Before proceeding with installation ensure all operating & dimensional specifications are suitable for the intended installation.

1.1 INSTALLATION COMPLIANCE REQUIREMENTS

Enware product’s must be installed in accordance with

AS/NZS 3500.1 & AS/NZS3500.2 – Plumbing and Drainage,

the Plumbing Code of Australia as well as imposed Local and

State / Territory Legislative requirements and the manufacturers

instructions.

The following clauses must be observed for a compliant installation

and correct operation of Enware tapware:

Water Services

Plumbing Code of Australia:

Part B1 Cold Water Services

AS / NZS 3500.1-2003 Water Services;

• Section 3.3.2 Pressure at outlets (min 200kPa is required for

valve to operate)

• Section 3.3.4 Max. pressure within buildings (500kPa

operating)

• Section 3.4 Velocity Requirement (Max 3.0m/s)

• Section 16 Testing and Commissioning; Flushing,

Hydrostatic testing, cleaning & disinfection of water services.

NOTE: Enware’s WC flushing units have Watermark License to

ATS5200.020 (For Flushing Valves for Water Closets and Urinals -

For use with Mains Supply), ATS5200.030 (Solenoid Valves) and

WELS registered to AS/NZS 6400

IMPORTANT TECHNICAL REQUIREMENTS

To ensure that the unit works correctly, it is important to ensure that

the site and location of installation meets the hydraulic requirements

of AS/NZS 3500.1. Also there must be:

• Minimum 20mm copper supply line for 1 stall or up to

450mm wall space. 600mm of wall space may require

25mm supply

• Minimum 200kPa for valve to operate

NOTE: WELS Flush Volume only achieved at 350kPa

• No more than 1 valve per urinal OR 600mm wall space

• Flush valve must be no more than 2m above ground level

• Flush valve should be installed min 300mm above wall

hung urinal and 450mm above continuous wall urinals

Pipe work to the valve fixture must be sized according to water

service rule calculations and simultaneous demand requirements.

To ensure that the pipeline reticulation system for the valve is

designed correctly for the satisfactory performance of the valve

a Hydraulic services Consultant and/or Engineer (or other

personnel appropriately qualified in hydraulic services design) must

be engaged.

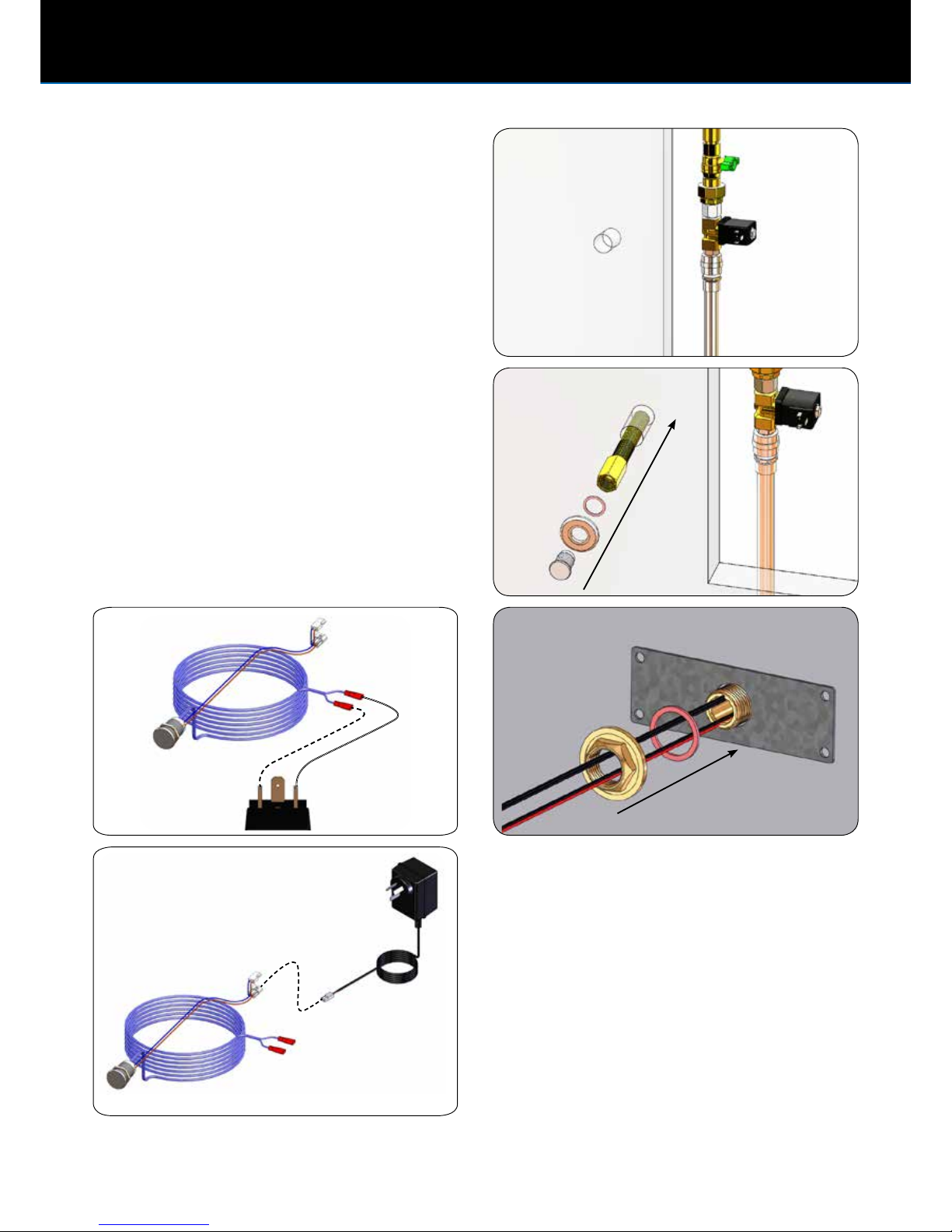

1.2 INSTALLATION INSTRUCTIONS

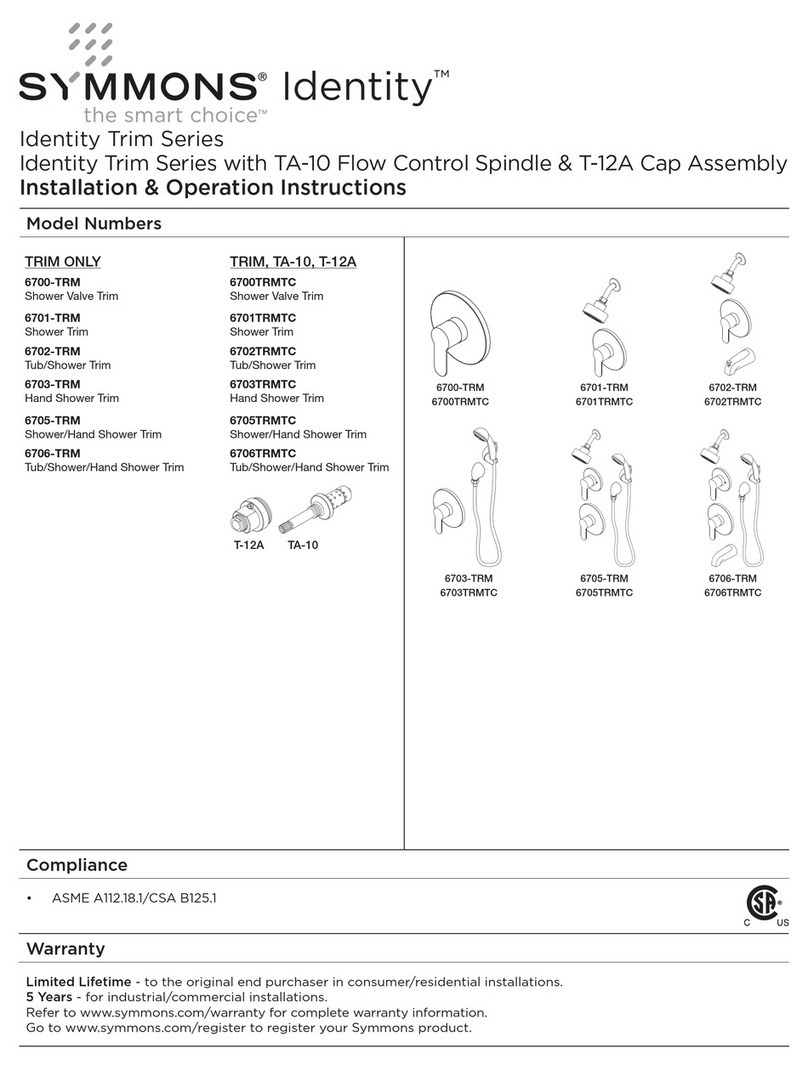

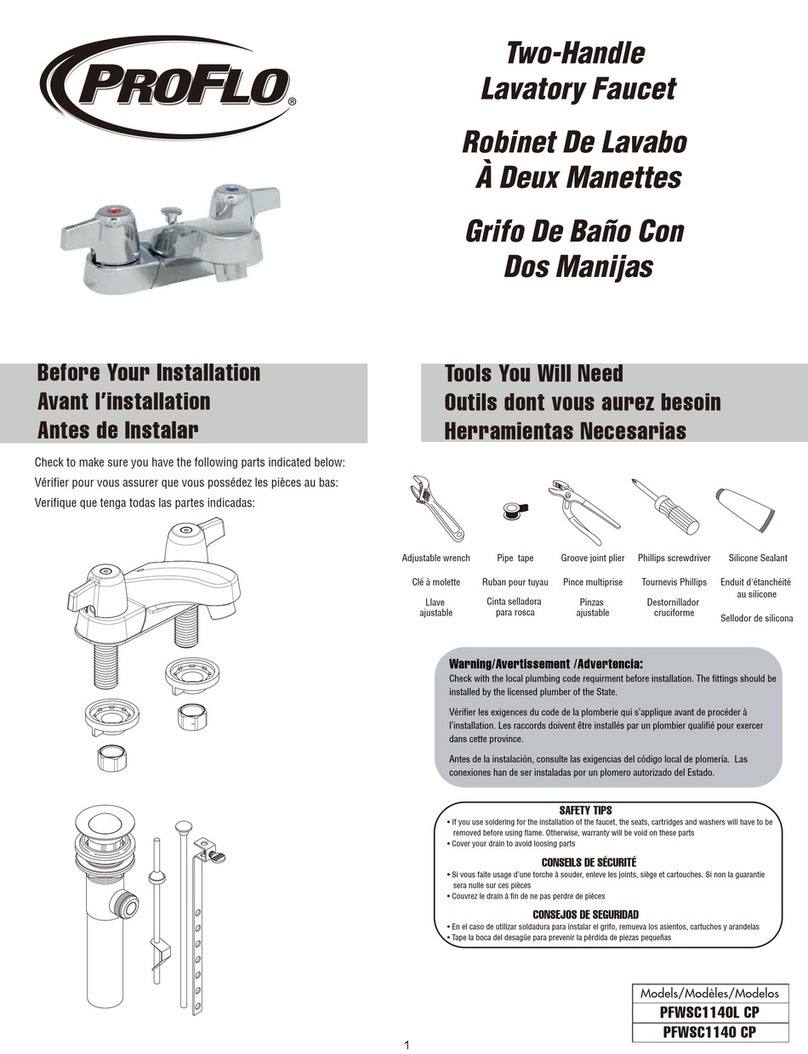

1. Separate parts from packaging & check each part

(figure 2.1). Parts will separate as shown in figure 1.2. Pay

attention to the different models variations. Make sure all parts

are accounted for before discarding any packaging material.

If any parts are missing, do not attempt to install your flushing

system until missing parts are obtained.

2. Flush water supply lines thoroughly before installing the flush

valve. Do not allow dirt, Teflon tape or metal particles to enter the

unit.

3. Shut off water supply and ensure shut off valve is closed

on flushing system.

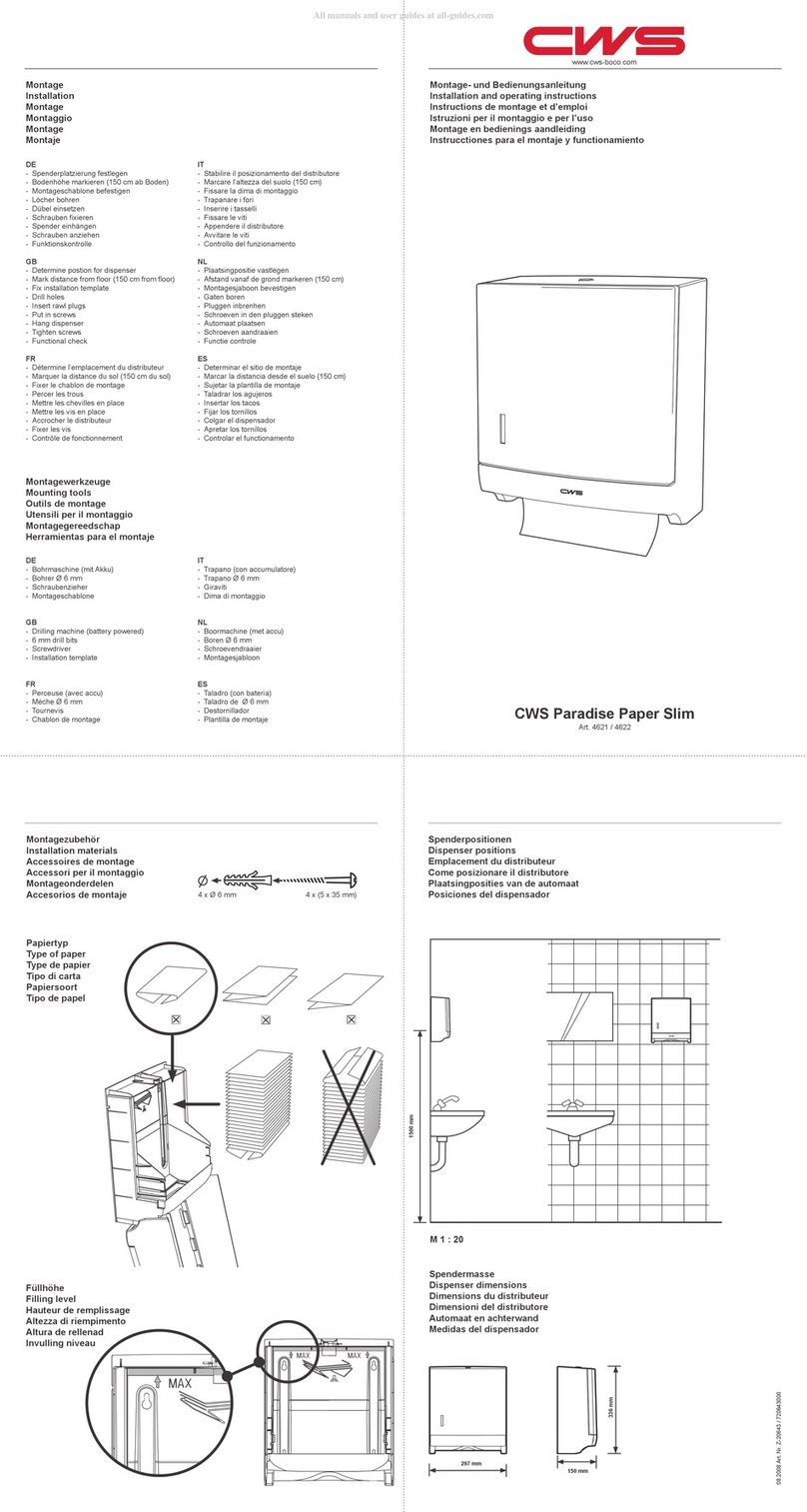

4. Decide on appropriate location combining piezo operation and

valve placement. Install height of between 1-1.5m recommended

for piezo placement.

5. Cut a 30mm hole in the wall for piezo assembly and an

appropriate gap in pipe work in which to fix the valve.

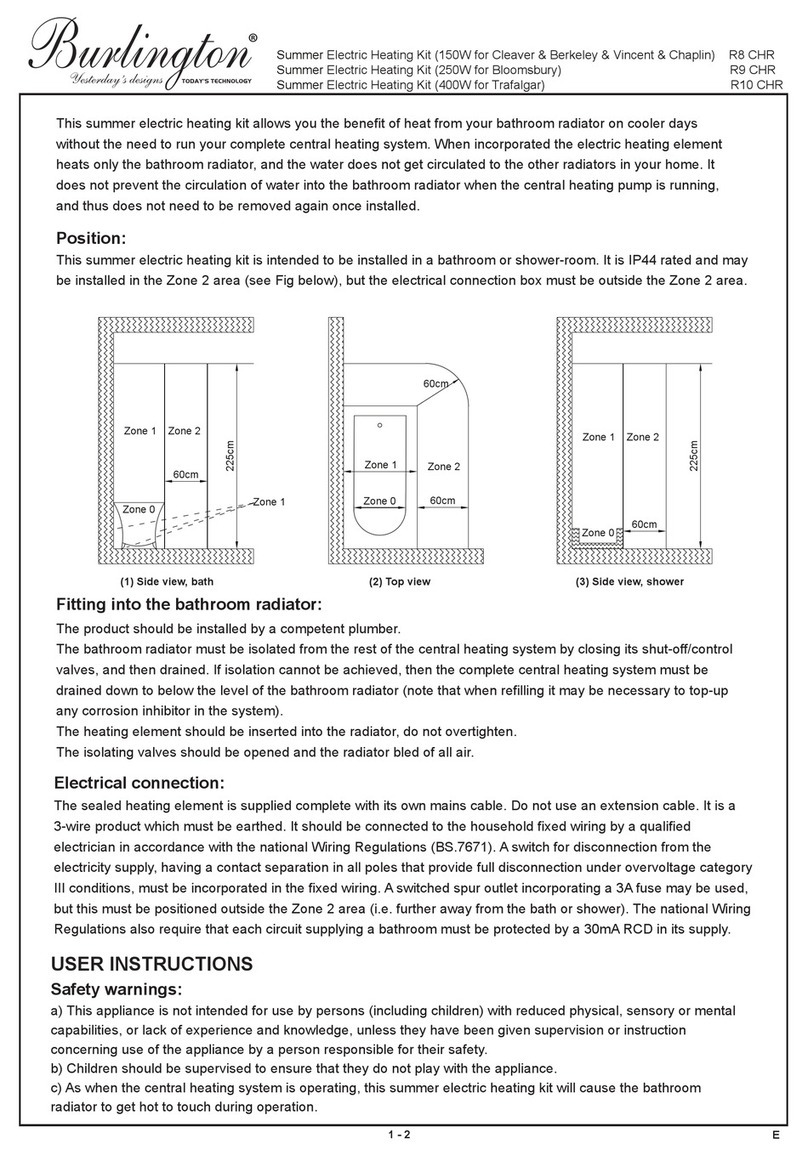

(FIGURE 1.1)

Note: Note: 20mm (min) inlet pipe with 1/2” BSP (male) adaptor

required for install.

Note: piezo can be installed away from valve box where

necessary, i.e. flush valve in wall cavity with activation on different

wall. Extensions can be purchased if required. AS3500.1

requirements are still required to be met.

6. Connect the shut off valve and upper section of the union (as

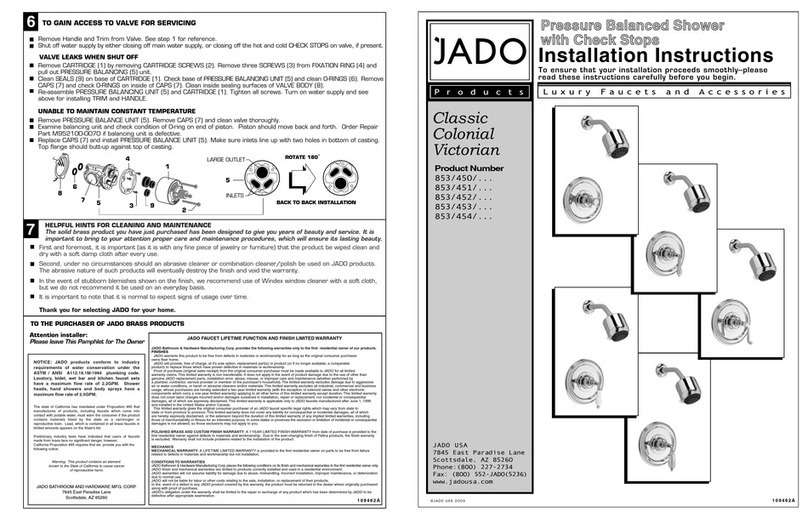

shown) (FIGURE 1.2 and 1.3)

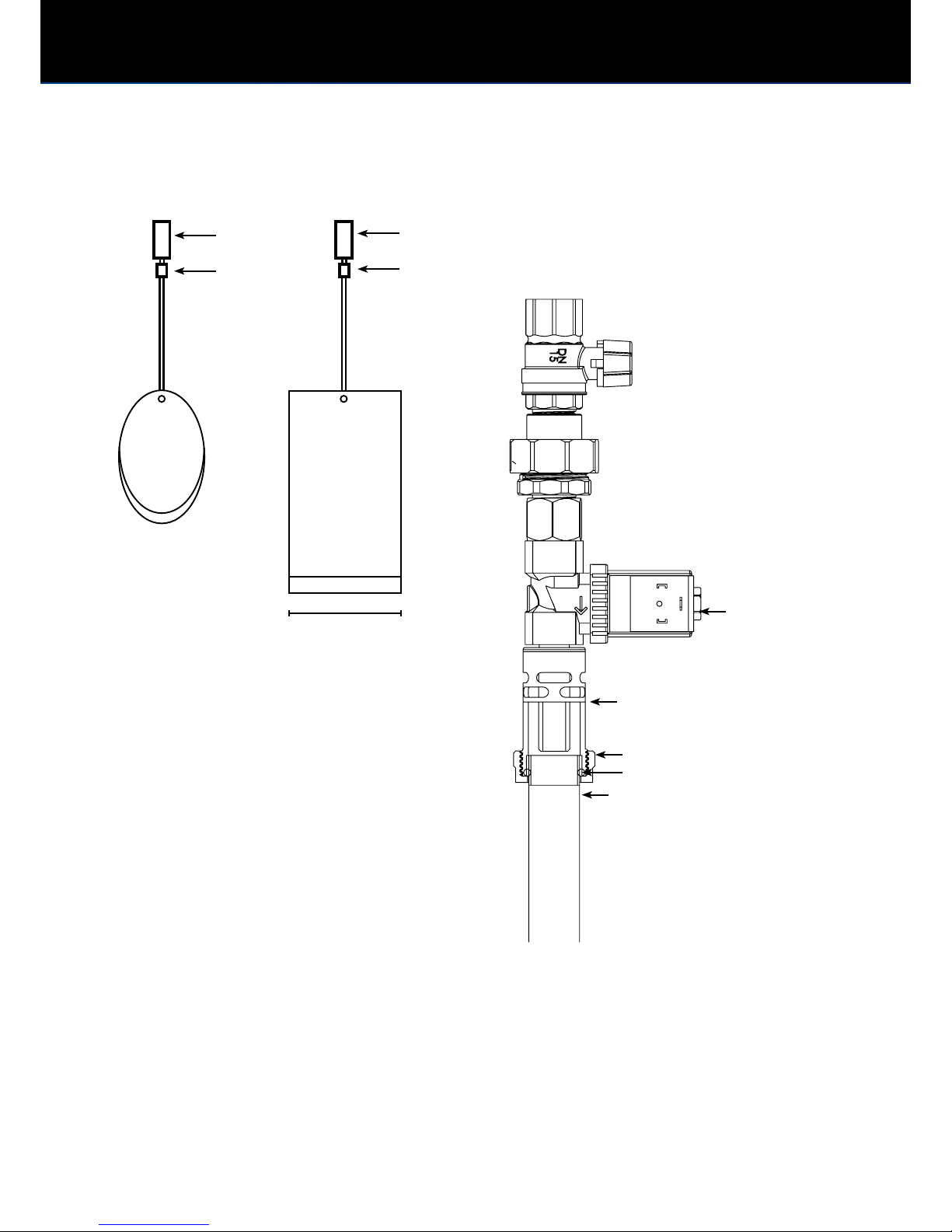

FIGURE 1.2 FIGURE 1.3

UPPER

SECTION OF

FLUSH VALVE

LOWER

SECTION OF

FLUSH VALVE

SPARGE

CONNECTION

(ADAPTOR OR AIR

GAP)

FIGURE 1.1

Ø30

INSTALLATION INSTRUCTIONS