Brano Z420-A User manual

translation of the original instructions for use (also applies to special designs)

BRANO a.s., 747 41 Hradec nad Moravicí

The Czech Republic

tel.: +420/ 553 632 303

http://www.brano-zz.cz; http://www.brano.eu;

OPERATION MANUAL

SAFETY PRINCIPLES, OPERATION AND MAINTENANCE

FOR

SINGLE BEAM TROLLEYS

Type Z420

modification according to the width of the running profile

– A, – B, – C

modification without drive, without "R" control

design for potentially explosive atmospheres

–

NEXP

lifting capacities 0,5t; 1t; 1,6t; 3,2t; 5t; 7,5t and 10t

Read this Operation Manual carefully before using these products. This manual

contains important safety, operation, installation, and maintenance information on the

product. Make this manual available to all responsible persons.

Keep for further use!

Edition 7

th

May 2022

Evidence number

1

-

56799

-

0

-

0

2

CONTENT

1 DEFINITION .......................................................................................................................... 3

2 DEVICE PURPOSE................................................................................................................ 3

3 SAFETY PRINCIPLES .......................................................................................................... 4

3.1 SAFETY SUMMARY ..................................................................................................... 4

3.2 SAFETY PRINCIPLES ................................................................................................... 4

3.2.1 Prior to use .................................................................................................................... 4

3.2.2 When in use................................................................................................................... 5

3.2.3 After use ........................................................................................................................ 5

3.2.4 Risk analysis.................................................................................................................. 5

3.2.5 Maintenance .................................................................................................................. 5

4 PACKING, STORAGE AND MANIPULATION ................................................................. 5

4.1 PACKING ........................................................................................................................ 5

4.2 STORAGE ....................................................................................................................... 6

5 MAIN TECHNICAL PARAMETERS ................................................................................... 6

5.1 DIMENSIONS ................................................................................................................. 6

5.2 DIVISION ........................................................................................................................ 8

5.3 MAIN TECHNICAL PARAMETERS ............................................................................ 8

5.4 MATERIAL AND DESIGN............................................................................................ 8

5.5 DATA ON PRODUCT .................................................................................................... 9

6 INSTALLATION OF THE PRODUCT ................................................................................. 9

CHECK PRIOR TO INSTALLATION ................................................................................. 9

6.1 LOAD CARRYING STRUCTURE................................................................................. 9

6.2 TRAVELLING (CRANE) TRACK................................................................................. 9

6.3 ASSEMBLY OF THE PRODUCT ................................................................................ 10

6.4 TEST PRIOR TO USE................................................................................................... 12

7 OPERATION ........................................................................................................................ 12

7.1 APPLICATION OF THE PRODUCT ........................................................................... 12

7.2 SAFE WORKING ENVIRONMENT ........................................................................... 12

8 INSPECTION OF THE PRODUCT ..................................................................................... 13

8.1 INSPECTION................................................................................................................. 13

8.1.1 Inspection classifications............................................................................................. 13

8.1.2 Daily inspection........................................................................................................... 13

8.1.3 Regular inspection....................................................................................................... 13

8.1.4 The product occasionally used .................................................................................... 14

8.1.5 Inspection record ......................................................................................................... 14

8.1.6 Inspection procedure ................................................................................................... 14

9 LUBRICATION.................................................................................................................... 15

9.1 GENERALLY................................................................................................................ 15

9.2 GEARINGS OF THE PRODUCT ................................................................................. 15

10 MAINTENANCE................................................................................................................ 15

10.1 SAFETY PRINCIPLES ............................................................................................... 15

10.3 GENERAL INSTRUCTIONS ..................................................................................... 16

10.4 CHECK ........................................................................................................................ 16

10.5 REPAIR........................................................................................................................ 16

10.6 TEST ............................................................................................................................ 16

11 PUTTING OUT OF OPERATION – DISPOSAL.............................................................. 16

12 RELATED DOCUMENTATION....................................................................................... 17

13 FINAL REQUIREMENTS OF THE MANUFACTURER TO THE CUSTOMER .......... 17

3

1 DEFINITION

! DANGER

Danger is used to indicate the presence of a hazard, which will

cause death or severe injury, if the operating staff does not avoid

it.

! WARNING

Warning is used to indicate the presence of a hazard, which can

cause death or severe injury, if the operating staff does not avoid

it.

! CAUTION

Caution is used to indicate the presence of a hazard, which can

cause minor injury, if the operating staff does not avoid it.

Caution can also warn against dangerous practices.

Lifting capacity (Q): indicates maximum permitted mass (working load limit), which

a product is designed to be loaded during operations under conditions specified in

this manual.

2 DEVICE PURPOSE

2.1 The single beam trolley(hereinafter referred to as product) type Z420 in any

modification Z420(R)-A (B, C) and designed for use in potentially explosive

atmospheres - NEXP(NEXP= structurally identical product, differing in surface

protection of selected parts, marking plate material and documentation) of lifting

capacities 1t, 1,6t, 3,2t, 5t, 7,5t and 10t is designed for horizontal travel on flanges of

I-beam. It is intended mainly for suspending of BRANO hand operated lifting devices

of the appropriate lifting capacity. The mass of a load must not exceed the nominal

lifting capacity.

2.2 The product has been designed to meet requirements provided by the Directive

2006/42/EC of the European Parliament and of the Council as amended by the

Czech technical regulation – ministerial order No. 176/2008 of the Coll. of Laws as

amended as well as requirements of the ČSN EN ISO 12100 and ČSN EN 13157+A1

harmonized technical standards.

2.3 The product has been designed in compliance with the requirements stipulated

by Directive 2014/34/EU of the European Parliament and of the Council, as amended

by the Czech technical regulation – Government Directive No. 116/2016 Coll., as

amended. The product has been designed as IM2ExhIMb equipment pursuant to

ČSN EN ISO 80079-36:2016 and ČSN EN ISO 80079-37:2016. It complies with the

conditions stipulated for use in mining environments classed as “hazardous

atmospheric conditions 2” pursuant to ČSN EN 1127-2.

2.4 The product has been designed in compliance with the requirements stipulated

by Directive 2014/34/EU of the European Parliament and of the Council, as amended

by the Czech technical regulation – Government Directive No. 116/2016 Coll., as

amended. The product has been designed as II2GExhIICT6Gb,

II2DExhIIICT85°CDb equipment pursuant to ČSN EN ISO 80079-36:2016 and

ČSN EN ISO 80079-37:2016. It complies with the conditions stipulated for use in

environments classed as „zone 1 and zone 21“, “ zone 2 and zone 22“ pursuant to

ČSN EN 1127-1.

Note: Articles 2.3 and 2.4 apply to NEXP product design.

4

3 SAFETY PRINCIPLES

3.1 SAFETY SUMMARY

Danger exists when traveling with a load, particularly when the product is not used

properly or is poorly maintained. Since an accident or serious injury could result,

special safety precautions must be observed in the course of work with the product

during its assembly, maintenance and inspection.

! WARNING

NEVER use product for transporting people.

NEVER transport loads over or near people.

NEVER lift and transport more than lifting capacity shown on the product

nameplate.

ALWAYS make sure the load carrying structure will provide the adequate support

to handle fully loaded product and all other operations.

ALWAYS let people around to know when a lift is about to begin.

ALWAYS read operation manual and safety instructions.

Remember that proper rigging, lifting and pulling techni

ques are the responsibility of

the operating staff. There

fore check all applicable national directions, regulations and

standards for further information on the safety work of your product.

3.2 SAFETY PRINCIPLES

! WARNING

3.2.1 Prior to use

ALWAYS ensure physically fit, qualified and instructed persons older than 18 years

of age, familiarized with this manual and trained in safety conditions and

way of work, operate the product.

ALWAYS check the product before daily use according to the article 8.1.2 „Daily

inspection“.

ALWAYS make sure that ends of rail girder are fitted with stop ends.

NEVER use damaged or worn out product.

NEVER use corroded, twisted or damaged hand chain.

NEVER use a product without a visible marking of lifting capacity on a nameplate.

NEVER use a product marked by the label „OUT OF OPERATION“.

ALWAYS consult with the manufacturer or his authorized representative use of the

product in non-standard or extreme environment

ALWAYS check that the product is grounded through the ground terminal when

working in an explosive atmosphere

ALWAYS wipe off any dust before handling the product in an explosive atmosphere

5

3.2.2 When in use

ALWAYS use manual power only.

ALWAYS ensure two persons operate products of lifting capacities 3,2 – 10t when

loading them with loads approaching the nominal lifting capacity.

NEVER use a product as a part for tensioning, pulling or anchoring loads.

NEVER allow swinging the load, causing impacts or vibrations.

NEVER load a product by diagonal pull.

NEVER leave a suspended load without supervision.

NEVER weld, cut or make any other operations on a suspended load.

3.2.3 After use

NEVER leave a load suspended on the product.

ALWAYS ensure the product against any incompetent use.

3.2.4 Risk analysis

The analysis of possible risks in light of design, operation and environment of the

product application is presented in freestanding document „Risk analysis“. This

document can be required in service centers.

3.2.5 Maintenance

ALWAYS enable qualified persons to inspect the product regularly.

ALWAYS ensure the sliding parts were greased enough.

Only such interventions can be done when maintaining the product that are in

compliance with requirements of the manufacturer specified in the chapters 10 and

13 of this manual.

IT IS NOT PERMITTED to carry out repairs and maintenance in other way than

specified by the manufacturer. It concerns namely the forbiddance of using of

unoriginal spare parts or carrying out modifications on the product without any

approval of the manufacturer.

4 PACKING, STORAGE AND MANIPULATION

4.1 PACKING

4.1.1 Products of lifting capacity 1t are supplied assembled, packed into paperboard

boxes. Products of lifting capacities 1,6t, 3,2t 7,5t and 10t are supplied assembled in

bulk on pallets. The hand chain is ensured against unrolling by the wire.

4.1.2 The following accompanying documentation is a part of the delivery:

a) Operation Manual

b) EC Declaration of Conformity

c) Certificates of Quality and Completeness and Guarantee Card.

c1) Guarantee period is stated in the Guarantee Card.

c2) The guarantee does not apply to defects caused by infringement of the

instructions stated in this Operation Manual and defects occurred owing

to improper use and unskilled intervention.

c3) The guarantee does not apply also to modifications on the product or

using of unoriginal spare parts without an approval of the manufacturer.

c4) A claim for defects in the product must be applied according to the

relevant provisions of the Commercial Code or the Civil Code, as

amended.

d) List of service centers (for the Czech and Slovak Republics only).

6

4.2 STORAGE

Store products in dry and clean stocks free of chemical influences and vapours.

(1) Always store a product without any suspended load.

(2) Remove from the product all dust, water or impurities.

(3) Lubricate the gear transmission and pivots of wheels.

(4) During further use follow instructions of the article 8.1.2 „Daily inspection“ or 8.1.4

„Product occasionally used“.

5 MAIN TECHNICAL PARAMETERS

5.1 DIMENSIONS

PIC. 5.1.1 PRODUCT TYP Z420, Lifting capacity 1 t

PIC. 5.1.2 PRODUCT DESIGN Z420R, Lifting capacity 1 t

7

Type

Z420

Design

Lifting

capacity

(t)

Main dimensions (mm) I – beam

( I, IPE, HEA, HEB )

a ~ h L v

d

1

r k m n b R

1)

-A

1

HEM

245 100

178

209

55

87

95

52 – 80 99 – 126 50 – 113

1000

-B 286 52 – 134 99 – 180 50 – 226

for

I

–

b max

143

-C 372 90 – 177 136 – 223

125 – 300

for

I

–

b max

143

R-A 178

177 63

52 – 80 - 50 – 113

R-B 286 52 – 134 - 50 – 226

for

I

–

b max

143

Notes: 1) R = minimal radius of the track curvature.

PIC. 5.1.3 PRODUCT TYP Z420, Lifting capacities 1,6t; 3,2t; 5t; 7,5t and 10 t

Type

Z420

Design

Lifting

capacity

(t)

Main dimensions (mm) I – beam

( I, IPE,

HEA, HEB, HEM )

a ~ h L v

d

1

r k m n b R

1)

-A

1,6 350 121,5

212

269 100 140 136

80 – 91 168 – 175 58 – 113

1700

-B 324 80 – 145 168 – 230 58 – 226

-C 396 129 – 181

214 – 266 137 – 300

-A

3,2 435 134

239

309 133 170 162

86 – 97 178 – 189 82 – 125

2500-B 340 86 – 146 178 – 238 82 – 226

-C 414 113 – 183

205 – 275 160 – 300

-A

5 505 149

275

391 148 218 227

101 – 116

199 – 214 90 – 137

2800-B 364 101 – 162

199 – 260 90 – 226

-C 436 133 – 198

231 – 296 170 – 300

7,5 685 248 415 432,5

196 300 222 150 – 186

294 – 330 125 – 185 (I) 5000

-C 518 161 – 238

301 – 382 170 – 300

10 765 278 448 503,5

228 328 256 160 – 193

306 – 339 125 – 185 (I) 9000

-C 552 185 – 245

331 – 391 180 – 300

Notes: 1) R = minimal radius of the track curvature.

8

5.2 DIVISION

Z420-A - basic design, with drive

Z420-B - longer cross beam, with drive

Z420-C - the longest cross beam, with drive

Z420R-A - basic design, without drive

Z420R-B - long cross beam, without drive

Z420R-C - the longest cross beam, without drive

Note: with drive = with chain wheel and hand chain.

5.3 MAIN TECHNICAL PARAMETERS

Type

Z420

Design

Lifting

capacity Q

(t)

Operating

force for

travel

3)

(N)

Travelling

speed

1)

(m/min)

Range of

working

temperatu

re

Basic

length of

chain

2)

(m)

Weight

(kg)

-

A

1

250 4,8

-20°C

to

+ 50°C

3

8,

7

-B 10,4

-

C

11,4

R

-

A

- - -

6

,4

R-B 7,8

-

A

1,6 150 2,25

3

2

1

-B 22,8

-

C

24

-A

3,2 280 2,3

35,9

-

B

37,8

-

C

39,5

-A

5 350 1,8

52,9

-

B

54,

7

-C 58

7,5 500 5,97

124,2

-C 128,2

10 500 7,3

179,5

-

C

187

Note:

1) Calculated on the presumption of winding off 30m of hand chain per minute.

2) Products with hand chain longer than 3m can be ordered separately.

3) At products with lifting capacities 3,2 – 10t it is necessary when loading with loads

approaching nominal lifting capacity to ensure the operation by two persons

5.4 MATERIAL AND DESIGN

5.4.1 All parts of the product are made of steel and cast iron. The bumpers are made

of rubber.

5.4.2. Materials inclinable to creation of an incendiary spark in terms of the annex No.

2 article 1.3.1 to the ministerial order No. 116/2016 of the Coll. of Laws and the

ČSN EN 1127-1 article 6.4.4, ČSN EN 1127-2 article 6.4.7 and ČSN EN ISO

80079-36 article 6.4.2.1 harmonized technical standards are not used in the

product design.

5.4.3. Materials with dangerous effects of static electricity within the meaning of the

ČSN EN 1127-1 article 6.4.7, ČSN EN 1127-2 article 6.4.7,

ČSN EN ISO 80079-36 article 6.7 and ČSN CLC/TR 60079-32-1 are not used in

the product.

9

5.4.4 The product does not exceed the noise values specified in the annex 1 article

1.7.4.2 letter u of the MO No. 176/2008 of the Coll. of Laws (EP and RE

directive No. 2006/42/EC)

Note: Articles 5.4.2 and 5.4.3 apply to NEXP product design.

5.5 DATA ON PRODUCT

Every product is fitted with label with specified data as follows:

Standard design:

N

EXP

p

roduct

d

esi

gn

:

Manufacturer’s identification Manufacturer’s identification

Address of the manufacturer

Ad

d

ress of the manufacturer

Type of product

Type of product

Lifting capacity

Lifting capacity

Serial number

Serial number

Year of production

Year of producti

on

CE marking

CE

marking

Symbol of protection type(I IM2ExhIMb for group I,

II2G

Ex

hII

C

T

6Gb,

II2

D

Ex

h

I

II

C

T

85

°C

Db

for group

II)

6 INSTALLATION OF THE PRODUCT

CHECK PRIOR TO INSTALLATION

Prior to installation, check carefully whether the product is not damaged.

The NEXP product must be installed in such a way as to prevent creeping charges.

Charging mechanisms stronger than manual friction must be avoided at the

installation site.

A NEXP product when used in a mine or other environment where the product could

collide with falling, flying… objects (rock, stones…) must be protected to minimize the

likelihood of a collision (sufficiently dimensioned cover, …).

6.1 LOAD CARRYING STRUCTURE

Travelling (crane) track and related load carrying structure (parts of buildings, etc.),

destined for the product operation must be documented by the drawing and stress

analysis.

! WARNING

ALWAYS make sure the travelling track and related load carrying structure are

firm enough to support the weight of the load and product. The installation shall not

be carried out onto the structure, where the carrying capacity cannot be verified.

ALWAYS make sure the travelling track is plane.

ALWAYS make sure the ends of the travelling track are equipped with firm stop

blocks.

ALWAYS the user is responsible for the load carrying structure!

6.2 TRAVELLING (CRANE) TRACK

! CAUTION

Products can be installed onto girders with the angle of the lower flange up to 20% or

with a flat flange. The range of lower flange width (b) and minimum radius of the

travelling track curvature (R) for particular lifting capacities are mentioned in the

article 5.1 DIMENSIONS.

10

! WARNING

The permitted maximum deflection of the travelling track caused by loading by the

actual weight and nominal lifting capacity is 1/500 of distance between suspensions

(supports).

The permitted maximum gradient of traveled surface is 0,3%.

The maximum height of the travelling track above the floor is 20m. Any application on

higher travelling tracks is necessary to be consulted with the manufacturer.

6.3 ASSEMBLY OF THE PRODUCT

! CAUTION

Prior to installation of the product, inspect it carefully for the possible damage.

Only qualified persons can perform assembly of the product.

Be careful during assembly of the product to the travelling track and ensure

appropriate conditions for assembly according to the environment character, to avoid

endanger or injury of people. Use safety equipment when assembling the product in

heights to avoid falls from height.

The user is responsible for creating conditions for installation and performing

the installation.

6.3.1 Condition for the correct travel of the product

A) The tolerance (x) between tyres of the travelling

wheels and flange of beam shall be

approximately 2 mm. For curved tracks it is

necessary to increase the tolerance appropriately.

B) The suspension shackle must be in the centre of

the beam.

C) Place coupling screws (at lifting capacities 1,6 –

10t) into openings in side plates, so that the

condition of tolerance between screw and lower

flange of the beam was 3 - 6mm.

6.3.2 Assembly of lifting capacity 1 t

1) Dismantle the side plates of the product.

2) Put on the bottom flange of the I – beam the side plate with geared travelling

wheels and hand chain wheel. (At type Z420R you can put on any side plate).

3) Put the cross beam to the bushing of the side plate and secure by the cotter

pin.

4) Put on the cross beam the relevant number of distance washers, so that the

suspension shackle was in the axe of the beam and the condition for the

correct function according to the article 6.3.1 was fulfilled.

5) Put the same number and the same size of distance washers on the other

side of the suspension shackle.

6) Place the other side plate on the cross beam and all the remaining washers

and secure by the cotter pin.

7) Stretch the ends of both cotter pins so that they cannot fall out.

8) Straighten the hand chain.

3-6mm

xx

11

6.3.3 Assembly of lifting capacities 1,6 t; 3,2 t; 5 t; 7,5t and 10t

1) Dismantle the side plate of the product (on side free of gear travel wheels and

hand chain wheel) as follows:

- dismantle outer nuts of the distance bolts and take out split washers,

- dismantle the split pin of the cross beam,

- remove the side plate,

- take out the distance washers and shackle from the cross beam.

2) By the help of distance washers set the side plate on the cross beam so that the

shackle was in the axe of beam and the condition for the correct function was

fulfilled according to 6.3.1.

3) The same number and the same size of distance washers put on the opposite

side of the shackle.

4) Hang up the side plate with the cross beam on the beam and put the other side

plate on the cross beam and on the distance bolts.

5) Set on the remaining distance washers onto the cross beam and secure by the

cotter pin.

6) Put spring washers on the distance bolts and screw on the nuts. Tighten up

properly all nuts of distance bolts.

7) Stretch the ends of both cotter pins so that they cannot fall out.

8) Straighten the hand chain.

9) For the assembly of the products of the lifting capacities 7,5 and 10t use an

appropriate load carrying structure (auxiliary lifting device, etc.).

6.3.4 SETTING OF THE HAND CHAIN

After the installation of the product in the workplace we

check the position of the hand chain. The distance of the

end of bottom loop of the hand chain over the level of the

surface, on which the operation staff stands during the

operation, must be in the range of 500 –1000mm. Products

are supplied with hand chains, the length of which is

proportional to the lift height of the chain block or lifting

device used for suspending on the product, and which

during the standard installation meet condition of correct

setting of the chain end.

In other cases, where regarding the way of use of the chain

block, the length of the hand chain does not meet specified

conditions, the chain must be shortened or lengthened.

Shortening of the chain: we disconnect the chain in place

of the coupling link by buckling free ends of the links. We

shorten the chain by required length and connect again by

coupling link. Free ends of the coupling link we bend to one

another.

Lengthening of the chain: we disconnect the chain in place

of the coupling link by buckling free ends of the links. We

attach other part of chain of required length by means of

two coupling links. Free ends of coupling links we bend to

one another.

The coupling links and hand chain of required length can

be bought as spare parts.

Note: the requirement for control chains of other length

than standard one can be made just in the order.

12

6.4 TEST PRIOR TO USE

! CAUTION

1) Inspect visually load bearing structure, whether it is without defects.

2) First look again through the previous articles of this manual and make sure all

steps were correctly done and all parts are safely assembled.

3) Check especially, whether the cotter pins on both sides of the cross beam are

properly secured against falling out.

4) By pulling the hand chain of the product (or by the move of the product at the type

Z420R) check the travel on the travelling track.

7 OPERATION

7.1 APPLICATION OF THE PRODUCT

The product has been designed entirely for the horizontal travel on flanges of I-

beams under normal atmospheric conditions in the workplace and in environments

with an explosion risk as well, if there is a symbol of the protection type on the label –

see articles 2.3 and 2.4 of this operation manual. The product is destined for

suspension of the chain block or other lifting equipment always of the appropriate

lifting capacity manufactured by the BRANO. When suspending the lifting device of

other manufacturer the upper hook shall correspond to the opening in the suspension

shackle of the product.

Consult with the manufacturer other application of the product.

The type Z420 is with travel drive by means of the hand chain and makes possible

moving loads in the working area of the travelling track.

The type Z420R is destined for travel by the application of a direct force on the

product. The travel of the product is possible as well by the application of a force on

the load (when observing the safety principles specified in the chapter 3 and in the

article 7.2), whereas the operating staff pushes the load – we do not recommend to

pull the load.

It is destined for organizations and private persons as well.

When installing in outside room protect the product against direct climatic influences

(shelter).

Since handling with heavy loads may involve unexpected danger, all the „Safety

instructions“ according to the chapter 3 must be followed.

! WARNING

NEVER suspend a lifting device of a greater lifting capacity than the nominal

lifting capacity of the product.

NEVER suspend a lifting device, the hook of which does not go freely through the

opening in the suspension shackle.

7.2 SAFE WORKING ENVIRONMENT

! WARNING

(1) The operating staff must be demonstrably familiarized with this operation manual,

must observe applicable safety and hygienic regulations and must be qualified for

operation of this equipment.

(2) The operating staff must be equipped with helmet and gloves when operating the

product.

13

(3) When more persons take a part in the operation, always one person must be

designated, trained in safety work, that is responsible for handling with the

product.

(4) He must have a clear and unobstructed view of the whole working area still before

starting the work. If it is not possible, one or more persons must help him to

supervise in the nearby area of the product.

(5) The operating staff must check the entire work place is safe and whether there is

a possibility of escaping in case of endanger before starting to operate the

product.

(6) For travel of the product the sufficient space for the operating staff shall be

ensured.

(7) When operating the product the adequate distance of the operating staff from the

suspended load must be kept. It is forbidden to transport bulky loads not allowing

keeping the sufficient distance.

8 INSPECTION OF THE PRODUCT

8.1 INSPECTION

8.1.1 Inspection classifications

(1) Initial inspection: precedes first use. All new or repaired products shall be

inspected by a responsible qualified person to ensure the qualified fulfillment of

requirements of this operation manual.

(2) Inspections of products operated regularly are generally divided into two

classifications based on the intervals at which should be performed. The intervals

depend on the condition of the critical components of the product and the degree of

the wear, deterioration or malfunction. The two general classifications are here

classed as daily and regular ones. The respective intervals are defined as follows:

(a) Daily inspection: visual inspection carried out by the operating staff designated

by the user at the beginning of each application.

(b) Regular inspection: visual inspection carried out by the qualified person

designated by the user.

1) normal operation – once per year

2) heavy operation – twice per year

3) special or infrequent operation – according to the recommendation of the qualified

person at first usage and according to the directions of the qualified employees

(maintenance workers).

8.1.2 Daily inspection

Regarding parts such as those recommended in section 8.1.6(1) „Daily inspection“

verify whether the products are without any defect. Provide this inspection also

during operation in the intervals between regular inspections. Qualified employees

will determine whether any defect or damage can constitute a hazard or whether

more detailed inspection is necessary.

8.1.3 Regular inspection

Complete inspections of the product perform as recommended regular inspections.

These inspections may be performed with the product in its normal location and do

not require dismantling of the product. Recommended regular inspection specified in

the section 8.1.6 (2) shall be performed under the supervision of qualified persons

that will determine, whether the complete disassembly of the product is necessary.

These inspections shall include the requirements of the daily inspection as well.

14

8.1.4 The product occasionally used

(1) The product, which has been idle for a period of one month or longer but less

than one year, remit to the inspection conforming to the requirements of the section

8.1.2 before follow-up putting it into operation.

(2) The product, which has been idle for a period of one year, remit to the inspection

conforming to the requirements of the section 8.1.3 before follow-up putting it into

operation.

8.1.5 Inspection record

Always keep the record of the performed tests, repairs, inspections and maintenance

of products. Dated inspection records perform in time intervals specified in the

section 8.1.1 (2) (b) and such records store in an accessible place designated by the

user. Defects found by the inspection or recorded during the operation must be

announced to the person responsible for safety and designated by the user.

8.1.6 Inspection procedure

(1) Daily inspection (carried out by the operating staff or qualified person)

PART INSPECTION

METHOD

LIMIT/CRITERIA

FOR DISCARD

REMEDY

1. Function of the

product

Visual, hearing Excessive operating

force.

Travel goes hard.

Clean and lubricate

the gear transmission

of the travel, lubricate

pins of the travel

wheels

2. Fastening parts Visual check of cotter

pins and nuts.

Damaged cotter pins.

Insufficiently ensuring

against falling out.

Cotter pins

replacement.

Proper stretching of

ends of cotter pins

Tightening nuts

2. Hand chain

Visual

Chain is kinked or

twisted.

Chain is deformed or

damaged and does not

enter the chain wheel

correctly.

Straight up the chain

and set it to the

normal position.

Replacement of the

chain.

3. Side plate of the

product

Visual Visible deformation of

the side plate.

Replacement of the

side plate.

(2) Regular inspection (carried out by qualified person)

PART INSPECTION

METHOD

LIMIT/CRITERIA

FOR DISCARD

REMEDY

1. Fastening parts

Visual check of

cotter pins and nuts.

Defective cotter pins,

inadequate ensured

against dropping out.

Exchange of cotter

pins, proper

stretching of cotter

pin ends.

Tightening the nuts.

2. All parts Visual check Worn or damage

parts.

Fouled and non

lubricated parts.

Replace by new

ones.

Dismantle, clean up,

lubricate and

assemble again.

15

3. Name plate – lifting

capacity marking

Visual check Lifting capacity is

illegible.

Repair or replace with

the new one.

Point up the lifting

capacity.

4. Deformation of side

plate

Visual check

Visible deformation of

parallelism of the side

plates.

Repair or replace

5. Deformation and

wear of the crossbeam

and suspension

shackle

Visual check or

check by the help of

the slide caliper.

Bent or worn out

cross beam or

suspension shackle

by more than 10%.

Product revision.

Replacement of the

cross beam or the

suspension shackle.

Putting out of

operation.

9 LUBRICATION

9.1 GENERALLY

Before the application of the new lubricant, remove the old one, clean parts by the

solvent and put the new lubricant. Use grease: Universal lithium plastic lubricant,

water resistant, usable in a minimum range of working temperatures from -20°C to

+50°C. For example A2, LV2EP.

! WARNING

All lubricants (grease, oil) used in the NEXP version must have an ignition

temperature higher than 135°C. E.g. LV2EP, Optitemp LG2….

9.2 GEARINGS OF THE PRODUCT

Remove the old lubricant from the gear transmission of the product and replace by a

new one.

10 MAINTENANCE

10.1 SAFETY PRINCIPLES

! WARNING

Only qualified persons (service organizations) trained in safety and

maintenance of these products can carry out maintenance, specialized

inspections and tests.

ALWAYS use entirely parts supplied by the manufacturer.

It is not permitted to perform repairs and maintenance in other way than specified by

the manufacturer. It concerns especially the forbiddance of using of unoriginal parts

or performing modifications on the product without any approval of the manufacturer.

ALWAYS check the function of the product after performing maintenance.

ALWAYS mark the defective product or product under repair by an appropriate

sign (e.g.: „OUT OF OPERATION“).

NEVER carry out maintenance when a load is suspended on the product.

NEVER use product, which is under repair!

ALWAYS when repairing the paint, it is necessary to observe the total thickness

of the paint layer maximum 0,2 mm (original + new paint, or after cleaning the

surface new paint, applies to NEXP product design).

16

10.2 BEARINGS

Sliding bearings (KU bushings) are used in the product. The theoretical service life of

bearings is several times higher than the theoretical service life of the product.

Therefore, they do not require any special maintenance except for cleaning (all) and

lubrication (except for roller bearings with a cover) during the regular inspection

interval, see 8.1. In the event that the bearing is damaged during disassembly,

assembly or due to dirt (sand, rock, dust ...) entering the working space of the

bearing, the bearing must be replaced immediately.

10.3 GENERAL INSTRUCTIONS

The following instructions give general important information on dismantling,

inspection, repair and assembly. If the product was dismantled from any reason,

proceed according to the following directions.

1. Carry out the maintenance in a clean environment.

2. NEVER dismantle product more than necessary to perform the needful repair.

3. NEVER use excessive power during dismantling of parts.

4. NEVER use heat as a means during dismantling parts, when parts are

determined for further use.

5. Keep the workplace clean and free of foreign compounds that could come to

bearings or other moving parts.

6. If the part is clamped in a vice, always use suitable inserts to protect the surface

of the parts.

10.4 CHECK

Check all dismantled parts, whether they are suitable for further use.

1. Check all gearings including the shaft, whether they are not worn out and have no

scratches or cracks.

2. Check, whether the side plates are not deformed.

3. Check, whether the cross beam and suspension shackle are not worn out or

damaged.

4. Check, whether the travelling wheels rotate free.

10.5 REPAIR

Worn out or damaged parts shall be replaced. Small burrs and scratches or other

small surface defects remove and smooth by the fine abrasive stone or an abrasive

cloth.

10.6 TEST

The loading test with load exceeding the lifting capacity by 50% shall be done at all

repaired products by a qualified person to verifying the product function.

11 PUTTING OUT OF OPERATION – DISPOSAL

Product does not contain any harmful substances; its parts are made of steel and

cast iron. After putting it out of operation, hand over it to a firm dealing with disposal

of the waste metal.

17

12 RELATED DOCUMENTATION

of Law as amended

12.1 EC declaration of conformity

12.2 This Operation Manual was elaborated in accordance with the following

technical regulations, technical standards and national regulations:

•Ministerial order No.176/2008 of the Coll. of Law as amended (EP and Council

directive 2006/42/EC)

•Ministerial order No.116/2016 of the Coll. of Laws as amended (EP and Council

directive 2014/34/EU)

•ČSN EN ISO 12100

•ČSN EN 13157+A1

•ČSN EN 1127 - 1

•ČSN EN 1127 - 2

•ČSN EN ISO 80079-36

•ČSN EN ISO 80079-37

•Regulation of CBM (Czech Bureau of Mine) No.22/89 of the Coll. of Laws

•ČSN CLC/TR 60079-32-1.

13 FINAL REQUIREMENTS OF THE MANUFACTURER TO

THE CUSTOMER

Any changes of the product, eventually usage of unoriginal spare parts can be

implemented only based on the approval of the manufacturer.

When not observing this condition the producer does not guarantee safety of

his product. In this case, any manufacturer’s guarantees do not apply to the

product.

This manual suits for next models

2

Table of contents

Other Brano Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

LOVATO ELECTRIC

LOVATO ELECTRIC EXS1032 instruction manual

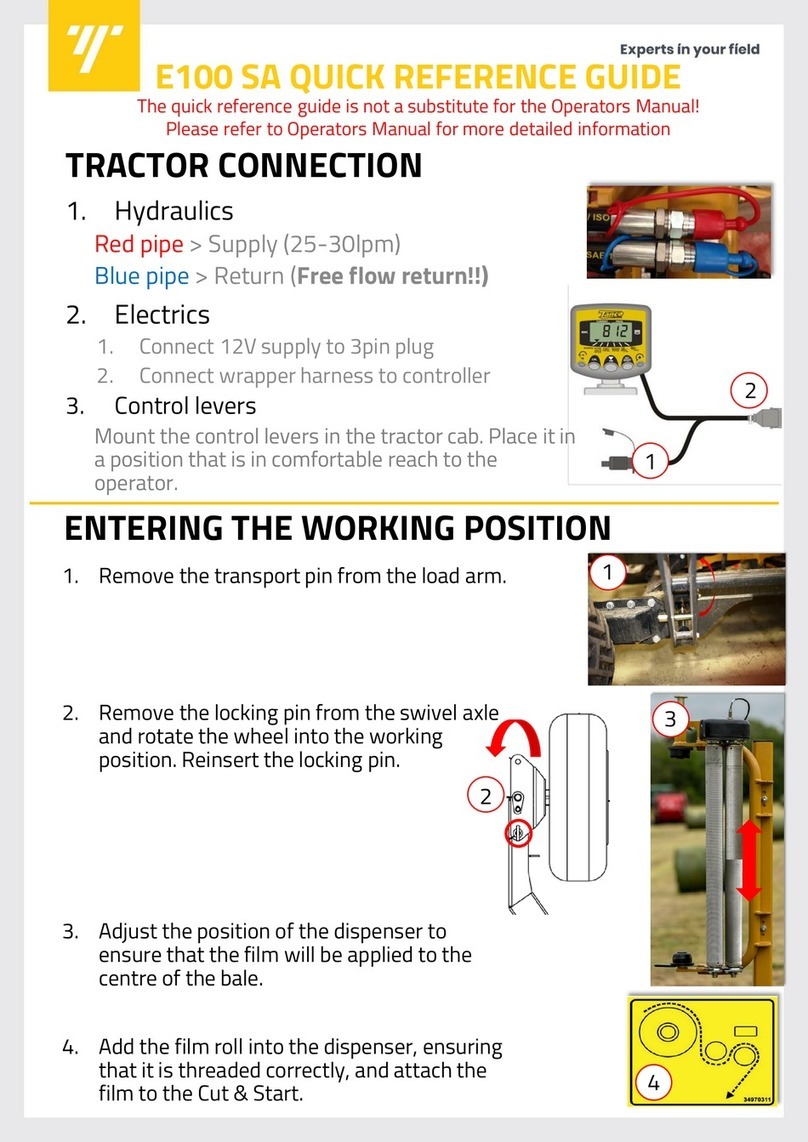

Tanco

Tanco E100 SA Quick reference guide

Siemens

Siemens MOTOX BA 2010 operating instructions

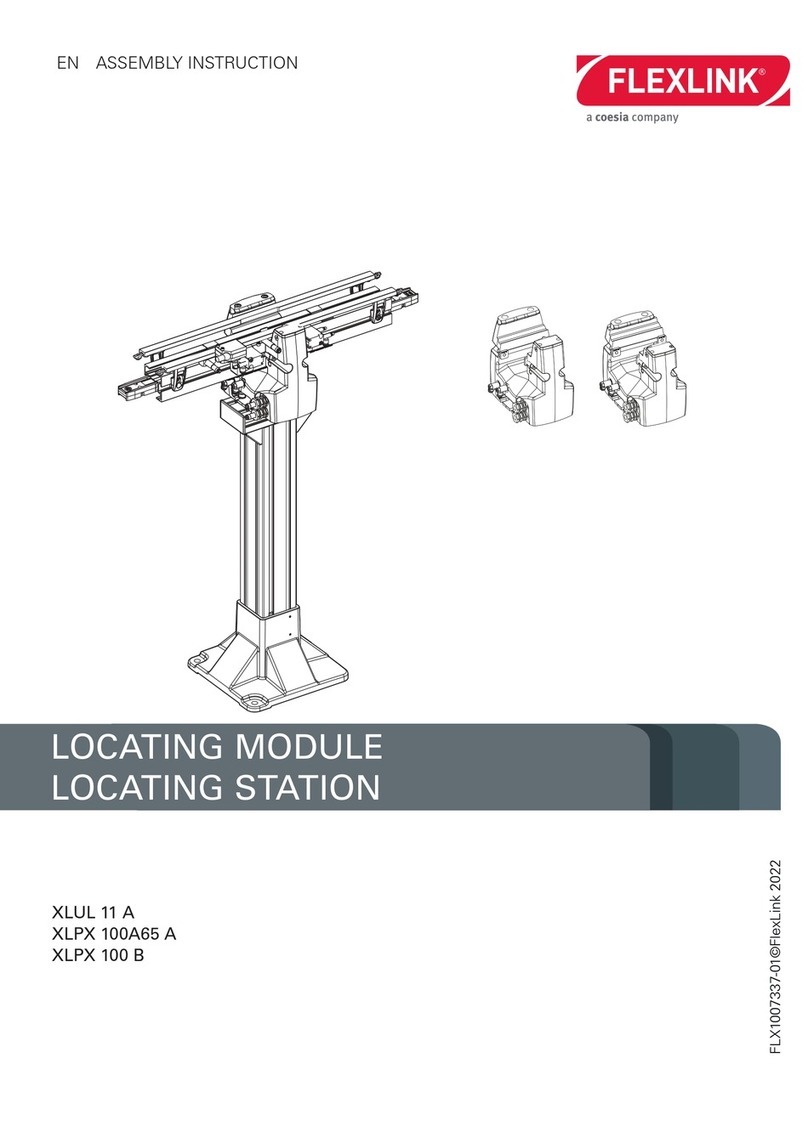

coesia

coesia FLEXLINK XLUL 11 A Assembly instruction

Siemens

Siemens Compact PLUS 6SE7024-1EP85-0AA0 operating instructions

Software Bisque

Software Bisque Paramount ME II manual