Envirotecnics Spill Buddy 3014 User manual

Spill Buddy

Product Recovery System

Operator’s Manual

PN 3014

Teléfono de soporte técnico

Tel: 872 080 542

REVISIONS

REV

DESCRIPTION

INITIALS

DATE

Initial Release

DFB

2/26/14

Envirotecnics Tel: +34 872 080 542 envirotecnics@envirotecnics.com www.envirotecnics.com

i

Spill Buddy Limited Warranty

All references to the customer herein shall mean the Purchaser or the Lessee as

applicable. CLEAN EARTH TECHNOLOGY, INC. (CET) warrants the Spill

Buddy to be free of substantial defects in material and workmanship for one year

from the date of shipment. Pumps are warrantied for 90 days. CET’s sole

responsibility under this warranty shall be to either repair or replace, at its option,

any component which fails during the applicable warranty period because of

defect in workmanship or material. No other liabilities shall be assumed by the

manufacturer or its agents, nor are they expressed or implied.

This warranty is contingent upon proper use of the Spill Buddy by the Customer

in accordance with CET’s published specifications. This warranty shall not be

valid if the alleged defect is the result of abuse, misuse, accident, alteration,

neglect, unauthorized repair, or acts of nature. Any repair shall be deemed

unauthorized unless it is made by CET or with the written consent of CET. This

warranty is the sole warranty made by CET to the Customer and is in lieu of all

other warranties or obligations, expressed or implied.

System upgrades will be made available to customers as they are completed.

Clean Earth Technology, Inc. is not obligated to provide those upgrades without

cost.

WARNING: In the event that equipment is returned to the factory for

any reason, a complete decontamination must be done before

shipment. See page 27 of this manual for the decontamination

procedure. Shipping hazardous materials improperly may be a

Federal offense.

WARNING: Unauthorized user modifications or application beyond

the published specifications may result in electrical shock hazards or

improper operation. Clean Earth Technology, Inc. will not be

responsible for any injuries sustained due to unauthorized equipment

modifications.

Envirotecnics Tel: +34 872 080 542 envirotecnics@envirotecnics.com www.envirotecnics.com

ii

Restrictions and Liabilities

Information in this document is subject to change and does not represent a commitment by

Clean Earth Technology, Inc. Changes made to the information in this document will be

incorporated in new editions of the publication. No responsibility is assumed by Clean Earth

Technology, Inc. for the use or reliability of software or equipment that is not supplied by Clean

Earth Technology, Inc. or by its affiliated dealers.

Safety Considerations

Use of this instrument is restricted to qualified personnel who recognize shock hazards and are

familiar with safety precautions used when operating electrical equipment. Read the manual

carefully before operating the Spill Buddy.

The following warnings and informational symbols may be found on the Spill Buddy and/or in

this manual:

Symbol

Description

Caution: Risk of electric shock

Direct / Alternating Current

Direct Current

Alternating Current

Protective Earth (ground)

Warning: Refer to accompanying documentation

Off (Power: disconnection from Mains)

On (Power: Connection to Mains)

Envirotecnics Tel: +34 872 080 542 envirotecnics@envirotecnics.com www.envirotecnics.com

iii

Hazard Warnings

Warning! Explosive Vapors. The Spill Buddy is not an explosion proof device.

Its use within a classified area requires monitoring of the work site to insure

explosive vapors are not present. The probe is designed to operate in an

explosive atmosphere, i.e. a recovery well. The reel body and recovery container

should be positioned outside of any classified hazardous area. CET

recommends maintaining a distance of three (3) feet or greater from the wellhead

during use.

Warning! Never leave the Spill Buddy operating unattended during recovery

events. This devise is not intended to for use without an operator present.

Warning! Risk of Grounding Arc! This device is designed to dissipate

potential static charge through its base grounding plate. Never operate this

device while it is not in contact with the ground. Portable product containers

must also be set on the ground with the discharge tube clamp connected to the

container. The clamp is electrically connected to the reel assembly.

Warning! Insure the Pump Flooding Procedure has been performed prior to

use, see page __.

Warning! Chemical Incompatibility. Do not use this device to pump any

Halogenated Hydrocarbon (HHC) solvent containing the following elements:

(Examples are not all inclusive)

Flourine (f) “-flour-“i.e. Dichloroflouromethane, Trichlorofiouromethane

Bromine (Br) “-bromo-“i.e. Methyl bromine, Ethylene dibromide

Chlorine (Cl) “-chloro-“i.e. Perchloroethylene, Trichloroehtane, Dichloromethane

Iodine (I) “-iodi-“i.e. N-butyl Iodide, Methyl Iodide

Failure to heed this warning may result in severe system damage, personnel injury,

and/or site damage.

CET recommends that any chemicals of concern (COC) be disclosed at the time of

quote requests and when a system is moved from its original site to another COC site.

Precautions

The following precautions are provided to help you avoid damaging the system:

Caution: Service. Only authorized service personnel should service the Spill Buddy.

Only qualified technical personnel should perform troubleshooting and service

procedures on internal components. Call the factory at 802-425-3710 if you believe

the Spill Buddy requires servicing beyond normal maintenance procedures.

Caution: Site Security. Access to the site and to the Spill Buddy must be controlled

at all times. The equipment is specialized and must only be operated by qualified

and trained personnel. Clean Earth Technology does not warranty damage to

Envirotecnics Tel: +34 872 080 542 envirotecnics@envirotecnics.com www.envirotecnics.com

iv

equipment due to vandalism or negligence.

Caution: Regular Maintenance. The down-well probe and pump should be regularly

inspected and maintained, as detailed in Chapter 2, page 13.The frequency of

maintenance will depend on your site conditions. Failure to provide regular

maintenance will damage your Spill Buddy and may result in unsafe operating

conditions. Clean Earth Technology is not responsible for damage to equipment or

injury to personnel resulting from improper maintenance practices.

Clean Earth Technology, Inc.

Environmental Equipment Return Policy

This policy refers to ANY EQUIPMENT OR PARTS being returned to Clean Earth Technology,

Inc. (CET), whether:

Customer owned, leased, or rented.

In warranty or out of warranty

NO equipment or parts should be shipped to CET without first contacting our service

department for a Return Material Authorization number (RMA). Contact our service department

at (802) 425-3710 to be assigned an RMA number.

CET reserves the right to refuse delivery of any equipment without a CET RMA number

clearly displayed on the exterior of the package(s).

CET reserves the right to refuse delivery of any equipment improperly decontaminated.

CET reserves the right to add a fee of $500.00 to the repair invoice of any equipment or

parts not decontaminated to the satisfaction of CET.

The policy below applies to both equipment sales and repair orders. For a Return

Material Authorization number, please call our Service Department. (802) 425-3710

Envirotecnics Tel: +34 872 080 542 envirotecnics@envirotecnics.com www.envirotecnics.com

v

Environmental Equipment Return Guidelines

All equipment must be thoroughly cleaned, purged of product and decontaminated prior

to shipment to CET. NOTE: CET recommends the use of Personal Protective

Equipment, level C or D, as defined in OSHA 29 CFR 1910.120.

CAREFULLY FOLLOW THE EQUIPMENT DECONTAMINATION PROCEDURES

FOUND ON PAGE 27 OF THIS MANUAL

Any equipment or parts shipped to CET must include the following documentation:

CET RMA/Repair Order form completed by customer. An “RMA number/REPAIR ORDER” form

to copy is found on page 31.

Description/name of product pumped.

Reason for return.

The CET RMA number clearly marked on the outside of ALL packages and paperwork.

All items being returned (including all warranty-claim shipments) must be sent freight prepaid to

our factory location:

Clean Earth Technology, Inc.

445 Long Point Road

N. Ferrisburgh, VT. 05473

When you ship an item to CET, we recommend using UPS, FedEx, or another reputable

shipper. We also recommend that you insure your shipment for its actual replacement cost.

Clean Earth Technology will not be responsible for lost shipments or instruments that are

received in damaged condition due to improper packaging or handling.

Use the original carton and packaging material for shipment. If they are not available, we

recommend the following guide for repackaging:

Use a double walled carton of sufficient strength for the weight being shipped.

Use sufficient industry approved, shock-absorbent packing material to protect all

surfaces and projecting parts. The items packed should not be able to slide or shift their

position within the box.

Envirotecnics Tel: +34 872 080 542 envirotecnics@envirotecnics.com www.envirotecnics.com

CONTENTS

Spill Buddy Limited Warranty .................................................................................................. i

Restrictions and Liabilities...................................................................................................... ii

Safety Considerations .............................................................................................................ii

Hazard Warnings....................................................................................................................iii

Precautions............................................................................................................................iii

Environmental Equipment Return Policy...............................................................................iv

Environmental Equipment Return Guidelines ..........................................................................v

Product Introduction................................................................................................................ 1

Intrinsic Safety 101................................................................................................................. 5

Flammability and Combustible Liquids Definitions 101.................................................... 5

Chapter 1- System Operation.................................................................................................. 7

Pump Flooding Procedure...................................................................................................... 8

Using the Spill Buddy to Pump LNAPLS (Floaters)................................................................. 9

Using the Spill Buddy to Pump DNAPLS (Sinkers)................................................................11

Chapter 2- Maintenance Operations......................................................................................13

Removing Moisture from the Pump .......................................................................................13

Field Shutdown Procedure ....................................................................................................14

Shop Cleaning Procedure......................................................................................................14

Cleaning the Probe................................................................................................................14

How To Remove the Pump....................................................................................................16

Pump Maintenance................................................................................................................18

How to Install/Reinstall the Pump..........................................................................................19

Battery Maintenance and Charging .......................................................................................20

Chapter 3- Troubleshooting...................................................................................................23

Chapter 4- System Specifications..........................................................................................25

Chapter 5- Equipment Decontamination Procedures...........................................................27

Chapter 6- Equipment Return Policy.....................................................................................29

Return Materials Authorization Form ....................................................................................31

Envirotecnics Tel: +34 872 080 542 envirotecnics@envirotecnics.com www.envirotecnics.com

1

Product Introduction

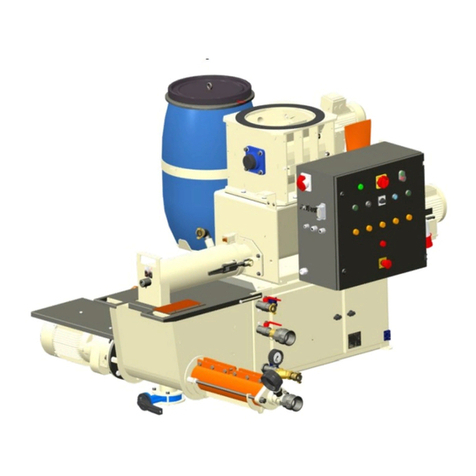

The Spill Buddy is a compact, manually

operated product skimming tool based on

proven Spill Buster technology. The Spill

Buddy is designed to be operated on site to

determine the location of the product/water

interface and skim small quantities of product

or water from recovery wells as small as 2” in

diameter.

The Spill Buddy is designed to effectively

pump products (both LNAPLs and DNAPLs)

with viscosities up to about 10-12 centipoise.

The Spill Buddy consists of a reel outfitted

with a down-well probe that is manually

lowered and raised by the operator. The

down-well probe comes in two lengths: 50 ft. and 100 ft. The Probe is connected inside the reel

to 10 ft. of Product Discharge Tubing with a combination valve and support clamp/ground,

located at the rear of the reel which can be attached to various types of recovered product

containers.

The 1.93” diameter Probe contains the patented ALPHA ARRAY™

interface sensors, as well as a small but powerful 12vdc electric

product pump. An audible feedback enables the user to keep the

pump positioned in the product layer, resulting in product skimming

without also pumping water.

The rugged, lightweight, and convenient Spill Buddy can

skim up to 0.7 gallons of product per minute. Spill Buddy

also has a self-contained, rechargeable battery for the

sensor electronics and pump. The battery is rechargeable

from a 12 VDC source. A wall transformer is provided

with the unit; or an optional cigarette lighter adapter may

be purchased that enables the Spill Buddy to be charged

by a vehicle, as well as an optional battery cable to

charge directly from your vehicle’s battery. Spill Buddy

can operate for up to one hour of continuous pumping

(approx. 40 gallons) per charge, depending on the

viscosity of the product being pumped.

“Exploded” view of the Probe showing

the pump, filter, spring and end cap

Envirotecnics Tel: +34 872 080 542 envirotecnics@envirotecnics.com www.envirotecnics.com

2

NOTE: For maximum performance, allow the Spill Buddy’s battery to charge

overnight before use.

Alpha Array Sensor Band Location

There is an array of sensor bands, internal to

the probe, including one dispensing a high

limit signal. The sensor usesa low

frequency, omni-directional signal to sense

the product/water interface. The sensor

operateson the principle that signal

transmission varies significantly due to the

transmission characteristics of the type of

fluid surrounding the antenna. The variation

in signal transmission is used to accurately

determine the interface location relative to the product inlet. The sensor is constructed of “state

of the art” polymer materials for corrosion resistance and long life.

The Front Panel of the Reel includes the System Power ON/OFF switch, the Pump ON push

button switch (momentary), the pump ON toggle switch (constant) and the Battery Charging

Jack.

Battery Access

Cover

Recharging Jack

Winding Knob

Pump Push Button

Switch (momentary)

Pump Toggle Switch

(constant)

System Power Switch

Spill Buddy Front Panel

`

ALPHA ARRAY™

SENSOR BAND AREA

Envirotecnics Tel: +34 872 080 542 envirotecnics@envirotecnics.com www.envirotecnics.com

3

Discharge

Tubing

Discharge Valve

and Spring Clamp/ Grounding

Assembly

Spill Buddy- Back View

Operator Safety

The National Electric Codes (NEC) does not certify portable electrical systems such as the Spill

Buddy. However, Clean Earth Technology has used the NEC as a guideline for the Spill

Buddy’s design, developing the operating instructions, and in our definitions of classified areas.

Please note that what we have written here is not meant to supersede anything that may be

written in detail in the NEC codes or applicable local codes. It is your responsibility and the

responsibility of the Authority Having Jurisdiction to study and follow these codes.

The Spill Buddy’s probe is designed to operate in a recovery well, which is a Class 1, Div 1

area, whereas the reel itself is not rated for use in a classified area. Therefore, it is important to

understand and follow the instructions in this manual for using the Spill Buddy in a manner

consistent with safe practices. Make certain that you have read the Hazard Warnings section

on page iii, as well as other notes and warnings written throughout the manual and the safety

labels located on the Spill Buddy itself.

Since this is such an important topic, in the next section we will present a few basics to help you

or your customers understand the meaning of the various terms defining safe use when

operating our equipment.

Envirotecnics Tel: +34 872 080 542 envirotecnics@envirotecnics.com www.envirotecnics.com

5

Intrinsic Safety 101

Intrinsic safety (IS) is a protection technique for safe operation of electrical equipment in

hazardous areas by limiting the energy available for ignition of explosive well gases. The

concept of (IS) circuits was originally driven by some devastating coal mine explosions in

Europe due to “firedamp” gases being ignited by “electrical shorts” in the wiring of early

communication devices such as the electric telegraph.

In signal and control circuits that can operate with low currents and voltages, the intrinsic safety

approach simplifies circuits and reduces installation costs over other protection methods. High-

power circuits such as electric motors or lighting cannot use intrinsic safety methods for

protection.

Approval standards for intrinsic safety barriers require that the barrier maintains only approved

levels of voltage and current flowing out to the specified components located in a classified

area. This is accomplished by preventing ignition of the protected device, and also by stopping

any ignition level sparking of damaged wiring to the protected components.

Many safety barriers are commercially available and may utilize a buss fuse, one or more

resistors, and one or more Zener diodes. These devices are certified and provided in a package

form where they can be easily inserted mechanically and electrically in the circuit branch going

into a classified area.

An example of an Intrinsically Safe (IS) certified Zener barrier is shown

here. Signals going to an electrical device located in a classified zone

are wired into one end of the modular barrier and then wired out into the

classified zone. These can be purchased off the shelf and are certified

Intrinsically Safe by various 3rd body testing laboratories.

We have utilized a certified Zener barrier such as this in the Spill

Buddy’s sensor circuits.

Flammability and Combustible Liquids Definitions 101

When using a Spill Buddy system it is important to understand the difference between the

definition of flammable liquids and combustible liquids. All flammable and combustible liquids

will vaporize into flammable gases at certain temperatures and pressures. The temperature

point at which a liquid turns to a gas vapor is referred to as the “flashpoint” of the liquid. The

determination of the flashpoint for each flammable or combustible liquid is done by performing

what is commonly known as the “closed cup” flashpoint test.

It should be mentioned that flashpoint was selected as the basis for classification of flammable

and combustible liquids because it is directly related to a liquid's ability to generate vapor, i.e.,

its volatility. Since it is the vapor of the liquid, not the liquid itself that burns, vapor

generation becomes the primary factor in determining the fire or explosive hazard.

Furthermore, the liquid’s vapor pressure is an important factor and is a measure of a liquid's

propensity to evaporate. The higher the vapor pressure, the more volatile the liquid and, thus,

the more readily the liquid gives off flammable or explosive vapors.

Envirotecnics Tel: +34 872 080 542 envirotecnics@envirotecnics.com www.envirotecnics.com

6

Clean Earth Technology has designed the Pump Flooding procedure described on page 8 to

mitigate the risk of vapor ignition in flammable liquids recovered by the Spill Buddy.

The results of flashpoint testing have been used to help regulating bodies determine the

temperatures at which potentially combustible liquids turn into a vapor, creating a flammable or

explosive gas.

Hazardous locations are further defined by means of the class/division system and have been

formulated by the NEC, CSA, OSHA, and the National Fire Protection Association (NFPA).

These definitions are as follows:

Flammable Liquids

Flammable fluids are defined as liquids having closed cup flash points below 100°F

(37°C). Flammable liquids are referred to as Class I liquids.

◆A class IA flammable liquid is a liquid with a flashpoint below 73ºF (22.8ºC) and a boiling

point below 100ºF (37.8ºC). An example of a class IA liquid is n-pentane, since its flashpoint

and boiling point are 56ºF (49ºC) and 97ºF (36ºC), respectively.

◆A class IB flammable liquid is a liquid with a flashpoint below 73ºF (22.8ºC) and a boiling

point at or above 100ºF (37.8ºC). An example of a class IB liquid is acetone, since

its flashpoint and boiling point are 0ºF (18ºC) and 133ºF (56ºC), respectively.

◆A class IC flammable liquid is a liquid with a flashpoint at or above 73ºF (22.8ºC) and

below 100ºF (37.8ºC). An example of a class IC liquid is turpentine, since its flashpoint

lies in the range from 95 to 102ºF (35 to 39ºC).

Combustible Liquids

Combustible fluids are defined as liquids having closed cup flash points at or above

100°F (37°C). Combustible liquids are referred to as Class II or Class III liquids.

◆Class II liquids - flash points at or above 100°F (37.8°C) and below 140°F (60°C).

◆Class IIIA liquids - flash points at or above 140°F (60°C) and below 200°F (93.4°C). c.

◆Class IIIB liquids - flash points at or above 200°F (93.4°C).

An example of a Combustible liquid is the Lamplight® Ultra Pure Red Paraffin Lamp Oil that

CET uses for testing new and repaired units before shipment. This material has a flashpoint of

250F (121C) making it a class III liquid. Furthermore, its low toxicity makes it a safe testing fluid

due to its high ignition temperature and the lack of chemicals that are listed in the CERCLA

Hazardous Substance list. CET uses a red colored fluid but it also can be found in clear, or

colored green or blue.

This fluid is easily found and can also be used as a pump flooding fluid as defined on page 8.

Envirotecnics Tel: +34 872 080 542 envirotecnics@envirotecnics.com www.envirotecnics.com

7

NOTE: Personal Protective Equipment, Level C or D, as defined in OSHA 29 CFR

1910.120, shall be worn as a minimum while operating or cleaning the Spill Buddy unit.

A suitable container should be used to contain product.

Chapter 1- System Operation

STANDARD EQUIPMENT LIST:

Spill Buddy, 50 ft. or 100 ft., as ordered, with battery installed

Battery wall charger

Pump Fill Kit

Pump Removal Tool

Operator’s Manual

Optional Items:

Roller with well head adapter

Cigarette lighter adapter battery charger

Battery charger cable with battery “alligator”clips

Additional product pumps

Extra battery

Warning! Explosive Vapors. The Spill Buddy is not an explosion proof device.

Its use within a classified area requires monitoring of the work site to insure

explosive vapors are not present. The AHJ may require a valid HOT WORK

permit, with testing of the LEL and HEL at intervals. The probe is designed to operate in

an explosive atmosphere, i.e. a recovery well. The reel body and recovery container

should be positioned outside of any classified hazardous area. CET recommends

maintaining a distance of three (3) feet or greater from the wellhead during use.

Warning! Never leave the Spill Buddy operating unattended during recovery

events. This devise is not intended to for use without an operator present.

Warning! Risk of Grounding Arc! This device is designed to dissipate

potential static charge through its base grounding plate. Never operate this

device while it is not in contact with the ground. Portable product containers

must also be set on the ground with the discharge tube clamp connected to the

container. The clamp is electrically connected to the reel assembly.

Warning! Insure the Pump Flooding Procedure has been performed prior to

use, see page 8.

Envirotecnics Tel: +34 872 080 542 envirotecnics@envirotecnics.com www.envirotecnics.com

8

Pump Flooding Procedure

Before the Spill Buddy Probe can be lowered down a well, the pump must be flooded with a

non-flammable fluid. (See page 6 for the definitions of flammable versus combustible liquids.)

The purpose of this procedure is to displace oxygen and vapors from within the pump body.

Once the Probe begins pumping product from the well, the added fluid will be pumped out to the

recovery container during the first recovery cycle. Note: CET does not ship new or serviced

systems with the pump pre-flooded.

Required Equipment:

A suction device, such as syringe pictured at right.

NOTE: If purchasing device separately, any O-ring

included should be replaced with a Viton ® O-ring to

prevent swelling.

Suitable container for the fluid

Approximately 8 fl oz of flooding fluid, such as Ultra-

Pure Paraffin Lamp Oil, mineral oil, or similar non

flammable fluid. DO NOT USE WATER, the pump

internals are NOT corrosion resistant.

Approximately 12”of 3/8 fuel line

A product pump, CET P/N 90-1318-019

Flood the pump

Attach the fuel line to the discharge side of the pump.

Attach the other end of the fuel line to the suction

device.

Place the pump inlet in the container of fluid.

Pull the fluid into the pump until it is observed in the fuel line.

Remove the fuel line from the pump.

Install (or re-install) the flooded pump into the Probe (reference the “Pump Installation”

section of the Maintenance Operations chapter of the Operator’s Manual).

If the pump is not immediately installed in the Probe, replace the red intake and

discharge caps. The pump can then be bagged for later use or storage.

Note: Always save the red caps from installed pumps for future use.

Once the flooded pump has been replaced in the Probe (See “Pump Installation” on page19),

you are ready to begin operating the Spill Buddy.

Envirotecnics Tel: +34 872 080 542 envirotecnics@envirotecnics.com www.envirotecnics.com

9

Warning! Explosive Vapors. The Spill Buddy is not an explosion proof device. Its use

within a classified area requires monitoring of the work site to insure explosive vapors

are not present. The AHJ may require a valid HOT WORK permit, with testing of the

LEL and HEL at intervals. The probe is designed to operate in an explosive

atmosphere, i.e. a recovery well. The reel body and recovery container should be

positioned outside of any classified hazardous area. CET recommends maintaining a

distance of three (3) feet or greater from the wellhead during use.

NOTE: Always perform the Pump Flooding procedure found on page 8 before lowering

the Probe into the well.

Using the Spill Buddy to Pump LNAPLS (Floaters)

1) For operation compliant with standard safety

practices, always use a roller (grooved wheel or

pulley) mounted on the well head to enable the

operator to lower the Spill Buddy’s probe down the

well from a distance at least three feet away. You

can order a roller and well head adapter from

Clean Earth Technology, or else supply your own.

2) Place the roller and adapter

on the well head

3) To recover product, clip discharge tube end to the

product discharge container and open the petcock. LNAPL

or DNAPL product can be pumped out of the well and into

the open Container. NOTE: The container should be

located 3 feet or more from the reel body.

4)Perform the Pump Flooding Procedure on page 8.

5) Remove the probe from its receptacle and rest it carefully over the roller.

Start to lower the probe by unreeling it into the well (use caution to avoid

scraping the tubing on sharp edges).

6)Once the operator and any other

personnel present are located at least three

feet from the well head, turn the unit on

using the SYSTEM POWER switch on the

Front Panel (See page 2). Spill Buddy will

respond with one beep every three seconds,

which indicates that the unit is ON, and the

battery is charged and functional.

Rollers mounted to well head adapters for

a two inch well and a four inch well.

Envirotecnics Tel: +34 872 080 542 envirotecnics@envirotecnics.com www.envirotecnics.com

10

WARNING: Always position the product recovery container more than 3 feet (1 Meter)

from the Spill Buddy reel.

7)Continue to lower the probe slowly into the well. When the Probe ALPHA-ARRAYTM sensor

contacts water, Spill Buddy will respond with a continuous beep.

8) To recover product raise the depth of the probe to a point just above the product/water

interface. (The continuous tone changes to one beep every three seconds). In the case of a

DNAPLE product when the solid tone stops then the pump intake is in the DNAPL product and

the pump can be turned on to recover product.

Press the push button (momentary) PUMP ON switch or flip the PUMP ON toggle switch

(constant) for continuous operation. Both switches are located on the Front Panel.

Use “fishing” motion. Once the tone changes from one beep/three seconds to continuous,

release the pump switch or raise the probe so that the water will not be pumped into the

discharge.

9)As water recharges the well, the interface level may change. To avoid pumping water, it is

recommended that the operator continue the “fishing” motion to reestablish the interface level,

then find product and restart the pump. Repeat this process several times to pump off the

maximum amount of product.

NOTES:

a) The pump will operate as long as the constant PUMP toggle switch is in the ON position. Spill

Buddy will pump water or product depending upon the elevation of the probe in the well relative

to the product/water interface. The operator selects the fluid to be pumped by listening to the

tones. The pump will not automatically turn itself off when it senses water.

b) If, during the course of the day, the pumping rate slows down, check the filter screen first.

Use large adsorbent pad to wrap probe between wells to prevent spillage.

Envirotecnics Tel: +34 872 080 542 envirotecnics@envirotecnics.com www.envirotecnics.com

11

NOTE: Always perform the Pump Flooding procedure found on page 8 before lowering

the Probe into the well.

Warning! Explosive Vapors. The Spill Buddy is not an explosion proof device. Its use

within a classified area requires monitoring of the work site to insure explosive vapors

are not present. The AHJ may require a valid HOT WORK permit, with testing of the

LEL and HEL at intervals. The probe is designed to operate in an explosive

atmosphere, i.e. a recovery well. The reel body and recovery container should be

positioned outside of any classified hazardous area. CET recommends maintaining a

distance of three (3) feet or greater from the wellhead during use.

Using the Spill Buddy to Pump DNAPLS (Sinkers)

1) For operation compliant with standard safety practices, always use a roller (grooved wheel or

pulley) mounted on the well head to enable the operator to lower the Spill Buddy’s probe down

the well from a distance at least three feet away. You can order a roller and well head adapter

from Clean Earth Technology, or else supply your own.

2) Place the roller and adapter on the well head

3) Perform the Pump Flooding Procedure on

Page 8.

4) To recover product, clip discharge tube end to the

product discharge container and open the petcock.

LNAPL or DNAPL product can be pumped out of the

well and into the open Container. NOTE: The

container should be located 3 feet or more from the

reel body.

5) Remove the probe from its receptacle and rest it carefully over the

roller. Start to lower the probe by unreeling it into the well (use caution

to avoid scraping the tubing on sharp edges).

6) Once the operator and any other

personnel present are located at

least three feet from the well head,

turn the unit on using the SYSTEM

POWER switch on the Front Panel

(See page 2). Spill Buddy will

respond with one beep every three

seconds, which indicates that the

unit is ON, and the battery is

charged and functional.

Envirotecnics Tel: +34 872 080 542 envirotecnics@envirotecnics.com www.envirotecnics.com

12

WARNING: Always position the product recovery container more than 3 feet (1 Meter)

from the Spill Buddy reel.

7) Continue to lower the probe slowly into the well. When the Probe ALPHA-ARRAYTM sensor

contacts water, Spill Buddy will respond with a continuous beep. Product can be pumped out of

the well by the following procedure: lower the Probe down through the water to reach the

product. When the probe sensor contacts the DNAPL, Spill Buddy will respond with one beep

every three seconds.

8) Press the push button (momentary) PUMP ON switch or flip the PUMP ON toggle switch

(constant) for continuous operation. Both switches are located on the Front Panel. The exact

level of the ground water/DNAPL interface may change as the product is being pumped off,

requiring the Probe to be lowered slightly. Keep Probe off the bottom of the well to avoid

pumping silt-laden product.

CAUTION: If the well contains both floating product and DNAPLS, pump off both

products as described above, but into separate containers for appropriate disposal.

NOTES:

a) The pump will operate as long as the constant PUMP toggle switch is in the ON position. Spill

Buddy will pump water or product depending upon the elevation of the probe in the well relative

to the product/water interface. The operator selects the fluid to be pumped by listening to the

tones. The pump will not automatically turn itself off when it senses water.

b) If, during the course of the day, the pumping rate slows down, check the filter screen first.

Use large adsorbent pad to wrap probe between wells to prevent spillage.

Envirotecnics Tel: +34 872 080 542 envirotecnics@envirotecnics.com www.envirotecnics.com

13

Chapter 2- Maintenance Operations

Removing Moisture from the Pump

The most essential maintenance operation for the Spill Buddy is removal of all moisture from the

pump at the end of each day’s use. Since the pump shutoff is a manual operation, some

amount of water is inevitably pulled into the pump during operation. Allowing any amount of

water to remain in the pump motor WILL damage the pump, even if only for a short period of

time. Moisture must be displaced from the pump motor even if the unit has not been

used to pump water. Displacing moisture can be accomplished by following these simple

procedures:

1. Place the Probe in a container of pure Lamp Oil, so that the pump intake is fully submersed in

product. Make certain there is no water in the container.

2. Activate the pump, by using the toggle switch or large blue button, on the side of the Spill

Buddy. Run pump for at least two seconds. This will ensure that an adequate amount of

product flows through the pump motor, thereby displacing the moisture. Store the unit in a dry

but ventilated place. NOTE: You will need to remove the pump from the Spill Buddy and

perform the Pump Flooding procedure on page 8 just before the Spill Buddy is next used.

3. If no Lamp Oil is available, remove the pump motor

from the probe (see page 16) and lubricate the pump

internals with a non-flammable commercially available

lubricant such as 3-In-One® oil . To lubricate, hold the

pump upside down (intake hole up) and squirt lubricant

into intake hole. This will allow lubricant to flow into

working parts of the pump. Also, squirt lubricant into the

product discharge nipple of the pump.

4. The lubricated pump can be stored in a sealed plastic

bag until just prior to the next use of the Spill Buddy. At

that point, make sure to perform the Pump Flooding

procedure on page 8 before reinstalling the pump into the Probe.

PLEASE NOTE: Leaving moisture in the pump, thereby damaging it,

voids the pump warranty.

Envirotecnics Tel: +34 872 080 542 envirotecnics@envirotecnics.com www.envirotecnics.com

Table of contents

Popular Water Pump manuals by other brands

Zehnder Pumpen

Zehnder Pumpen ZKH 15 operating instructions

WELCH-ILMVAC

WELCH-ILMVAC 2585B-01 owner's manual

EasyPro

EasyPro EX3600 Installation and service manual

KIRLOSKAR

KIRLOSKAR IN 40/160 IL Instructions on Installation, Operation and Maintenance Manual

Cal Pump

Cal Pump Torpedo General instructions

Server

Server Express 07745 manual

ITT

ITT Engineered Valves 903 Installation, operation and maintenance manual

VUOTOTECNICA

VUOTOTECNICA VTS 25FG OPERATION AND MAINTENANCE BOOK

Grundfos

Grundfos ALPHA1 L instructions

poolstar

poolstar SPAWER POOLEX O'SPA 30 Installation and user manual

ITT

ITT 3610 i-FRAME manual

PFT

PFT FERRO 100 II operating manual