WD1500 G3

No. DANSK. DEUTSCH. ENGLISH. FRANÇAIS.

140 Skrue Schraube Screw Vis

206 Split Splint Split pin Goupille

828 Fitting Fitting Fitting Raccord

1144 Skrue Rietstockschraube Pointed screw Vis pointue

1208 Trykfjeder Feder Spring Ressort

1314 Skive Scheibe Washer Rondelle

1324 Spændstift Spannstift Elastic pin Goupille de serrage

1421 Skrue Schraube Screw Vis

1540 Fitting Fitting Fitting Raccord

1711 Oliebremse Senkbremse Oil valve Frein d`huile

2067BL Hjul Rad Wheel Roue

2185 Fitting Fitting Fitting Raccord

2641 Møtrik Mutter Nut Ecrou

2802 Møtrik Mutter Nut Ecrou

2934 Bolt Bolzen Bolt Boulon

3036 Fjedersplit Splint Split pin Goupille

3046 Låsemøtrik Mutter Nut Ecrou

3064 Skrue Schraube Screw Vis

3076BL Plastprop Kunststoffverschluß Cap Bouchon

3192 Skrue Schraube Screw Vis

3384 Låsering Seegerring Lock ring Circlips

3402 Pumpe, komplet Pumpe, komplett Pump, complete Pompe, complète

3440 Kugle/håndtag Kugel Ball Bille

3441 Håndtag Handgriff Handle Manche

3443 Skrue Schraube Screw Vis

3444 Skrue Schraube Screw Vis

3446 Rulle Rolle Roller Poulie

3453 Aksel Achse Shaft Axe

3454 Bøsning Buchse Bushing Manchon

3456 Stop f. cylinder Halt Stop Arrêt

3457 Trykrør Druckrohr Pressure pipe Tuyau de refoulment

3458A Tårn, teleskop Zwinger, teleskop Tower, telescope Chateau, télescope

3459 Støtterør, komplet Stürtz Rohr, komplett Supporting pipe, compl. Support de Tuyau, compl.

3460 Rulleophæng, komplet Chassis, komplett Chassis, complete Châssis, complète

3461A Tårn Zwinger Tower Chateau

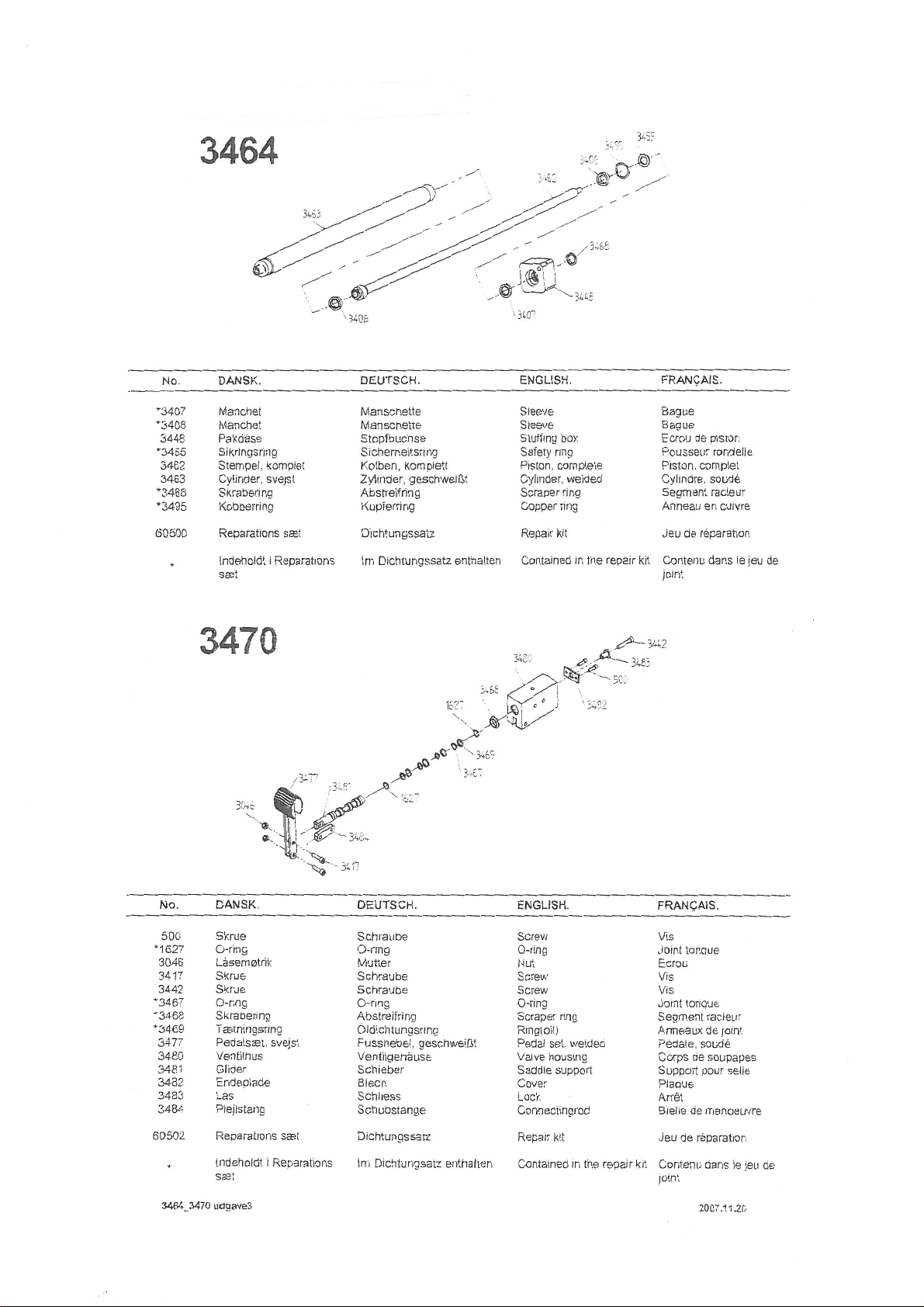

3464 Cylinder, komplet Zylinder, komplett Cylinder, complete Cylindre, complète

3470 Omskiftventil, komplet Ventil, komplett Valve, complete Soupape, complète

3471 Trykrør, komplet Druckrohr, komplett Pressure pipe, complete Tuyau de refoulment, co.

3472 Trykrør Druckrohr Pressure pipe Tuyau de refoulment

3473 Pumpearm, komplet Pumpenarm, komplett Fulcrum arm, complete Levier de pompage, com.

3474 Trykrør Druckrohr Pressure pipe Tuyau de refoulment

3475 Trykrør Druckrohr Pressure pipe Tuyau de refoulment

3485 Hus f. Lås Gehäuse Housing Corps

3486 Låsetap Zapfen Pin Cliquet de àrrêt

3487 Knop f. Lås Handgriff Handle Manche

3488 Skærm Blech Sheet Plaque

3489 Hus f. bremse Gehäuse Housing Corps

3492 Skrue Schraube Screw Vis

3496 Hjul m. bremse, komplet Rad mit bremsen, komplett Wheel w. breakes, compl. Frain pour roue, complète

3497 Hjul, komplet Rad, komplett Wheel, complete Roue, complète

0AL006 Skilt Abseichen Badge Insigne

0CC028 Nagle Bolzen Shaft Rivet