Entec LBS-751 User manual

Version 1.1

Quick Start Guide www.Entec-USA.com

Date: June 2018

LBS-751 Electronic

Sectionalizer Control

Patent Pending Technology

Quick Start Guide

LBS-751 Control

2

www.Entec-USA.com

ENTEC is packaging a new Sectionalizer Control with our Load Break Switch (LBS) featuring an

SEL-751 relay, innovative smart-logic and patent pending technology. Known as LBS-751, this

new unit expands traditional sectionalizer applications and modernizes power system protection.

With three simple setpoints the factory program is push-button-ready. Let’s get started.

Important Documents Inside Cabinet

LBS Routine Test Record

SEL Production Test Report

User Manual

Product Guide

Quick Start

Flash Stick with Factory Docs, acSELerator Application and RDB Template

Computer Setup

1. Copy factory docs, acSELerator Setup file, and RDB from flash stick to laptop. Rename

RDB as desired.

2. Stow away flash stick in a safe place.

3. Install acSELerator using v6.7.0.1 Setup file included. This loads the application and

latest 751 driver. For Step-By-Step acSELerator installation see APPENDIX 1.

(acSELerator and drivers also available online at www.selinc.com)

4. Set comm parameters on laptop: IP 192.168.1.10

Subnet 255.255.255.0

Gateway 192.168.1.1

5. Open acSELerator and go to Tools>Options>Settings

Check the checkbox to enable “Prompt for Action on Settings Read”

751 Setup

6. Choose RDB: click Open, use tool at end of selection box to navigate and open RDB

Template then click Cancel to close window.

7. Connect to 751 with standard ethernet cable. Set IP on communications configuration in

acSELerator to 192.168.1.2.

8. Select “Read From” and enter Level-One password when prompted: OTTER

9. Read prompt will pop-up with options. Select “Open Settings with Editor”.

10. Save settings as OEM file, name as desired (e.g. “Customer Field Device OEM”).

11. Re-Read from 751 a second time. When prompt window appears make sure to select

(highlight) “LBS-751 SVN-007 Template” and then select option to merge from relay

template. When template view appears save file as “LBS-751 SVN-007 Template v1.0”

12. Program setpoints, save and send to 751.

Phase Pickup, Ground Pickup, Operations. Enter relay name if desired

13. Set Time and Date: use HMI => Control Window while connected 751

Scada Setup

14. See APPENDIX 2

Congratulations … All Done

Quick Start Guide APPENDIX 1

LBS-751 Control

3

www.Entec-USA.com

APPENDIX 1

Install acSELerator Application

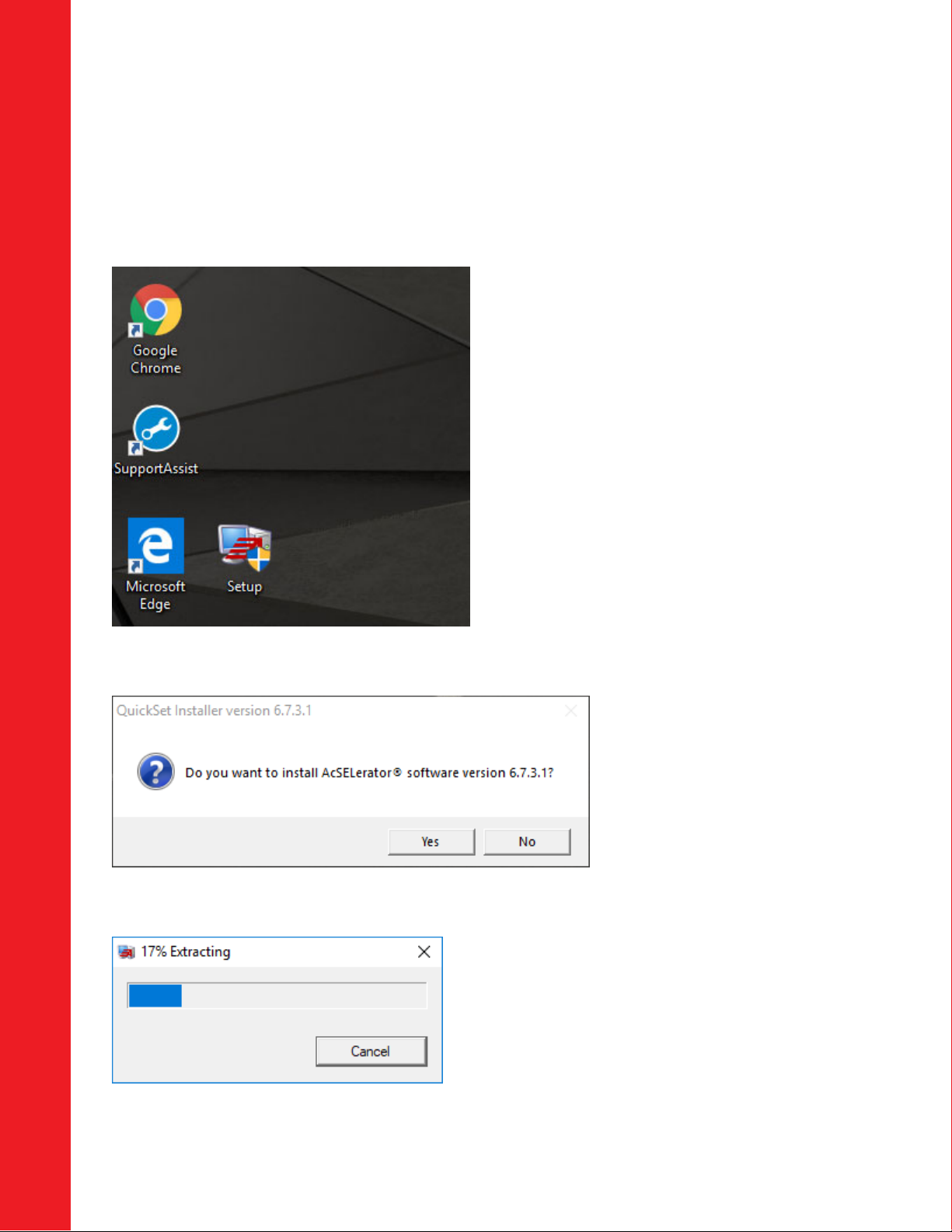

SAVEINSTALLATIONFILEONDESKTOPTHENDOUBLE‐CLICKTOSTARTINSTALL

AFTERDOUBLECLICKINGTHISWINDOWAPPEAR

AFTERCLICKINGYES

Quick Start Guide APPENDIX 1

LBS-751 Control

4

www.Entec-USA.com

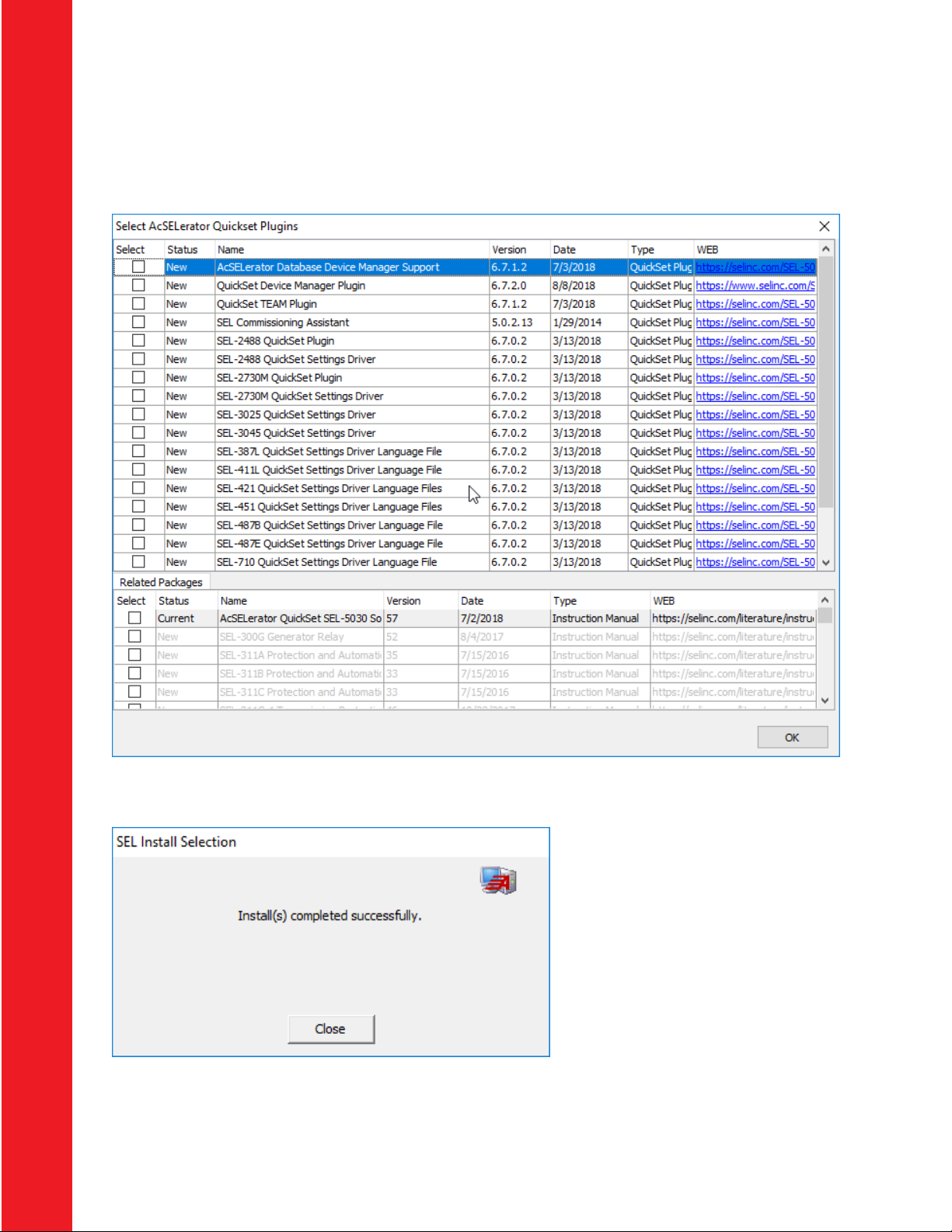

AFTEREXCTRACTIONISCOMPLETE.CHECKBOXESAREGRAYED‐OUT…CLICKOK.

LICENSEAGREEMENTAPPEARSNEXT.CLICK“IAGREE”TOCONTINUE.

Quick Start Guide APPENDIX 1

LBS-751 Control

5

www.Entec-USA.com

AFTERYOUAGREETHISWINDOWAPPEARS.SELECT“IAGREE”AGAIN.

THISWINDOWAPPEARSNEXT,TAKESABOUT2‐3MINUTETOINSTALL

Quick Start Guide APPENDIX 1

LBS-751 Control

6

www.Entec-USA.com

AFTERINSTALLTHISWINDOWAPPEARSLISTINGDRIVERSFORALLSELRELAYS.YOUHAVETHECHOICE

TOUNCHECKBUTTHEEASIESTOPTOINISCLICKOK.

AFTERYOUCLICKOKPROGRESSWINDOWAPPEARSWHILEINSTALLINGALLTHEDRIVERS.THISTAKESA

COUPLEOFMINUTESTOINSTALL

Quick Start Guide APPENDIX 1

LBS-751 Control

7

www.Entec-USA.com

AFTERINSTALLINGDRIVERS,THISWINDOWISNEXT.CLICKOKTOPROCEED.

AFTERCLICKINGOK,THISWINDOWISNEXT.INSTALLATIONCOMPLETE.

Quick Start Guide APPENDIX 2

LBS-751 Control

8

www.Entec-USA.com

APPENDIX 2

Scada Setup

Port Settings

1. Open RDB with acSELerator and select OEM file saved previously in Step 4. Save-As

OEM Comm Config (e.g. Customer Field Device OEM Comm Config).

2. Use setting editor to open Port config. Make changes, save and upload new Port

settings to 751.

Quick Tip

Make sure to enable a session in either Modbus or DNP protocol when using Port 1

(Ethernet), scroll down to the bottom of Port 1 page.

Quick Start Guide APPENDIX 2

LBS-751 Control

9

www.Entec-USA.com

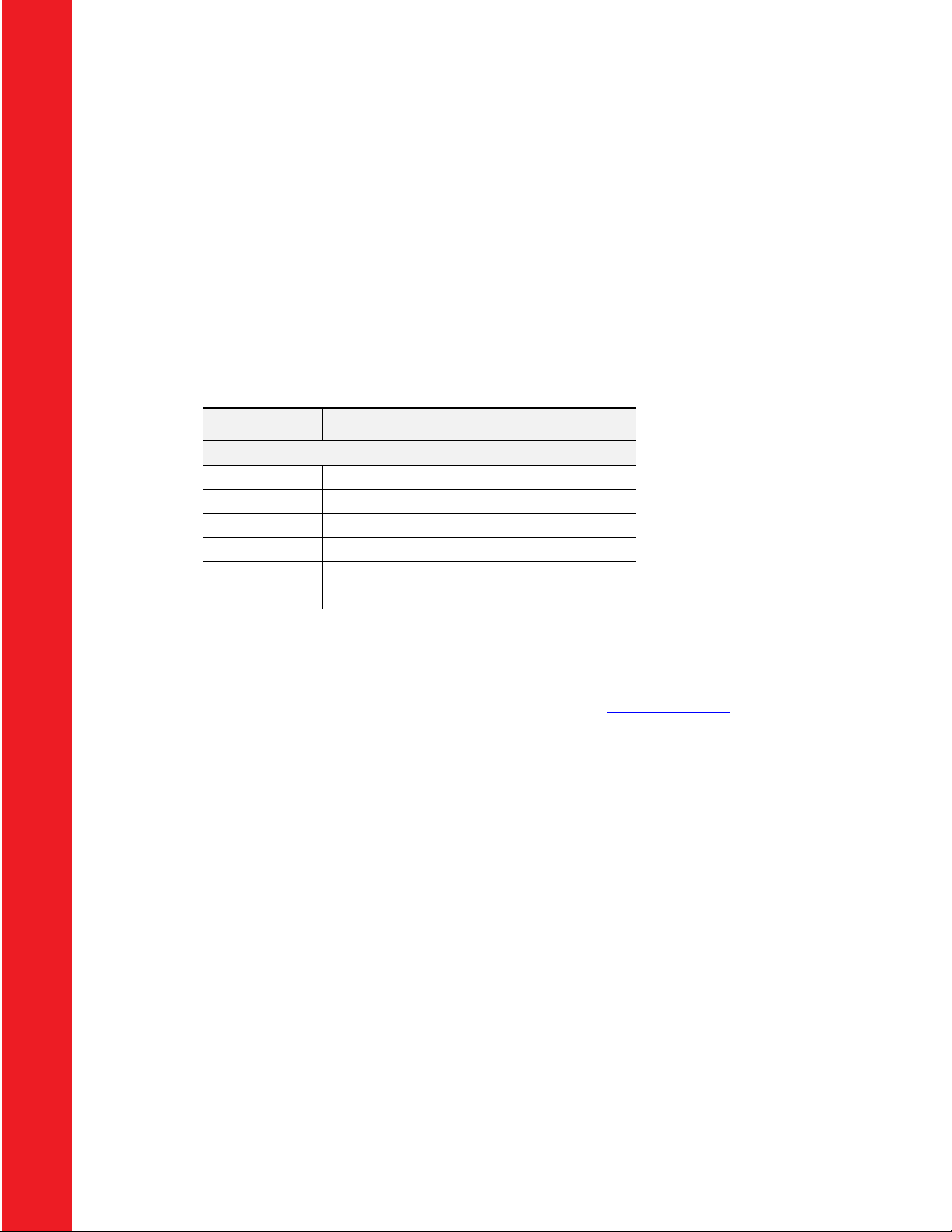

Modbus User-Defined Assignment Map

Boolean Points

StatusBits SourceLocation

02hRead 03hRead

Tag WordMap Bit

Coil

UserTable Address Bit

BreakerClosed(52A) IN302 Row18 6 150 MOD_040

165 6

BreakerOpen(52B) IN303 Row18 5 149 MOD_040

165 5

HandleLock(69) IN301 Row18 7 151 MOD_040

165 7

DiagnosticAlarm T03_LED Row38 3 307 MOD_044

169 3

BatteryFail T04_LED Row38 2 306 MOD_044

169 2

ACPowerFail T05_LED Row38 1 305 MOD_044

169 1

Polarity: Logic 1 = True Condition

Quick Start Guide APPENDIX 2

LBS-751 Control

10 www.Entec-USA.com

Analog Points

SpecialAnalogValues SourceLocation 03hRead

Tag Scaler UserTable Address DataType

Operations MV01 0.01 MOD_001 126 32BitSigned

PhasePU(Amps) MV02 0.01 MOD_003 128 32BitSigned

GroundPU(Amps) MV03 0.01 MOD_005 130 32BitSigned

TripCounter SC03 1 MOD_065 190 16Bit

Control Points

ControlBits SourceLocation 05hForceSingleCoil

Tag CoilAddress DataType

PB01–LockPushButtons RB01 27 RemoteBitCoil

PB02–LoopModeEnable RB02 28 RemoteBitCoil

PB03–CLOSESwitch RB03 29 RemoteBitCoil

PB04–TRIPSwitch RB04 30 RemoteBitCoil

TargetReset RB05 31 RemoteBitCoil

TripCountReset RB06 32 RemoteBitCoil

ResetMax/Min RB07 33 RemoteBitCoil

Polarity: Logic 1 = Active Condition (Set Coil)

Modbus Protocol Codes

02h Read Input Status (Coils) Command

Use function code 02h to read bits as individual coil values. The coil method increases data

size and may require multiple polls to completely read one device, but single binary values

placed in one coil greatly simplifies binary state determinations at the Scada master. Use

the 02h coil address provided in the status bit table above to collect data.

Bytes Field

02hReadrequestformatfromMaster

1byte SlaveAddress

1byte FunctionCode(02h)

2bytes CoilAddress

2bytes Numberofcoilstoread(n)

2bytes CRC‐16

02hSuccessfulresponseformatfromSlave

1byte SlaveAddress

1byte FunctionCode(02h)

1byte Coilsofdata(n)

nbytes Data

2bytes CRC‐16

Quick Start Guide APPENDIX 2

LBS-751 Control

11 www.Entec-USA.com

03h Read Holding Register Command

Use function code 03h to read holding register values containing “bit words” or analog data.

To determine data address, add 125 (decimal) to Setting location in the Modbus User-

Defined Assignment Map above.

Example 1: Phase-A Current Demand (IAD) is available using the 03h function to

read address 133 (Mod_08 Setting location + 125 = 133).

Example 2: AC Power Fail is available using the 03h function to read address 169 as

noted in the Status Bit table above. AC Power Fail can be determined from the state of bit 1

using polarity convention where Logic 1 = True Condition. The Scada master will typically

collect 16 bits (2 Bytes) from address 169. The desired bit location is determined counting

from Right to Left starting with Bit-0. The second bit counting from the right is Bit-1

representing AC Power Fail. (1 = AC Power Fail True, 0 = False).

Bytes Field

03hReadrequestformatfromMaster

1byte SlaveAddress

1byte FunctionCode(03h)

2bytes Startingregisteraddress

2bytes Numberofregistersread(n)

2bytes CRC‐16

03hSuccessfulresponseformatfromSlave

1byte SlaveAddress

1byte FunctionCode(03h)

1byte Bytesofdata(n)

nbytes Data(2‐250Bytes)

2bytes CRC‐16

03h command will collect all data from the LBS-751 User-Defined Assignment Map with a

single poll (125 registers). In many systems this method will collect Binary and Analog

points with a single poll allowing more devices to communicate with the Scada master.

Large Scada systems utilize 03h to collect binary words versus using 02h to retrieve single

binary bits.

Quick Start Guide APPENDIX 2

LBS-751 Control

12 www.Entec-USA.com

Modbus Protocol Codes, continued

05h Force Single Coil Command

Use function code 05h to set and clear a coil. Remote bit coil will track the binary state

value forced with the 05h function. State value “1” will Set remote bit coil and “0” will Clear

the coil. Refer to Control Point table for coil assignments and address.

Example 1: Apply “Push Button Lock” with 05h function using Scada to force coil

address 27. Set Logic “1” for three seconds then clear to Logic “0” operates Button Lock

same as pressing PB1 directly on the front panel.

Bytes Field

05hForceSingleCoilformatfromMaster

1byte SlaveAddress

1byte FunctionCode(05h)

2bytes CoilReference

1byte OperationCode(FF=Set;00=Clear)

1byte Placeholder

2bytes CRC‐16

For additional information about Modbus commands and a comprehensive data map refer to the

SEL 751 user manual Appendix E: Modbus Communications. A PDF copy is included on the

flash stick located inside the control cabinet or available online at www.selinc.com.

SEL ® is a registered trademark of Schweitzer Engineering Laboratories, Inc. (SEL)