2 309277

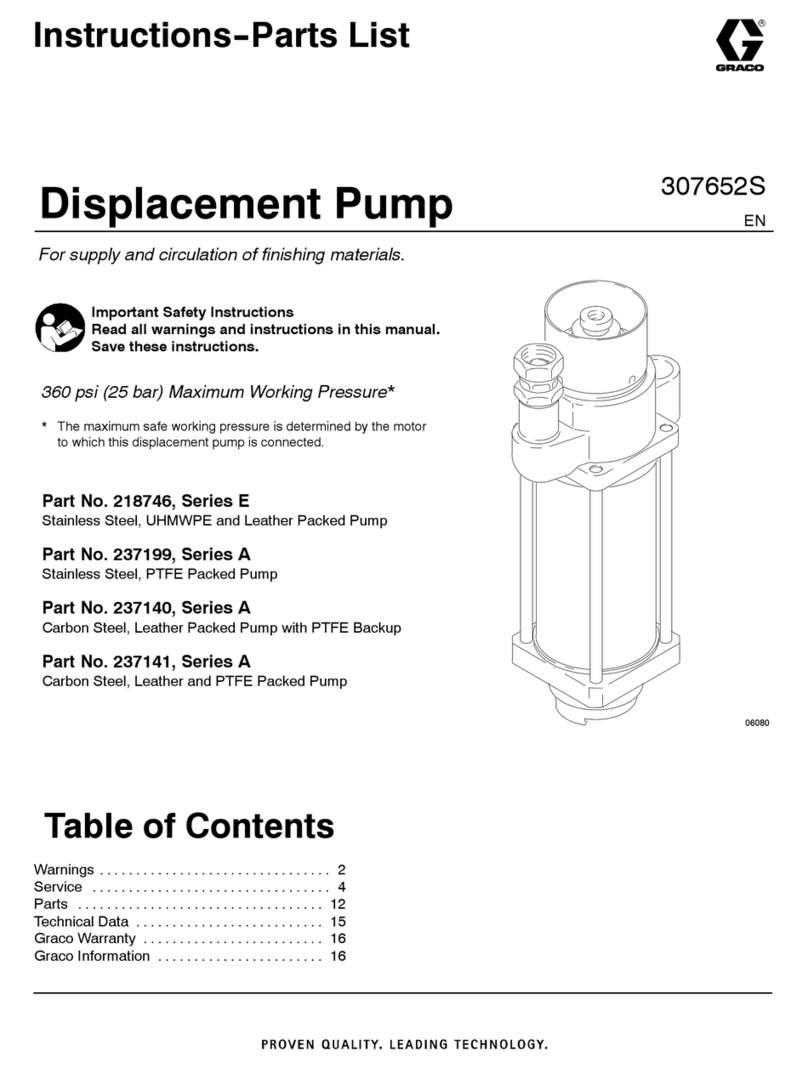

Table of Contents

Warnings 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts, Pump

244197 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

244224 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

244201 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

244409 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

245902 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

245904 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

244954 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

244957 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

245889 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

287946 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

246257 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

287815 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

287814 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

248736 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

248971 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

277068 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

WARNING

INSTRUCTIONS

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

This equipment is for professional use only.

Read all instruction manuals, tags, and labels before operating the equipment.

Use the equipment only for its intended purpose. If you are uncertain about usage, call your Graco

distributor.

Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

Do not exceed the maximum working pressure of the lowest rated system component. Refer to the

Technical Data on page 15 for the maximum working pressure of this equipment.

Use fluids and solvents compatible with the equipment wetted parts. Refer to the Technical Data

section of all equipment manuals. Read the fluid and solvent manufacturer’s warnings.

Do not use 1,1,1–trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents in pressurized aluminum equipment. Such use could result in a

chemical reaction, with the possibility of explosion.

Comply with all applicable local, state, and national fire, electrical, and safety regulations.

MOVING PARTS HAZARD

Moving parts can pinch or amputate your fingers.

Keep clear of all moving parts when starting or operating the pump.

Before servicing the equipment, follow the Pressure Relief Procedure on page 3 to prevent the

equipment from starting unexpectedly.