Server Express 07745 User manual

Other Server Water Pump manuals

Server

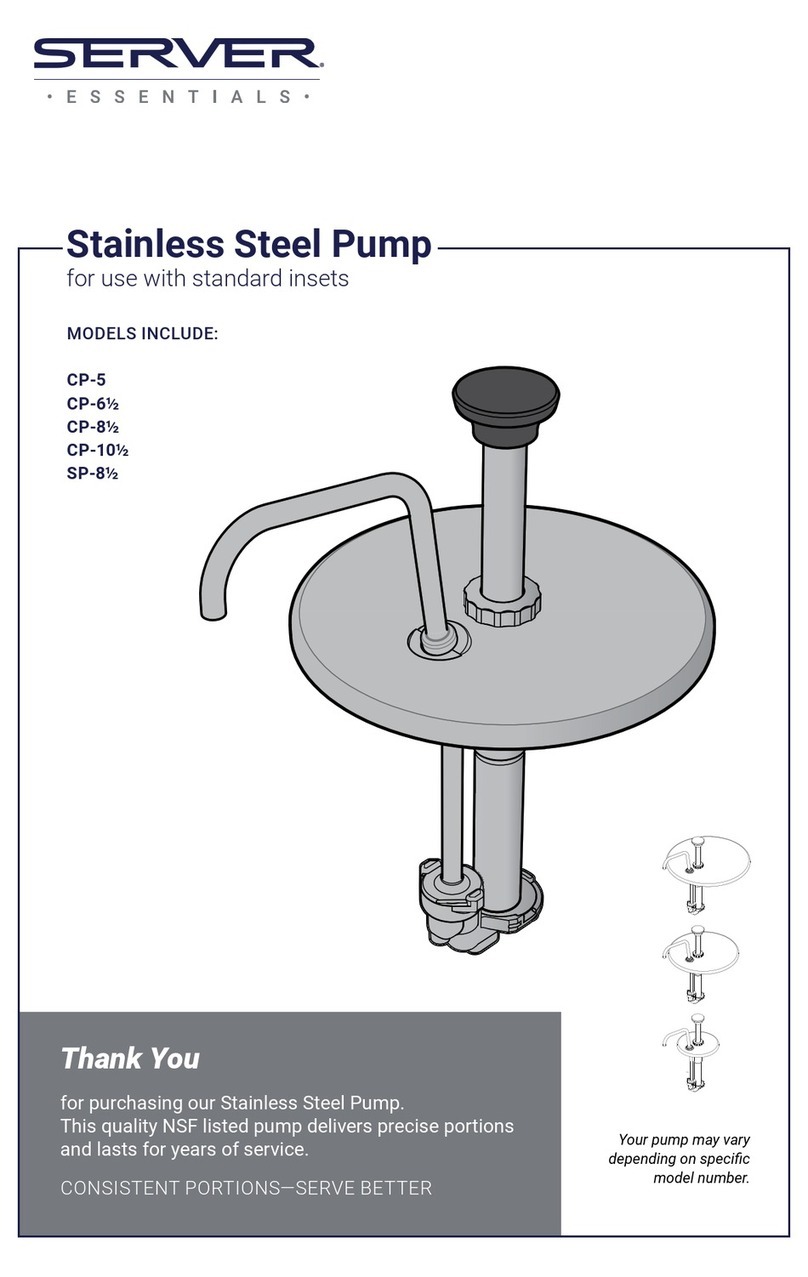

Server CP-5 User manual

Server

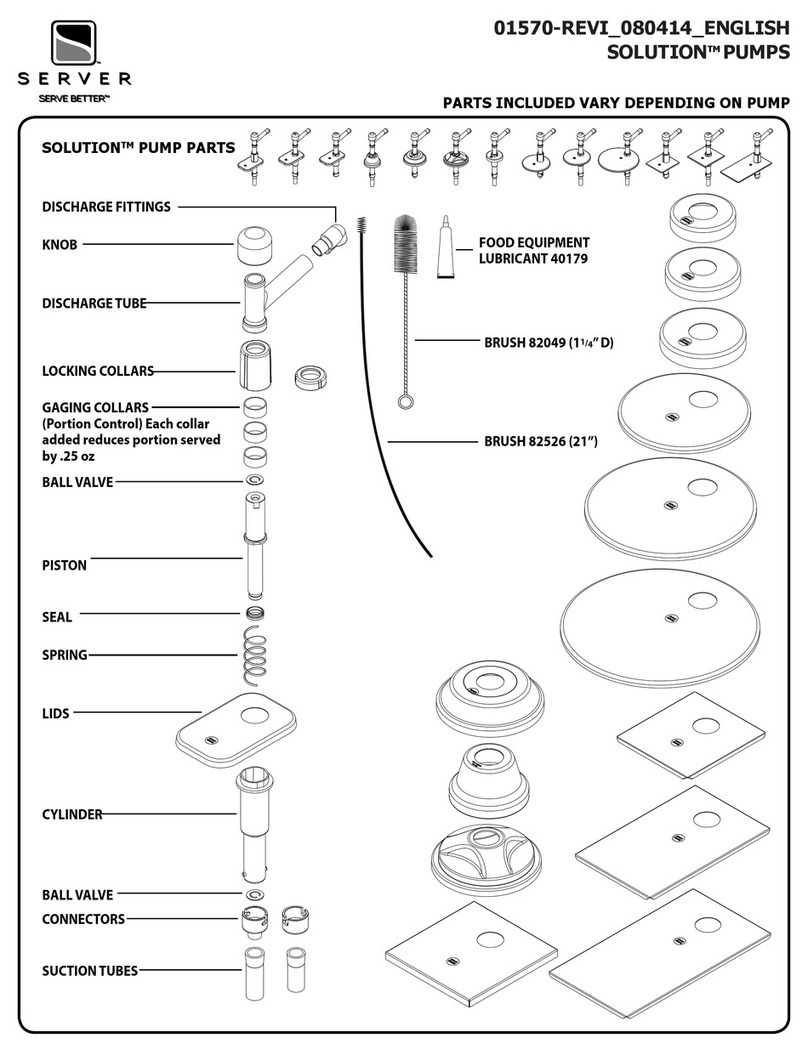

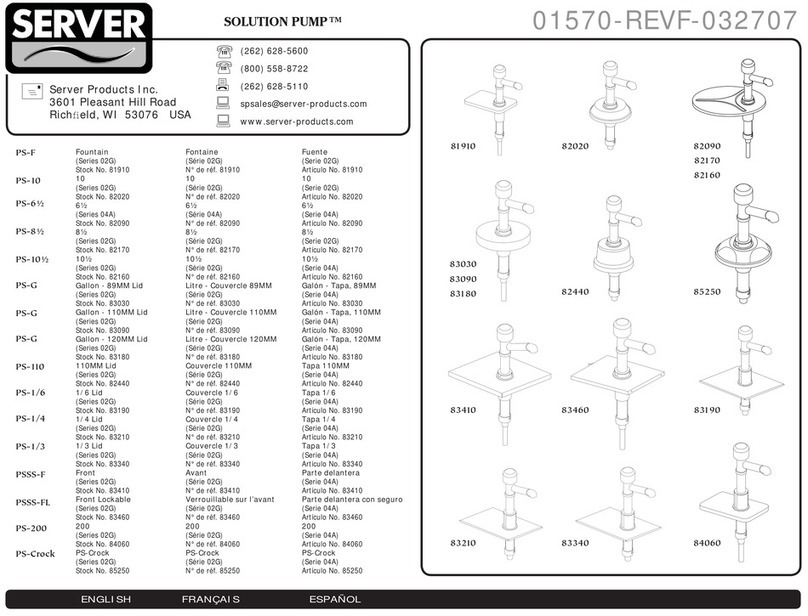

Server SOLUTION PUMP 81910 User manual

Server

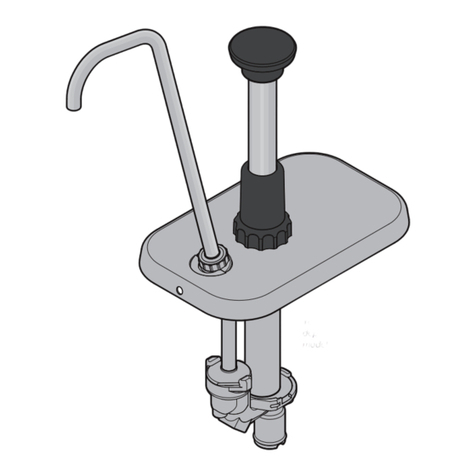

Server 85820 User manual

Server

Server Serve Better CP-RP User manual

Server

Server BP-1 User manual

Server

Server 07794 User manual

Server

Server SP User manual

Server

Server 100239 User manual

Server

Server Eco BP-1 User manual

Server

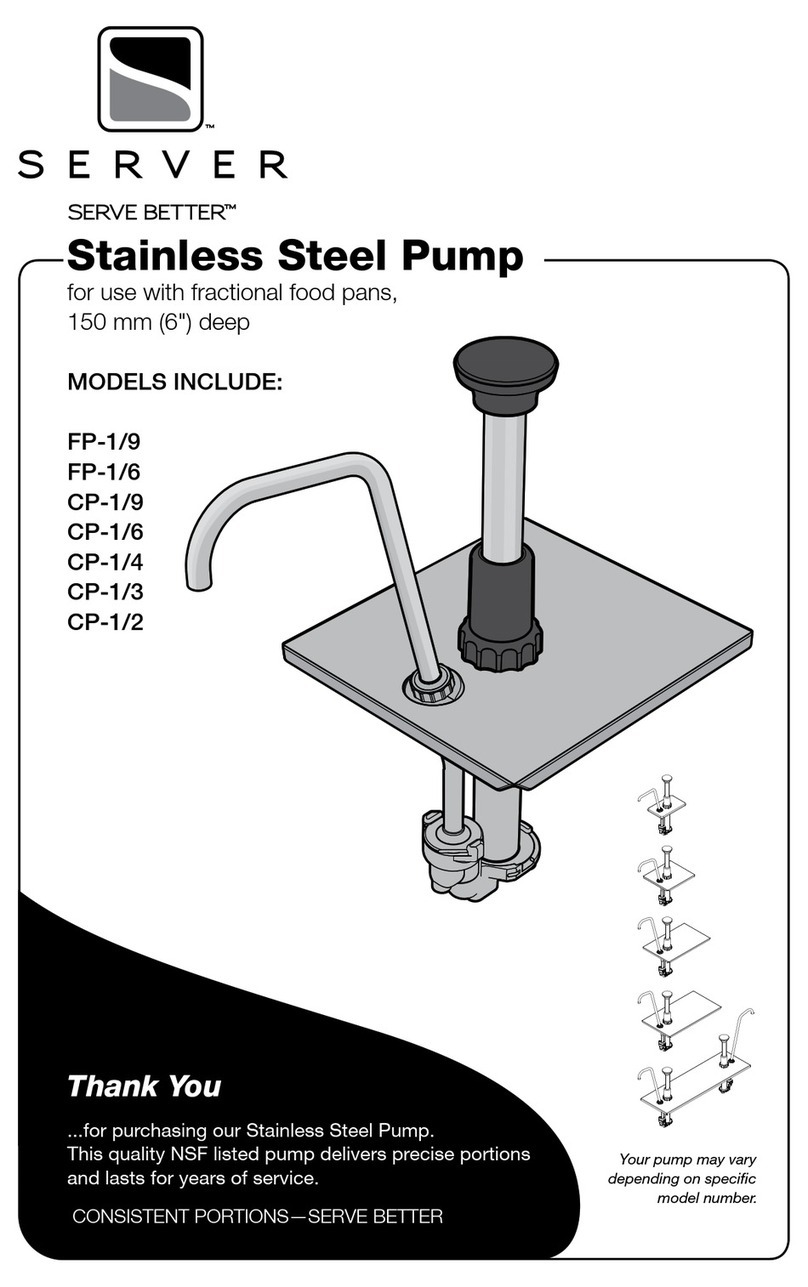

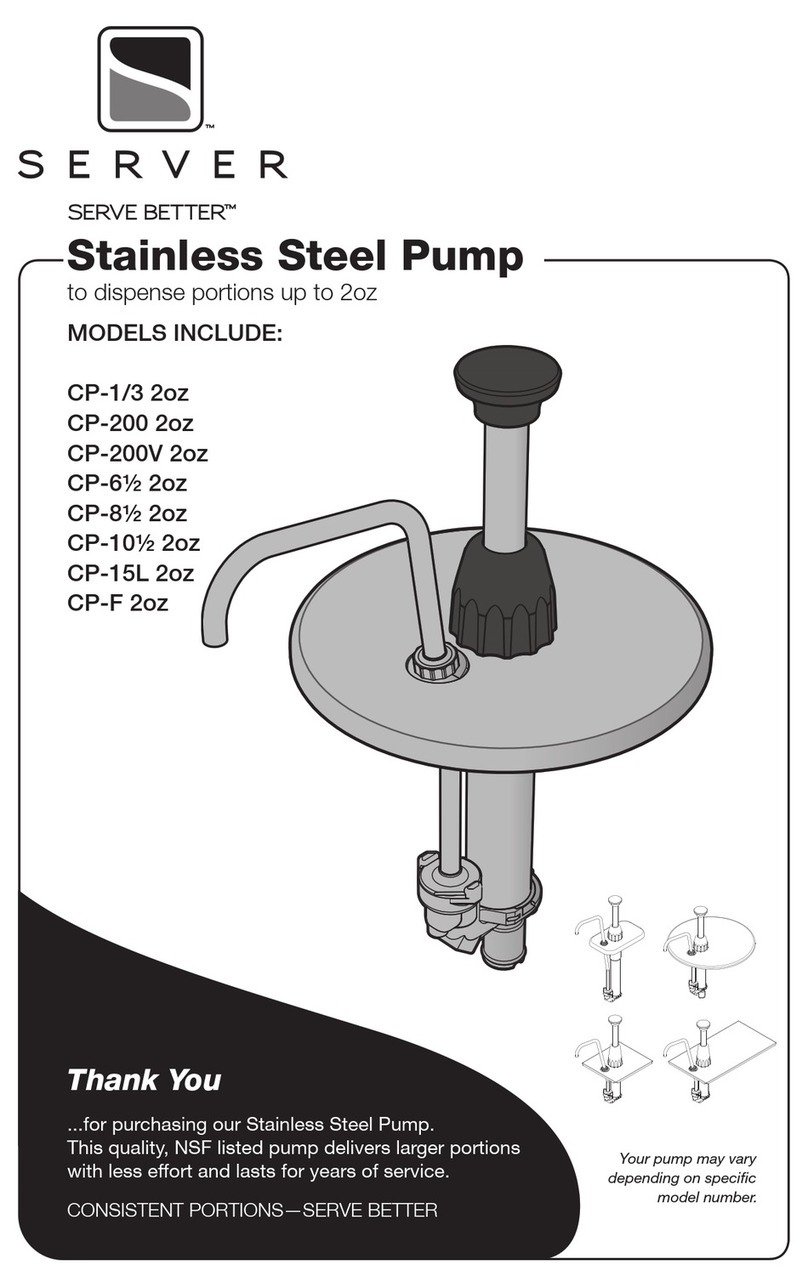

Server SERVE BETTER CP-1/3 2oz User manual

Server

Server BP-1 User manual

Server

Server Eco Pump BP-1/4 User manual

Server

Server CP-3L User manual

Server

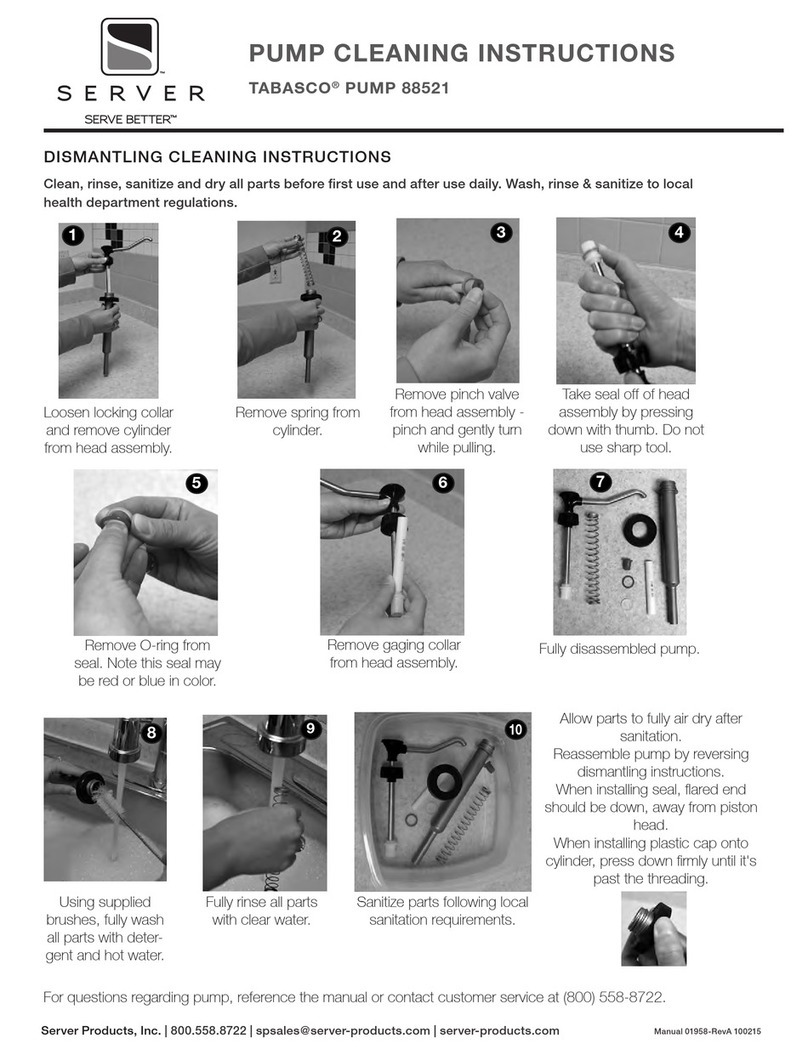

Server TABASCO 88521 Configuration guide

Server

Server Express 07737 User manual

Server

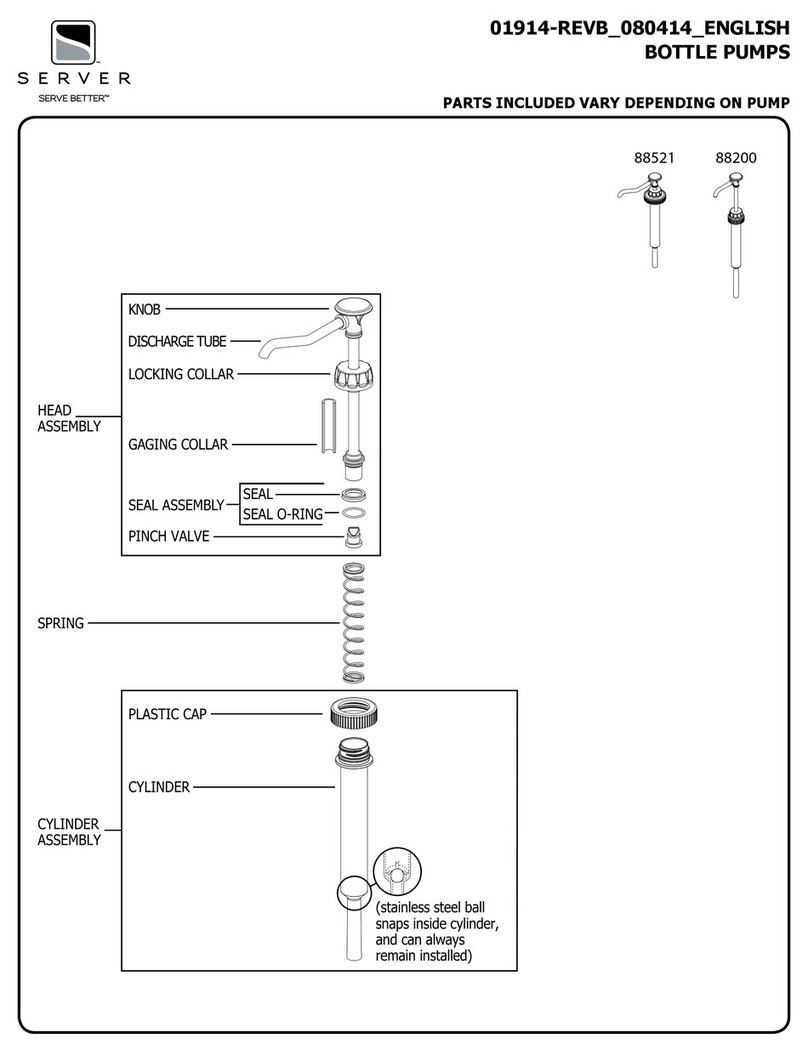

Server 88521 User manual

Server

Server Express 07392 User manual

Server

Server SP-3 User manual

Server

Server 100239 User manual

Server

Server BP-1/4 User manual

Popular Water Pump manuals by other brands

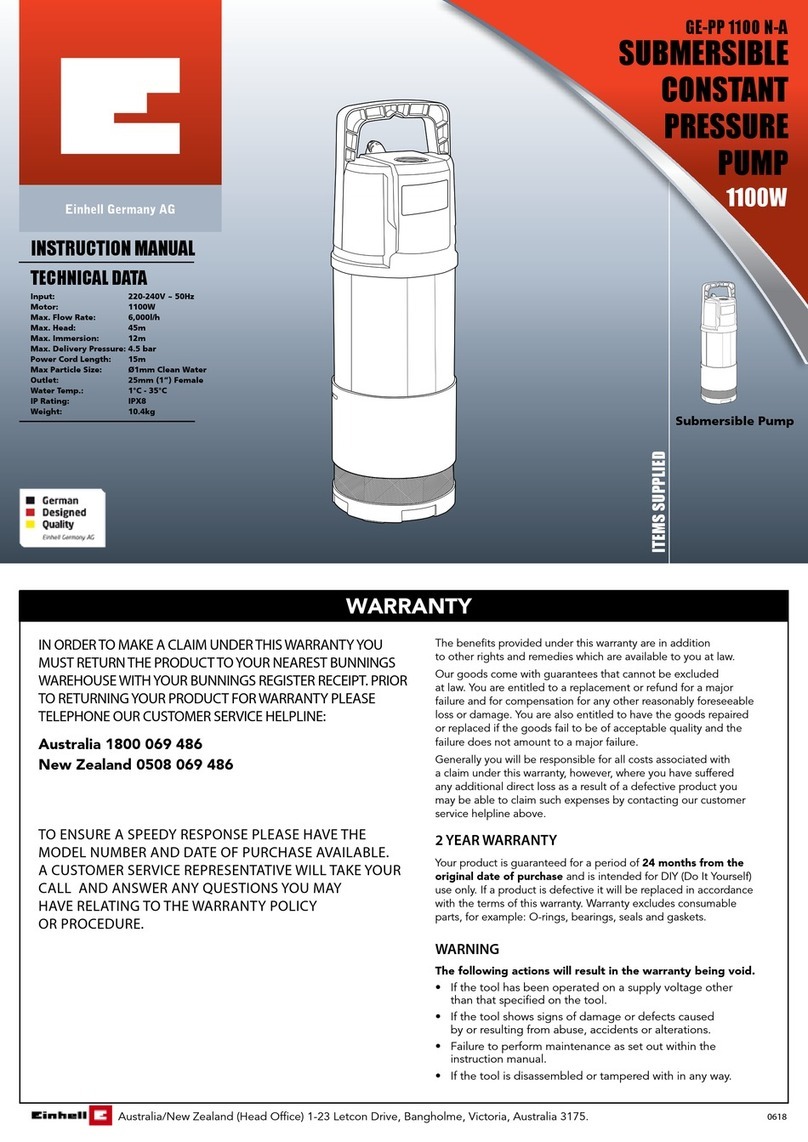

EINHELL

EINHELL GE-PP 1100 N-A instruction manual

Liberty Pumps

Liberty Pumps SBX Series installation manual

Gardena

Gardena 13000 aquasensor Operator's manual

Ebsray

Ebsray HD600 Installation, operation & maintenance instructions

ProMinent

ProMinent DULCOflex DFBa Series operating instructions

WilTec

WilTec 51530 Operation manual

Annovi Reverberi

Annovi Reverberi AR503-SP instruction manual

GORMAN-RUPP

GORMAN-RUPP AMT 316T-95 Specifications information and repair parts manual

VET

VET Slim instruction manual

Parkside

Parkside PDSS A1 Operation and safety notes

Watson Marlow Pumps

Watson Marlow Pumps 504S manual

Franklin Electric

Franklin Electric RM2 Series owner's manual