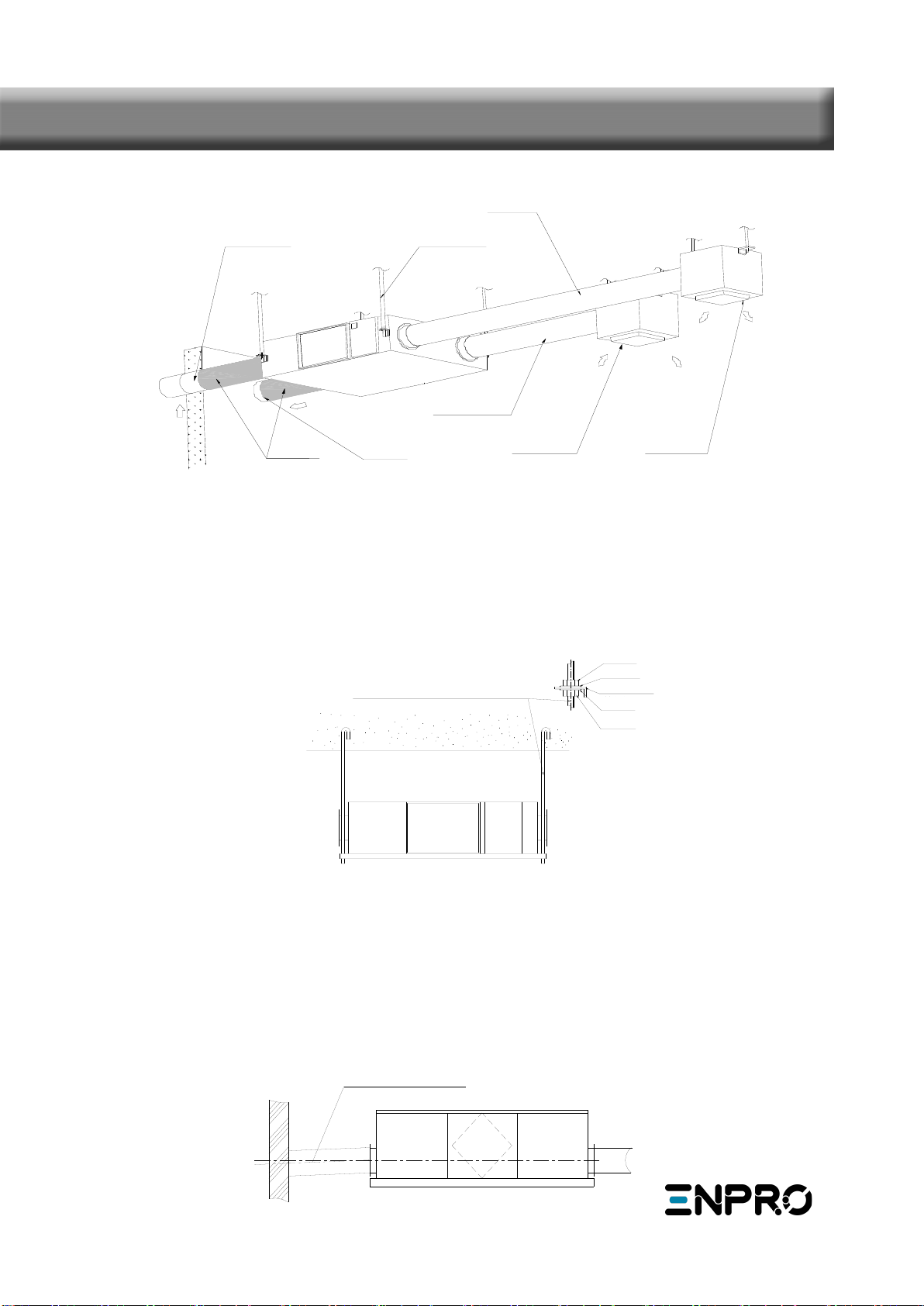

EHR-S 250 and EHR-S 500 Models

6

Dimensioned Drawings

Electric

Box

EA

OA

EA

OA SA

RA RA

SA

Electric

Box

Model ABCEFGIKMN

EHR-S 250 599 744 100 675 657 19 315 111 270 Φ144

EHR-S 500 904 824 107 754 960 19 500 111 270 φ194

Electric

box

E

A

O

A

S

A

R

A

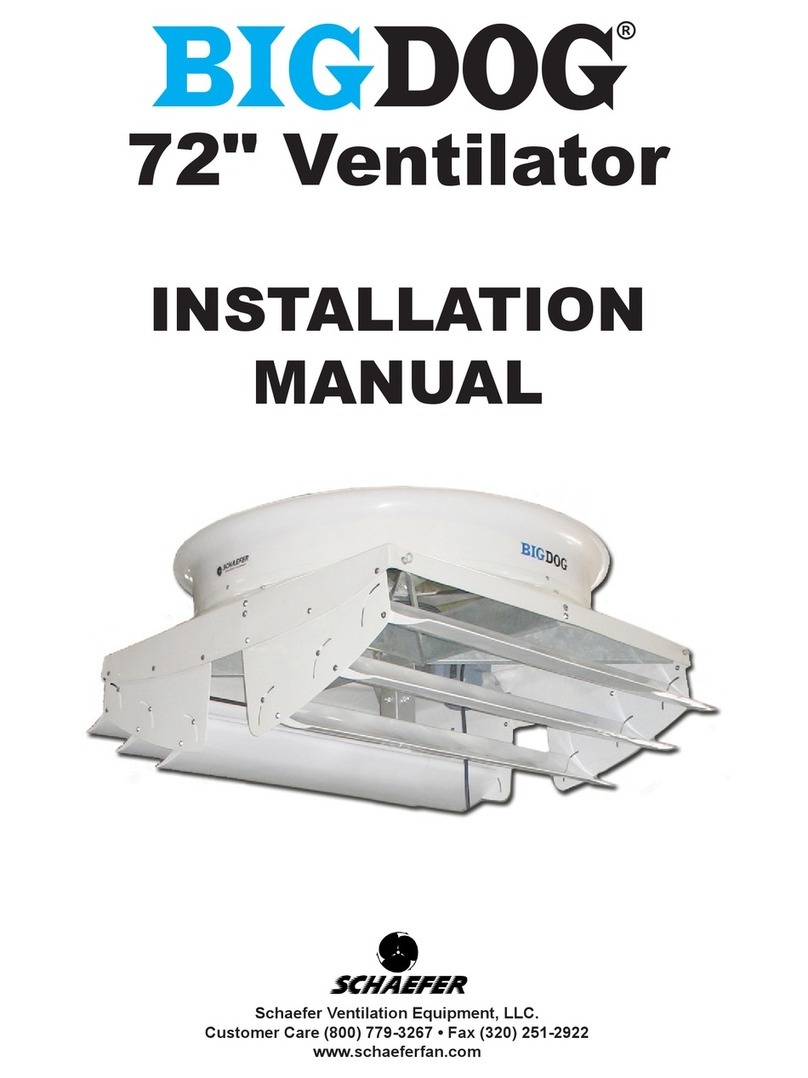

Model LL1 WW1 HH1 NCDEFG

EHR-S 1000 1129 1060 1216 1273 388 171 Φ242 86 147 152 621 21

EHR-S 1000 Model

Installation Considerations

Protect the unit to avoid dust or other obstructions entering the unit and accessories during installation,

or whilst in storage on site. Service ports should be installed to allow access for filter maintenance.

7

Installation Considerations

Model AInner ceiling

height B

EHR-S 250 599 320

EHR-S 500 904 320

EHR-S 1000 1216 450

EA

RA

OA

SERVICE PORT

EA

SA RA

OA

SERVICE PORT

SA

天花板吊装螺杆

(Φ10-Φ12)

螺母

垫圈

吊装部件

垫圈

螺母

Suspending screw pole

Nut

Gasket

Suspending Part

Gasket

Nut

Installation Diagram

Fresh Air In

Exhaust Air Out

Outside Fresh Air Duct

Insulation Discharge Duct

Suspending Pole

Fresh Air Duct

Exhaust Duct

Return Air Supply Air

Return Air

Supply Air

Physical Installation

1.Installer to prepare suitable threaded hangers with adjustable nuts and gaskets.

2.Install as shown by the image above. Installation must be level and securely fastened.

3.Failure to observe proper fixing could result in injury, equipment damage and excessive vibration.

Uneven installation will also effect damper operation.

Notes for reverse installation of the unit

4.Reverse labeling shows the unit is upside down.

Ducting

1. Connection of unit vents and ducts should be taped or sealed to prevent air leakage, and should com-

ply to relevant guidelines and regulations.

2. The two outdoor vents should face downward toward the outside to prevent any rain water ingress.

(angle 1/100 1/50).

3. Insulation must be with the two ducts outside to prevent condensation.

Material: glass cotton, Thickness: 25mm

Installation Considerations

8

坡度1/100-1/50

Gradient1/100-1/50

1. Be sure the ceiling height is no less than the Figures in above table B column.

2. Unit must not be installed close to boiler flues.

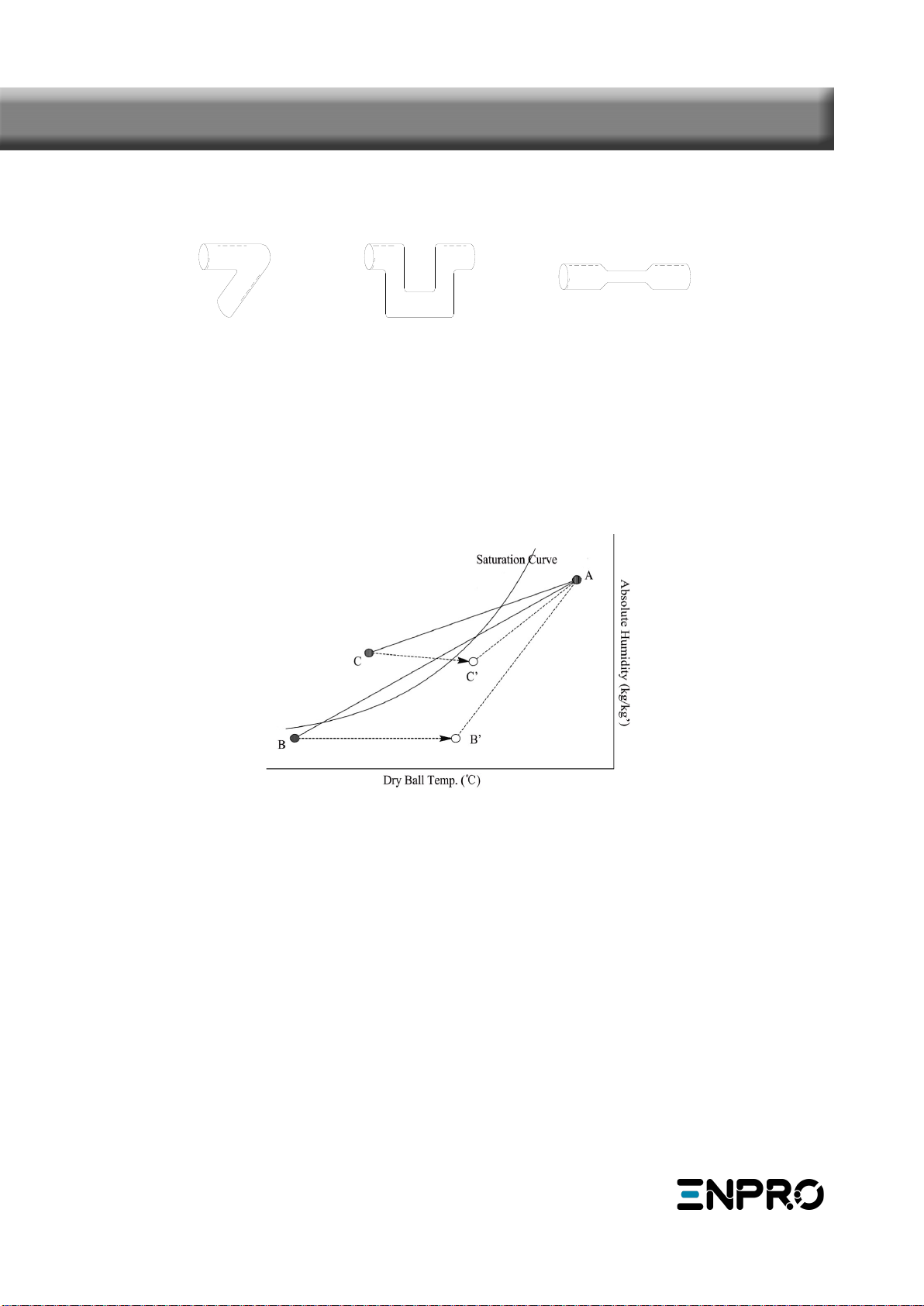

3. Following phenomenon should be avoided in the ducting installation.

Serve bends Multiple reducers/ crimped duct

Multiple direction changes

4. Exessive use of flex-duct and long flex-duct runs should be avoided.

5. Fire dampers must be fitted as per national and local fire regulations.

6. Unit must not be exposed to ambient temperature above 40℃ and should not face an open fire.

7. Take action to avoid dew and frost.

As shown by drawing below, unit will produce dew or frost when saturation curve is formed from A to C.

Use pre-heater to ensure conditions are kept to right of the curve (B to B',to move C to C) to prevent

condensation or frost formation.

8. To avoid the outdoor exhaust air cycling back to indoor, the distance between the two vents installed

on the outside wall should be over 1000mm.

9.If heater is equipped to the unit, operation of heater should be synchronous with the unit, so that the

heater starts to work only when unit starts.

10.Duct muffler may be considered if user wants indoor noise to be minimized.

Installation Considerations

9

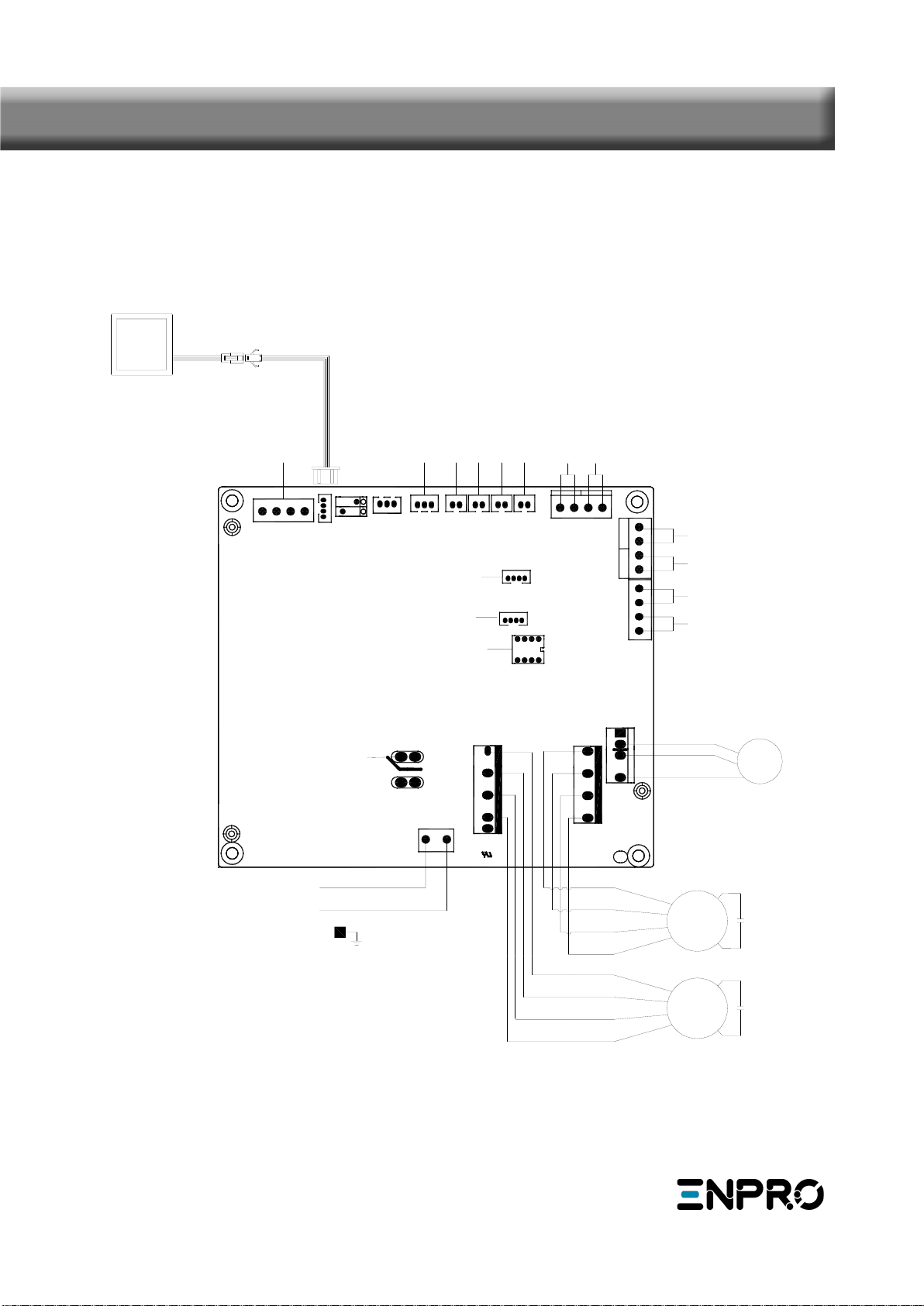

Power must be isolated during installation and before maintenance to avoid injury by electric shock. The

specifications of cables must strictly match the requirements, otherwise it may cause performance fail-

ure and danger of electric shock or fire.

Power supply is AC220V/50HZ/1 Phase. Open the cover of electrical box, connect the 4 wires to the ter-

minals and connect the cable of the control panel to the board according to the wiring diagram, and join

the control panel to the cable.

We do not accept any liability for any problems caused by the user’s self and non-authorized re-

engineering to the electrical and control systems.

10

Electrical Installation

Model Capacitor Power Supply Control Panel Model

EHR-S 250 1.5μF450V AC

220-240V/1Ph/50Hz

Touch screen

controller

EHR-S 500 3.5μF450V AC

EHR-S 1000 10μF450V AC

Model Spec. of power supply

cable

Spec. of normal controller

cable

EHR-S 250

4×1.5mm2 4×0.5mm2

EHR-S 500

EHR-S 1000

EHR-S 250 to EHR-S 1000

11

Wiring Diagrams

94V0

PORT 4

PORT 3

PORT 2

PORT 1

L N

12V AGND

B

AN2

AN1 AN3 AN4

COMM1S1

S2

*

*

C02

*

CN10

CN8

CN12

CN11

CN9

CM-DM

CN-SAFM

CN-EAFM

LD4

LD3

CN13

CN3 CN7 CN6 CN4

CN5

CN2

SW4

CN27

L

N

Connect with

heater or relay

By-pass switch

Fire alarm signal input

Fault signal output

Running signal output

External swith

SA temp.

FR(EA) temp.

OA temp.

RA temp.

CO2 sensor

Reserve switch

RS485 ports

Humidity sensor

Dial switch

M1

M2

Yellow

Blue

White

Black

Yellow

Blue

White

Black

Control panel

Joint of control panel and cable

Standard length: 5m

Exhaust fan

Supply fan

Connect the tin end of cable

to the port, no sequence

Voltage:220V-1ph-50/60Hz

PE

WIFI

WIFI ports

GM

Yellow

White

Black

By-pass

Check that all cable sizes, circuit breakers and wire connections are correct before following below com-

missioning steps:

1. Press button ON/OFF to turn on/off the ventilator.

2. Match the correct fan speed displayed on touch screen controller to ERV.

Under Off status, press MODE button for 6 seconds to enter parameters setting and at this

time the parameter number is shown in the middle of the screen, press button SET to switch to

parameter No. 23 (refer to parameters list in comming page) then press MODE button shortly to

enter the parameter setting, default value “0” flesh in the middle of panel, press UP and DWON

buttons to change the value be “1 (3 speeds control)” then press SET button again to confirm

setting.

3. Then check the mode and fan speed switch. Press button MODE shortly to switch to OA, RA, SA or EA

mode, check whether the temperature of the corresponding mode is correct. Under SA or RA mode,

Press UP and DOWN button to switch the fan speed, check if the airflow is adjusted corresponding to

H(high) speed, M(middle) speed and L(low) speed .

4. Check the operation of bypass. The default opening temperature of bypass is 19-21C (adjustable),

press button MODE button to check the temperature of OA. If the present OA temperature is among

19-21C, then bypass will open automatically. If the OA temperature is not within 19-21C, say 18C,

then under OFF status press MODE button more than 6 seconds to enter the parameter setting.

Press SET button to switch to parameter number 02, default value 19 flashes shown at the top right

corner, Then press MODE button shortly to enter setting, by pressing UP and DOWN buttons and set

the value to be “X”, “X” should be less than 18℃(present OA temperature), then press SET again to

confirm. with the same way to set parameter number 03 value to be “Y”, if “X”<OA temperature

<“X+Y”. then bypass will open automatically, after bypass open, user can adjust the values under

parameters 2 and 3 to make OA<“X” or OA>“X+Y”, then bypass will close automatically, please pay

attention that bypass open/closed will be around 1 minute delayed.

Note:

In ON status, press MODE button for 6 seconds to check the indoor air quality (if IAQ sensor connected).

In OFF status, press MODE button for 6 seconds to adjust the parameters in the Modbus.

Loose or incorrect wiring connection can

cause explosion or fire when the unit starts

to work. Use only rated power voltage.

Don’t put fingers or objects into vents of

fresh air or exhaust air supply. Injury may

be caused by the rotation of the impeller.

Don’t install, move or re-install the unit by

yourself. Improper action may cause unit

instability, electric shock or fire.

Don’t change, disassemble or repair the

unit by yourself. Improper action may cause

electric shock or fire.

Running the unit continuously in an abnormal

status may cause failure, electric shock or

fire.

Switch off the power and breaker when you

clean the exchanger.

Don’t site intake supply vent in hot and hu-

mid

conditions , as it may cause failure, current

leakage or fire.

Don’t put any burner directly facing the

fresh air discharge, otherwise it may cause

an insufficient burning.

Isolate power during extended off periods

Isolate power and take care when cleaning

unit. (Risk of electric shock)

Observe guidelines and regulations relating

to incomplete combustion when use is asso-

ciated with fuel burning appliances.

Clean the filter regularly. A blocked filter may

result in poor indoor air quality.

Commissioning

12

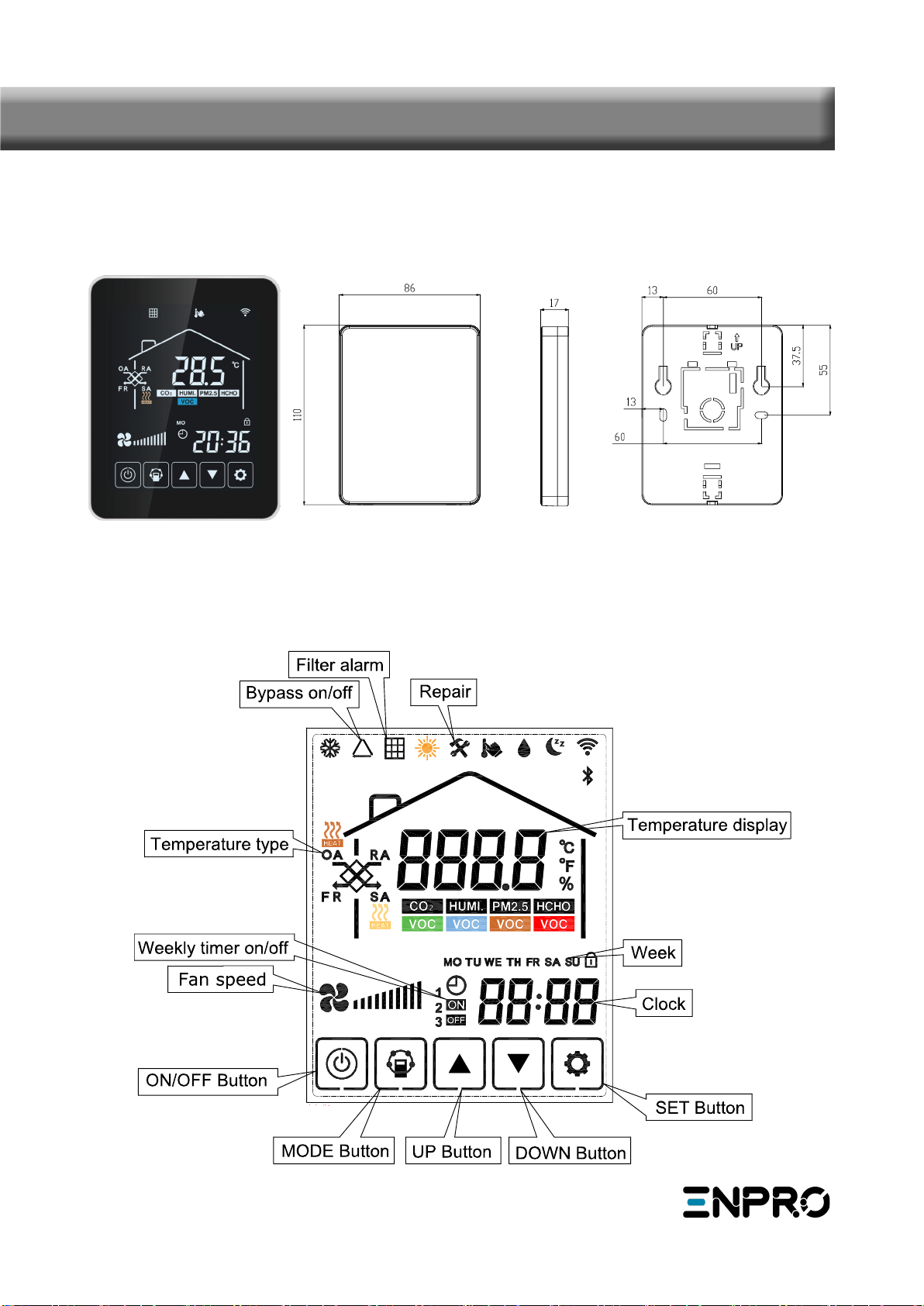

Display screen and Buttons

Control Panel

Touch Screen Intelligent Controller

The intelligent controller is surface mounted and comes with a touch screen LCD display screen.

Standard connection cable is 5 meters, in case of a longer cable is needed, then please use the shielded

cable, to avoid the signal interference which may lead to communication error.

13

Operation Instructions

1. ON/OFF: press ON/OFF button once for starting; twice for closing. In ON status, backlit LCD display

lights up, in OFF status, backlit LCD display off, without operation for 6 seconds, backlit LCD display

off too. By pressing ON/OFF button for around 6seconds can lock and unlock the controller.

SA temperature

FR temperature

2. Mode switch: press MODE button to choose display the RA-OA-FR(EA)- SA Setting-CO2 status or Hu-

midity control status.

OFF state

RA temperature OA temperature

ON state

Lock state Unlock state

Touch Screen Intelligent Controller

14

Remark:

1) Under SA setting mode, after connecting the electrical heater to the PCB (LD3 and LD4) and change

parameter 01 to value 1, users can set the supply air temperature by pressing up and down button. The

setting temperature range is 10-25oC.

A) 0℃<setting temperature minus SA temperature<5 ℃,1st stage heater on, 2nd stage heater off

B) Setting temperature minus SA temperature >5℃,1st and 2nd stage heater on

2) The CO2 symbol appears when the CO2 sensor is connected. ERV runs at boost speed when CO2

concentration higher than setting value.

3) The humidity symbol appears when the “temperature and humidity sensor” is connected. ERV runs at

boost speed when humidity higher than setting value.

Under “humidity control” mode, users can set the setting humidity by pressing up and down button. The

setting range is 45% ~ 90%. And the Dial switch SW4-3 on the PCB should be switched ON to switch

from CO2 control function to humidity control function.

3. Air volume setting: Under SA or RA temperature interface. Users can set the return air volume in

“RA” status, and set the supply air volume in “SA” status by pressing up and down button. Totally 10

speeds control.

Speed 3 Speed 5 Speed 10

SA temperature setting CO2 concentration

Humidity control

Touch Screen Intelligent Controller

15

5. Bypass setting: when bypass is on, the triangle bypass symbol appears, when bypass is off, the sym-

bol disappears, please refer to page 15 commissioning part for the detailed setting introduction.

4. Error code checking: under the main interface, press the SET button for short, user can check the

error code of ventilator, refer to below table.

6. Filter alarm: When running time of ventilator is over the setting filter alarm time, the filter alarm

symbol flashes to remind user clean/replace the air filters. After filters being cleaned/replaced, please

sweep the filter alarm by setting parameter Number 24, value 1.

16

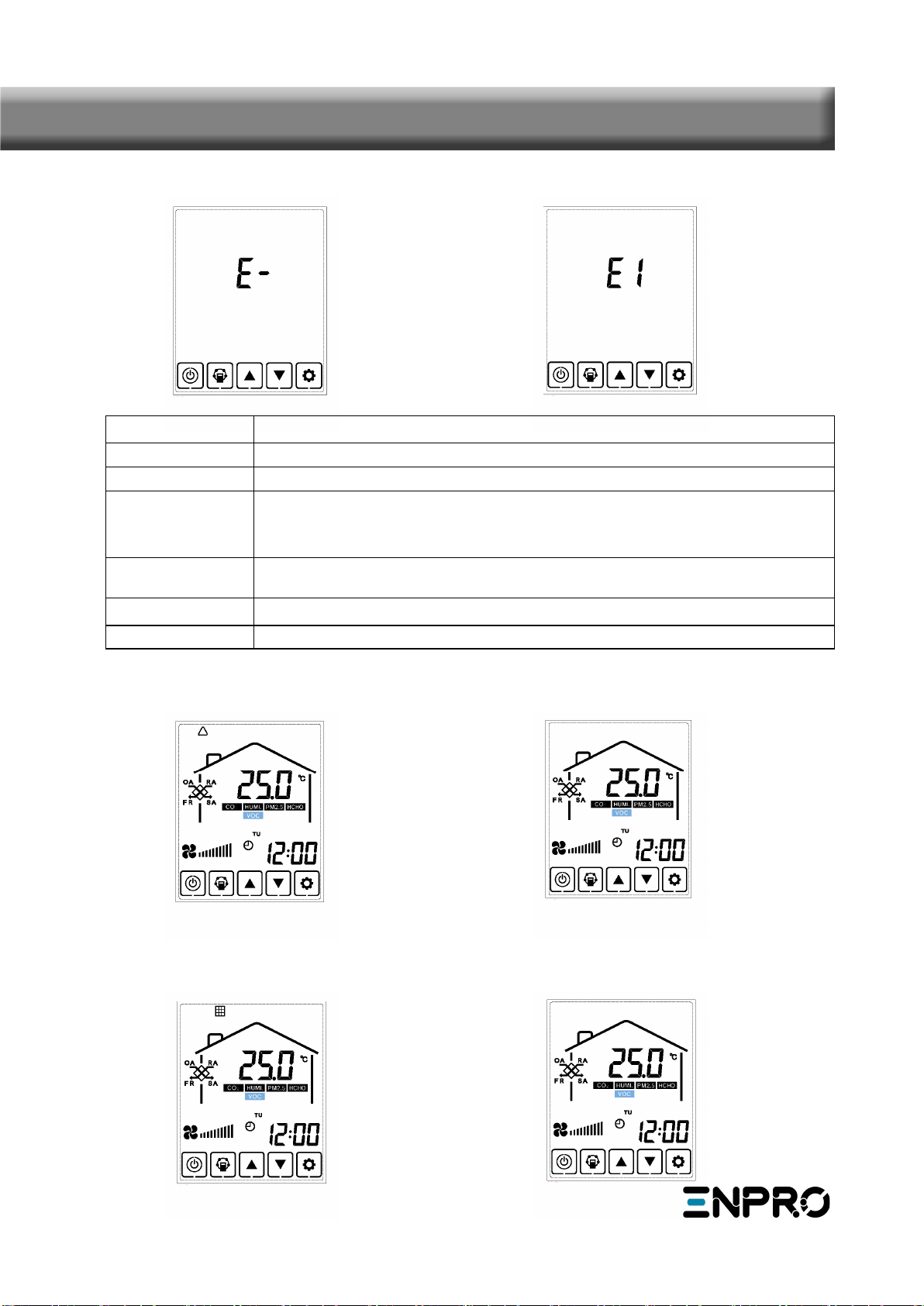

Code Error

E1 Fresh air temperature sensor error

E2 EEPROM error

E3 If SW4-3 on the PCB is OFF, the return air temperature sensor error. If SW4-3

on the PCB is ON, the humidity sensor is abnormal.

E4 Exhaust air temperature sensor error (defrosting temperature error)

E5 Communication error

E6 Reserved

Touch Screen Intelligent Controller

No Error Error alarm

Bypass on Bypass off

Filter alarm on Filter alarm off

17

Touch Screen Controller Instructions

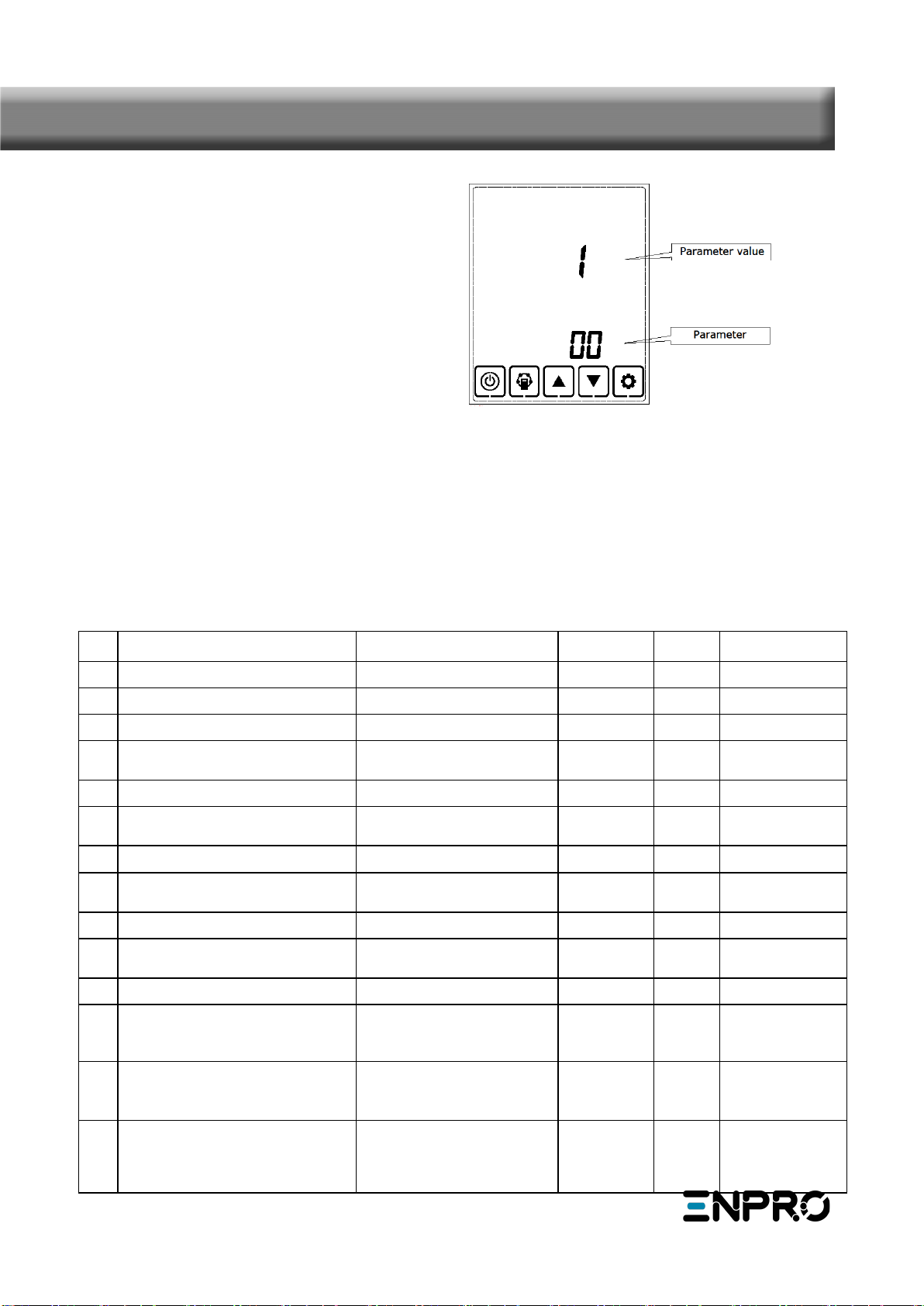

7. Parameters setting: Under OFF status, keep pressing the MODE button for 6 seconds, after buzzing to

enter the parameter setting interface.

After entering the parameter setting interface, press SET button shortly to change the parameter num-

ber, every pressing will make parameter value +1 (until number 25 then repeat again). After choosing

the correct parameter number, press Mode button for short, parameter value flashes in the middle of

panel, at this time to change the value by UP and DOWN buttons. After parameters setting then press

SET button to save.

Attention:

1) After parameters setting, system need around 15 seconds to record, during this period power should

not be off.

2) Please refer to below valid parameters table to set the suitable parameters according to different re-

quests.

No

.

Contents Range Default Unit Record Position

00 Power to auto restart 0-11Main control

01 Electrical heater available 0-10Main control

02 Bypass opening temperature X 5-30 19 ℃Main control

03 Bypass opening temperature

range Y

2-15 3℃Main control

04 Defrosting interval 15-99 30 Minute Main control

05 Defrosting entering tempera-

ture

-9-5- 1 ℃Main control

06 Defrosting duration time 2-20 10 Minute Main control

07 CO2 sensor function value 28-C8(392-1960PPM) 66

(1000PPM)

Main control

08 ModBus/ERV ID address 1-16 1Main control

21 Air speed mode selection (valid

for DC motors only)

0-70Main control

22 Reserved 0-40Main control

23 Fan speed display selection 0: 2 speed (H L)

1: 3 speed (H M L)

2: 10 speed (DC fan)

0

24 Multiple function setting 0: Reserved

1: Filter alarm clearance

2: Weekly timer clearance

0

25 Filter alarm timer 0: 45 days

1: 60 days

2: 90 days

3: 180 days

Main control

Instruction of Parameter Settings

1) Parameter 00 refers to power to auto restart

0: Invalid, 1: Valid

2) Parameter 01 refers to Supply air electrical heater function

0: Not available 1:Available

When connecting with supply air electrical heater, user should choose 1 to activate the electrical heater,

and under the SA temperature setting interface (see page 17), the SA temperature can be set by press-

ing up and down button. The setting temperature range is 10-25℃.

3) Parameter 02-03 refers to automatic bypass function

The bypass is opened on the condition that the outdoor temperature is equal or higher than X

(parameter 02)and less than X+Y (parameter 03). Bypass is closed on other conditions.

4) Parameter 04-06 refers to automatic defrost function

When EA side of heat exchanger temperature lower than –1℃(defrosting entering temperature, param-

eter 05) and last for 1 minute, and the interval of defrosting is longer than 30 minutes (parameter 04),

the exhaust fan will run at high speed automatically for defrosting, and supply fan will stop, until EA

side temperature higher than defrosting entering temperature +15℃ for 1 minute, or the defrosting

time is longer than 10 minutes (parameter 06).

5) Parameter 07 refers to CO2 concentration control function (optional)

After connecting the optional CO2 sensor, the CO2 symbol will display on the screen. If CO2 concentra-

tion is higher than setting value, then ERV runs at high speeds automatically, after CO2 concentration is

lower than setting value, then ERV returns back to the previous status (stand by, low speed or medium

speed), if the ERV is already in high speed when CO2 concentration higher than setting value, then ERV

keeps the high speed running.

6) Parameter 08 refers to the central control function to identify the address of ERV.

7) Parameter 23 refers to the fan speed display, for the ERV with AC motor, user should change value

from 0 to 1 for three speed control.

8) Parameter 24 refers to clear filter alarm and weekly timer setting.

9) Parameter 25 refers to set the filter alarm timer.

18

Touch Screen Controller Instructions

19

Touch Screen Controller Instructions

Time setting Week setting

Weekly timer on Weekly timer off

A. Time setting: under time setting interface, press SET button for short, at this time “hour” flashes,

press UP and DOWN button to change “hour”. After setting “hour”, press MODE button for short to

switch to “minute” setting, at this time “minute” flashes, press Up and Down button to change “minute”.

After time setting, press SET button to save and return to the main interface.

Hour setting Minute setting

8. Time setting

Keep pressing the SET button for 6 seconds, after buzzing to enter the time setting interface. Under this

interface, press the MODE button shortly, then can switch from time setting, day setting, weekly timer

on and weekly timer off setting.

23

B. Day setting: under day setting interface, press SET button for short to begin the day setting, by

pressing UP and DOWN buttons to select the correct day, after this finished, press SET button to save

and return to the main interface.

Timer on valid Timer on invalid

Day setting

Touch Screen Controller Instructions

Period 1 timer on Period 2 timer on

Timer on hour setting Timer on minute setting

C. Weekly timer on setting: under weekly timer on setting interface, press SET button to begin the tim-

er on setting, press SET button time after time to select Monday period 1 to Sunday period 2 (namely

Monday period 1 to Sunday period 2).

After selecting the day, press ON/OFF button to confirm timer on is valid/invalid.

When timer on is valid, press MODE button to enter “hour” setting, by pressing UP and DOWN button to

set “hour”. After “hour” setting, press MODE button to enter “minute” setting. After “minute” setting,

press SET button to save and switch to the next day timer on setting, and repeat the above steps to set

all days and periods timer on. After setting all the time on, press SET button to save the data.

This manual suits for next models

2

Table of contents

Popular Fan manuals by other brands

System air

System air Fantech FLEX VHR 150R Installation and operation manual

Arneg

Arneg HPF series Direction for Installation and Use

Sterling

Sterling F-29A instructions

LUNOR

LUNOR VA-40 operating manual

LUCCI Air

LUCCI Air Altitude Eco Led Installation instructions manual

Bionaire

Bionaire BWF0910AR Instruction leaflet