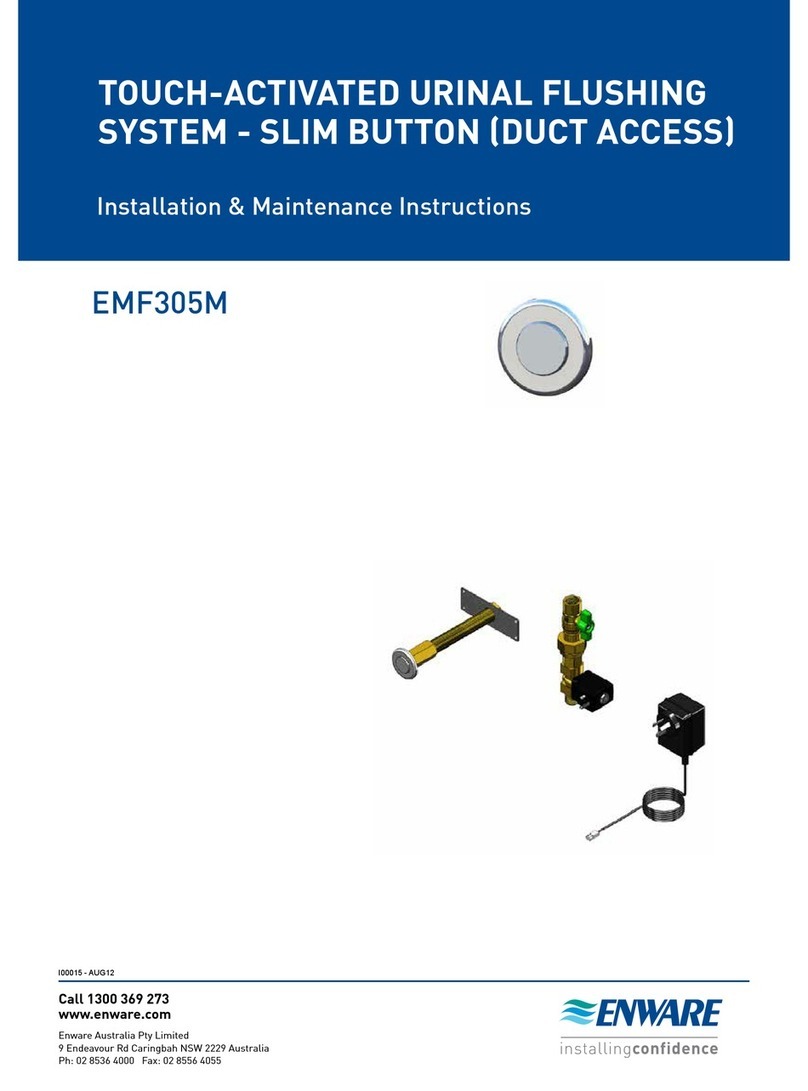

www.enware.com.au Call 1300 369 273 19

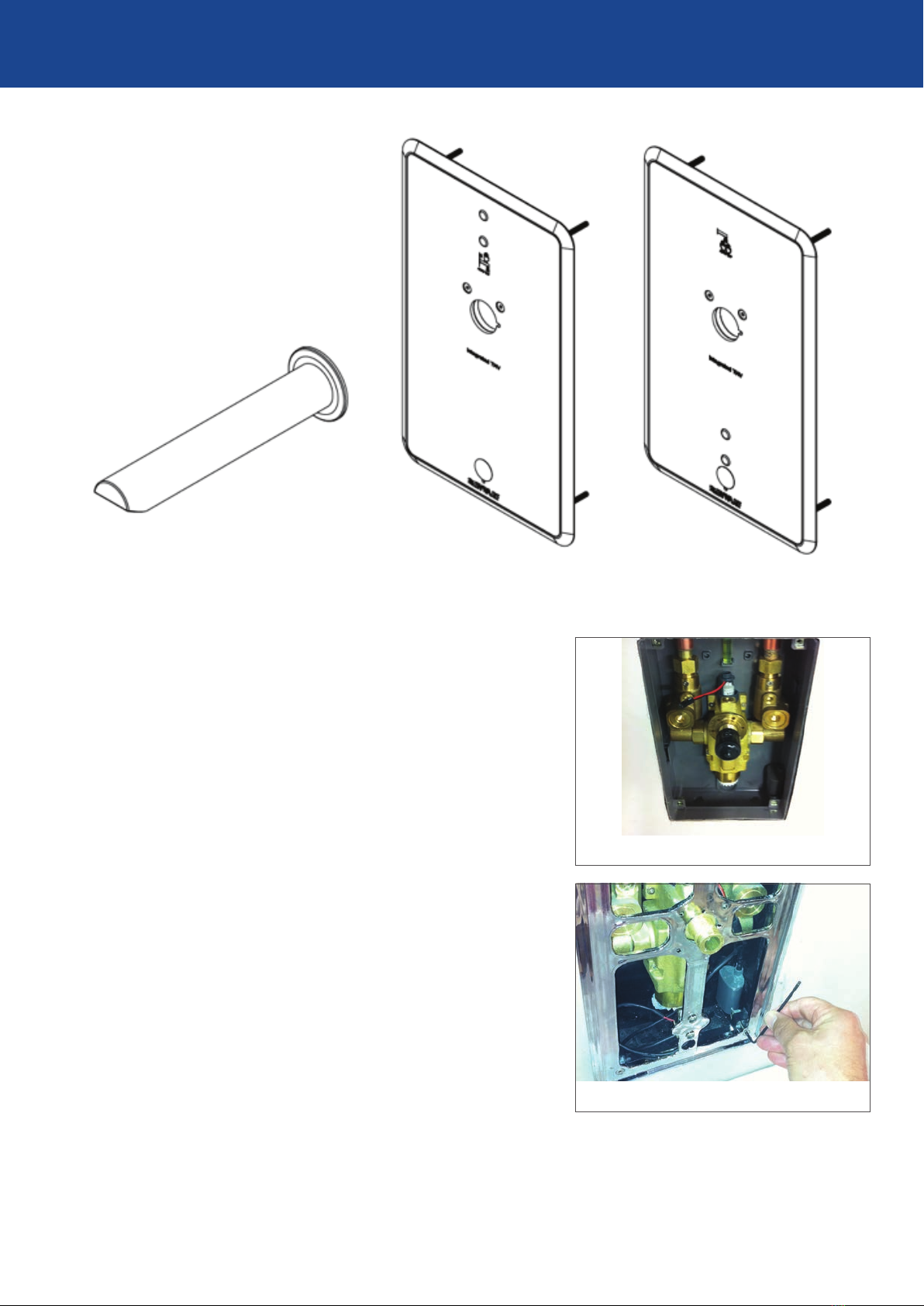

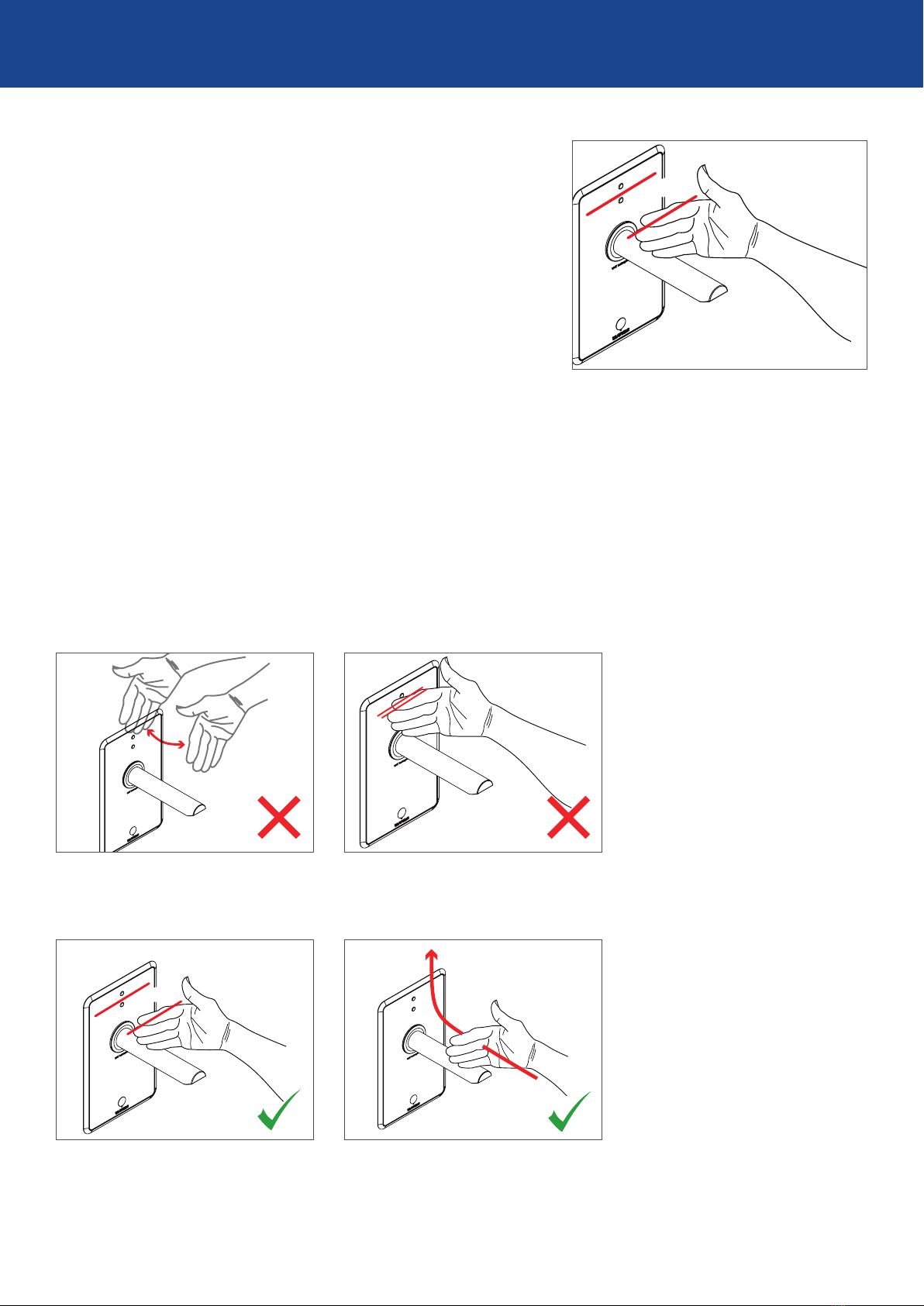

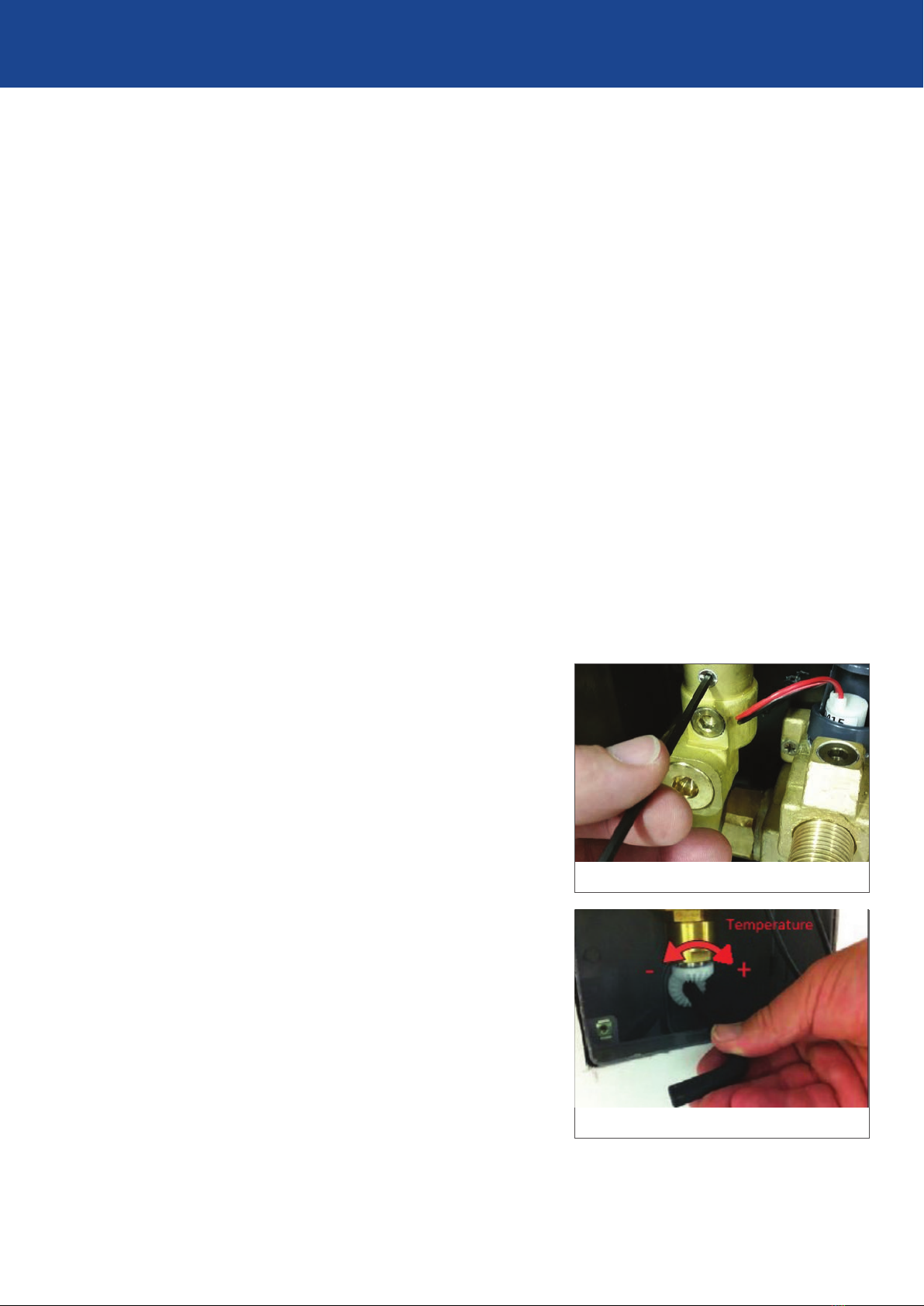

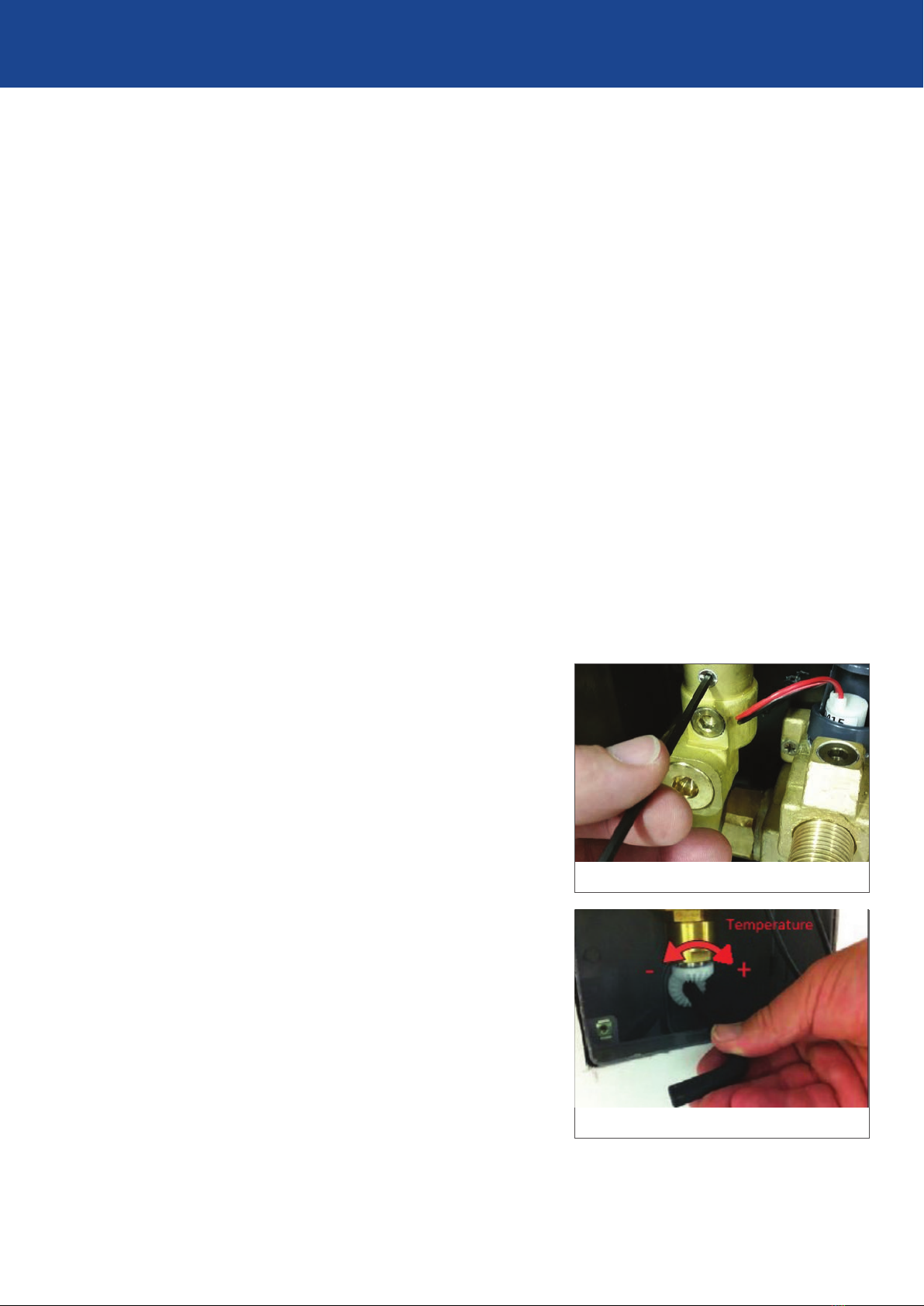

SETTING OUTLET TEMPERATURE

STEP 1 Turn on the integral isolation valves using a 2.5mm

Allen key or at head screw driver (if not already

turned on).

SEE IMAGE 26

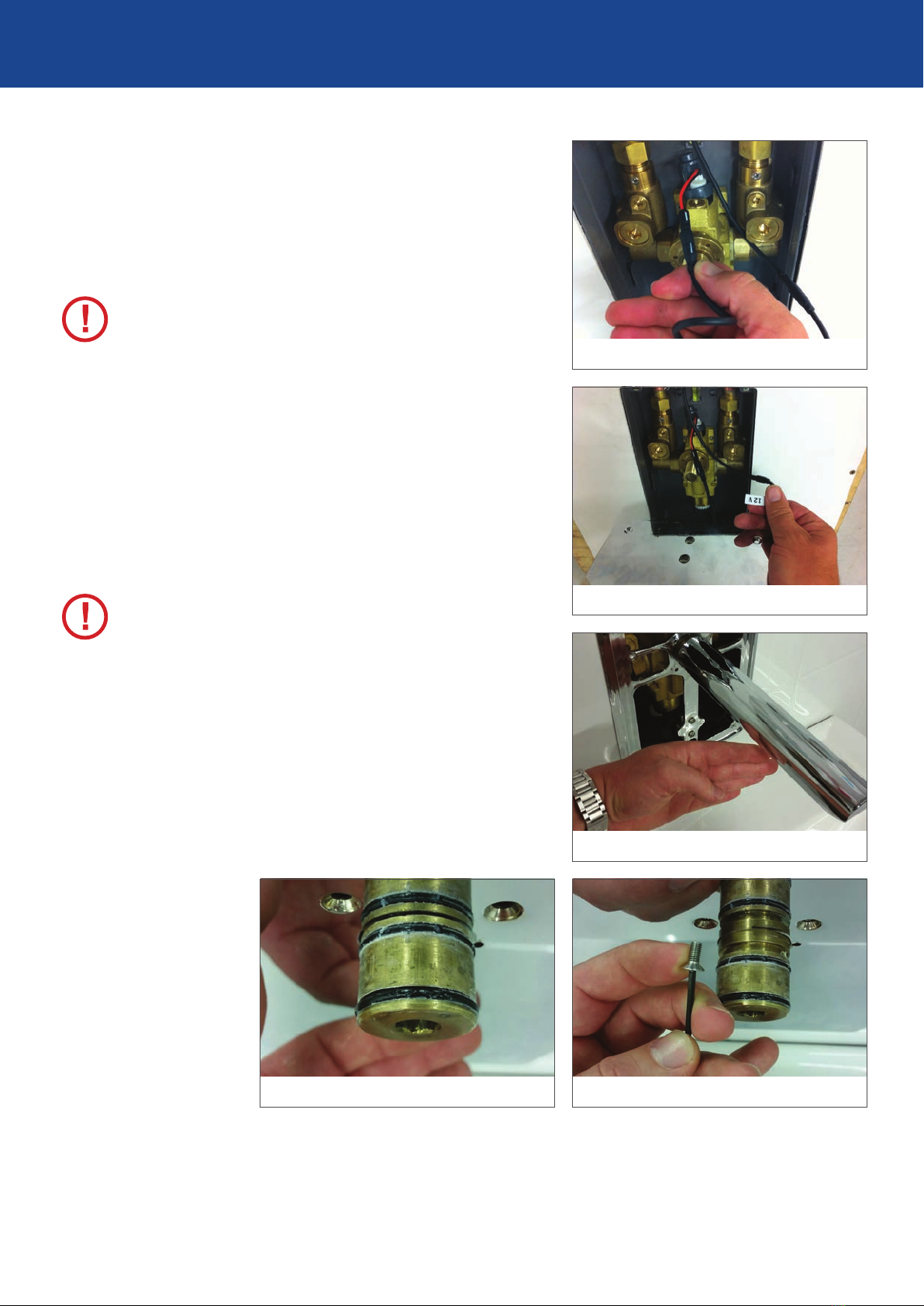

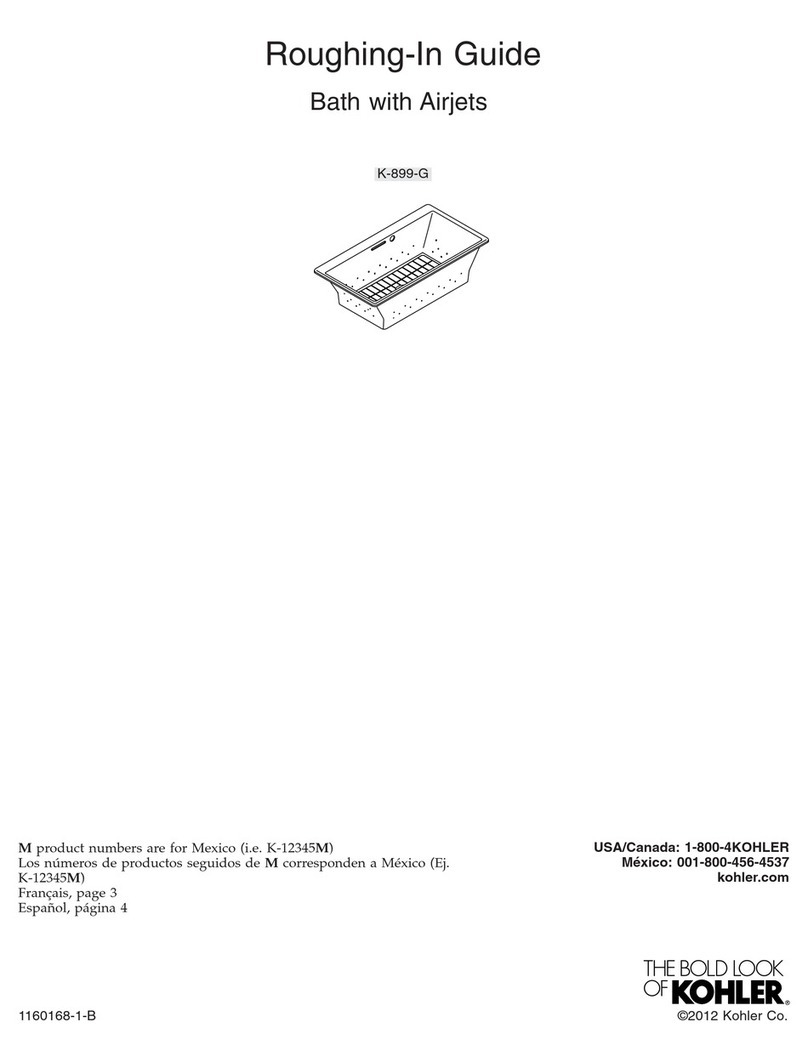

STEP 2 Insert the 3/8” Allen key into the mixer’s

temperature adjustment gear.

STEP 3 If the thermostatic mixer is closed, turn the tap

on by rotating the Allen key clockwise. Check the

temperature of the water with a hand held digital

thermometer. With the thermometer held within the

ow stream, rotate the Allen key until the desired

(maximum) temperature is achieved.

SEE IMAGE 27

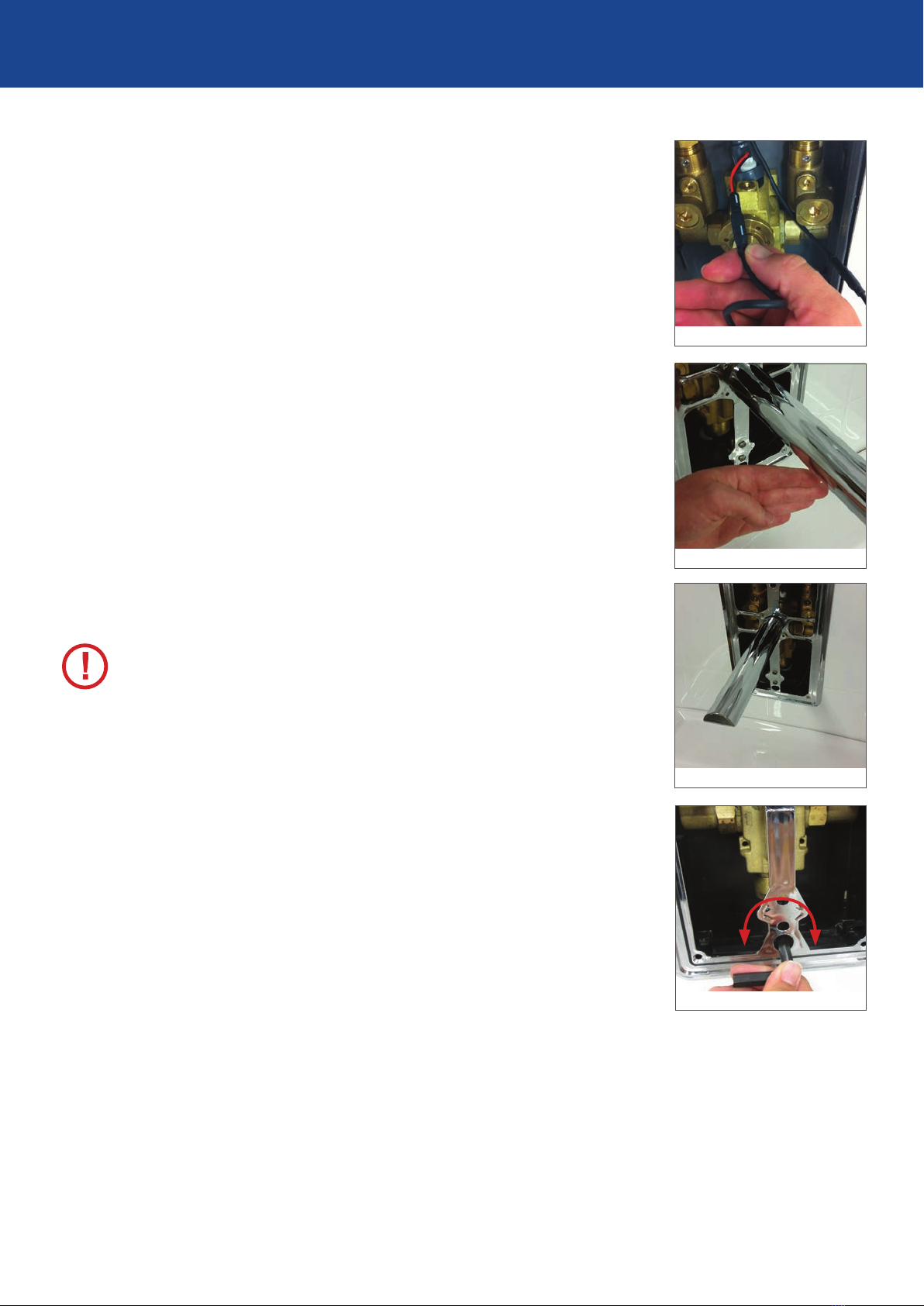

STEP 4 Once this desired temperature is set, make sure it

stays steady for a minimum of 60 seconds. Remove

the Allen key without changing the temperature

gear position.

Due to the installed water supply conditions being

different from those applied in the laboratory test,

it is appropriate at commissioning to carry out

simple checks and tests on each mixer to provide

a performance reference point for future scheduled

servicing.

In all cases the following must be checked to ensure

correct operational performance of the SQX™ valve:

• The intended installation matches the

performance brief of the SQX™ point of use

thermostatic.

• The supply temperatures and pressures are

within the permitted range as specied

in the Technical table - Installation Conditions

on Page 6.

Upon completion of the installation, the valve

should be tested and commissioned as per the

procedure outlined in this guide or as specied by

the local authority. The entire procedure should be

read through thoroughly prior to commissioning the

valve. A calibrated digital thermometer, having rapid

response time with maximum temperature hold

will be required to check and set the outlet mixed

temperature of the valve.

To test the temperature, allow the mixed heated

water to ow for at least 60 seconds - this allows

for a stable temperature reading. For optimum

performance, a ow rate of at least 4 Lpm is

recommended.

NOTE: The solenoid valve is a latching solenoid - it remains in either open or closed position

if power supply is not connected. Factory setting is at fully open position.

COMMISSIONING OF THE VALVE

IMAGE 26

IMAGE 27

COMMISSIONING