12

13

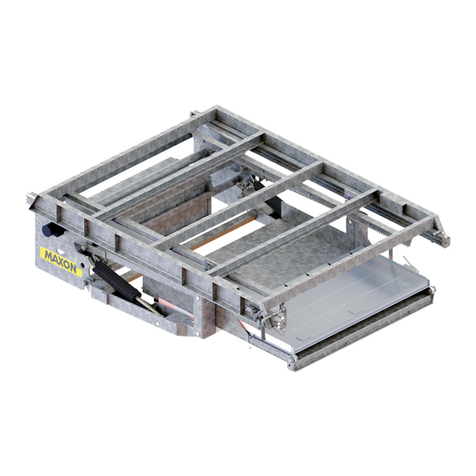

60 Spring washer 6 4 88 Safety rod 2

61 Nut M6 4 89 Bushing 8

62 Nut M8 4 90 Screw M10×40 2

63 Spring washer 8 9 91 External scissors for chassis 1

64 Washer 2 92 Bushing 2

65 Spring washer 12 2 93 Roller for chassis 2

66 Hex screw M12×30 2 94 Washing 4

67 Screw M10×25 16 95 Bushing 2

68 Front wheel 2 96 Pin axle 2

69 Nut M10 16 97 Pin axle for chassis 1

70 Front wheel 2 98 Pin axle for chassis 2

71 Chassis 1 99 Pin axle for table 1

72 Screw M6x8 1 100 Bushing 2

73 Table 1 101 Screw M6×16 2

74 Roller for table 2 102 Cable 1

75 Bushing 2 103 Cable velcro strap 1

76 Retaining ring for axle 20 6

OPERATION INSTRUCTION ENERGY SERVICE-FREE LEAD – ACID STORAGE BATTERY

1. Storage and Transportation

◇ Uncharged ENERGY storage battery needs no maintenance,Please store it in dry and frostless

place.

◇ If the density of electrolyte in filled battery is less than 1.23kg/l,it shall be recharged as soon as

possible,If the density of electrolyte filled in is 1.23kg/l,the storage battery shall be recharged when it is

below 1.18kg/l.

◇ During transportation or storage,the filled storage battery shall be kept upright vertically to prevent

acid liquid from overflowing.

◇ Cover opening、 short circuit、 sliding and other damage shall be avoided in the course of

transportation.

2. PUT INTO USE

◇ Precharged but unfilled ENERGY storage battery can be put into use at once without charging after

electrolyte is filled in it.

◇ When it is being filled,the temperature of battery and electrolyte should be 10℃ at least.

◇ Each unit of battery shall be filled with special acid whose density is 1.28kg/l.(1.23kg/l in the area of

tropics), and be filled up to the line indicating the maximum level or to the height of

15mm over the top of pole plate.

◇ Refill proper electrolyte if necessary.

◇ Screw or press the sealing hole tightly.

◇ Clean the acid liquid left on its surface.

◇ The storage battery can be in good condition without any service within 5 years at the

temperature of 20℃.

NOTE: If the output of the battery is not enough due to temperature or storage,Please recharge the

storage battery.

3. CHARGING

◇ Before recharging,please take the battery down.

◇ The storage battery is allowed to be charged with DC power,Connect the plus pole and minus pole

of storage battery correspondingly to the poles of the charger.

◇ Ensure to connect the poles rightly,switch on the charger.

◇ When the battery be charged sufficiently,cut off the charger.

◇ Recommended charging current is 1/10 of battery capacity(e.g.1/10×44=4.4A for the storage

battery with capacity of 44Ah.)

◇ In the course of charging,the temperature of electrolyte is not allowed to be above55℃.

◇ If the temperature of electrolyte is above 55℃,stop charging.

◇ If the density of electrolyte and the voltage of the battery stop increasing for 2 hours,the storage

battery could be thought to be charged sufficiently.

◇ When the charging is ended,please check the level of electrolyte,Add pure water to the maximum

level indicating line if necessary.

4. Maintenance

To ensure the service life of storage battery,the following points must be followed.