Entec Solar E-1500 User manual

Entec Solar

User manual

E-1500 / E-1000

E-Sens y E-Temp

Smart I-Vcurve tracer

V1.2

2 www.entecsolar.es

Índice

0. Thank You Letter.............................................04

1. Warnings..........................................................05

1.1. Used Symbols......................................................06

1.2. Safety Measures during Use............................07

2. Overview..........................................................08

2.1. Equipment Functionality...................................09

2.2. External Connectors and Part

Descriptions...................................................................10

2.2.1. E-1500................................................................10

2.2.2. E-1000................................................................11

2.2.3. E-Sens.................................................................12

2.2.4. E-Temp................................................................13

2.3. Description of Elements on the Initial

Screen...................…........................................................14

2.3.1. E-Sens.................................................................14

2.3.2. E-Temp................................................................15

2.4. Supply Scope........................................................16

3. Measured Quantities and Operating

Conditions ............................................................17

3.1. Measured Quantities..........................................17

3.2. Operating Conditions.........................................18

4. Preparations Prior to Measurements..........19

4.1. First Use of the Device.......................................19

4.2. Battery Charging.................................................19

4.3. Inserting the Memory Card...............................20

4.4. Initial Configuration............................................20

4.5. Mounting Irradiance and Temperature

Sensors and Connecting to E-Sens........................21

4.5.1.Irradiance Sensor..............................................21

4.5.2.Temperature Sensor.........................................21

4.6. Connection of the Module or Generator

Under Test .....................................................................22

5. Configuration and Operation........................24

5.1. Startup....................................................................24

5.2. Main Screen...........................................................25

5.2.1. Main Screen Information................................25

5.2.2. Main Screen Controls.....................................26

5.2.2.A. TC Sensor Selection...................................26

5.2.2.B. Access to Settings Menu...........................26

5.2.2.C. Save Curve.....................................................26

5.2.2.D. Measure Curve.............................................26

5.2.2.E. File Name.......................................................26

5.3. I-V Curve Measurement....................................26

5.3.1. General Considerations.................................26

5.3.2. Manual Measurement....................................28

5.3.3. Auto-Measurement........................................28

5.3.4. Continuous Measurement............................30

5.3.5. Barcode Registration......................................31

5.3.6. Temperature Measurement with

E-Temp ..........................................................................31

5.3.7. Measurement Process Results....................32

5.4. Saving I-V Curve.................................................32

5.4.1. Manual Save......................................................33

5.4.2. Automatic Save................................................32

5.4.3. Saved File Format............................................33

5.5. Settings................................................................. 34

5.5.1. Bifacial Measurement....................................35

5.5.2. Load Module.....................................................35

5.5.3. Measurement Settings...................................36

5.5.3.A. G Limit............................................................36

5.5.3.B. V Range..........................................................37

5.5.3.C. Measurement Tolerance............................37

5.5.3.D. Tc Comp..........................................................38

5.5.4. Module Settings...............................................38

5.5.4.B. Save and Load Module

Configurations..............................................................38

5.5.5. Generator Settings..........................................40

5.5.6. Sensor Settings................................................41

5.5.6.A. Irradiance Sensor.........................................41

5.5.6.B. Temperature Sensor...................................41

5.5.7. Continuous Measurement............................42

5.5.8. Auto Save...........................................................42

5.5.9. Auto Measurement.........................................42

5.5.10. Barcode (Optional).......................................42

5.5.11. Others...............................................................43

5.5.11.A. Set Time/Day..............................................43

5.5.11.B. Update Firmware......................................43

5.5.11.C. Generate Report........................................43

“Innovative technological developments for the photovoltaic solar energy industry”

3 www.entecsolar.es

Índice

5.5.11.D. Language Selection..................................45

5.5.11.E. Sound On/Off..............................................45

5.5.11.F. Info..................................................................45

5.5.12. APK Connect...................................................45

5.5.13. Display STC Curve........................................46

6. Bifacial Curve Configuration and

Measurement.......................................................47

6.1. Required Materials..............................................47

6.2. Assembly and Connection................................47

6.3. Bifacial Operation Procedure...........................49

7. Data Download.............................................. 51

7.1. Data Download to PC........................................ 51

7.2. Opening Saved Files in a Data

Sheet............................................................................... 51

8. User Manual - APK Connect..........................54

9. User Manual - I-V Curve App........................58

9.1. Introduction...........................................................58

9.2. Plant Creation.......................................................58

9.3. Uploading Files and Data Processing...........60

9.3.1. File Upload.........................................................60

9.3.1.1. Automatic File Upload via Rosetta..........60

9.3.2. Data Processing................................................61

9.4. Results Visualization..........................................62

9.4.1. Statistical Analysis..........................................62

9.4.2. Numeric Summary...........................................62

9.4.3. Curve Visualization..........................................62

9.4.4. Reports................................................................62

10. Quick Measurement Guide..........................63

11. Technical Specifications ..............................64

12. Warranty, Calibration, and Repair............68

13. Common Errors and Solutions...................69

“Innovative technological developments for the photovoltaic solar energy industry”

4 www.entecsolar.es

Thank you for purchasing

the Entec Solar I-V Curve Tracer.

With the goal of creating hardware tools to facilitate

the work of individuals, Entec Solar has developed

the E-1000 and E-1500 I-V Curve Tracers. Both have

been developed in collaboration with the company

QPV ( ).This company specializes in

audits and quality control of large photovoltaic power

plants and has highlighted the current needs in the

field of I-V curve measurement. The combination of

Entec Solar's hardware development expertise and

QPV's experience in I-V curve measurement has

resulted in the fastest and most innovative I-V curve

tracers on the market, all with unparalleled

measurement precision.

This high-precision instrument allows for the

measurement of several hundred I-V curves per

working hour, whether from photovoltaic modules or

strings up to 1500V and 35A. In addition, it

incorporates several new features, including a

barcode reader for automatic identification of the

module under test and its position in the installation;

an automated report generation tool to reduce

processing time; an automatic measurement option to

free up the operator's hands during panel connection

and disconnection; a wireless sensor (E-Sens) with a

communication range of several hundred meters to

measure irradiance and temperature conditions; a

mobile phone application for remote device control;

and many more options that will revolutionize your

I-V curve measurement campaigns.

Furthermore, through a WiFi connection, the I-V curve

tracer synchronizes with PVET® servers

(www.pvet.es), facilitating storage, comparison, and

post-processing of measurement campaigns for fault

diagnosis in your plants.

www.qpv.es

(www.pvet.es)

“Innovative technological developments for the photovoltaic solar energy industry”

5 www.entecsolar.es

1. Warnings

The E-1000 is an I-V curve tracer designed to

work with voltages of up to 1,000 VDC, which can

be hazardous to humans. That is why the E-1000

and its accessories should only be used with the

components supplied by Entec Solar. Before using

the E-1000, read this manual in its entirety and

pay special attention to the points related to

electrical safety and the points highlighted by the

warning and risk of electric shock symbols (see

section 1.2).

The use of unapproved accessories can affect the

safety of this device and can cause considerable

damage to equipment or people. The E-1000

should be used only by personnel trained in low

voltage electrical installations and preferably with

specific training in photovoltaic solar energy

installations. Entec Solar will not assume any

responsibility for damages caused due to misuse

of the device or its associated components. The

E-1000 and its components must not be

manipulated, modified, opened, or repaired by any

personnel other than those of Entec Solar. Any

tempering of the device by third-party personnel

may result in loss of equipment warranty. In case

the E-1000 or any of its associated accessories or

components need repair or re-calibration, please

contact Entec Solar or any of its distributors.

“Innovative technological developments for the photovoltaic solar energy industry”

6 www.entecsolar.es

1.1. Used Symbols

• Double or reinforced continuous insulation (protection class II).

•

•

•

•

i

Caution danger! Pay attention to the documentation! This

symbol is placed in front of instructions that must be followed

to prevent material damage and harm to individuals.

Take into account all the documentation provided with the

measuring instrument.

Caution high voltage, danger of death.

Measurement instruments should not be disposed of with

household waste.

“Innovative technological developments for the photovoltaic solar energy industry”

7 www.entecsolar.es

1.2. Safety Measures During Use

The I-V Curve Tracer has been designed and

manufactured in accordance with the standard

EN61010-1:2011 "Safety Requirements for

Electrical Equipment for Measurement, Control,

and Laboratory Use" and has been certified by an

independent laboratory under the criteria of this

standard as equipment with reinforced insulation

CAT II 1000V DC.

To ensure that all safety measures designed into

the equipment are met, the following rules must

be strictly adhered to:

- Before using the equipment, carefully read the

entire manual and pay special attention to points

related to electrical safety.

- Use the equipment only for measurements in

photovoltaic installations. Other current or

voltage sources that are not of photovoltaic origin

can damage the measuring instrument.

- Disconnect the photovoltaic circuit under test

from any other connected circuit (e.g., inverter,

charge controller, battery, etc.) before connecting

the I-V Curve Tracer.

- Before taking measurements, ensure that they

do not exceed the operating limits of the

equipment: for the E-1000, these are 1,000V and

20A; for the E-1500, they are 1500V and 35A. A

measurement that exceeds these limits could

cause irreparable damage to the equipment.

- The equipment should only be used by

personnel trained in low voltage electrical

installations who have been specifically trained in

the use of this equipment.

- During measurements, use recommended

personal protective equipment (PPE) for electrical

measurements: insulated gloves, safety boots,

face shield, etc.

- Never disconnect measurement cables while a

measurement is being performed. This could

cause an electric arc and damage to the

equipment and individuals.

- Avoid contact with the photovoltaic circuit under

test and with any other metallic part in the vicinity.

- Avoid exposing the equipment to direct sunlight.

- Do not perform measurements in humid

environments or in rainy conditions, and ensure

that no liquids enter the equipment.

- Do not perform measurements in environments

with gas, explosive materials, flammable

substances, or dusty environments.

- Use only genuine Entec Solar original

accessories.

- For the E-1500, a 1500V fuse holder is provided

that connects to the four-point cables via an MC4

connector. Entec Solar always recommends its

use during measurements as an additional

protective measure.

“Innovative technological developments for the photovoltaic solar energy industry”

8 www.entecsolar.es

2. General Description

The Entec Solar I-V Curve Tracer consists of a

main unit, either the E-1500 or E-1000, which is

complemented by several devices (E-Sens,

E-Temp, barcode reader), each with its specific

functionality.

The I-V Curve Tracer, either the E-1500 or

E-1000, is the device responsible for the physical

measurement of photovoltaic panels. It connects

using four-point cables and is in charge of

measuring voltage and current, receiving

information from other devices, processing the

data, displaying it on the screen, and storing it.

The E-Sens is an independent device that

complements the I-V Curve Tracer. Its purpose is

to measure irradiance and temperature values of

the provided calibrated cell, as well as the

temperature of up to three optional PT-1000

sensors. It needs to be physically connected to the

calibrated cell for measurements. Communication

with the I-V Curve Tracer is automatically done

through radio waves, eliminating the need for a

physical connection. This feature allows for more

flexible positioning.

The E-Temp is an optional device designed for

measuring the temperature of photovoltaic

panels. While there are various ways to measure

panel temperature, Entec Solar has developed

this quick and convenient solution. It operates

independently and communicates through radio

waves, offering flexibility and making

temperature measurements in less accessible

locations easier.

The barcode reader is an optional device designed

to read identification labels found on photovoltaic

modules. The reader must be physically

connected to the I-V Curve Tracer via USB and

activated by the operator. It is particularly useful

for measuring I-V curves of modules, as it enables

unique identification of each measurement using

the module's barcode.

“Innovative technological developments for the photovoltaic solar energy industry”

9 www.entecsolar.es

2.1. Equipment Functionality

El E-1500 / E-1000 puede ser utilizado de manera

autónoma o de manera conjunta con otros

accesorios, como el E-Sens, el E-Temp o el lector

de código de barras.

El uso del E-1500 / E-1000 junto con todos sus

accesorios proporciona la mayor comodidad y

precisión en la medida de curvas I-V.

A continuación, se listan todas las funcionalidades

que proporcionan el E-1500 / E-1000 y todos sus

accesorios.

-Medida de la tensión de circuito abierto, VOC.

(E-1500 / E-1000)

-Medida de la corriente de cortocircuito, ISC.

(E-1500 / E-1000)

-Medida de la curva I-V a 4 puntas hasta 1500V y

35A. (E-1500 / E-1000)

-Medida de la irradiancia a través de una célula

calibrada o módulo de referencia (E-SENS)

-Medida de hasta tres puntos de temperatura

mediante PT-1000 (E-SENS)

-Medida de temperatura de un módulo de

referencia (E-SENS)

-Medida de temperatura mediante sensor de

infrarrojo (E-Temp)

-Transmisión inalámbrica de los datos

de irradiancia y temperatura (E-1500 / E-1000,

E-Temp)

-Extrapolación de las curvas I-V medidas a STC

mediante IEC-60891 (E-1500 / E-1000)

-Selección del sensor de temperatura para la

extrapolación (E-1500 / E-1000)

-Lectura del código de barras del módulo bajo

ensayo (E-1500 / E-1000)

-Generación automática de informes

diarios (E-1500 / E-1000)

-Modo automático de medida (E-1500 / E-1000)

-Modo automático de guardado de la medida

(E-1500 / E-1000)

-Modo de medida continua mediante periodo

seleccionable (E-1500 / E-1000)

-Almacenamiento de datos en tarjeta SD extraíble

(E-1500 / E-1000)

-Almacenamiento de datos en tarjeta MicroSD

extraíble (E-Sens)

-Lectura de datos mediante conexión inalámbrica

WiFi (E-1500 / E-1000)

-Visualización y control de medidas a través de

App móvil (E-1500 / E-1000)

“Innovative technological developments for the photovoltaic solar energy industry”

10 www.entecsolar.es

2.2. External Connectors and Parts Description

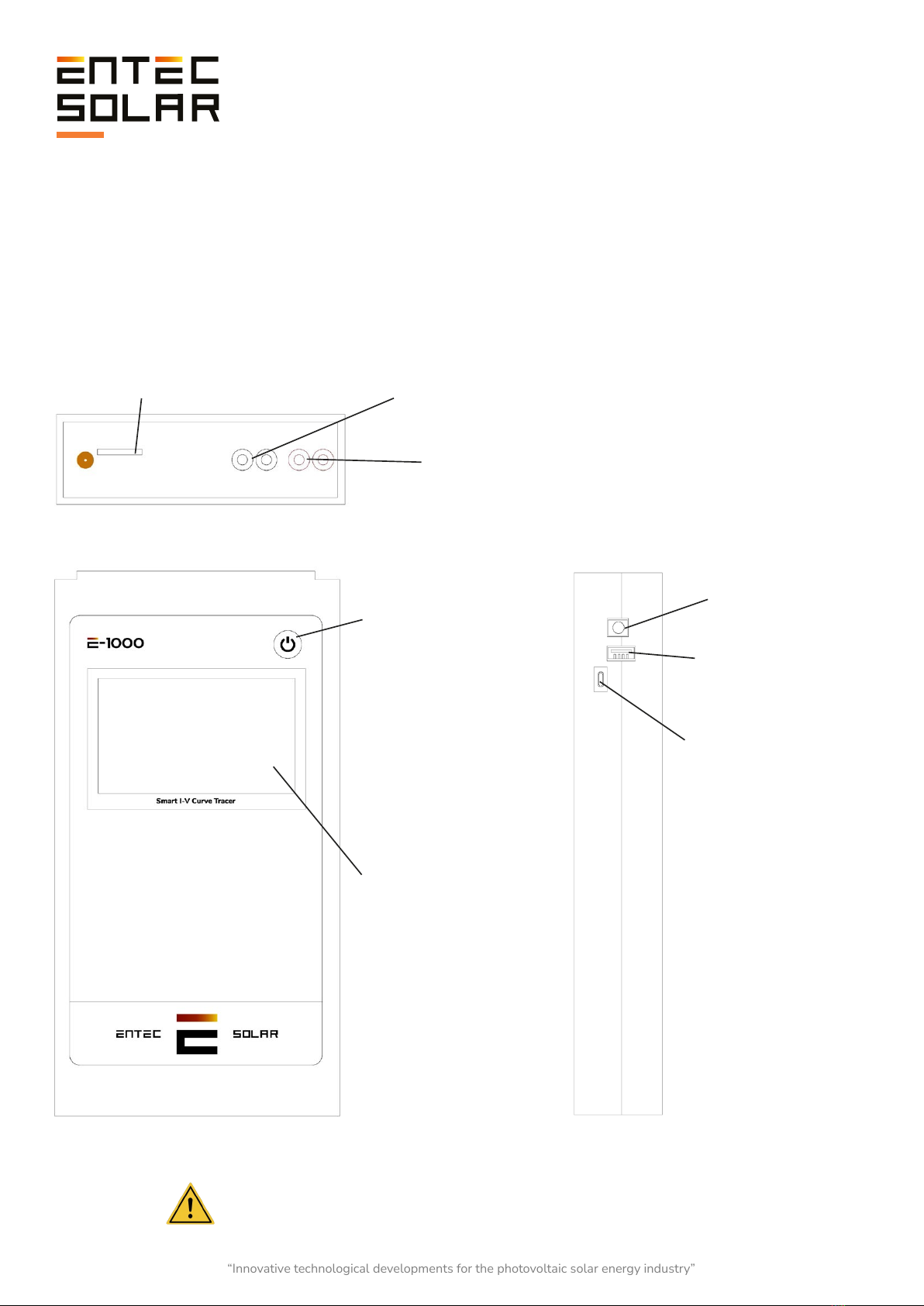

2.2.1. E-1500

Figure 2.3 displays the side connectors

and their description.

2. Battery Charger

Jack Connector

1.

USB Connector for

Barcode Reader

Connection

Figure 2.1 shows the upper connectors

and their description.

1. SD Card Slot

2. Negative Terminal Inputs for I-V

Curve Measurement

3. Positive Terminal Inputs

for I-V Curve Measurement

Figure 2.2 displays the front connectors

and their description.

1. Power Button

2. Touchscreen Display

ATTENTION: Avoid prolonged exposure to direct sunlight.

“Innovative technological developments for the photovoltaic solar energy industry”

11 www.entecsolar.es

2.2.2. E-1000

Figure 2.6. Shows the side connectors

and their description.

1. Battery charger

Jack connector

2. USB connector for

barcode reader

connection

3. micro USB connector

for SD card access

Figure 2.4. Shows the top connectors and their description.

1. SMA connector for external antenna

2. SD card slot 3. Negative pole inputs for I-V curve measurement

4. Positive pole inputs for I-V curve measurement

Figure 2.5. Shows the front connectors

and their description.

1. Power button

2. 5-inch color

touchscreen.

Resolution 800x480

ATTENTION: Avoid prolonged exposure to direct sunlight.

“Innovative technological developments for the photovoltaic solar energy industry”

12 www.entecsolar.es

2.2.3. E-Sens

Figure 2.10. Illustrates the side connectors

and their description.

1.USB connector

for battery

charging

2. Battery charging

LED indicator

Figure 2.9. Illustrates the front connectors

and their description.

1. Power button

2. Color display

1. SMA connector for external antenna

2. microSD card slot

Pt1000-3

1. Reference cell PT1000

2. .Reference

cell

Pt1000-2

Pt1000-1

ATTENTION: Avoid prolonged exposure to direct sunlight.

Figure 2.7. Shows top connectors

and its description.

Figure 2.8. Shows the connectors

below and their description.

“Innovative technological developments for the photovoltaic solar energy industry”

13 www.entecsolar.es

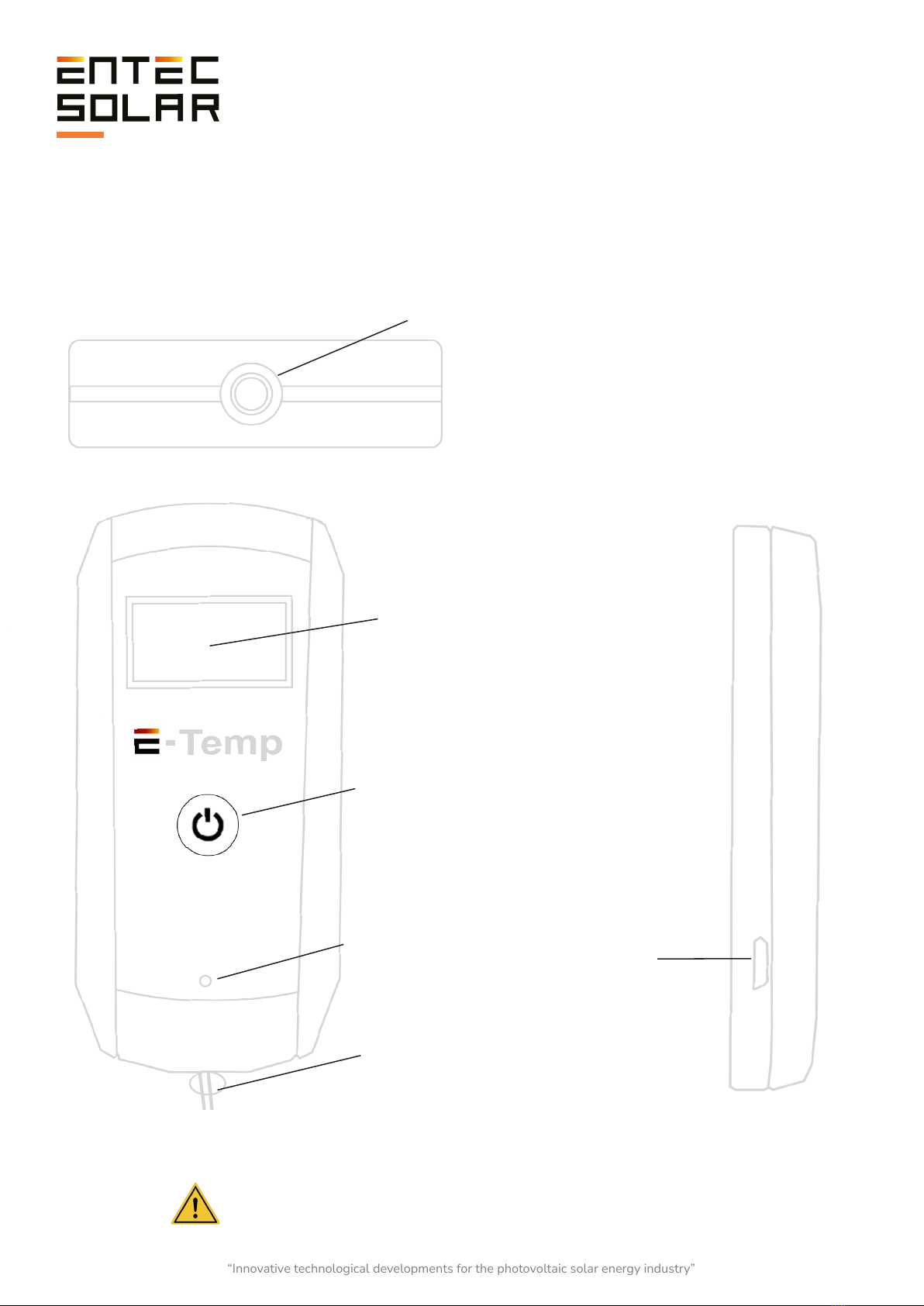

2.2.4. Optional: E-Temp (IR Sens)

Figure 2.13. Illustrates the micro USB

charging port on the side.

1. Micro USB

port.

Figure 2.12. Illustrates the front display and button.

2. Power button.

1. Color display.

Figure 2.11. Illustrates the infrared sensor on the top.

1. Sensor

3. LED.

4. Grip tape.

ATTENTION: Avoid prolonged exposure to direct sunlight.

“Innovative technological developments for the photovoltaic solar energy industry”

14 www.entecsolar.es

2.3. . Description of Elements on the

Initial Screen

2.3.1. E-Sens

In this section, we will focus on the E-Sens and

E-Temp devices, as the elements on the curve

tracer screen are available in Section 5 of this

manual.

To power on and off the E-Sens, press the black

button on the top right of the screen. While the

device is booting up, the loading screen will be

displayed for a few seconds.

On this screen, the message "Initializing..." is

shown, along with two important pieces of

information. The first is "SN," which corresponds

to the Serial Number of the device. The second is

"Fw V," which corresponds to the Firmware

version of the device.

Once the device has finished initializing, the main

E-Sens screen will be displayed. This is the screen

where all the device information is shown.

In the upper bar, from left to right, you will find the

following elements:

- Device logo

- MicroSD detected and initialized icon

- Battery status icon

- Date and time

The following data is displayed in a vertical order:

- ISC: Measurement of the voltage of the

calibrated reference cell in millivolts to obtain

irradiance.

- Tc Isc: Temperature measurement of the PT1000

of the calibrated reference cell.

- PT1: Temperature measurement of channel 1.

- PT2: Temperature measurement of channel 2.

- PT3: Temperature measurement of channel 3.

- VBAT: Measurement of the battery voltage.

Figure 2.14. E-Sens screen during device

startup.

Figure 2.15. E-Sens screen during device

startup.

“Innovative technological developments for the photovoltaic solar energy industry”

15 www.entecsolar.es

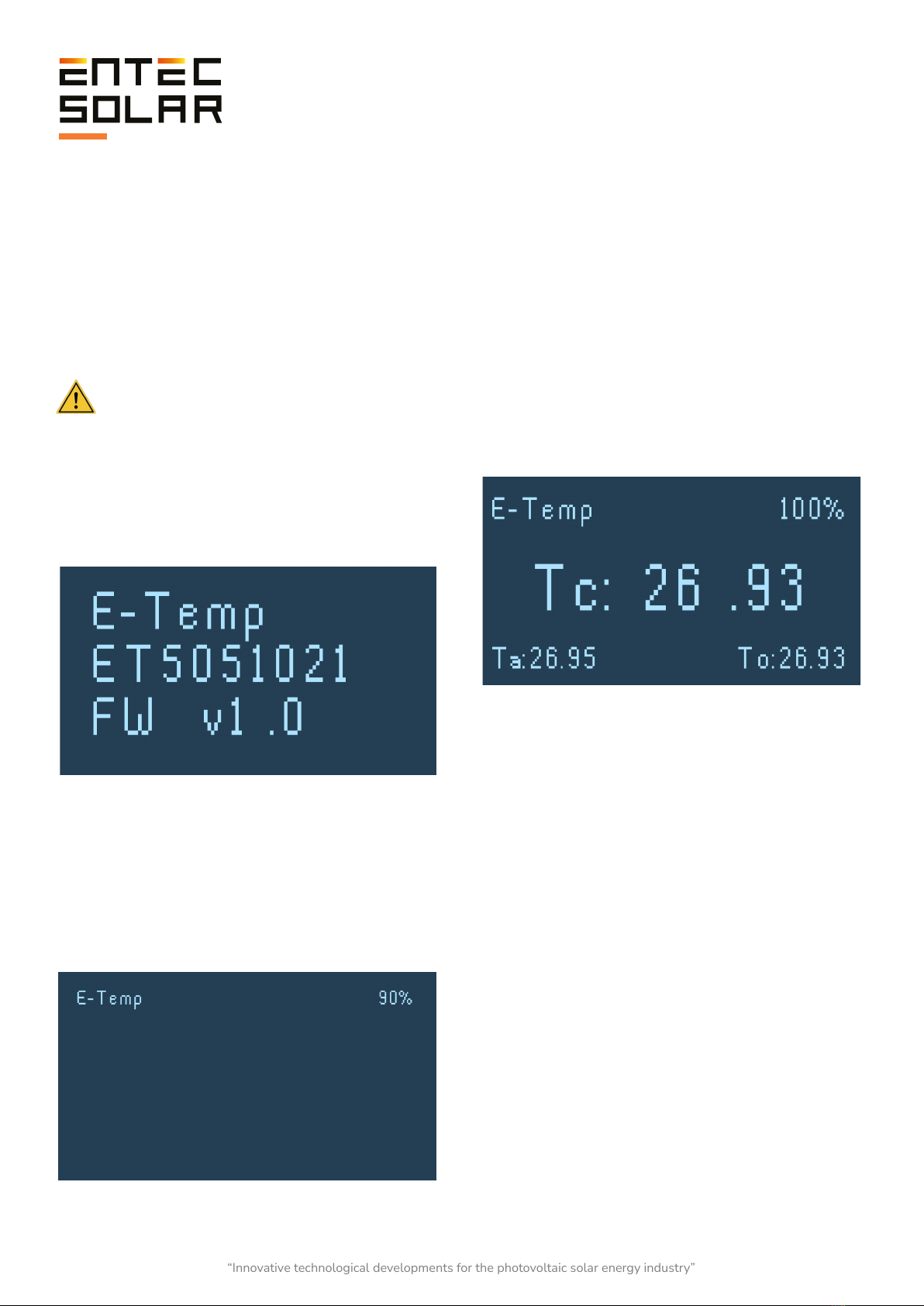

2.3.2. E-Temp

To power on the E-Temp, briefly and gently press

the power button once, and wait for a couple of

seconds until the startup screen is displayed.

Similarly, to turn off the device, press and hold

the same button for 5 seconds.

IMPORTANT: During startup, it is important

not to press the button multiple times in

succession or press it for an extended period, as

this may turn off the device.

The initial data displayed includes the device

name, the device's serial number, and the

firmware version.

Once the device initialization is complete, the

standby screen will be shown. In this mode, the

device is ready to take measurements but

displays minimal information to save battery

power by reducing screen energy consumption.

Figure 2.16. E-Temp screen during device startup.

Figure 2.18. E-Temp measurement screen.

Figure 2.17. E-Temp standby screen.

Once the device initialization is complete, the

standby screen will be shown. In this mode, the

device is ready to take measurements but

displays minimal information to save battery

power by reducing screen energy consumption.

Subsequently, three temperatures will be

displayed on the screen:

- Tc: This corresponds to the temperature of the

measured point and is located in the center,

displayed larger. This is the temperature stored in

the curve tracer's SD card data.

- Ta: This corresponds to the ambient

temperature, located at the bottom left.

- To: This corresponds to the temperature of the

temperature sensor packaging. Excessive

temperature can affect the accuracy of the device.

It is located at the bottom right.

When performing the measurement, the data will

be displayed on the screen for approximately five

seconds. At the end of this period, the device

returns to the standby state.

Please note that the same button is used to power

on the device, take measurements, and power off

the device, so you should be cautious when

pressing it. It is important not to press the button

multiple times in succession or press it for an

extended period.

“Innovative technological developments for the photovoltaic solar energy industry”

16 www.entecsolar.es

Figure 2.19. Devices and accessories included.

2.4. Supply Package

The E-1000 can be purchased in its basic version

or with various options. Below is a list of

accessories included in the basic version and

optional accessories.

Included in the Basic Version:

- 1 x E-1500 / E-1000.

- 1 x E-Sens.

- 1 x Padded transport case with wheels.

- 1 x Set of four-point measurement cables with

MC4 terminals.

- 1 x SD card for E-1000.

- 1 x MicroSD card for E-Sens.

- 1 x Charger for E-1000.

- 1 x Set of crocodile clips.

- 1 x USB cable for charging E-Sens.

- 1 x Calibrated reference cell.

- 1 x PT-1000.

- 1 x Wireless communication antenna.

- 1 x 1500V fuse in cable (for E-1500).

Optional Accessories:

- Barcode reader.

- Infrared temperature sensor (E-Temp).

- Access to PVET for data storage and advanced

analysis.

- Additional PT-1000 sensors.

“Innovative technological developments for the photovoltaic solar energy industry”

17 www.entecsolar.es

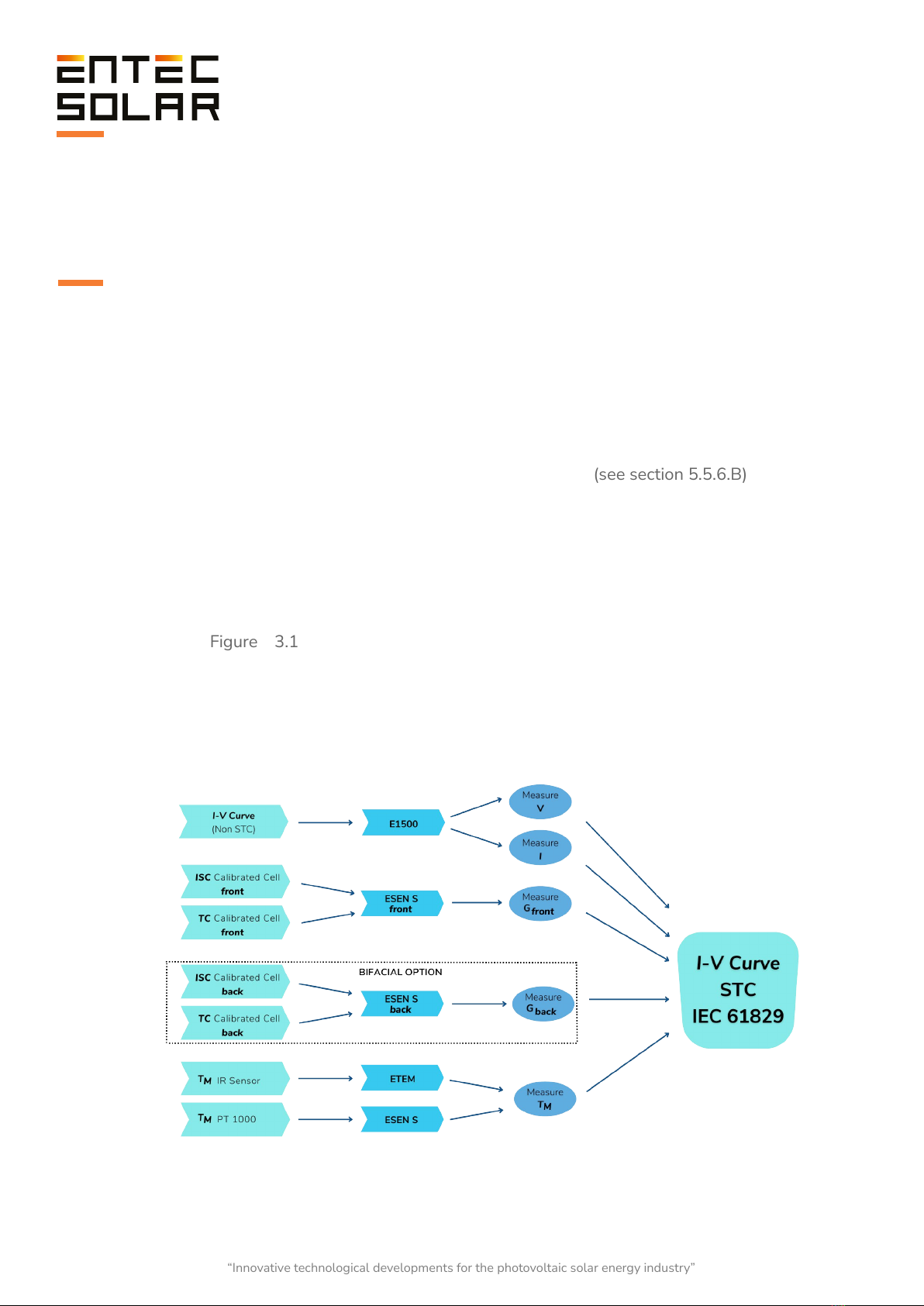

3. Measurement Quantities and Operating Conditions

3.1. Measured Quantities

Unlike measuring I-V curves under controlled

conditions, such as with a flash tester, measuring

I-V curves in the field under variable operating

conditions requires extrapolation of the measured

curves to standard test conditions (STC).

The E-1500 performs this extrapolation

automatically according to the procedure

described in IEC 61829 and based on

measurements of irradiance, module

temperature, and the I-V curve. To facilitate the

measurement of these quantities, Entec Solar has

devised a solution that involves using the E-1500

I-V curve tracer along with the E-Sens and

E-Temp devices. Figure 3.1 illustrates the

measured quantities and the processes carried

out to obtain the I-V curve under STC conditions.

To obtain irradiance (G), the E-Sens measures the

short-circuit current (ISC cell) and temperature

(Tc cell) of the calibrated cell and sends these

values to the E-1500 / E-1000. The E-1500

processes these quantities and converts them to

irradiance using the calibration values of the

calibrated cell (see section 5.5.6.B).

To obtain the module temperature1(TM), there

are two options:

- E-Temp: An infrared thermometer designed

by Entec Solar, which allows practical and

non-contact temperature measurement of

various points on the tested element.

- E-Sens: It has up to three channels for the

use of Pt1000 sensors.

1 It's important not to confuse this temperature with the temperature of the cell.

They are different temperatures and are obtained and used differently.

Figure 3.1: Illustration showing the measured quantities, the equipment used, and the procedures carried out

to obtain the curve measured under STC conditions.

“Innovative technological developments for the photovoltaic solar energy industry”

18 www.entecsolar.es

3.2. Operating Conditions

Measuring I-V curves under actual sunlight

requires special care regarding the weather

conditions during the test. Irradiance and module

temperature are the variables that most

significantly affect the final result. Therefore,

special attention must be given to measuring

these variables to obtain accurate and consistent

results. To achieve this, the following precautions

should be taken:

Regarding Irradiance Measurement:

- Conduct measurements during periods of clear

sky throughout the day. If the reference cell and

the tested circuit are exposed to different levels of

irradiance due to factors like passing clouds, the

extrapolation to standard test conditions (STC)

results may not be consistent.

- Ensure coplanarity and proximity between the

reference cell and the tested circuit. Differences in

orientation, tilt, or measured irradiance between

the reference cell and the tested circuit can lead to

inconsistent extrapolations to STC.

- IEC 61829 recommends a minimum irradiance

of 700 W/m2 during measurements. However,

more accurate results are achieved with irradiance

closer to 1000 W/m2.

- Avoid having the angle of solar incidence on the

tested circuit exceed 40°.

Regarding Temperature Measurement:

- Avoid measurements on very windy days. Wind

can cause significant variations between the

actual cell temperature and the measured

temperature, as well as temperature differences

within the tested circuit. In the case of module

chains, wind can cause substantial differences

between end modules and those in the center of

the structure, or between modules in lower and

upper rows. Large temperature differences

between the tested circuit and those measured by

the E-Sens can lead to inconsistent extrapolations

to STC.

- To minimize errors due to temperature

differences within the tested circuit (e.g.,

temperature differences between cells within a

module or between modules in module chains), it

is recommended to measure temperatures at

various points within the tested circuit.

- IEC 61853-1 recommends measuring the

temperature of a module at the three positions

shown in Figure 3.1 and using the average of the

three temperatures for extrapolation to STC. The

E-1000 has been programmed to average up to

three PT-1000 measurements taken with the

E-Sens or to use the average with a user-selected

number of points measured with the E-Temp.

- For temperature measurement in module chains,

it is recommended to measure the temperature of

at least three modules in the chain, using the

three points indicated in Figure 3.2 within each

module. It is advisable to measure a module near

the end of the chain and two modules from the

center of the chain. The use of the E-Temp, which

enables wireless measurements, is highly

recommended for this purpose.

Figure 3.2. Positions for placing temperature

sensors on a photovoltaic module

based on IEC 61853-1.

“Innovative technological developments for the photovoltaic solar energy industry”

19 www.entecsolar.es

4.

Preparation Prior to Measurements

4.1.

First Use of the Device

The E-1500 / E-1000, before being shipped, has

undergone rigorous quality controls during its

production and has been electrically and

mechanically inspected after manufacturing. All

functionalities of the device have been tested, and

every possible precaution has been taken to

ensure the device is delivered without any

damage or operational defects. However, it is

advised to thoroughly examine the device and test

its operation upon receipt and before beginning a

measurement campaign. If any defects or

anomalies in operation are detected, contact Entec

Solar or your nearest distributor immediately.

4.2. Battery Charging

Both the E-1500 / E-1000 and the E-Sens have a

rechargeable lithium-ion battery inside. The

complete device package includes a specific

charger for the E-1000 / E-1500 battery and

another specific charger for the E-Sens. Each

charger has a different type of connector: the

E-1000 uses a Jack connector, and the E-Sens

uses a micro-USB connector. The charging

connector for each device can be seen in Figures

2.3 and 2.6 in sections 2.2.2 and 2.2.3.

By default, both devices are distributed with a

battery charge level of 60%. Before the first use of

the devices, make sure to charge both batteries to

100% to maximize their usage time. With a fully

charged battery, the E-1500 / E-1000 can operate

for more than 8 hours, while the E-Sens can

operate for more than 10 hours.

The E-1500 / E-1000 charger includes an LED

that indicates the charging status. During battery

charging, this LED will be red, and once the device

is fully charged, it will turn green. The E-Sens is

charged using a standard micro-USB cable from

any 5V source, such as a computer USB port or a

mobile phone charger. While the E-Sens is

charging, an LED inside it lights up, located just

above the micro-USB connector and visible from

the outside (See Figure 2.10).

During charging, this LED emits a red light, and

when charging is complete, it emits a green light.

The battery charge status of both devices (E-1500

/ E-1000 and E-Sens) can also be seen in the

top-right corner of their respective screens (Figure

5.3). The indicator displays the charge status in

levels, where each level indicates a specific charge

status (Figure 5.3).

- One red square: charge between 0-10%.

- One white square: charge between 10-25%.

- Two white squares: charge between 25-50%.

- Three white squares: charge between 50-75%.

- Four white squares: charge between 75-100%.

On the E-Sens screen, the actual battery voltage

can also be seen. This value provides a more

accurate representation of the battery's charge

level, where below 3.5V, immediate charging of

the device is recommended.

“Innovative technological developments for the photovoltaic solar energy industry”

20 www.entecsolar.es

2 Para la obtención de los valores de calibración de la célula de referencia consulte el certificado de calibración entregado con su equipo.

The E-1500 / E-1000, before being shipped, has

undergone rigorous quality controls during its

production and has been electrically and

mechanically inspected after manufacturing. All

functionalities of the device have been tested, and

every possible precaution has been taken to

ensure the device is delivered without any

damage or operational defects. However, it is

advised to thoroughly examine the device and test

its operation upon receipt and before beginning a

measurement campaign. If any defects or

anomalies in operation are detected, contact Entec

Solar or your nearest distributor immediately.

Insert the cards into the slots located at the top of

each of the devices (Figures 2.1 and 2.4).

IMPORTANT: The battery charge level is

indicative and depends on various variables, such

as ambient temperature, the rate of device usage,

battery lifespan, manufacturing differences

between batteries, etc. The displayed levels are

approximate and based on a standard battery.

These levels can change over time, causing the

battery to discharge earlier than expected or even

jump between levels more quickly than the

percentages described in this section. As the

device is used, these levels may change, and the

user should be aware of this to avoid running out

of battery during a measurement campaign.

4.3. Memory Card Insertion

The E-1500 and E-1000 store all measured data

on SD cards, while the E-Sens uses a MicroSD

card. Both cards are supplied with the device

shipment. Both devices can function without these

cards, but it will not be possible to store data

without them. In the event of loss or replacement

of the supplied cards, the use of reputable brand

SD cards is recommended to avoid potential data

loss or memory corruption.

4.4. Initial Configuration

The E-1500 / E-1000 has been designed to offer

very simple operation. However, minimal

configuration is required before each

measurement campaign. The following are the

main steps to follow in configuring the E-1500 /

E-1000 before starting a measurement campaign:

1. Set the local time and synchronize it with the

E-Sens (See section 5.5.11.A.).

2. Configure the module and tested generator

characteristics: The E-1500 / E-1000 uses key

electrical characteristics of the tested module

(VOC, ISC, VM, IM, α, β, and NS, provided by the

manufacturer) as well as the generator

configuration (number of modules in series and

parallel) as input parameters to calculate series

resistance and the parameter k, both necessary for

extrapolation to STC according to IEC-61829 (See

section 5.5.4).

3. Configure the irradiance and temperature

sensors2: Set the calibration values of the

reference cell (irradiance sensor) and select the

temperature measurement method (e.g.,

PT-1000, reference module, E-Temp) as detailed

in section 5.2.2.A.

Before each use of the device, ensure that the SD

cards are inserted and functioning properly to be

able to store all measurements

Insert the cards into the slots located at the top of

each of the devices (Figures 2.1 and 2.4).

IMPORTANT: Insertion and removal of the

cards should be done with the devices turned off

to avoid damage to the cards and the possibility of

losing stored data.

IMPORTANT: The format of the cards should

be FAT32.

“Innovative technological developments for the photovoltaic solar energy industry”

Other manuals for E-1500

1

This manual suits for next models

1

Table of contents

Other Entec Solar GPS manuals