1.2.1 DESCRIPTION OF BLOCKS

RECTIFIER: In PLT300 Series UPSs, a DSP controlled IGBT rectifier with PWM technique is used to

increase input power factor (PFC) and to decrease input current harmonics (THDI).

The IGBT rectifier accepts 3-phase AC input and produces a dual polarity DC voltage for both supplying

the inverter and charging the batteries.

BATTERIES: Batteries are used as reserve DC power supply for the Inverter in case of mains failure. In

PLT300 Series, batteries are connected in series with a center-tap output to obtain a dual polarity DC

supply.

Batteries are discharged by the inverter during mains failure. The discharged batteries are re-charged by

the IGBT Rectifier on a constant voltage / current limiting basis, if AC mains power is available.

INVERTER: It is manufactured by using the latest IGBT and DSP (Digital Signal Processing) technologies,

and Pulse Width Modulation (PWM) technique. The Inverter converts the DC BUS voltage supplied by the

IGBT Rectifier and / or the batteries into a well regulated, fully digital controlled 3-phase AC voltage with

fixed voltage and frequency.

The output of the inverter is used to supply the critical loads connected to the UPS output.

STATIC TRANSFER SWITCH (STATIC BYPASS): This is an electronically controlled transfer switch, which

enables the critical load to be connected either to inverter output or to by-pass power source. During normal

operation, the load is supplied by the inverter output, but in case of an overload or a UPS failure it is

automaticallytransferred to the bypass source without any interruption.

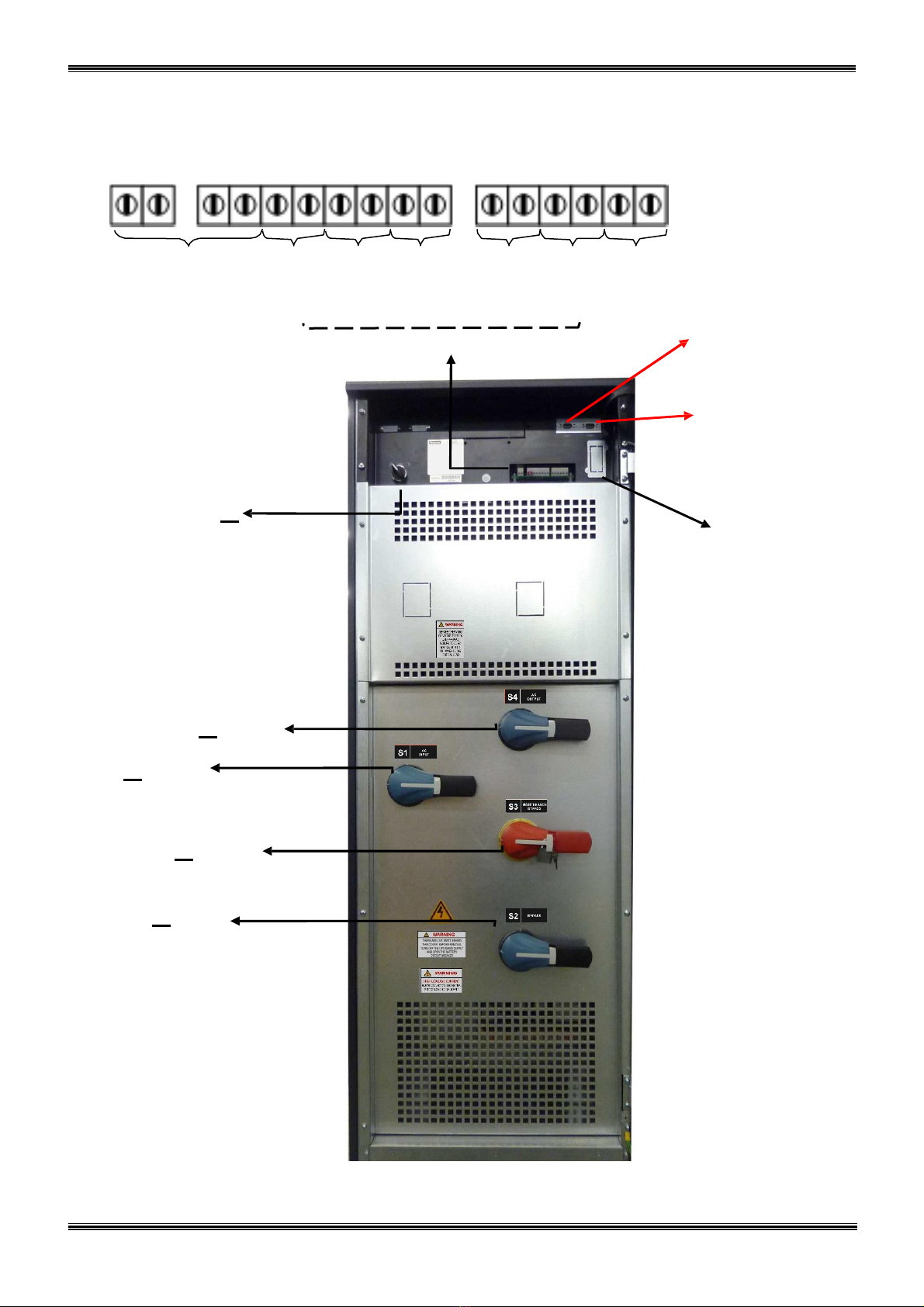

MAINTENANCE BYPASS SWITCH (MBS): This is a manually controlled mechanical switch, which is used

to supply the critical load, using the bypass source, when the UPS is shut down for maintenance or

troubleshootingpurposes.

The load is unprotected against mains supply disturbances and black-outs when it is connected to either

static or maintenance bypass supply.

1.2.2. OPERATING CONDITIONS OF UPS

UPS may be in one of the following operating

conditions:

A. Normal Operation (If Mains supply is available):

All fuses and power switches are closed (except the Maintenance Bypass Switch), and the load is supplied

by the Inverter Output. During normal operation, the Rectifier supplies DC power to the Inverter and charges

the Batteries at the same time.

B. Battery Operation :

The Batteries are connected to the Rectifier output. In case of a mains failure (mains power outage or AC

input voltage out of tolerance), the Rectifier stops operating and the DC voltage necessary for the inverter

operation is supplied by the batteries. Therefore the AC voltage output supplying the critical load is not

interrupted, until the batteries are fully discharged. At the end of the discharging time the inverter is turned

off and it start again automatically, together with the rectifier, when the mains power is restored, and the

UPS returns o normal operation. For UPS with a split bypass source, at the end of discharging time, static

transfer switch transfers the load to the split bypass source without interruption if the split bypass source is

available and in acceptable tolerances about voltage and frequency, as still the rectifier input is not available.

The Rectifier is also turned off and inverter operates on batteries during automatic or manual battery test

procedure.

C. By-Pass Operation :

If the Inverter output is overloaded or in case of a problem in the UPS, the static switch transfers the load to

the bypass supply without any interruption, provided that the bypass supply is available and within the

tolerated limits regarding voltage and frequency. At the end of the overloading period, if the fault condition

is restored, static switch transfers the critical load again to the inverter output. Note that, during operation

from the bypass supply, the critical load may be effected by any possible disturbances or power failure in

the bypass supply.