AMF-BRUNS K70 User manual

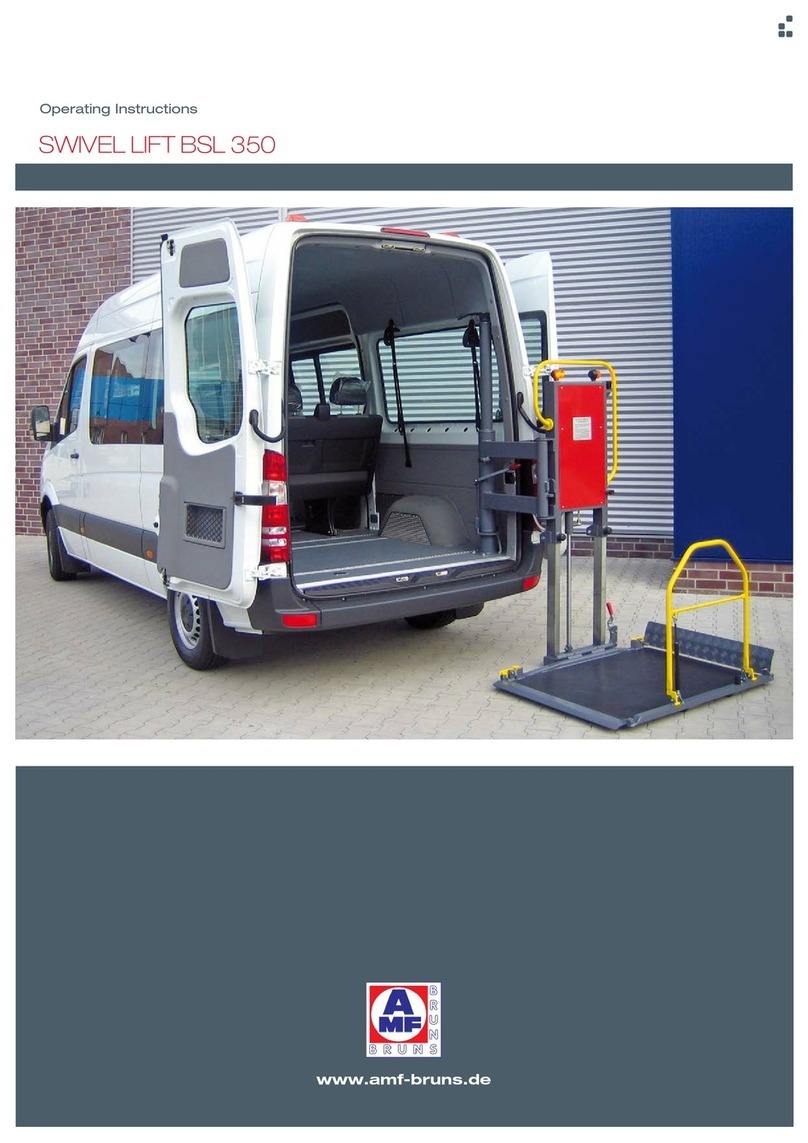

Operating Instructions

BACK-IN-BOX LIFT K70 K90 / K90 ACTIVE

www.amf-bruns.de

Foreword

Back-in-Box-Lift K70 / K90 / K90 ACTIVE Page 3 of 100

Foreword

Dear Reader,

these Operating Instructions provide all information neces-

sary to safely operate the Back-in-Box-Lifts K70, K90 and

K90 ACTIVE.

The Back-in-Box-Lifts are designed and constructed in ac-

cordance with state of the art technology and recognised

safety standards. Persons and materials can however be

endangered, as not all danger areas can be eliminated if

the functional capability is to be maintained. Accidents

caused by these dangers can however be prevented by

strictly observing these Operating Instructions. Over and

above this, the operational efficiency of your Back-in-Box-

Lift can be used to the full and unnecessary faults can be

prevented.

After reading these Operating Instructions for the first time,

keep them in a safe place for future reference over the en-

tire lifetime of the Back-in-Box-Lift. Chapter 10 of these

Operating Instructions contains an Inspection Log that is

required by the technical expert for his / her annual inspec-

tion of the Back-in-Box-Lift.

If you sell the Back-in-Box-Lift, hand these Operating In-

structions over to the new owner.

All details, figures and dimensions contained in these Op-

erating Instructions are non-binding. No claims in any form

can be derived from these.

This document must not be reproduced or duplicated, in

full or in part, without the prior, written permission of the

manufacturer.

The Back-in-Box-Lift must never be converted or modified

in any way, without seeking the prior, written permission of

the manufacturer. The manufacturer will not be held re-

sponsible in any way whatsoever if conversions or modifi-

cations are carried out without authorisation.

Use only original spare parts or spare parts which have

been approved of by the manufacturer. If spare parts other

than these are used, this can have a negative effect on the

specified characteristics, the functionality and safety of the

Back-in-Box-Lift. Using non-original or unauthorised spare

parts will render the guarantee null and void.

Contact our customer services department to order spare

parts or accessories (see Chapter 13, page 98).

Foreword

Page 4 of 100 Back-in-Box-Lift K70 / K90 / K90 ACTIVE

Explanation of symbols and signs

To improve understanding, the following conventions

should be met for these Operating Instructions:

1.

The following conventions are used to highlight important

information:

DANGER!

• warns of a situation of immediate danger, which will lead

to severe or fatal injuries, if not avoided.

WARNING!

• warns of a potentially dangerous situation, which will

lead to severe or fatal injuries, if not avoided.

CAUTION!

• warns of a potentially dangerous situation, which will

lead to slight or minor injuries or material damage if not

avoided.

ATTENTION!

...warns of a potentially dangerous situation, which can

cause material damage, if not avoided.

...contains general notes and useful information.

...gives a reference to important information in other sec-

tions and documents.

2.

Some texts serve a particular purpose. These are identified

as follows:

• Lists.

ð Instructional text, e.g. a sequence of activities.

Contents

Back-in-Box-Lift K70 / K90 / K90 ACTIVE Page 5 of 100

Contents

Foreword .............................................................. 3

Contents ............................................................... 5

1 Safety............................................................... 8

1.1 Proper Use ............................................................ 8

1.2 Improper Use ........................................................ 9

1.3 User Requirements...............................................10

1.4 Product Monitoring............................................... 11

1.5 Danger Zone ........................................................ 11

1.6 Safety Devices...................................................... 12

1.6.1 Roll-off guard ..............................................12

1.6.2 Signalling systems .......................................12

1.6.3 Door contact switch ....................................12

1.7 Safety and Accident Prevention Regulations.........13

1.8 Disposal................................................................14

2 Description...................................................... 15

2.1 Layout and Function .............................................15

2.1.1 Platform ...................................................... 17

2.1.2 Mechanics and hydraulics with carrier

arms........................................................... 20

2.1.3 Cassette .....................................................21

2.2 Rating plate ......................................................... 22

2.3 Operating Controls and Indicators....................... 23

2.3.1 Cable-connected remote control ............... 23

2.3.2 Bluetooth remote control (optional extra).... 24

2.3.3 Remote control per Smartphone APP ........ 26

2.4 Technical Data..................................................... 27

3 Transportation ............................................... 28

4 Installation / Commissioning........................... 29

5 Operation ....................................................... 30

5.1 Safety Regulations for Operation ......................... 30

5.2 Embarkation Procedure....................................... 33

5.3 Disembarkation Procedure .................................. 38

5.4 Refuelling the Vehicle (K70 and K90 only).............41

Contents

Page 6 of 100 Back-in-Box-Lift K70 / K90 / K90 ACTIVE

6 Emergency Mode ........................................... 42

6.1 Emergency Operation K70 / K90 ......................... 42

6.1.1 Extending the platform from the cassette .. 42

6.1.2 Raising the platform ................................... 44

6.1.3 Lowering the platform ................................ 45

6.1.4 Retracting the platform into the cassette ... 46

6.2 Emergency Operation K90 ACTIVE...................... 48

6.2.1 Raising the platform ................................... 48

6.2.2 Lowering the platform ................................ 49

6.2.3 Retracting the platform into the cassette ... 50

7 Maintenance and Repair ................................ 53

7.1 Safety Regulations for Maintenance and Repair .. 53

7.2 Routine Maintenance Work ................................. 54

7.2.1 Maintenance schedule ............................... 54

7.2.2 Maintenance record................................... 54

7.3 Functional Test of the Safety Devices .................. 55

7.3.1 Roll-off guard ............................................. 55

7.3.2 Signalling system........................................ 55

7.3.3 Door contact switch ................................... 55

7.4 Inspection of the Hydraulic Hoses. ...................... 56

7.5 Yearly Inspection ................................................. 56

7.6 Maintenance and Repair Record ......................... 57

8 De-Commissioning and Conservation ............ 58

9 Faults and Troubleshooting............................ 58

9.1 Adjustments if the Platform Jerks When Being

Retracted Into the Cassette (K70 / K90).............. 62

9.1.1 Adjusting the switching point for the

retract position (K70 / K90) ........................ 64

9.1.2 Adjusting the rollers (K70 / K90)................. 67

9.2 Adjusting the Switching Point for the Retract

Position (K90 ACTIVE) ......................................... 68

9.3 Charging the Bluetooth Remote Control Battery . 70

9.4 Teaching the Bluetooth remote control in............. 71

9.5 Installing the remote control App and

teaching it in ........................................................ 72

Contents

Back-in-Box-Lift K70 / K90 / K90 ACTIVE Page 7 of 100

10 Inspection Log ............................................... 73

10.1 Inspection Log Master Data Sheet ...................... 74

10.2Inspection List ..................................................... 75

10.3Inspection Results ............................................... 76

11 Electrical Circuit Diagrams............................. 87

11.1 Electrical Circuit Diagram, Bluetooth Remote

Control K70 (optional).......................................... 87

11.2 Electrical Circuit Diagram, Bluetooth Remote

Control K90 /K90A (optional)............................... 87

11.3 Electrical Circuit Diagram K70.............................. 88

11.4 Electrical Circuit Diagram K90.............................. 90

11.5 Electrical Circuit Diagram K90 ACTIVE................. 93

12 Hydraulic Line Diagrams ................................ 95

12.1 Hydraulic Circuit Diagram K70 ............................. 95

12.2Hydraulic Circuit Diagram K90 ............................. 96

12.3Hydraulic Circuit Diagram K90 ACTIVE ................ 97

13 Customer Service .......................................... 98

14 Declaration of Conformity .............................. 99

Safety

Page 8 of 100 Back-in-Box-Lift K70 / K90 / K90 ACTIVE

1 Safety

CAUTION!

There are a number of risks of suffering personal injury and

material damage involved in the operation and mainte-

nance of the Back-in-Box-Lift.

Therefore:

• It is imperative, that these Operating Instructions are

read thoroughly before operating your Back-in-Box-Lift.

Always observe the notes and information contained

therein, in particular the safety instructions.

• If these Operating Instructions or parts thereof are lost

or become illegible, please request a new copy from the

manufacturer.

Prerequisite to the safe handling and trouble-free opera-

tion of the Back-in-Box-Lift is a thorough knowledge of the

applicable safety information and the safety regulations.

It is therefore imperative that this Chapter is read thor-

oughly before operating the Back-in-Box-Lift and that the

instructions and warnings herein are strictly observed. The

safety information and warnings, given at the appropriate

places in the following Chapters, must also be strictly ob-

served. The manufacturer will not be held responsible if

safety information and warnings are not observed.

In addition to the information given in these Operating In-

structions, local legislative regulations must be taken into

consideration, in particular those regarding safety and ac-

cident prevention.

1.1 Proper Use

The Back-in-Box-Lift must only be used for lifting and low-

ering disabled persons seated in wheelchairs or empty

wheelchairs. By using the Back-in-Box-Lift, persons can

be embarked into or disembarked from the vehicle to

which it is fitted.

Proper use also includes strictly adhering to the infor-

mation given in these Operating Instructions.

Safety

Back-in-Box-Lift K70 / K90 / K90 ACTIVE Page 9 of 100

WARNING!

If the Back-in-Box-Lift is used for any other purpose than

that described above, this may result in dangerous situa-

tions for persons or to material damage being caused.

Therefore:

• Only use the Back-in-Box-Lift for the purpose for which

it was intended.

• Always adhere to information given in these Operating

Instructions.

• Do not use the Back-in-Box-Lift for any other purposes,

particularly those given in Section 1.2. These are

deemed to be improper use.

1.2 Improper Use

Any use other than that described in Section 1.1 is deemed

to be improper use.

The Back-in-Box-Lift is deemed to be improperly used if

for example:

• it is used for lifting and lowering goods,

• it is used for lifting and lowering persons who are not

seated in a wheelchair,

• it is operated by persons who do not fulfil the necessary

requirements (see Section 1.3).

Safety

Page 10 of 100 Back-in-Box-Lift K70 / K90 / K90 ACTIVE

1.3 User Requirements

The Back-in-Box-Lift must only be handled by persons

who:

• have been instructed in how to operate the Back-in-

Box-Lift,

• have read and understood these Operating Instructions

and

• have the technical knowledge to operate the wheel-

chair's brakes and switch the motors of electrically driv-

en wheelchairs ON and OFF.

Over and above this, the following applies if the Back-in-

Box-Lift is used commercially or communally:

The Back-in-Box-Lift must only be operated by persons

who:

• are of legal age,

• have been expressly assigned to do so by the owner

and

• are in a position to adapt themselves to the particular

behaviour and needs of disabled persons.

Transportation, installation, commissioning, maintenance,

repair, fault finding and disposal of the Back-in-Box-Lift

must only be carried out by persons with the correspond-

ing technical training and experience.

Safety

Back-in-Box-Lift K70 / K90 / K90 ACTIVE Page 11 of 100

1.4 Product Monitoring

Please contact AMF-Bruns GmbH & Co. KG immediately if

faults or problems are encountered when operating your

Back-in-Box-Lift or if accidents or "near-misses" occur.

AMF-Bruns will effect a solution to the problem with your

help and the knowledge gained will flow into future pro-

jects.

NOTE

Guarantee work on the Back-in-Box-Lift must only be car-

ried out with the prior agreement of AMF-

Bruns GmbH & Co. KG.

The costs of such work will not be accepted by AMF-Bruns

without prior agreement.

1.5 Danger Zone

The danger zone is any area on, below or within the range

of movement of the platform, as well as around the drive

and carrier system, in which persons are exposed to the

risk of injury or damage to health.

CAUTION!

Risk of injury through movements of the Back-in-Box-Lift.

There are a number of risks of personal injury if standing

within the danger zone.

Therefore:

• Only operate the Back-in-Box-Lift if there are no per-

sons standing within the danger zone.

• Keep the danger zone under observation and stop the

Back-in-Box-Lift if any persons enter the danger zone.

Safety

Page 12 of 100 Back-in-Box-Lift K70 / K90 / K90 ACTIVE

1.6 Safety Devices

1.6.1 Roll-off guard

As soon as the platform is raised from the ground, the roll-

off guard rises. This prevents the passenger in their wheel-

chair from rolling backwards off the platform.

1.6.2 Signalling systems

The Back-in-Box-Lift gives a warning sound when the plat-

form extends from the cassette. Blinkers are fitted to both

sides of the platform. These signalling systems prevent

hazards that are caused by the platform being overlooked.

1.6.3 Door contact switch

A door contact switch is fitted to the vehicle door, above

the Back-in-Box-Lift. It disables all functions of the

Back-in-Box-Lift when the door is closed. This prevents

the Back-in-Box-Lift from being operated inadvertently or

by unauthorised persons.

Safety

Back-in-Box-Lift K70 / K90 / K90 ACTIVE Page 13 of 100

1.7 Safety and Accident Prevention

Regulations

Adhere to the following notes in order to prevent personal

injuries and material damage.

• The Back-in-Box-Lift must only be operated if all safety

and protective devices are correctly fitted (see Sec-

tion 1.6, page 12). Such devices must only be removed

in order to enable maintenance and repair work to be

carried out. All safety and protective devices must be

replaced immediately after such work has been com-

pleted. If they are not replaced correctly, there is a risk

of injury.

• The Back-in-Box-Lift must only be used for the purpose

for which it is intended, otherwise dangerous situations,

with resultant injuries, may occur (Proper use: see Sec-

tion 1.1, page 8).

• The owner is responsible for ensuring that proper use is

adhered to, in particular that the Back-in-Box-Lift is only

operated by authorised persons.

• It is forbidden for persons to ride on the platform if they

are not in a wheelchair.

• Proper use of the Back-in-Box-Lift also includes adher-

ence to the specified maintenance and repair work, in

particular the strict adherence to the maintenance inter-

vals (see Chapter 6, page 42). If such work is not car-

ried out, trouble-free operation cannot be guaranteed.

Risks of personal injury and material damage can occur.

We recommend that maintenance records are kept.

• The Back-in-Box-Lift must be inspected by a technical

expert after it has been installed. During the inspection,

faults affecting the safety should be systematically iden-

tified and remedial action taken (see "Inspection Log",

page 69).

This inspection must be repeated at intervals of not

more than one year if the Back-in-Box-Lift is used

commercially or communally.

We recommend that this annual inspection is also car-

ried out if the Back-in-Box-Lift is used privately.

Safety

Page 14 of 100 Back-in-Box-Lift K70 / K90 / K90 ACTIVE

• An inspection must also be carried out by a technical

expert before the Back-in-Box-Lift is put back into ser-

vice if modifications are made to the construction or

major repairs are carried out on load-bearing parts of

the Back-in-Box-Lift.

• The Back-in-Box-Lift must not be operated in a faulty

condition, as severe injuries may be caused by this. If

faults occur, do not use the Back-in-Box-Lift until re-

pairs have been effected.

• Do not deposit any items on the Back-in-Box-Lift. Per-

sons can suffer injuries if such items fall off the platform.

• Switch the Back-in-Box-Lift OFF before carrying out

maintenance or repair work, this includes cleaning work.

Make certain that no other person can switch the Back-

in-Box-Lift ON (e.g. by disconnecting the starter bat-

tery). If this is not done, there is a risk of injury.

• Use only original spare parts or spare parts which have

been approved of by the manufacturer. If non-original or

unauthorised replacement parts are used, this will ren-

der the guarantee null and void.

1.8 Disposal

When the Back-in-Box-Lift's useful life has expired, it must

only be disposed of by qualified specialists. The manufac-

turer will accept no liability for damage caused by incorrect

disposal.

Description

Back-in-Box-Lift K70 / K90 / K90 ACTIVE Page 15 of 100

2 Description

Persons who are wheelchair-bound can be embarked into

or disembarked from a vehicle using the Back-in-Box-Lift.

The main components of the Back-in-Box-Lift are:

• the platform,

• mechanics and hydraulics with carrier arms,

• the cassette and

• the operating controls.

The aim of this chapter is to illustrate the construction and

function of the Back-in-Box-Lift. To this end, the individual

assemblies and components are described in the following

sections.

2.1 Layout and Function

Figure 1: Back-in-Box Lifts K70 and K90

Platform

Carrier arms

Transfer

plate

Roll-off guard

Carrier

arms

Cassette

Hydraulic aggregate

Description

Page 16 of 100 Back-in-Box-Lift K70 / K90 / K90 ACTIVE

Figure 2: Back-in-Box-Lift K90 ACTIVE

Platform

Roll-off guard

Carrier

arms

Cassette

Hydraulic aggregate

Transfer

plate

Description

Back-in-Box-Lift K70 / K90 / K90 ACTIVE Page 17 of 100

2.1.1 Platform

The platforms on the Back-in-Box-Lifts K70, K90 and K90

ACTIVE are of differing design:

With the K70 and K90, the wheelchair is pushed onto the

platform in the direction of the door of the vehicle, below

which the lift is installed (see Figure 3).

Figure 3: Back-in-Box Lifts K70 and K90, Platform Access

With the K90 ACTIVE, the wheelchair is pushed onto the

platform parallel to the vehicle, in the direction of the rear

of the vehicle (see Figure 4).

Figure 4: Back-in-Box-Lift K90 ACTIVE, Platform Access

All platforms are provided with a roll-off guard that auto-

matically rises when the platform is raised off the ground.

This prevents the wheelchair from rolling backwards off the

platform.

Transfer plate

Platform

Platform

side

guards

Roll-off guard

Transfer plate

Platform

Platform rear

guard

Roll-off guard

Platform side guard

Description

Page 18 of 100 Back-in-Box-Lift K70 / K90 / K90 ACTIVE

The side nearest the vehicle is provided with a transfer

plate. During the raising and lowering procedure, this

transfer plate forms a guard that prevents the passenger’s

feet from being caught between the platform and the un-

derside of the vehicle (see Figure 3 and Figure 4, page 17).

When the platform reaches the same level as the floor in-

side the vehicle, the transfer plate folds down onto the

floor. The passenger then uses the transfer plate as a

bridge to cross from the platform into the vehicle (see Fig-

ure 5 and Figure 6).

Figure 5: Back-in-Box Lifts K70 and K90, Interior Floor Level

Figure 6: Back-in-Box-Lift K90 ACTIVE, Interior Floor Level

Guards are provided on all other sides of the platform to

prevent the wheelchair from rolling off the platform (see

Figure 5 and Figure 6).

Transfer plate

Transfer plate

Description

Back-in-Box-Lift K70 / K90 / K90 ACTIVE Page 19 of 100

On the K70 and K90, one of the platform’s two side guards

is optionally shortened to extend roughly half way along

that side. This provides side access to the platform, mak-

ing it easier for the passenger to roll on and off the plat-

form when there is limited space available outside the ve-

hicle (see Figure 7).

Figure 7: Back-in-Box-Lifts K70 and K90 with Side Access

When the platform on the K70 or K90 is retracted into the

cassette, the raised roll-off guard acts as a cover for the

cassette (see Figure 8). With the K90 ACTIVE, the platform

side guard acts as a cover for the cassette (see Figure 9).

In each case this prevents dirt from entering the mechan-

ics of the Back-in-Box-Lift.

Figure 8: Back-in-Box Lifts K70 and K90, Retracted

Figure 9: Back-in-Box-Lift K90 ACTIVE, Retracted

Short platform

side guard

Roll-off guard

Platform

side guard

Description

Page 20 of 100 Back-in-Box-Lift K70 / K90 / K90 ACTIVE

2.1.2 Mechanics and hydraulics with carrier

arms

The hydraulically-powered carrier arms of the lift raise and

lower the platform and keep it horizontal. In order to do

this, the carrier arms are designed as parallelograms.

When the carrier arms have lowered the platform to the

height of the cassette, the platform can be retracted into

the cassette. In this position, the carrier arms are in the

horizontal and parallel to the platform. The transfer plate

automatically folds down when the platform is retracted.

On the K70 and K90 there are two carrier arms on both

the left- and right-hand sides of the platform (see Figure

10).

Figure 10: Back-in-Box Lifts K70 and K90, Retract Position

On the K90 ACTIVE there are two carrier arms between

the platform and the cassette (see Figure 11).

Figure 11: Back-in-Box-Lift K90 ACTIVE, Retract Position

Transfer plate

Carrier arms

Transfer plate

Carrier arms

Carrier arms

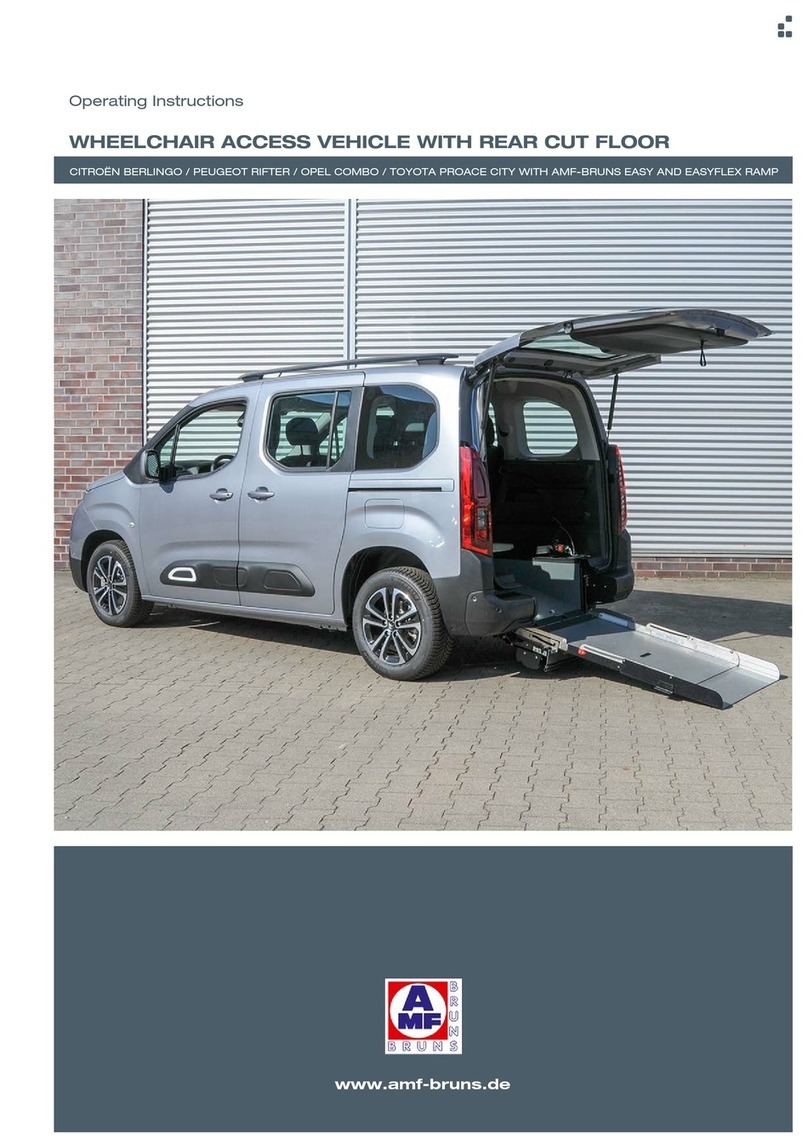

Other manuals for K70

1

This manual suits for next models

2

Table of contents

Other AMF-BRUNS Lifting System manuals

AMF-BRUNS

AMF-BRUNS Linearlift Series User manual

AMF-BRUNS

AMF-BRUNS K70 User manual

AMF-BRUNS

AMF-BRUNS HUBMATIK K90 User manual

AMF-BRUNS

AMF-BRUNS BSL 350 User manual

AMF-BRUNS

AMF-BRUNS Easy-Flex-Ramp User manual

AMF-BRUNS

AMF-BRUNS LINEARLIFT AL1 User manual

AMF-BRUNS

AMF-BRUNS BSL 350 User manual

AMF-BRUNS

AMF-BRUNS LINEARLIFT AL1 User manual

AMF-BRUNS

AMF-BRUNS BSL 350 User manual