www.enware.com

To ensure that the mixing valve operates correctly it is

necessary that the pipework is thoroughly ushed with

clean water before the valve is installed. This will remove

any physical contaminants from the pipework, ensuring

trouble-free operation. During the ushing procedure care

should be taken to prevent water damage occurrng to the

surrounding area.

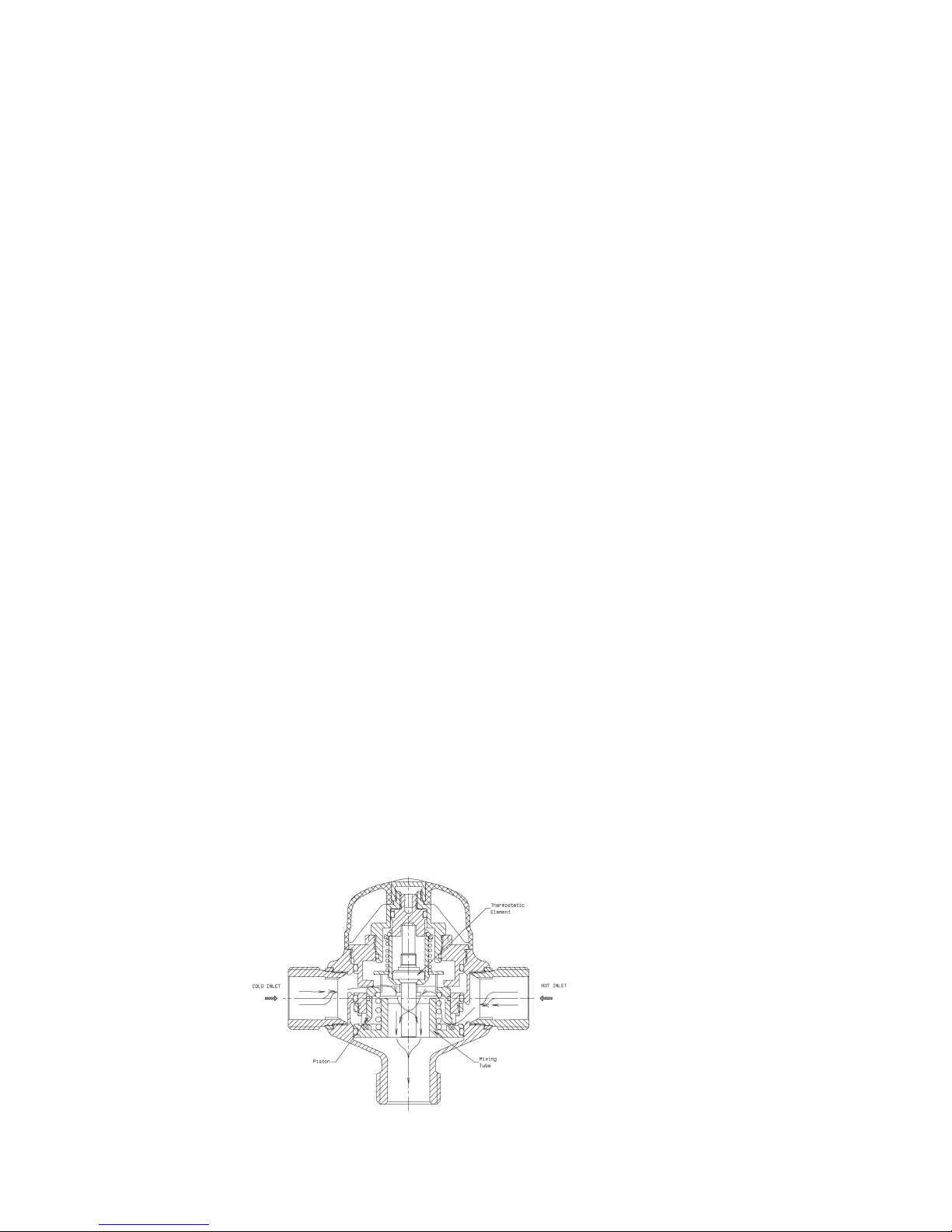

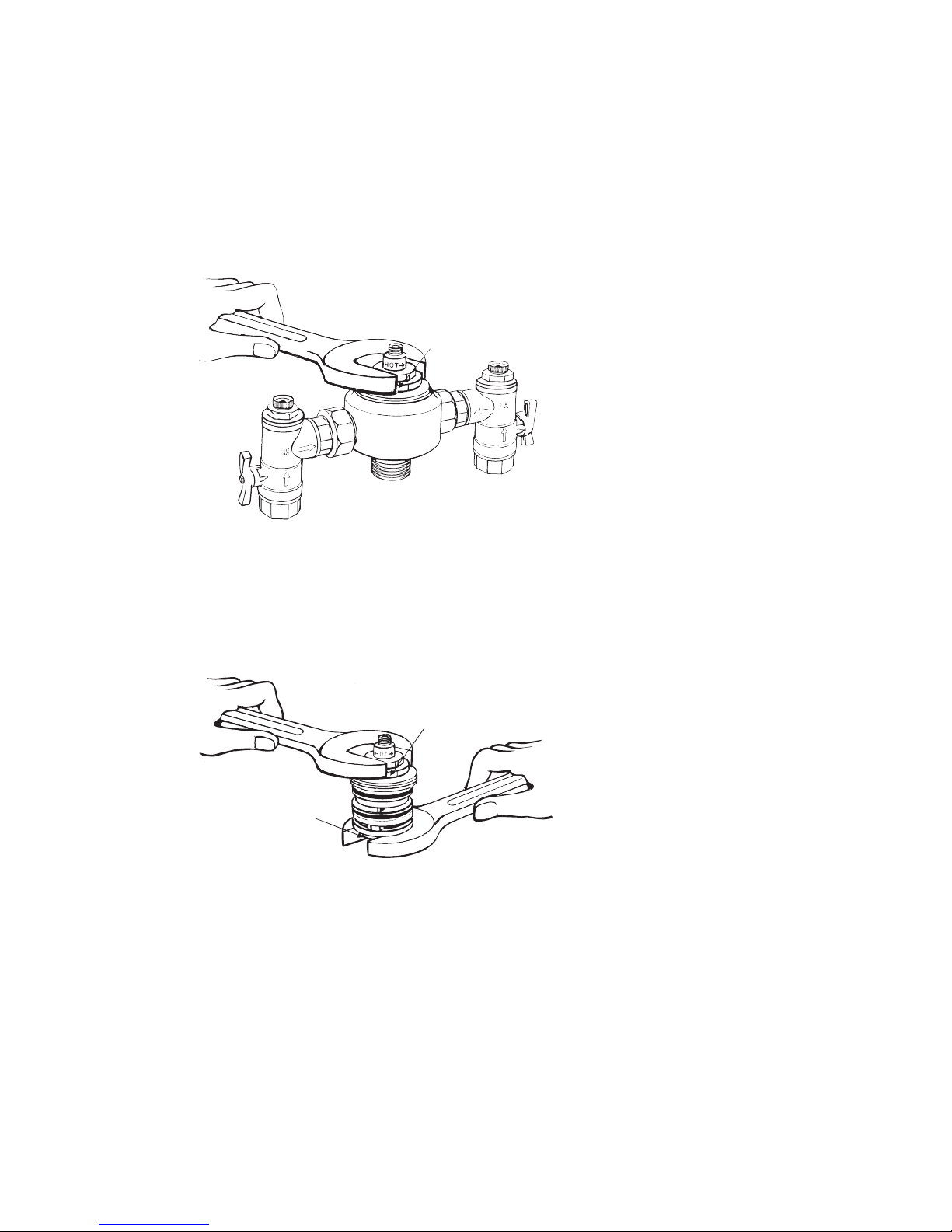

It is required by AS3500.4 that “Each thermostatic mixing valve

shall have an isolating stop tap/valve, line strainer & non-return

valve tted to the hot and cold water supply lines”. The inlet

ttings supplied with each TMV will ensure this requirement is

met. If the ENWARE AQUABLEND 2500 Thermostatic Mixing

Valve is to be installed without the supplied inlet control valves

then it will be necessary to install a separate isolating valve, non-

return valve and strainer to both inlets to the valve. Strainers

must be tted to prevent any particulate contamination from

entering the valve. These strainers should be 60 Mesh stainless

steel. Isolating valves are required so that the water supply to the

valve can be isolated in the event that servicing is required. Non-

return devices must also be tted to both the hot and cold inlets

to prevent cross-connection.

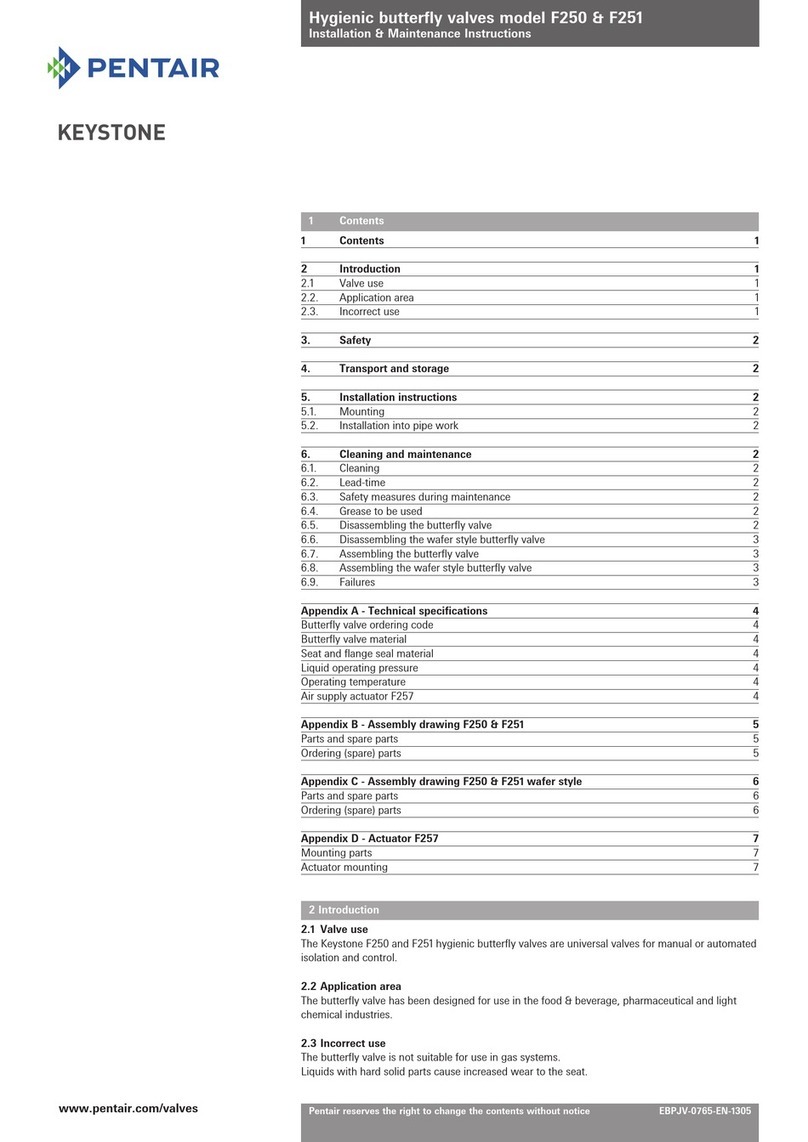

Ensure that the test plugs in the top of the inlet ttings are tight.

The 4mm Allen key for adjusting the temperature can be used to

tighten the test plugs.

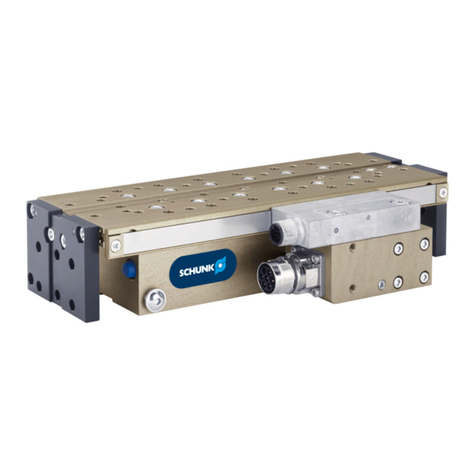

The valve should be installed so it can be accessed easily for

maintenance or servicing. The pipework to and from the valve

must not be used to support the weight of the valve. Saddle clips

or pipe support brackets must be used to mount the inlet control

valves and TMV rmly to a wall or rigid support structure. If the

inlet control valves are not used then a suitable support bracket

or saddle is required to support the weight of the valve. This is to

ensure that the pipework is not under load from the valve.

The valve can be installed in a wall cavity, under a basin or on a

wall, however it is essential that the mixing valve and inlet ttings

are easily accessible for servicing.

During installation or servicing, heat must not be applied

near the mixing valve and inlet ttings during installation

or servicing as this will damage the valve and inlet ttings

internals. Failure to comply with this requirement will damage

the valve and ttings. It will put the user at risk, and it will void the

warranty of the valve.