Epcom EPC9058 User manual

Development Board

EPC9058

Quick Start Guide

EPC2110

High Frequency Class-E Wireless Power Amplier

Revision 1.0

QUICK START GUIDE

2 | | EPC – EFFICIENT POWER CONVERSION CORPORATION | WWW.EPC-CO.COM | COPYRIGHT 2017

Demonstration System EPC9058

DESCRIPTION

The EPC9058 is a high eciency, dierential mode Class-E amplier

development board that can operate up to 15 MHz, including 6.78 MHz

which is popular for wireless power. However, this board is not pre-

congured for any particular frequency. The purpose of this development

board is to simplify the evaluation process of class-E amplier technology

using eGaN® FETs by allowing engineers to easily mount all the critical

class-E components on a single board that can be easily connected into

an existing system.

This board may also be used for applications where a low side switch is

utilized. Examples include, and are not limited to, push-pull converters,

current-mode Class D ampliers, common source bi-directional switch,

and generic high voltage narrow pulse width applications such as LiDAR.

The amplier board features the 120 V rated EPC2110 eGaN FET. The

amplier is set to operate in dierential mode and can be re-congured to

operate in single-ended mode and includes the gate driver and logic

supply regulator.

For more information on the EPC2110 eGaN FETs please refer to the

datasheet available from EPC at www.epc-co.com. The datasheet should

be read in conjunction with this quick start guide.

DETAILED DESCRIPTION

The Amplier Board (EPC9058)

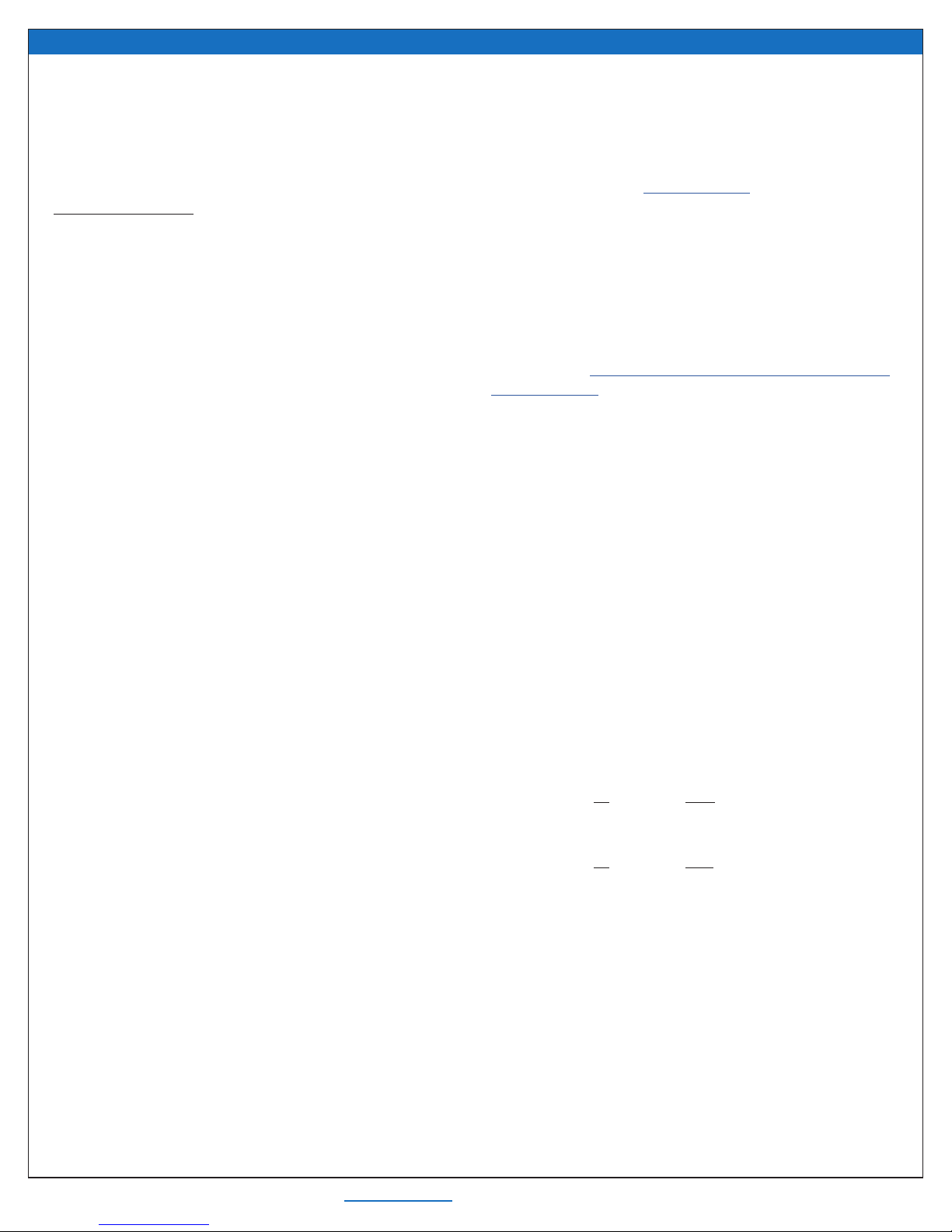

Figure 1 shows the schematic of a single-ended, Class-E amplier with

ideal operation waveforms where the amplier is connected to a tuned

load such as a highly resonant wireless power coil. The amplier has not

been congure due to the specic design requirements such as load resis-

tance and operating frequency. The design equations of the specic Class-

E amplier support components are given in this guide and specic values

suitable for a RF amplier application can then be calculated.

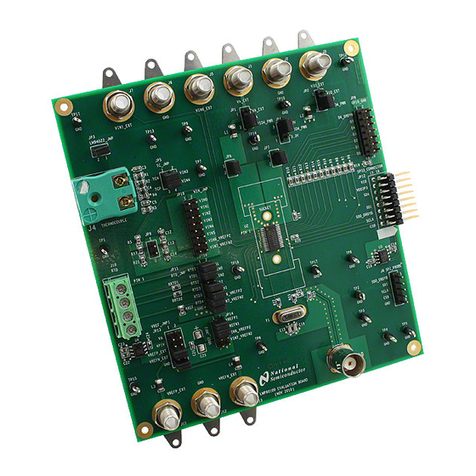

Figure 2 shows the dierential mode Class-E amplier EPC9058 demo board

power circuit schematic. In this mode the output is connected between

Out 1 and Out 2. A block-wave external oscillator with 50 % duty cycle and

0 V – 5 V signal amplitude is used as a signal for the board. Duty cycle

modulation is recommended only for advanced users who are familiar with

the Class-E amplier operation and require additional eciency.

The EPC9058 is also provided with a 5 V regulator to supply power

to the logic circutis and gate driver. Adding a 0 Ω resistor in position

R90 allows the EPC9058 to be powered using a single-supply

voltage; however in this conguration the maximum operating voltage

is limited to between 7 V and 12 V.

Single-ended Mode operation

Although the default conguration is dierential mode, the demo board

can be re-configured for single-ended operation by shorting out

C74 (which disables only the drive circuit) and connecting the

load between Out 1 and GND only (see gures 2 and 5 for details).

Class-E amplier operating limitations

The impact of load resistance variation is signicant to the performance of

the Class-E amplier, and must be carefully analyzed to select the optimal

design resistance.

The impact of load resistance (RLoad – Real part of ZLoad) variation on the

operation of the Class-E amplier is shown in gure 3. When operating

a Class-E amplier with a load resistance (RLoad – Real part of ZLoad)

that is below the design value (see the waveform on the left of

gure 3), the load tends to draw current from the amplier too

quickly. To compensate for this condition, the amplier supply

voltage is increased to yield the required output power. The shorter

duration of the energy charge cycle leads to a signicant increase in

the voltage to which the switching device is exposed. This is done

in order to capture sucient energy and results in device body

diode conduction during the remainder of the device o period.

This period is characterized by a linear increase in device losses as a

function of decreasing load resistance (RLoad).

When operating the Class-E amplier with a load resistance (RLoad) that

is above the design value (see the waveform on the right of gure 3), the

load tends to draw insucient current from the amplier, resulting in an

incomplete voltage transition. When the device switches there is a

residual voltage across the device, which leads to shunt capacitance

(COSS + Csh) losses. This period in the cycle is characterized by an expo-

nential increase in device losses as function of increasing reected load

resistance.

* Maximum current depends on die temperature – actual maximum current will be subject to switching

frequency, bus voltage and thermals.

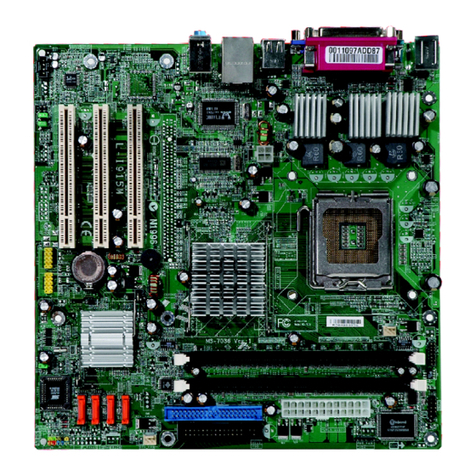

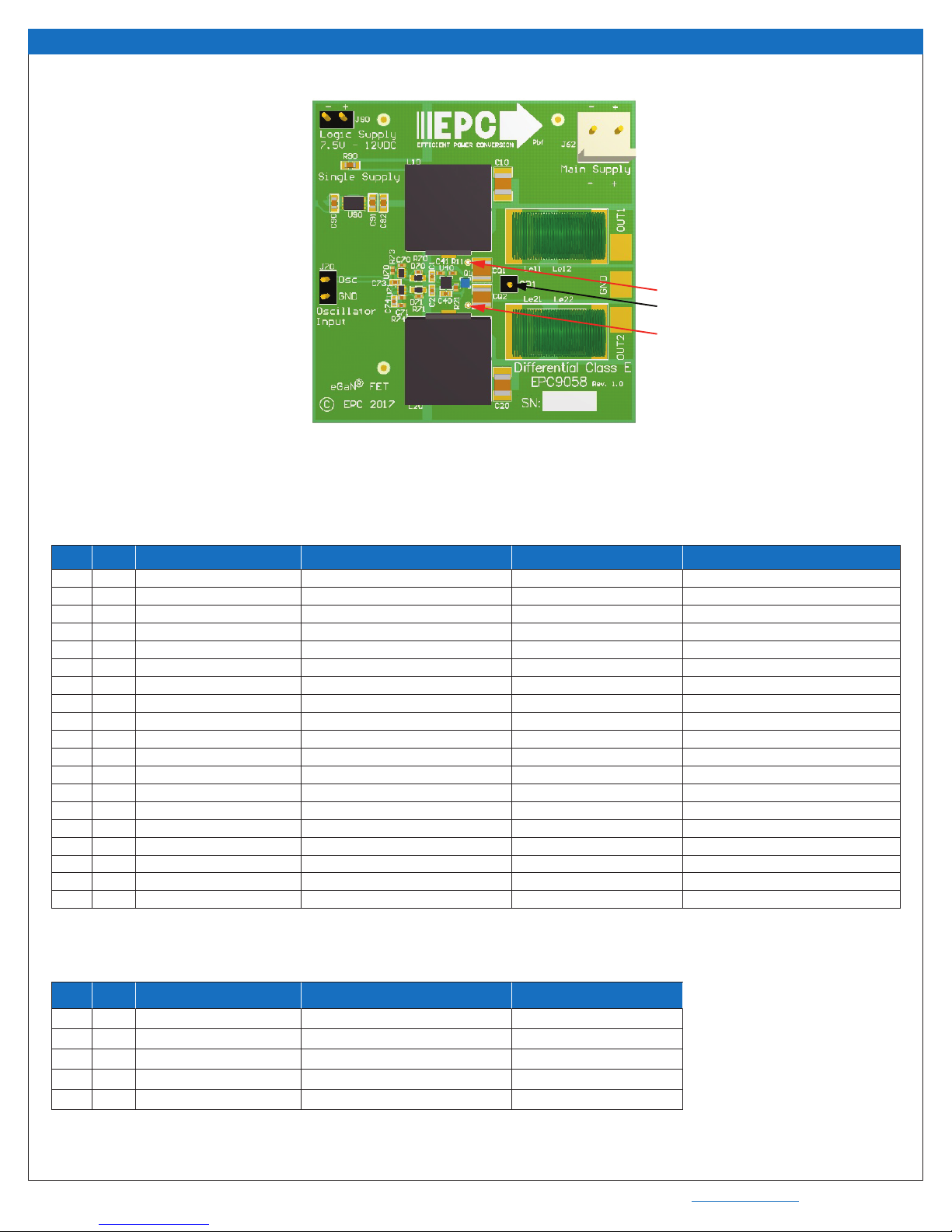

EPC9058 amplier board.

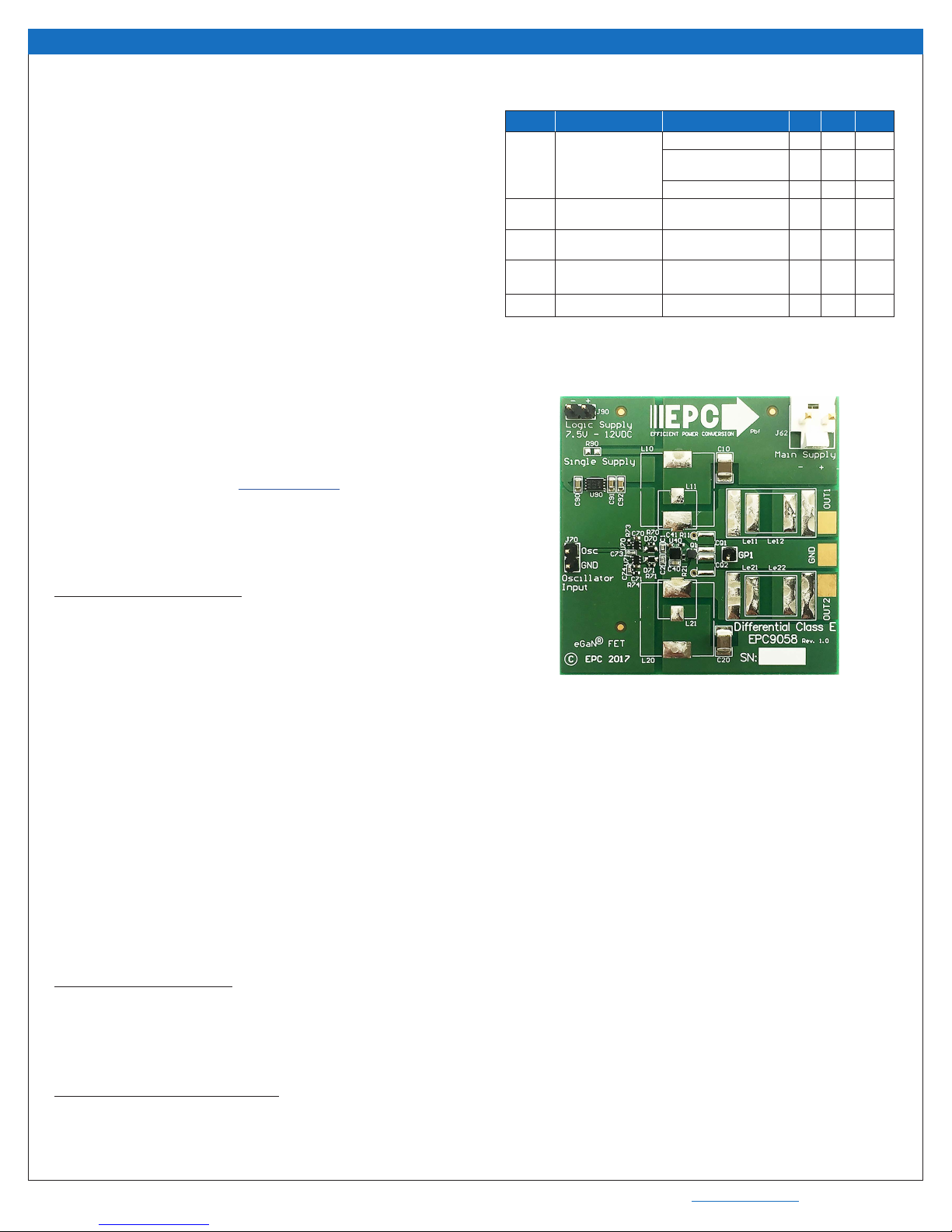

Table 1: Performance Summary (TA= 25°C) EPC9058

Symbol Parameter Conditions Min Max Units

VIN

Main Supply Voltage

Range

Class-E Conguration 0 20 V

Current Mode Class-D

Conguration 0 20 V

Push-Pull Conguration 0 52 V

VDD

Control Supply Input

Range 7 12 V

IOUT

Switch Node Output

Current (each) 2* A

VOSC

Oscillator Input

Threshold Input ‘Low’ -0.3 1.5 V

Input ‘High’ 3.5 5 V

QUICK START GUIDE

EPC – EFFICIENT POWER CONVERSION CORPORATION | WWW.EPC-CO.COM | COPYRIGHT 2017 | | 3

Demonstration System EPC9058

Given these two extremes of the operating load resistance (RLoad), the

optimal point between them must be determined. In this case, the

optimal point yields the same device losses for each of the extreme load

resistance points and is shown in the lower center graph of gure 3. This

optimal design point can be found through trial and error, or using circuit

simulation.

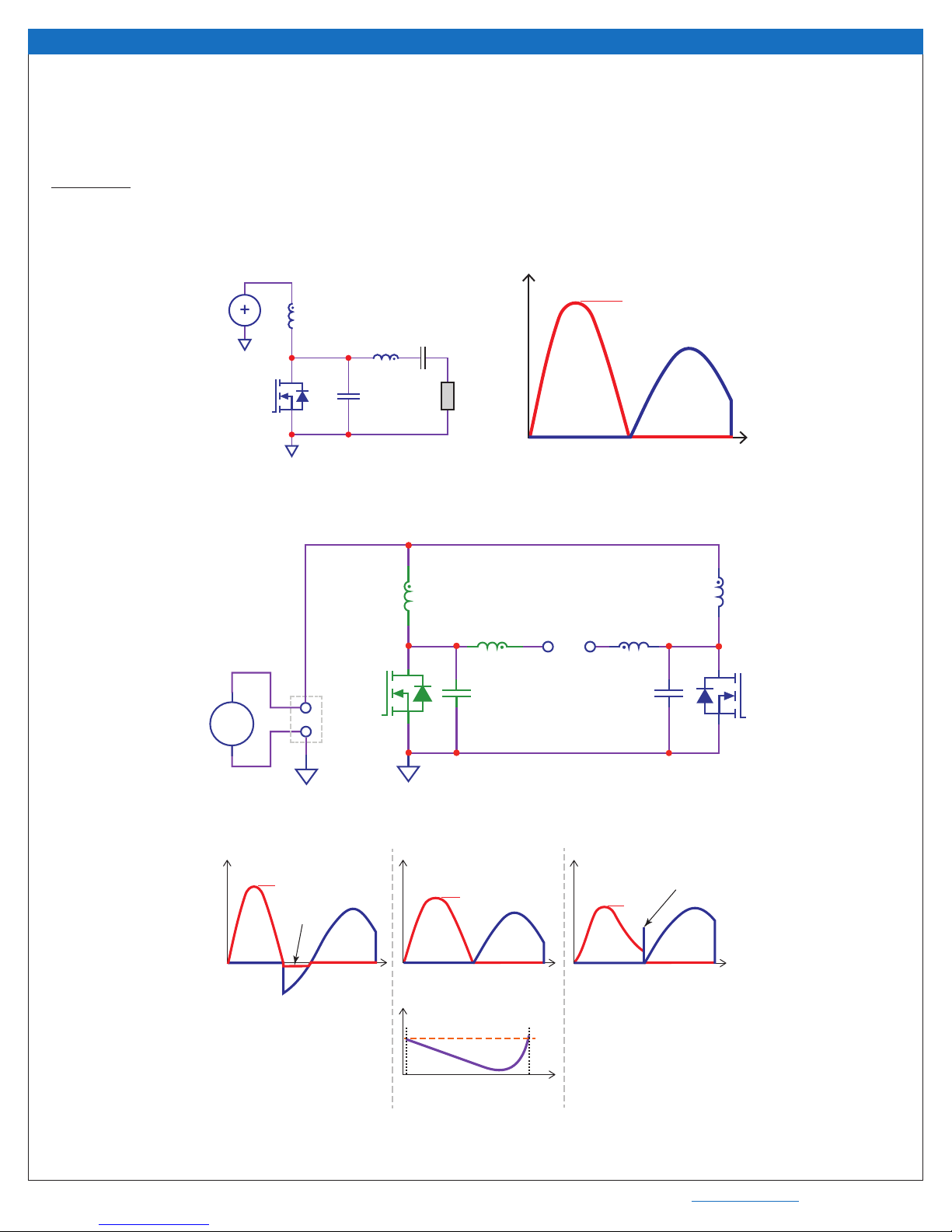

Class-E amplier design

For this amplier only three components need to be specically

designed; 1) the extra inductor (Le), 2) the shunt capacitor (Csh) and, 3) the

selection of a suitable switching device. The RF choke (LRFck) value is less

critical and hence can be chosen or designed.

The design equations for the Class-E amplier have been derived by

N. Sokal [1]. To simplify these equations, the value of QLin [1] is set to

innity, which is a reasonable approximation in most applications within

the frequency capability of this development board. The design needs to

have a specic load resistance (RLoad) value and desired load power (PLoad)

that is used to begin the design, which then drives the values of the other

components, including the magnitude of the supply voltage.

The Class-E amplier passive component design starts with the load

impedancevalue(ZLoad)showningure1.ThereactivecomponentofZLoad

is tuned out using a series capacitor CS, which also serves as a DC block,

resulting in RLoad. It is a common mistake to ignore the need for the DC

block, where a failure to do so can yield a DC current from the supply

through to the load, and lead to additional losses in several components

in that path.

First, using the equations in gure 4, both the extra inductor

Le (equation 2 and shunt capacitor (equation 3) values can be

determined [2], [3]. The value of the shunt capacitor includes the

COSS of the switching device, which must be subtracted from the

calculated value to yield the actual external capacitor (Csh) value. To

do this, rst the magnitude of the supply voltage (VDD) is calculated

using equation 1, which in turn can be used to determine the peak

device voltage (3.56 · VDD).

The RMS value of the peak device voltage is then used to determine the

COSSQ of the device at that voltage. This is the capacitance that will be

deducted from the calculated shunt capacitor to reveal the external

shunt capacitor (Csh) value. The COSSQ of the device can be calculated by

integrating the COSS as function of voltage using equation 4. If the

COSSQ value is larger than the calculated shunt capacitance, the design

cannot be realized for the load resistance specied and a new load

resistance (RLoad) must be chosen.

Finally, the choke (LRFck) can be designed using equation 5 and, in this case,

a minimum value is specied. Larger values yield lower ripple current,

which can lead to a more stable operating amplier. A too-low value will

leadtoincreasedoperatinglossesandchangethemodeofoperationofthe

amplier. In some cases this can be intentional.

Here:

RLoad = Load Resistance [Ω]

PLoad = Load Power [W]

VDD = Amplier Supply Voltage [V]

f = Operating Frequency [Hz]

Le= Extra Inductor [H]

Csh = Shunt Capacitor [F]

COSS = Output Capacitance of the FET [F]

COSSQ = Charge Equivalent Device Output Capacitance [F]

(See gure 6 of the EPC2110 datasheet)

VDS = Drain-Source Voltage of the FET [V]

LRFck = RF Choke Inductor [H]

CS= Series Tuning Capacitor [F]

ZLoad = Load Impedance [Ω]

NOTE.For dierential mode amplier design details, please refer to the

application note ‘AN021: eGaN FETs for Low Cost Resonant Wireless

Power Applications’

[1] N.O. Sokal,“Class-E RF Power Ampliers,”QEX, Issue 204, pp. 9–20,

January/ February 2001.

[2] M. Kazimierczuk, “Collector amplitude modulation of the Class-E

tuned power amplier,”IEEE Transactions on Circuits and Systems,

June 1984, Vol.31, No. 6, pp. 543–549.

[3] Z. Xu, H. Lv, Y. Zhang, Y. Zhang,“Analysis and Design of Class-E Power

Amplier employing SiC MESFETs,“ IEEE International Conference on

Electron Devices and Solid-State Circuits (EDSSC) 2009, 25–27

December 2009, pp 28–31.

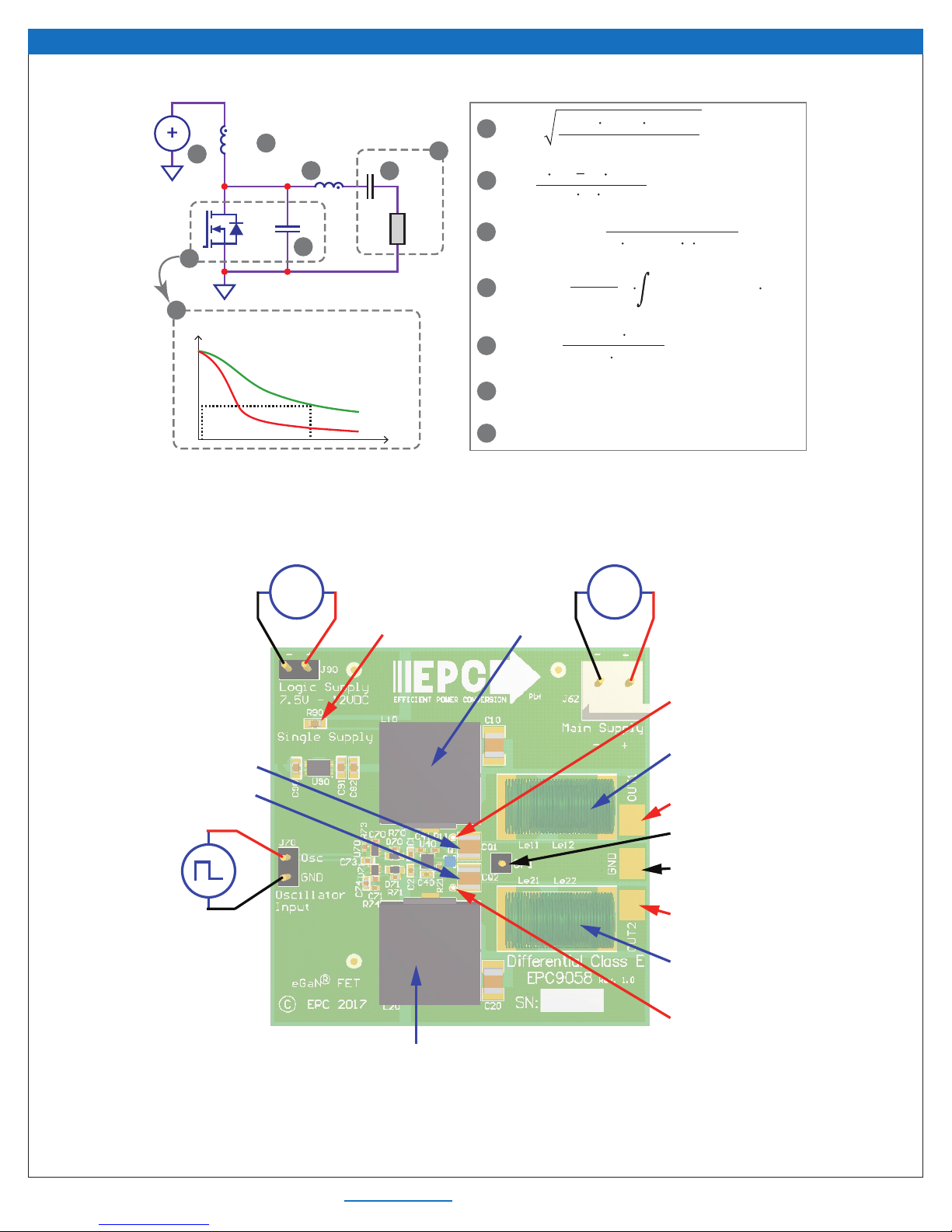

QUICK START PROCEDURE

The EPC9058 amplier board is easy to set up to evaluate the

performance of the eGaN FET in a class-E amplier application. Once

the design of the passive components has been completed and

installed, then the board can be powered up and tested.

1. Make sure the entire system is fully assembled prior to making

electrical connections including an applicable load.

2. With power o, connect the main input power supply bus to J62

as shown in gure 5. Note the polarity of the supply connector.

Set the voltage to 0 V.

3. With power o, connect the logic input power supply bus to J90

as shown in gure 5. Note the polarity of the supply connector.

Set the voltage to between 7 V and 12 V.

4. Make sure all instrumentation is connected to the system.

This includes the external oscillator to control the circuit.

5. Turn on the logic supply voltage.

6. Turn on the main supply voltage starting from 0 V, and increase

to the desired value. Note operating conditions and in particular

the thermal performance and voltage of the FETs to prevent over-

temperature and over-voltage failure.

7. Once operation has been conrmed, observe the device voltage,

eciency and other parameters on both the amplier and

device boards.

8. For shutdown, please follow steps in the reverse order.

QUICK START GUIDE

4 | | EPC – EFFICIENT POWER CONVERSION CORPORATION | WWW.EPC-CO.COM | COPYRIGHT 2017

Demonstration System EPC9058

NOTE. When measuring the high frequency content switch-node, care must be taken

to avoid long ground leads. An oscilloscope probe connection (preferred method) has

been built into the board to simplify the measurement of the Drain-Source Voltage

(shown in gure 6). The choice of oscilloscope probe needs to consider tip capacitance

where this will appear in parallel with the shunt capacitance thereby altering the operating

point of the amplier.

Pre-Cautions

The EPC9058 development board showcases the EPC2110 eGaN FETs in

a class-E amplier application. Although the electrical performance

surpasses that of traditional silicon devices, their relatively smaller size

does require attention paid to thermal management techniques.

Figure 3: Class-E operation under various load conditions that can be used to determine the optimal design load resistance (Rload).

Figure 2: EPC9058 power circuit schematic.

Figure 1: Single-ended, Class-E amplier with ideal operation waveforms.

+

Le1x Le2x

LRFck1 LRFck2

Q1 Q2

CCQ1 CCQ2

Coil connection

J1

VIN

VDD

LRFck

Le

Csh

CS

ZLoad

Q1

50% Time

V / I

VDS ID

3.56 x VDD

Ideal waveforms

IDID

V / IV / I

PFETloss

RLoad

RLoad_Design

V / I

VDS VDS ID

VDS

50%

50%

50%

Time TimeTime

RLoad < Design point

RLoad = Design point

RLoad > Design point

Body diode

conduction

Capacitance

(COSS + Csh)

losses

~6.5 xVDD

~2 xVDD

Optimal design

3.56 xVDD

Drives FET voltage rating Drives FET COSS choice

The EPC9058 development board has no current or thermal protection

and care must be exercised not to over-current or over-temperature

the devices. Excessively wide load impedance range variations can lead

to increased losses in the devices. The operator must observe the

temperature of the gate driver and eGaN FETs to ensure that both are

operating within the thermal limits as per the datasheets. Always check

operating conditions and monitor the temperature of the EPC devices

using an IR camera.

QUICK START GUIDE

EPC – EFFICIENT POWER CONVERSION CORPORATION | WWW.EPC-CO.COM | COPYRIGHT 2017 | | 5

Demonstration System EPC9058

Figure 4: Class-E amplier design process with equations.

Figure 5: Proper connection and measurement setup for the amplier board.

VIN supply

(note polarity)

Output 1 pad

Le1

CSh1

CSh2

Le2

External oscillator

Out A oscilloscope probe

Ground post

Single supply jumper

RF Choke 2

+

7 V - 12 VDC

+

0 V - 20 VDCmax

VLogic supply

(note polarity)

Out B oscilloscope probe

Ground pad output

Output 2 pad

RF choke 1

32 π f

V

DD

LRFck

Le

Csh

CS

ZLoad

Q1

Capacitance

Voltage

COSSQ

COSS

COSSQ = COSS (VDS)dvDS

1

VDD

VDD

0

15

2

3

4

4

7

6

DC Block

RLoad

COSSQ + Csh =

RLoad PLoad (π2+ 4)

RLoad

1

2

3

4

8

(π2+ 4)

4 f

RLoad

π (π24)

f RLoad

π2 (π2+ 4)

VDD =

LRFck

Le=

>

4

5

6

7

QUICK START GUIDE

6 | | EPC – EFFICIENT POWER CONVERSION CORPORATION | WWW.EPC-CO.COM | COPYRIGHT 2017

Demonstration System EPC9058

Figure 6: Proper measurement of the drain voltage.

Table 2: EPC9058 Bill of Materials

Item Qty Reference Part Description Manufacturer Part #

1 4 C1, C2, C73, C74 22 pF, 50 V Würth 885012005057

2 2 C10, C20 2.2 µF 100 V Taiyo Yuden HMK325B7225KN-T

3 1 C40 4.7 µF, 10 V Samsung CL05A475MP5NRNC

4 3 C41, C70, C71 100 nF, 16 V Würth 885012205037

5 3 C90, C91, C92 1 µF, 25 V Würth 885012206076

6 2 D70, D71 40 V 30 mA Diodes Inc. SDM03U40

7 1 GP1 .1" Male Vert. Würth 61300111121

8 1 J62 .156" Male Vert. Würth 645002114822

9 2 J70, J90 .1" Male Vert. Würth 61300211121

10 1 Q1 120 V, 3.4 A, 60 mΩ EPC EPC2110

11 2 R11, R21 2.2 Ω Yageo RC0402JR-072R2L

12 2 R70, R71 0 Ω Samsung RC1005J000CS

13 1 R73 10 kΩ Yageo RC0402FR-0710KL

14 1 R74 10 kΩ Panasonic ERJ-2GEJ103X

15 1 R90 0 Ω (EMPTY) Stackpole RMCF0603ZT0R00

16 1 U40 100 V eGaN Driver Texas Instruments LM5113TM

17 1 U70 2 In NAND Fairchild NC7SZ00L6X

18 1 U71 2 In AND Fairchild NC7SZ08L6X

19 1 U90 5.0 V 250 mA DFN Microchip MCP1703T-5002E/MC

Table 3: Optional Components

Item Qty Reference Part Description Manufacturer

1 2 CQ1, CQ2 Capacitor size 1111 Designed for Johanson

2 2 L10, L20 Inductor 13 x 13 mm Designed for Würth

3 2 L11, L21 Inductor 6.9 x 6.9 mm Designed for Würth

4 2 Le11, Le21 Coil size 2929SQ Designed for CoilCraft

5 2 Le12, Le22 Coil size 2222SQ Designed for CoilCraft

QUICK START GUIDE

EPC – EFFICIENT POWER CONVERSION CORPORATION | WWW.EPC-CO.COM | COPYRIGHT 2017 | | 7

Demonstration System EPC9058

Vsup

7.5VDC

- 12VDC

Logic Supply Regulator

V7in

Vsup

Main Supply

Vsup

2.2 Ω

2.2 Ω

1 2

R11

1 2

R21

GRH

GRL

5V

5 V

5 V

5 V

GLH

GLL

Gate Driver

U40

L M5113TM

L_Sig

R_Sig

LOGIC

SDM03U40

40 V, 30 mA

D71

5 V

5 V

5 V

Deadtime Left

Deadtime Right

Oscillator input

A

B

U70

NC7SZ00L6X

5 V

OSC

GRHGRL

GL L

GLH

TBD

L 10

TBD

L20

OSC

OSC

OSC

Logic

Supply

Vsup

Vsup

Vsup

Single Supply Conguration

TBD

CQ2

TBD

CQ1

V7in

OutA

OutB

2.2 μF, 100 V

C20

2.2 μF, 100 V

C10TBD

Le11

TBD

L e12

TBD

Le21

TBD

Le22

TBD

L 21

SDM03U40

40 V, 30 mA

D70

A

B

Y

U71

NC7SZ00L6X

0 Ω

0 Ω

1 2

R90

Out1

Out2

GND

.1" Male Vert.

1

2

J90

5VV7in

MCP1703T-5002E/MC

5.0 V 250 mA DFN

OUT

GND

IN

GND

U90

nSD

nSD

5 V

10 k

1

2

R74

.1" Male Vert.

1

2

J70

4.7 μF, 10 V

C40

1 2

R70

1 2

R71

10 k

1

2

R73

1

.1" Male Vert.

GP 1

Ground Post

1

ProbeHole

PH1

1

ProbeHole

PH2

1

2

.156" Male Vert.

J62

100 nF, 16 V

C70

100 nF, 16 V

C71

100 nF, 16 V

C41

22 pF, 50 V

C1

22 pF, 50 V

C2

22 pF, 50 V

C73

22 pF, 50 V

C74

1 μF, 25 V

C90

1 μF, 25 V

C91

1 μF, 25 V

C92

Q1

EPC2110

Figure 7: EPC9058 Class-E amplier schematic.

EPC Products are distributed through Digi-Key.

www.digikey.com

For More Information:

Please contact info@epc-co.com

or your local sales representative

Visit our website:

www.epc-co.com

Sign-up to receive

EPC updates at

bit.ly/EPCupdates

or text“EPC”to 22828

Demonstration Board Warning and Disclaimer

The EPC9058 board is intended for product evaluation purposes only and is not intended for commercial use. Replace components on the Evaluation Board only with those parts shown on

the parts list (or Bill of Materials) in the Quick Start Guide. Contact an authorized EPC representative with any questions.

This board is intended to be used by certied professionals, in a lab environment, following proper safety procedures. Use at your own risk.

As an evaluation tool, this board is not designed for compliance with the European Union directive on electromagnetic compatibility or any other such directives or regulations. As board

builds are at times subject to product availability, it is possible that boards may contain components or assembly materials that are not RoHS compliant. Ecient Power Conversion

Corporation (EPC) makes no guarantee that the purchased board is 100% RoHS compliant.

The Evaluation board (or kit) is for demonstration purposes only and neither the Board nor this Quick Start Guide constitute a sales contract or create any kind of warranty, whether express

or implied, as to the applications or products involved.

Disclaimer: EPC reserves theright atany time,without notice,to make changes toany products described hereinto improve reliability, function, or design.EPC does not assumeany liability

arising out of the application or use of any product or circuit described herein; neither does it convey any license under its patent rights, or other intellectual property whatsoever, nor the

rights of others.

Table of contents