Page 3

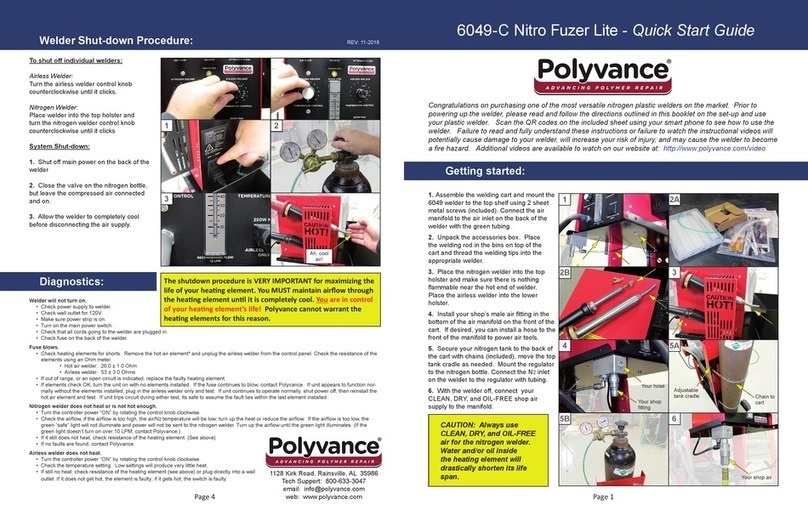

1. Most bumper repairs can be done with the air/nitrogen ow set at 12 LPM, but up

to 15 LPM is commonly used. The chart above may be used as a general guide for

welding various materials. Using settings outside the range on the chart is generally

not needed, unless you are welding unusually thin or thick material or if the material

you are welding has an unusually high or low melting point.

It’s important to note that when increasing the temperature without increasing the

airow, the heating element can be over-heated easily, causing a dramatic reduction in

the life-span of the element. Over-heating is indicated by a glowing outer steel torch

barrel. If this happens, immediately turn down the temperature and turn up the air and

nitrogen ow. If an over-heat condition continues uncorrected, the heating element

will burn out and the handle may be destroyed by the excessive heat becoming a

potential re hazard.

2. To change from air to nitrogen, simply turn the selector valve to the desired source.

Be sure to switch back to the air setting when the weld is complete to avoid using

excess nitrogen.

3. Once the welder has warmed up, welding is accomplished by directing the heated

nitrogen at the intersection of the area to be repaired on the base material and the

welding rod. The welding rod should be applied perpendicular to the base material

with the welder aimed at approximately a 45° angle between the two.

4. The substrate should begin to gloss over in 3 to 5 seconds after applying the heat.

At this point, begin pressing the rod downward onto the surface, rolling it towards the

heat. Be sure the surface of the rod and the surface of the substrate are both melted

when pushing the two materials together.

For more information on welding plastic, please watch the instructional videos found at

www.polyvance.com.

Welding Basics: 1

2

3

4

12 LPM

Temperature Setting Suggestions*

* Most welding operations will be at the recommended settings. Welding outside the recommended range may be needed if the plastic being welded is

very thin or thick or if a higher or lower airow is used. Extreme care must be taken to avoid overheating the element.

Type of Plastic Melting Temp. Series of

Welding Rod

Recommended Temperature

Setting on Nitrogen Welder Air Flow

Polyurethane (RIM, PUR) N.A. R01 8-10 (AIRLESS WELDER ONLY) N.A.

Polypropylene (PP) 160-166°C (320-331°F) R02 7 12

ABS 105°C (221°F) R03 6-7 12

Polyethylene (LDPE) 105-115°C (221-239°F) R04 7-8 12

TPO 177°C (350°F) R05 7-8 12

Nylon (PA) 269°C (516°F) R06 8 12

Polycarbonate (PC) 155°C (311°F) R07 7- 12

PPE+PS, PPO 260°C (500°F) R08 7 12

PVC 177°C (350°F) R09 6+ 12

FiberFlex®N.A. R10 12 (AIRLESS WELDER ONLY) N.A.

PBT (Polybutylene Terephthalate) 225°C (437°F) R11 7-8 12

Polyethylene (HDPE) 190°C (375°F) R12 7-8 12

PET 254°C (490°F) R13 8- 12

ASA 220°C (428°F) R14 6-7 12

GTX (Nylon blend) 275-300°C (527-572°F) R15 8 12

POM (Acetal, Delrin®) 215°C (419°F) R16 6+ 12

Acrylic/PVC (Kydex®) <204°C (<400°F) R17 6-7 12

PP+GF15 160-166°C (320-331°F) R18 7 12

HDPE+GF15 190°C (375°F) R19 7-8 12

PC+ABS 155°C (311°F) R20 7- 12