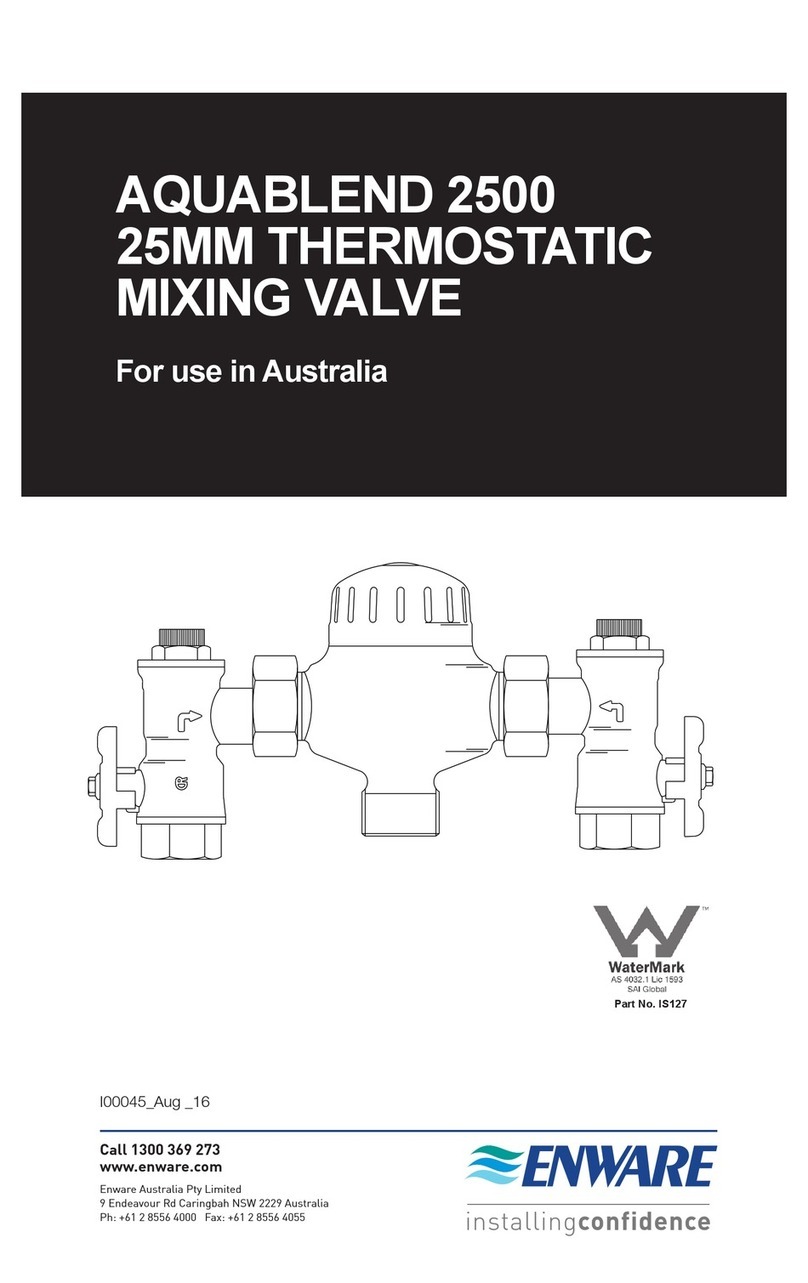

enware Aquablend 1500 User manual

Installation Instructions

FOR USE IN AUSTRALIA

15MM THERMOSTATIC MIXING VALVE

Call 1300 369 273

www.enware.com

Enware Australia Pty Limited

9 Endeavour Rd Caringbah NSW 2229 Australia

Ph: +61 2 8556 4000 info@enware.com.au

AQUABLEND 1500

THERMOSTATIC

MIXING VALVE

WITH THERMAL FLUSH

I00103_Jul 18

NEW AQUABLEND 1500

FAQ and technical info available at

www.enware.com.au/1500info

I00105 VC463

IS123

2 Call 1300 369 273 www.enware.com.au

THIS PAGE HAS INTENTIONALLY BEEN LEFT BLANK

www.enware.com.au Call 1300 369 273 3

PRODUCT FEATURES

Complies with the

requirements of AS4032

- Thermostatic Mixing

Valves

Provides high stability

of mixed water

temperature even

under changing inlet

conditions

Ensures rapid shut

down of mixed outlet

ow in the event of hot

or cold water supply

failure

Designed for quick and

simple in-situ servicing

Suitable for installation

into AS3500 compliant

systems with hot water

temperature as low as

55°C

Fitted with a Tamper

Resistant temperature

adjustment mechanism

Built-in Thermal Flush

feature allows controlled

thermal ush to the

TMV and warm water

plumbing system

Enware reserves the right to change any product specification or information

contained in this publication, at any time and without notice. Every care has

been taken to ensure accuracy in the preparation of this publication

which has been issued for guidance only. No liability can be accepted for any

consequences which may arise as a result of its application.

Enware is a trade mark of Enware Australia Pty Limited - A.C.N. 003 988 314

Aquablend TMV’s are exclusively manufactured for Enware Australia Pty Limited

by Reliance Worldwide 27-28 Chapman Place, Eagle Farm, Qld, 4009 Australia.

The ENWARE AQUABLEND

1500 THERMOSTATIC MIXING

VALVE is a high performance

Thermostatic Mixing Valve

suitable for a wide range

of applications. The valve

is designed to comply with

AS4032 - Thermostatic

Mixing Valves.

AQUABLEND 1500 THERMOSTATIC MIXING VALVE

4 Call 1300 369 273 www.enware.com.au

THIS PAGE HAS INTENTIONALLY BEEN LEFT BLANK

www.enware.com.au Call 1300 369 273 5

CONTENTS

SAFETY page 6

PRODUCT DESCRIPTION page 7

RECOMMENDED PRESSURES

AND TEMPERATURES page 10

FLOW SIZING GRAPH page 11

INSTALLATION page 12

COMMISSIONING OF THE VALVE page 15

MAINTENANCE & SERVICING page 18

THERMAL FLUSH page 20

TROUBLE SHOOTING page 22

SPARE PARTS page 24

COMMISSIONING REPORT page 25

SERVICING REPORT page 28

WARRANTY page 30

AQUABLEND 1500 THERMOSTATIC MIXING VALVE

6 Call 1300 369 273 www.enware.com.au

SAFETY

The ENWARE AQUABLEND 1500 Thermostatic Mixing Valve

is a high performance valve designed to give stable and

dependable operation, provided it is installed, commissioned,

operated and maintained as per the recommendations

outlined in this manual. It should be noted however that this

valve should not be considered as an alternative to adequate

supervision and duty of care during its use and operation.

Note: When installed, the mixing valve, inlet controls, pipework

and the surrounding area may become hot, which may cause

burn injuries. Precautions should be taken to ensure that these

surfaces cannot cause such injuries.

www.enware.com.au Call 1300 369 273 7

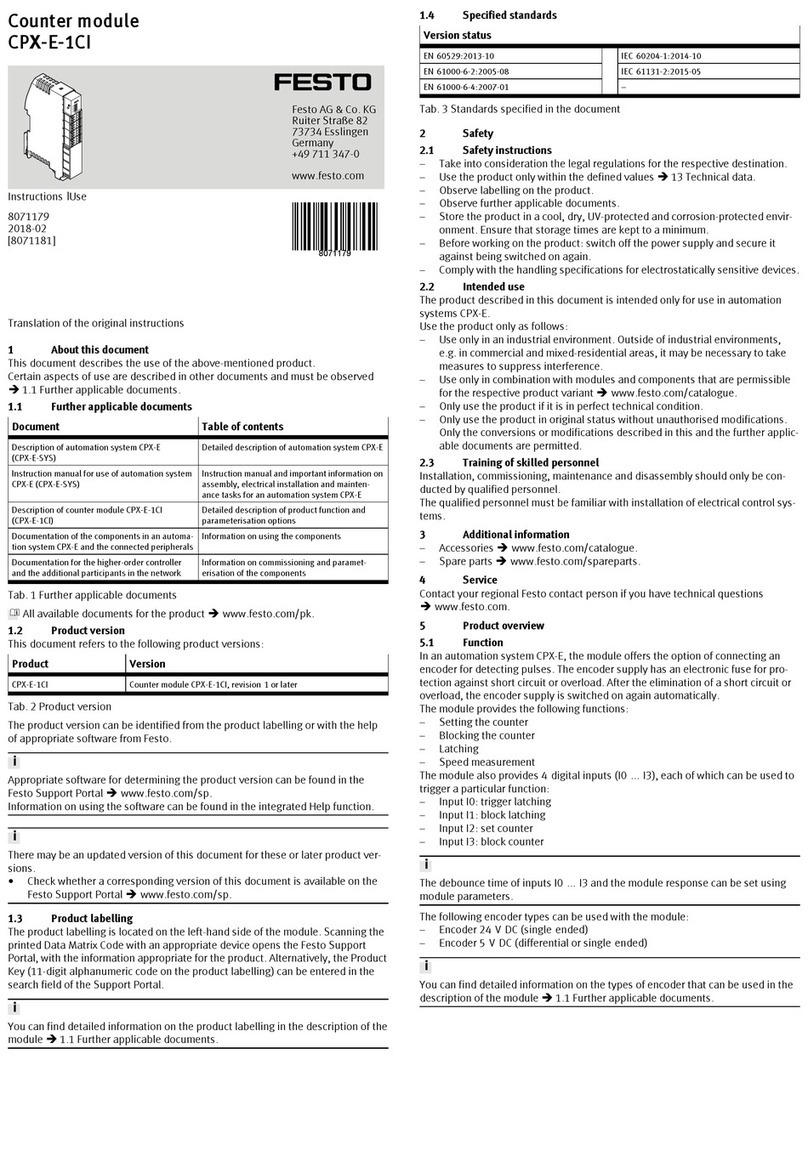

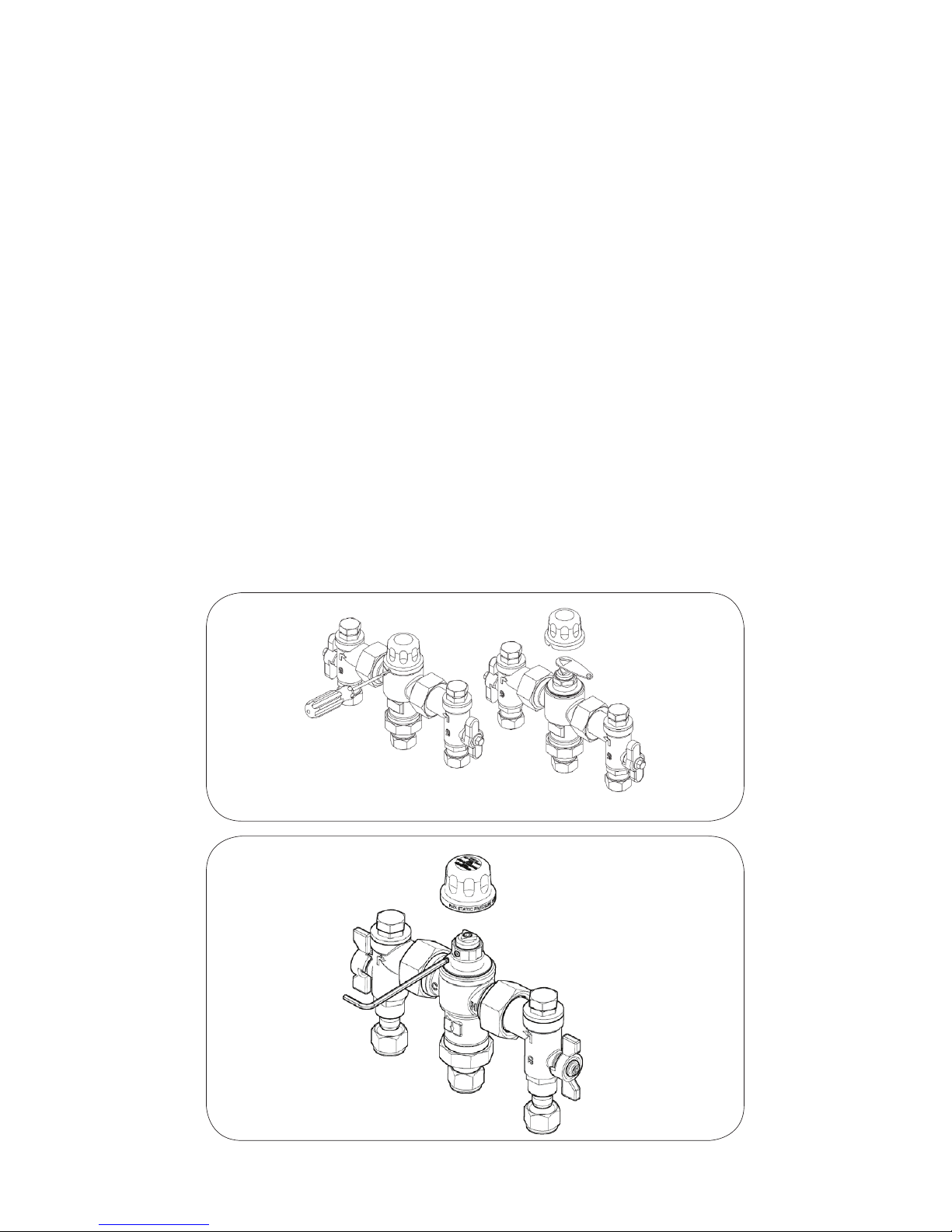

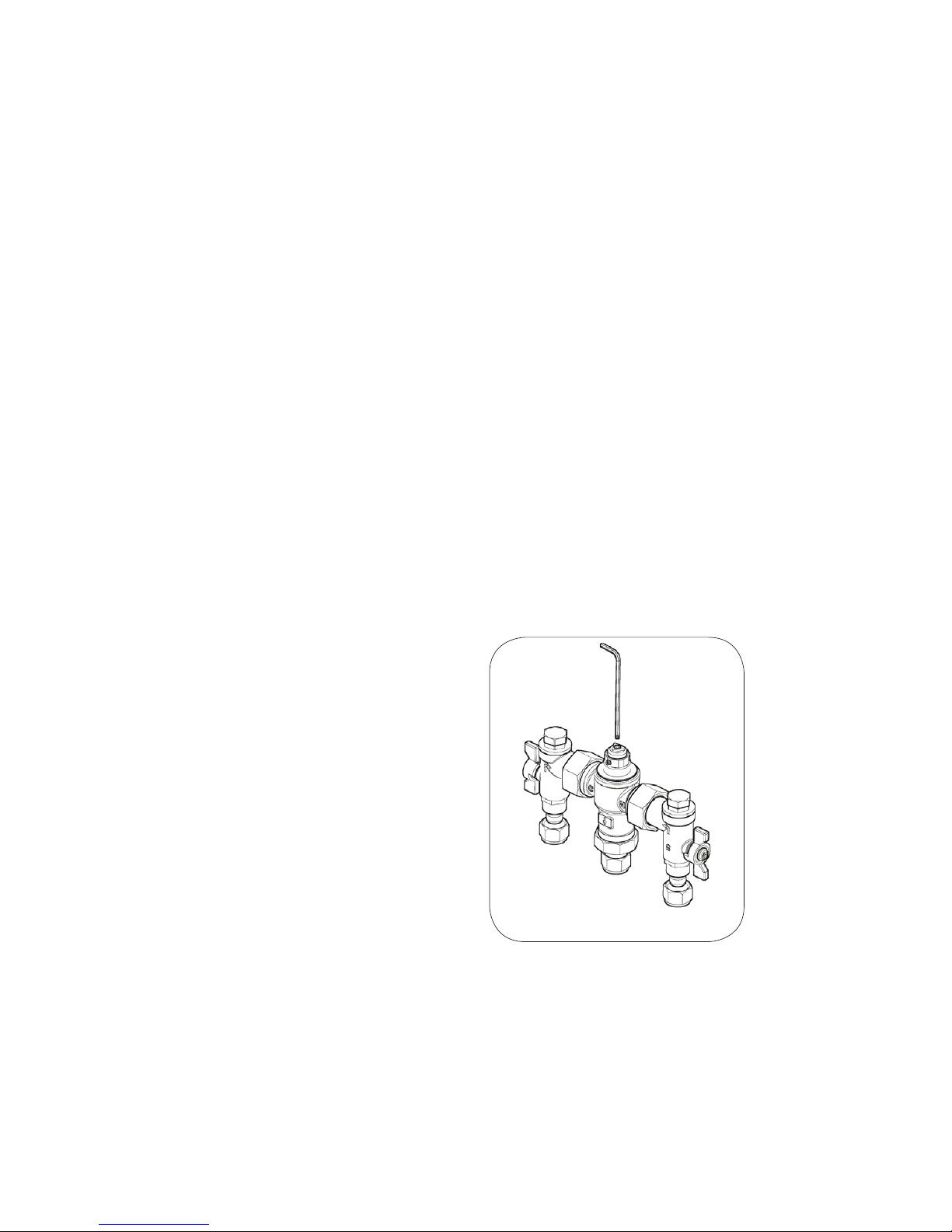

PRODUCT DESCRIPTION

The ENWARE AQUABLEND 1500 Thermostatic Mixing Valve

is available complete with inlet service ttings. The inlet to

the ttings is ½” BSP male, and the outlet from the valve is

½” BSP male adapter with an optional ¾” BSP male adaptor.

The service ttings consist of isolating ball valves, strainers,

pressure test points and non-return valves. The strainers can

be serviced and cleaned without disturbing the installation

(refer to Maintenance and Servicing section). The inlet service

ttings also incorporate union type ttings enabling the

thermostatic mixing valve to be removed from its installation

without disturbing its pipework.

AQUABLEND 1500

Enware Product Code ATM700

Outlet Size 1” with 1/2" and 3/4" BSP adaptors

Inlet 1/2" BSP male with compression nuts

Dry Weight 2 kg

Finish Nickel Plated

160

80

225

125

1” BSP (½” & ¾” BSP

ADAPTORS SUPPLIED)

1/2" BSP

IMAGE 1

8 Call 1300 369 273 www.enware.com.au

PRODUCT DESCRIPTION

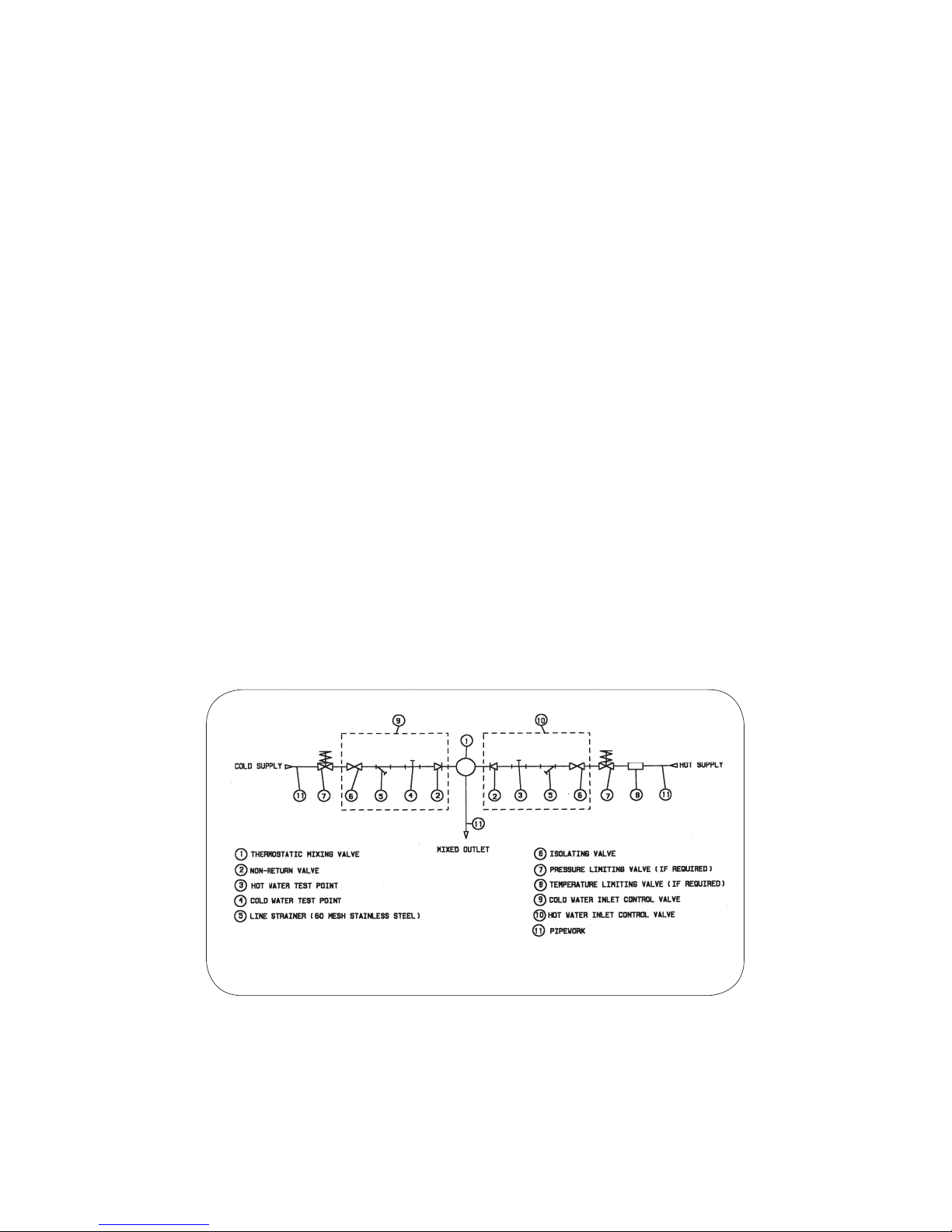

Method of operation is illustrated in IMAGE 2 below:

Hot and cold water is supplied to each side of the valve

respectively. The hot water enters through a port below the

Piston, the cold water enters above the Piston. Upon entry

the water begins to blend and enters the Mixing Tube. At

this point the mixed water contacts the thermostatic wax

Element. The Element will extend or contract to match the

water temperature it is exposed to causing the Piston to move,

thereby regulating the amounts of hot and cold water entering

the valve. This thermostatic mechanism maintains the mixed

water temperature at a constant temperature.

IMAGE 2 - GENERAL ARRANGEMENT DRAWING

www.enware.com.au Call 1300 369 273 9

PRODUCT DESCRIPTION

If, for example the inlet hot pressure dropped, the ow of

hot water into the valve would be reduced and the valve

would react as per the following sequence of events:

• Element is exposed to mixed water at a reduced

temperature

• Thermostatic Element contracting

• Piston is pushed upwards by the return spring restricting

cold ow, consequently opening more of hot port.

• Valve attempts to restore itself to original temperature

setting.

Similarly if the hot inlet temperature dropped, the element

would again see blended water at a lower temperature and

therefore the Element would again contract reducing the

cold port piston gap and hence supply more hot water and

less cold. Once again the valve attempts to restore itself to

its original setting. This will occur for all changing conditions

including changes to ow rate, inlet temperatures and inlet

pressures.

In the event of a sudden loss of the cold water supply the

Piston will shut off the hot port thus stopping any ow through

the valve. The valve will also shut down the cold supply if there

is a hot water failure.

10 Call 1300 369 273 www.enware.com.au

RECOMMENDED PRESSURES

& TEMPERATURES

MIXED OUTLET TEMPERATURE

Temperature Adjustment Range 35-48°C

INLET TEMPERATURES

Cold Supply Minimum 5°C

Maximum 30°C

Hot Supply Minimum 55°C

Maximum 90°C

Hot to Mix Temperatures Differential for

Stable Operation Minimum 10°C

Cold to Mix Temperatures Differential

for Stable Operation Minimum 5°C

FLOW RATES - TO ENSURE STABLE CONDITIONS SEE IMAGE 3

Minimum 4 litres/minute as per ow sizing graph

Maximum 39 litres/min @ 300kPA Pressure loss as per ow

sizing graph

DYNAMIC INLET PRESSURES

Hot & Cold Inlet Pressures Minimum 20kPa

Maximum 500kPa

STATIC INLET PRESSURES

Hot & Cold Inlet Pressures Maximum 1600kPa

INLET PRESSURE RATIO

H - PL = H¹

C - PL = C¹

H¹ : C¹ = Max 10:1

C¹ : H¹ = Max 10:1

H = Hot inlet pressure

C = Cold inlet pressure

PL = Pressure Loss

NOTE: For optimum operation it is recommended that the hot

& cold water supply pressures be balanced to within +/- 10%.

Notwithstanding the above, compliance with AS3500 must be

maintained.

www.enware.com.au Call 1300 369 273 11

HEADLOSS CHARACTERISTICS OF AQUABLEND 1500

NOTE: To ensure optimum performance the minimum

outlet ow of the mixing valve during operation should be at

least 4 litres/minute.

It is important that the valve is sized such that the ow

rates from the outlets are not less than those listed in

AS3500.1.Section 3. The pipework between the valve and the

system must be sized in accordance with AS3500.1 Section 3

and Appendix C to ensure the water velocity in the pipework is

within the allowed limit.

If the valve is to be installed and operated under unequal

inlet pressures the lower inlet pressure determines the outlet

ow rate. However, for optimum performance and stability

it is recommended that the valve be installed with balanced

dynamic inlet pressures (+/- 10%).

FLOW SIZING GRAPH

The ENWARE AQUABLEND 1500 Thermostatic Mixing Valve

is suitable for many applications.

The Headloss Characteristic for Mixed Outlet Flowrate

versus Balanced Inlet Pressure is shown below in IMAGE 3.

It is important that the valve is not oversized for its intended

application.

IMAGE 3 - Headloss Characteristics

12 Call 1300 369 273 www.enware.com.au

INSTALLATION

The ENWARE AQUABLEND 1500 Thermostatic Mixing Valve

should be installed using the appropriate Standard, Code of

Practice and legislation applicable to each state and following

the details outlined in this section.

The ENWARE AQUABLEND 1500 must be installed by a

licensed plumber, or where applicable, a licensed plumber who

has undertaken TAFE training in Thermostatic Mixing Valves.

NOTE: To effectively control microbial hazards

during system design, installation, commissioning and

maintenance, the requirements outlined in AS/NZS3666 and

local legislation shall be adhered to.

Inlets and outlet connections of the valve are clearly marked.

The letters H and C cast into the valve body indicates the Hot

and Cold Inlet respectively. An arrow cast into the body of the

valve identies the valve outlet direction.

If the valve is not installed correctly then it will not function

correctly and may put the user in danger. It may also void the

warranty of the valve.

Prior to the installation of the valve, the system must be

checked to ensure that the system operating conditions fall

within the recommended operating range of the AQUABLEND

1500 Thermostatic Mixing Valve as detailed on page 10 -

recommended temps & pressures.

If the hot water supply temperature is greater

than 90°C the valve may be damaged. A suitable

temperature limiting valve must be tted to the hot water

supply, prior to the inlet ttings, if the temperature of the

hot water will rise above 90°C. This temperature limiting

valve must be installed as per the manufacturer’s instructions.

Alternatively, use AQUABLEND 1500 SOLAR - Code ATM715.

It is also important that both of the inlet dynamic

supply pressures are 500kPa or less. If either

supply pressure exceeds 500kPa then a suitable pressure

reducing valve must be tted prior to the inlet control

valve to reduce the pressure to an acceptable limit.

www.enware.com.au Call 1300 369 273 13

INSTALLATION

These pressure reducing valves must be installed as per the

manufacturer’s instructions. For optimum performance from the

valve it is recommended that the inlet pressures are balanced

to within 10% of each other.

The water quality conditions should be checked to ensure they

do not exceed the limits as listed in AS3500.4, Section1.6. If

they do exceed the limits it will be necessary to install a water

softener or water treatment device.

NOTE: In some installations where certain types of faucet

devices such as ick mixers and solenoid valves are used,

the water pressure may be seen to spike outside that

recommended for the valve during rapid shut off conditions

created by these types of devices. Even if the spike only

lasts a split second it is still considered to be outside the

operating conditions, and may cause the valve to operate

incorrectly. In the event that this does occur, measures must

be taken to control the spike, such as an inline pressure

reducing valves directly before the valve inlets.

To ensure that the mixing valve operates correctly it is

necessary that the pipework is thoroughly ushed with

clean water before the valve is installed. This will remove

any physical contaminants from the pipework, ensuring

trouble-free operation. During the ushing procedure care

should be taken to prevent water damage occurring to the

surrounding area.

It is required by AS3500.4 Section 3.3 that “Each thermostatic

mixing valve shall have an isolating stop tap/valve, line strainer

and non-return valve tted to the hot and cold water supply

lines”. The inlet ttings supplied with each TMV will ensure this

requirement is met.

If the ENWARE AQUABLEND 1500 Thermostatic Mixing Valve

is to be installed without supplied inlet control valves then it will

be necessary to install a separate isolating valve, non-return

valve and strainer to both inlets to the valve.

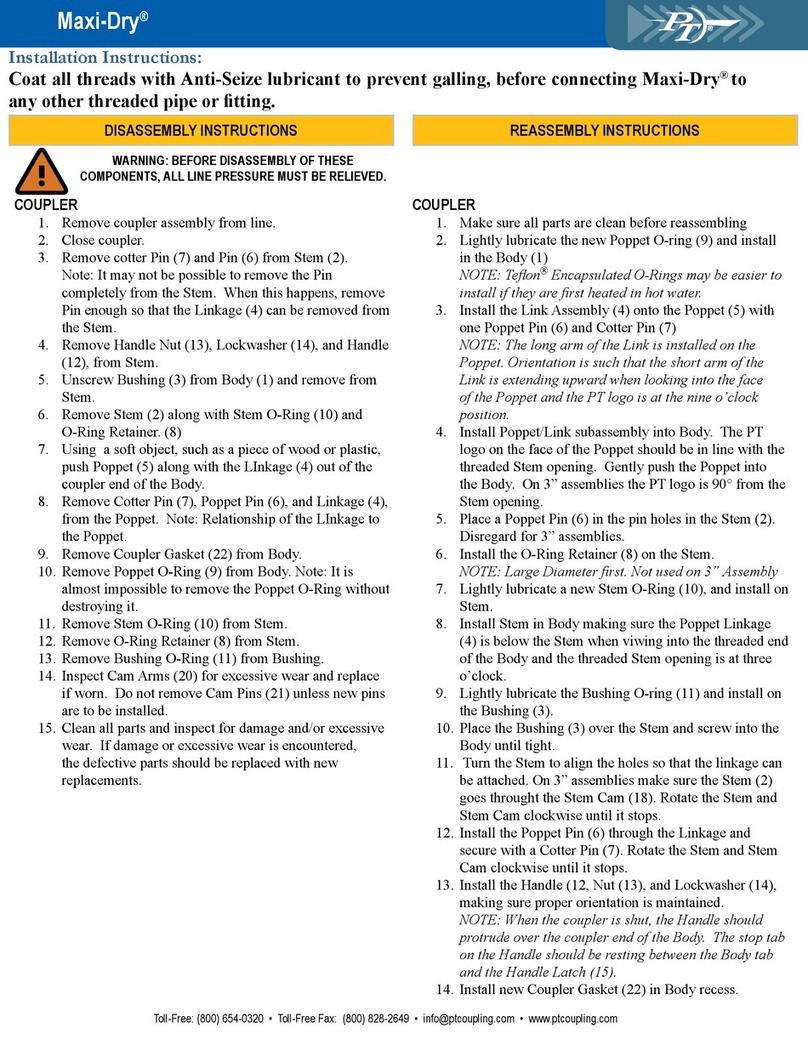

SEE IMAGE 4 on following page.

14 Call 1300 369 273 www.enware.com.au

INSTALLATION

Strainers must be tted to prevent any particulate

contamination from entering the valve. These strainers should

be 60 Mesh stainless steel. Isolating valves are required

so that the water supply to the valve can be isolated in the

event that servicing is required. Non-return devices must

also be tted to both the hot and cold inlets to prevent cross-

connection. SEE IMAGE 4

Ensure that test plugs in the top of the inlet ttings are tight.

The valve should be installed so it can be accessed easily

for maintenance or servicing. The valve can be installed in a

wall cavity, under a basin or on a wall, however it is essential

that the mixing valve and inlet ttings are easily accessible for

servicing.

During installation or servicing heat must not

be applied near the mixing valve or inlet ttings,

as this will damage the valve and inlet tting

internals. Failure to comply with this requirement will

damage the valve and ttings. It will put the user at risk,

and it will void the warranty of the valve.

IMAGE 4 - Schematic Installation Diagram

www.enware.com.au Call 1300 369 273 15

COMMISSIONING OF THE VALVE

Upon completion of the installation, the valve should be

tested & commissioned as per the procedure outlined below

or as specied by the local authority. The entire procedure

should be read through thoroughly prior to the commissioning

of the valve. A calibrated digital thermometer having rapid

response time with maximum temperature hold, a small at

bladed screwdriver and the adjusting key (supplied with the

AQUABLEND 1500) will be required to check & set the outlet

mixed temperature of the valve.

Ensure all outlets that will be serviced by the valve have

adequate warning signs posted to ensure that no outlet is used

during commissioning.

Open the cold supply line to the valve, then open the hot

supply line, ensuring there are no leaks.

Open the outlet that is serviced by the shortest length of pipe

work between the mixing valve and outlet xture.

Allow the mixed outlet to ow for at least 60 seconds to allow

the temperature to stabilise before taking a temperature

reading at the outlet with a digital thermometer. The ow

rate should be at least 4L/min. The ow rate can be checked

with the aid of a known size container and a stopwatch. The

temperature should be taken at the closest outlet served by

the thermostatic mixing valve.

If the outlet temperature requires adjustment please follow

steps below.

TEMPERATURE ADJUSTMENT

1. Using a small at bladed screw driver, lever the Red Lock

Shield (protective cover) off the valve. SEE IMAGE 5

(over page)

2. Loosen the temperature adjustment locking grub screw

located on the Hex of the top cap using 2mm Allen Key.

SEE IMAGE 6

If the grub screw is not easily accessible, relocate the grub

screw to the most accessible screw hole (3 screw holes are

provided on the top cap for convenience). Leave the grub

screw loose.

16 Call 1300 369 273 www.enware.com.au

COMMISSIONING OF THE VALVE

3. Fit supplied key over the adjusting spindle. SEE IMAGE 5

• To increase the mixed outlet temperature,

rotate the spindle anti-clockwise.

• To decrease the mixed outlet temperature,

rotate the spindle clockwise

4. Allow the mixed outlet temperature to stabilize for 60 secs

and once again take a temperature reading. Repeat the

procedure until the desired temperature has been reached.

5. Tighten the temperature adjustment locking grub screw.

SEE IMAGE 6

6. Push the top cover rmly back on to the top of the valve

until it ‘snaps’ back into place.

7. Check the outlet temperature is stable over the full range of

ow rates and that ow rate is adequate for the application.

8. Close the outlet.

9. The mixing valve is now set and locked.

IMAGE 5

IMAGE 6

www.enware.com.au Call 1300 369 273 17

COMMISSIONING OF THE VALVE

SHUT DOWN TEST

Now that the mixing valve has been set and locked it is

necessary to perform a shut down check. Allow the mixed

water temperature to stabilise and note the outlet temperature.

While holding a digital thermometer in the outlet ow, quickly

isolate the cold water supply to the valve. The outlet ow

should quickly cease owing. As a rule of thumb the ow

should be less than 0.1L/min following the isolation. Monitor

the maximum outlet ow temperature, and record this on the

Commissioning Report. The temperature should not exceed

that allowed by the applicable standard or code of practice for

each state. Restore the cold water supply to the valve. After

the mixed water temperature has stabilised note the outlet

temperature ensuring the outlet temperature has

re-established.

Repeat the above test, except this time quickly isolate

the hot water supply to the valve. The outlet ow should

quickly slow to a trickle. As a rule of thumb the trickle should

typically be less than 0.4L/min@500kPa down to less than

0.1L/min@100kPa following the isolation. Restore the hot

water supply to the valve. After the mixed water temperature

has stabilised, measure and record the outlet temperature,

ensuring the outlet temperature has re established.

Ensure that all details of the Commissioning Report are

completed & signed by the relevant signatories & a copy is

kept with the installer and owner of the premises.

The valve is now commissioned and it can be used within

the technical limits of operation.

18 Call 1300 369 273 www.enware.com.au

MAINTENANCE AND SERVICING

The ENWARE AQUABLEND 1500 Thermostatic Mixing Valve

will only require minimal preventative maintenance work to

ensure it operates at its optimum level of performance. The

valve should be commissioned and serviced annually, unless

the installed conditions dictate more frequent servicing is

necessary.

ANNUAL MAINTENANCE PROCEDURE

Every 12 months the ENWARE AQUABLEND 1500 should be

inspected & tested. The valve’s external surfaces should be

given a light wipedown. The valve & surrounding area should

be inspected for leaks or water damage and action taken if

required. Ensure a clean dry work area is available.

Cleaning the Strainers

Firstly isolate the hot and cold supplies to the mixing valve by

closing the inlet ball valves. With a suitable spanner remove

inlet tting top cover then remove mesh strainer SEE IMAGE 7

Clean strainers with a suitable descaling solvent (such as

CLR) diluted with water. Check for physical damage and

thoroughly rinse with clean water. Strainers can then be re-

installed into the valve and top cover replaced and tightened to

a maximum torque of 15Nm into the inlet valve bodies.

IMAGE 7

www.enware.com.au Call 1300 369 273 19

Non-Return Valve Operation

To check Non-Return Valve on the HOT inlet side,

carry out the following steps:

1. Turn OFF the isolation tap on the HOT inlet only

(COLD inlet must be open)

2. Open Test Port Cap on the HOT inlet side

3. Observe water level in the HOT inlet side test port.

4. If there is a rising water level this may indicate a fouled or

faulty Non-Return Valve. If this is the case, inspect the non-

return valve for damage or any debris, and replace Non-

Return Valve if required.

6. Replace the test port cap on HOT inlet side ensuring it is

tightly secured.

7. Turn back ON the isolation tap on the HOT inlet.

8. To check Non-Return Valve on the COLD inlet side, repeat

steps above using the COLD inlet side.

Check that the test plug in the top of the inlet ttings are tight,

and that there is no evidence of water leakage.

The valve must then be recommissioned as per page 15,

including temperature adjustment and the shut down test.

If the valve fails to shut down or fails to maintain its set

temperature, refer to the troubleshooting solutions outlined on

page 22.

The valve piston ‘O’ ring and thermostatic element/piston

assembly must be replaced at intervals not exceeding 5 years.

20 Call 1300 369 273 www.enware.com.au

THERMAL FLUSH OPTION

The ENWARE AQUABLEND 1500 includes a built-in Thermal

Flush feature allowing the facilities maintenance team or

licensed service contactors to perform a controlled thermal

ush to the TMV and warm water plumbing system.

NOTE: The thermal ush procedure is optional and does

not form part of commissioning and service requirements

set out in AS4032.3

Before commencing the thermal ush, a site-specic

procedure must be implemented to control the risk of

scalding. Hot water will run directly to the outlets fed by the

Thermostatic Mixing Valve, and precautions shall be taken to

prevent the chance of injury.

1. Isolate both hot and cold inlet valves to the TMV.

2. Remove the TMV’s Red Lock Shield (protective cover).

3. Check that the temperature adjustment locking grub screw

(located on the hex of the top cap) is tight (see IMAGE 6).

4. Insert a 3mm Allen key into

the Thermal ush activation

point located in the centre of

the temperature adjustment

screw on the valve’s top cap.

5. Wind Thermal activation

screw anti-clockwise until it

stops. A red indicator will be

visible.

6. Turn the hot water TMV

inlet valve to the on

position.

7. Turn the tapware outlet to the on position

Note: full temperature hot water will ow from the

tapware. Care must be taken to prevent scalding

8. Once the required time set in the facility’s Thermal Flush

procedure has passed, turn the hot water TMV inlet valve to

the off position.

IMAGE 8

Table of contents

Other enware Control Unit manuals

Popular Control Unit manuals by other brands

Raytheon Electronics

Raytheon Electronics ST6000 Plus Owner's handbook

ABB

ABB Relion 615 series List manual

Homematic IP

Homematic IP HmIP-MOD-TM quick start guide

National Instruments

National Instruments NI 9214 Operating instructions and specifications

ABB

ABB Welcome M2307 Online manual

Sony

Sony MSU-900 Operation manual