Epever GoMate Series User manual

.

GoMate Series

——Flush Mount Solar Charger

User Manual

Model: GM3024N

.

.

Contents

Important Safety Instructions.................................................... 1

1. Overview................................................................................. 2

2. Exterior.................................................................................... 3

2.1 Designations of models............................................. 3

2.2 Accessories (Included)............................................... 4

2.3 Accessories (Optional)............................................... 4

3. Installation and wiring............................................................ 5

3.1 Install the controller.................................................... 5

3.2 Wiring........................................................................... 6

4. LCD display ............................................................................ 8

5. Protection.............................................................................. 10

6. Troubleshooting.................................................................... 11

7. Technical Specifications...................................................... 12

8. Disclaimer............................................................................. 14

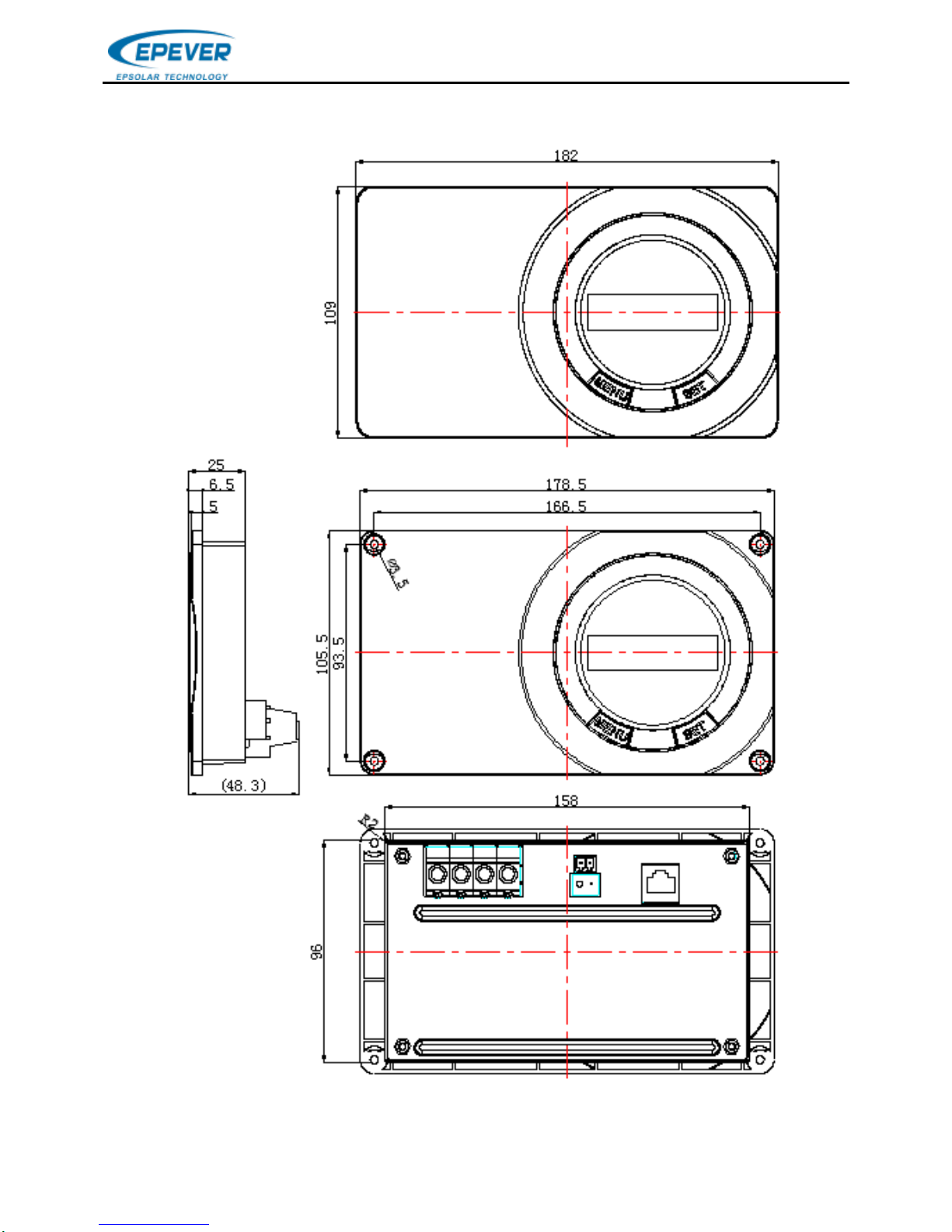

9. Dimensions........................................................................... 15

BEIJING EPSOLAR TECHNOLOGY CO.,LTD.

1

Thank you for selecting the GoMate series solar charge controller.

Please read this manual carefully before using the product and pay

attention to the safety information. Please reserve this manual for

future review.

Important Safety Instructions

This manual contains all instructions of safety, installation, and operation of GoMate

series controller (“the controller” is referred to this manual).

Read all the instructions and warnings carefully before installation.

No user serviceable component inside the controller. DO NOT disassemble or

attempt to repair the controller.

Avoid direct sunlight, high temperatures and DO NOT install the controller at

locations where water can get in.

Install the controller at well-ventilated places, the controller’s heat sink will be very

hot during the system operation.

Appropriate external fuses or breakers are suggested.

Please cut off all connections of the PV array, fuses or breakers which close to the

battery before the controller installation and adjustment.

Power connections must remain tight to avoid excessive overheating from the

loose connection.

BEIJING EPSOLAR TECHNOLOGY CO.,LTD.

2

1. Overview

The GoMate is a negative-ground, flush mount solar charge controller,

designed for an aesthetically clean and integrated look on RV and Vessel,

also included surface mount cover to suit personal preference. The

GoMate adopts highly efficient PWM charging mode, also comes

equipped with special LCD display to show the real-time operating status

of the system. This charge controller is fully controlled automatically,

which provide simple usage pattern to users.

Features:

Flush mounted and embedded installation design

High quality and low failure rate components (ST/IR) to ensure the

product lifetime

3-Stage intelligent PWM charging: Bulk, Boost/Equalize and Float

Battery type: Sealed, Gel, Flooded, and User

Real-time energy statistics feature

Battery temperature compensation feature

Digital LCD monitor for informative display of operational parameters

and fault messages

Voltage drop and temperature compensation sampling interface design

RS485 communication port with Modbus protocol, and short circuit

protection for 5V/200mA power supply

Multiple communication peripherals

Rated charging current at working temperature without de-rating

Extensive electronic protections

Monitor and set the parameters via PC software or APP

BEIJING EPSOLAR TECHNOLOGY CO.,LTD.

3

2. Exterior

❶

Controller case

❻

Battery terminals

❷

Mounting hole sizeφ4.5mm

❼

PV terminals

❸

SET button

❽

Remote temperature sensor port⑴

❹

LCD

❾

RS485 communication port

❺

MENU button

❿

Remote battery voltage sensor port⑵

(1)The controller will charge the battery at 25℃as default and no temperature

compensation when the temperature sensor is damaged.

(2) The port can detect accurate battery voltage(a 2P/1.5mm2wire (Red+, black-)

with insulation protection is suggested). One end connects the 5.08-2P terminal to

insert ❿port, the other end connects the battery, and make sure the “+” and “-”

poles are connected correctly.

2.1 Designations of models

BEIJING EPSOLAR TECHNOLOGY CO.,LTD.

4

2.2 Accessories (Included)

(Model: RT-MF58R47K3.81A)

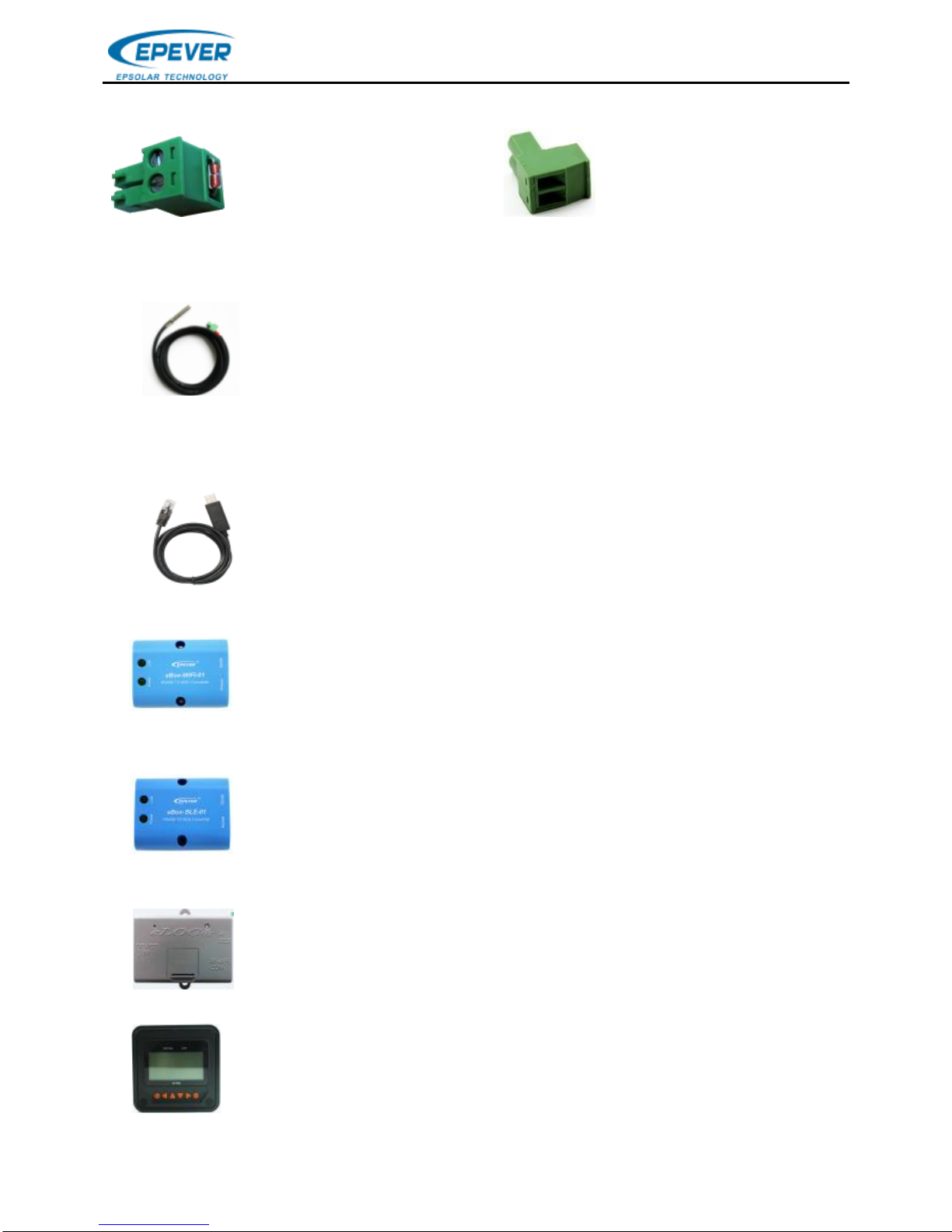

2.3 Accessories (Optional)

1)Remote Temperature Sensor(Model:RTS300R47K3.81A)

NOTE: The temperature sensor short-circuited or damaged, the controller

will be charged or discharged at the default temperature of 25 ℃.

2)USB to RS485 communication cable(Model:CC-USB-RS485-150U)

3)RS485 TO WIFI Converter (Model:eBox-WIFI-01)

4)RS485 TO BLE Converter(Model:eBox-BLE-01)

5)Logger(Model:eLOG01)

6)Remote Meter(Model:MT50)

Temperature Sensor

Acquisition of battery temperature for undertaking temperature

compensation of control parameters, the standard length of the

cable is 3m (length can be customized). The RTS300R47K3.81A

connects to the port ❽on the controller.

USB to RS485 converter is used to monitor each controller using

Solar Station PC software. The length of cable is 1.5m.

TheCC-USB-RS485-150U connects to the RS485 Port on the

controller.

After the controller is connected with the eBox-WIFI-01 through

the standard Ethernet cable (parallel cable), the operating status

and related parameters of the controller can be monitored by the

mobile APP software through WIFI signals.

After the controller is connected with the eBox-BLE-01 through

the standard Ethernet cable (parallel cable), the operating status

and related parameters of the controller can be monitored by the

mobile APP software through Bluetooth signals.

After the controller is connected with the eLOG-01 through the

RS485 communication cable, it can record the operating data of

the controller or monitor the real-time operating status of the

controller via PC software.

MT50 displays various operating data and fault info the system.

The information can be displayed on a backlit LCD screen, the

buttons are easy-to-operate, and the numeric display is readable.

5.08-2P Terminal

BEIJING EPSOLAR TECHNOLOGY CO.,LTD.

5

3. Installation and wiring

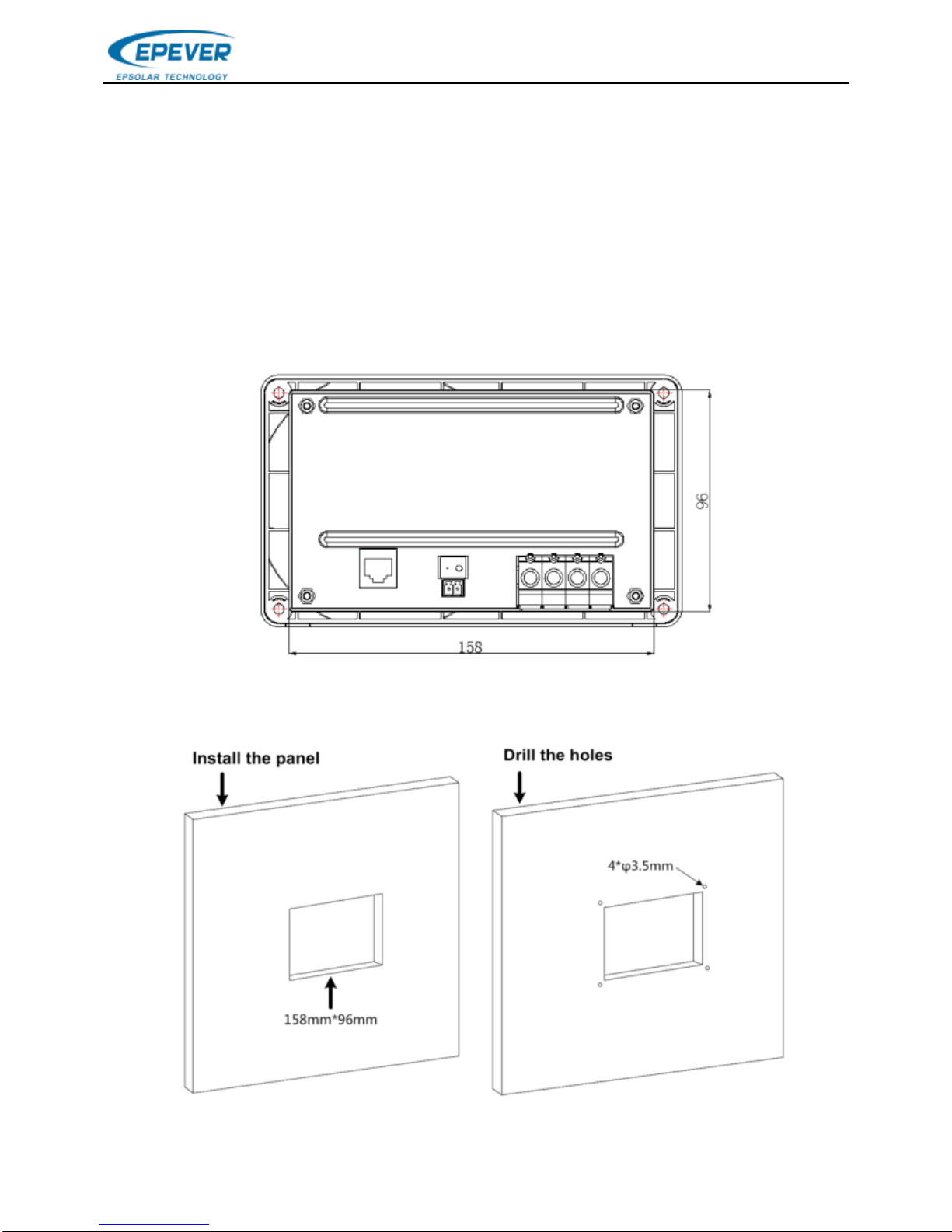

3.1 Install the controller

1) Determine the Installation Location and Heat-dissipation Space

Determination of installation location: The controller shall be installed in a place with

sufficient air flow through the radiators of the controller and a minimum clearance of

150 mm from the upper and lower edges to ensure natural thermal convection.

2) Determine the size of Installation Location (158*96mm)

3) Cut out the section (158*96mm)

4) Mark holes and drill holesφ3.5mm*4

BEIJING EPSOLAR TECHNOLOGY CO.,LTD.

6

5) Secure the controller

6) Install the control case

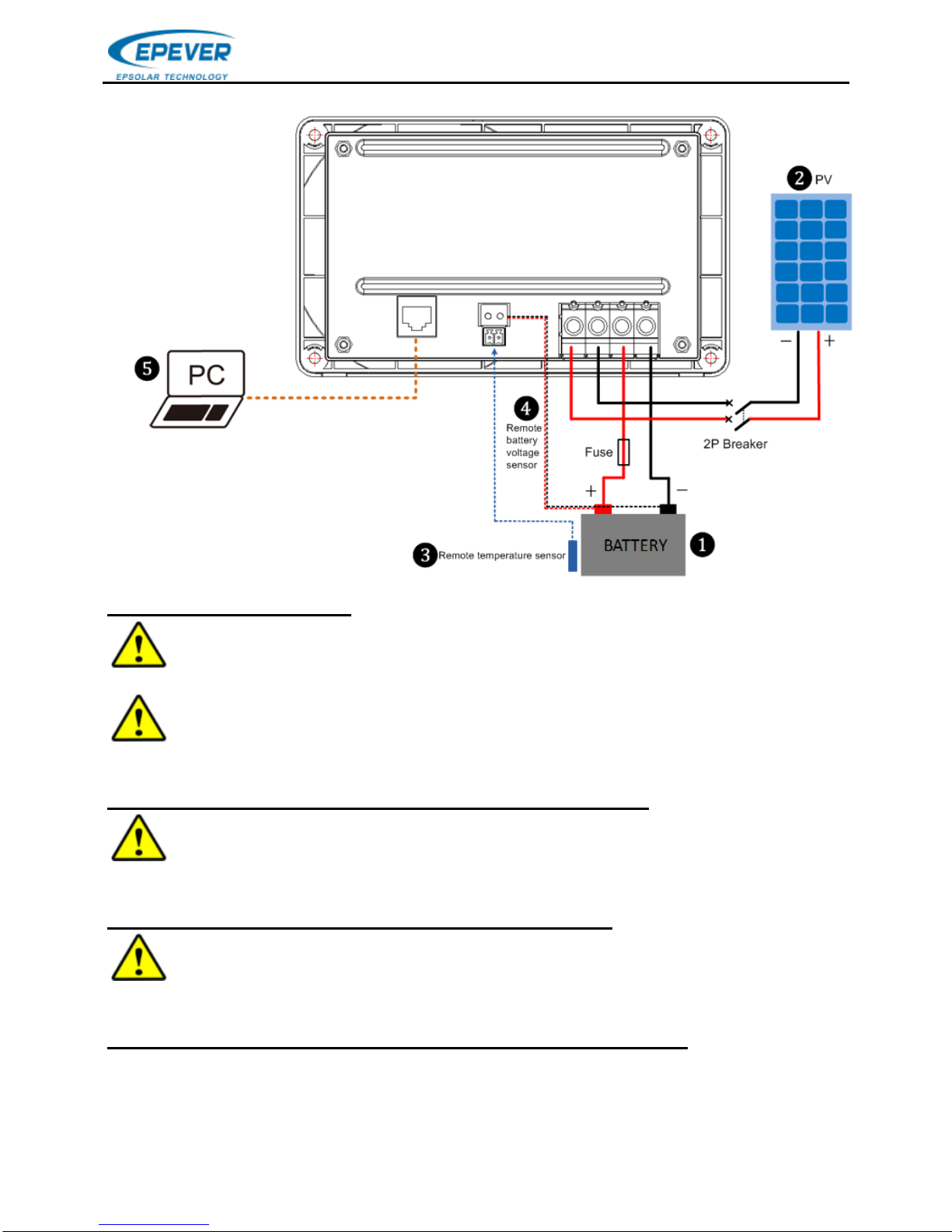

3.2 Wiring

Step1: connect the battery ❶

CAUTION: A fuse which current is 1.25 to 2 times the rated current of the

controller must be installed on the battery side with a distance from the battery not

greater than 150 mm.

BEIJING EPSOLAR TECHNOLOGY CO.,LTD.

7

Step2: Connect the PV ❷

CAUTION: While wiring the controller do not turn on the breaker or fuse and

make sure that the leads of "+" and "-" poles are connected correctly.

CAUTION: If the controller is used in the ungoverned or frequent lightning

area, must install a reasonable arrester in the PV array input side.

Step3:Connect the Remote temperature sensor cable ❸

NOTE: The controller will charge or discharge the battery at 25℃as default

and no temperature compensation when the temperature sensor is damaged.

Step4:Connect the Remote battery voltage sensor ❹

CAUTION: Make sure that the battery voltage sensor cable of "+" and "-"

poles are connected correctly when wiring.

Step5:Connect the PC via the RS485 communication port ❺

Refer to the chapter 4 "Remote set battery type".

BEIJING EPSOLAR TECHNOLOGY CO.,LTD.

8

4. LCD display

1) Automatic cycle interface

Display: PV voltage,PV current,PV power,Battery voltage and Battery temperature

2) Clear the generated energy

Operation:

Step 1: Press the “SET”button and hold 5s under the PV power interface and the

value is flashing.

Step 2: Press the “SET”button to clear the generated energy

3) Switch the battery temperature unit

Press the “SET”button and hold 5s under the battery temperature interface.

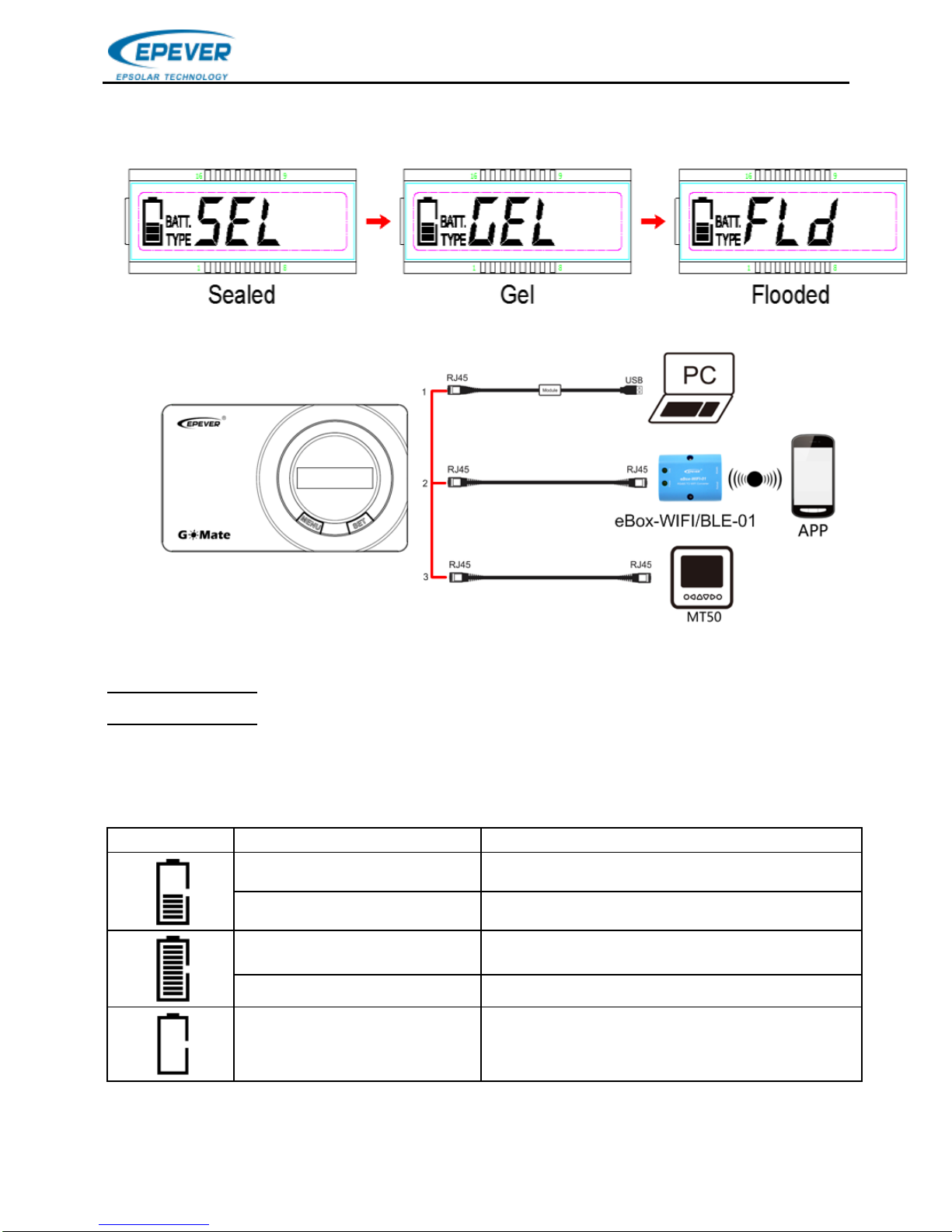

4) Battery type

Battery type

Sealed Gel Flooded User⑴

Set battery type by LCD⑴

Operation:

Step1: Press the “SET”button and hold 5s under the battery voltage interface.

BEIJING EPSOLAR TECHNOLOGY CO.,LTD.

9

Step2: Press the “MENU”button when the battery type interface is flashing.

Step3: Press the “SET”button to confirm the battery type.

Set battery type by PC⑴

Download software

www.epever.com——Solar Station Monitor

www.epever.com——ChargeController(Sealed)

(1)Only Sealed, Gel and Flooded via the LCD, The battery type of User can be set

via the PC software, APP software and MT50.

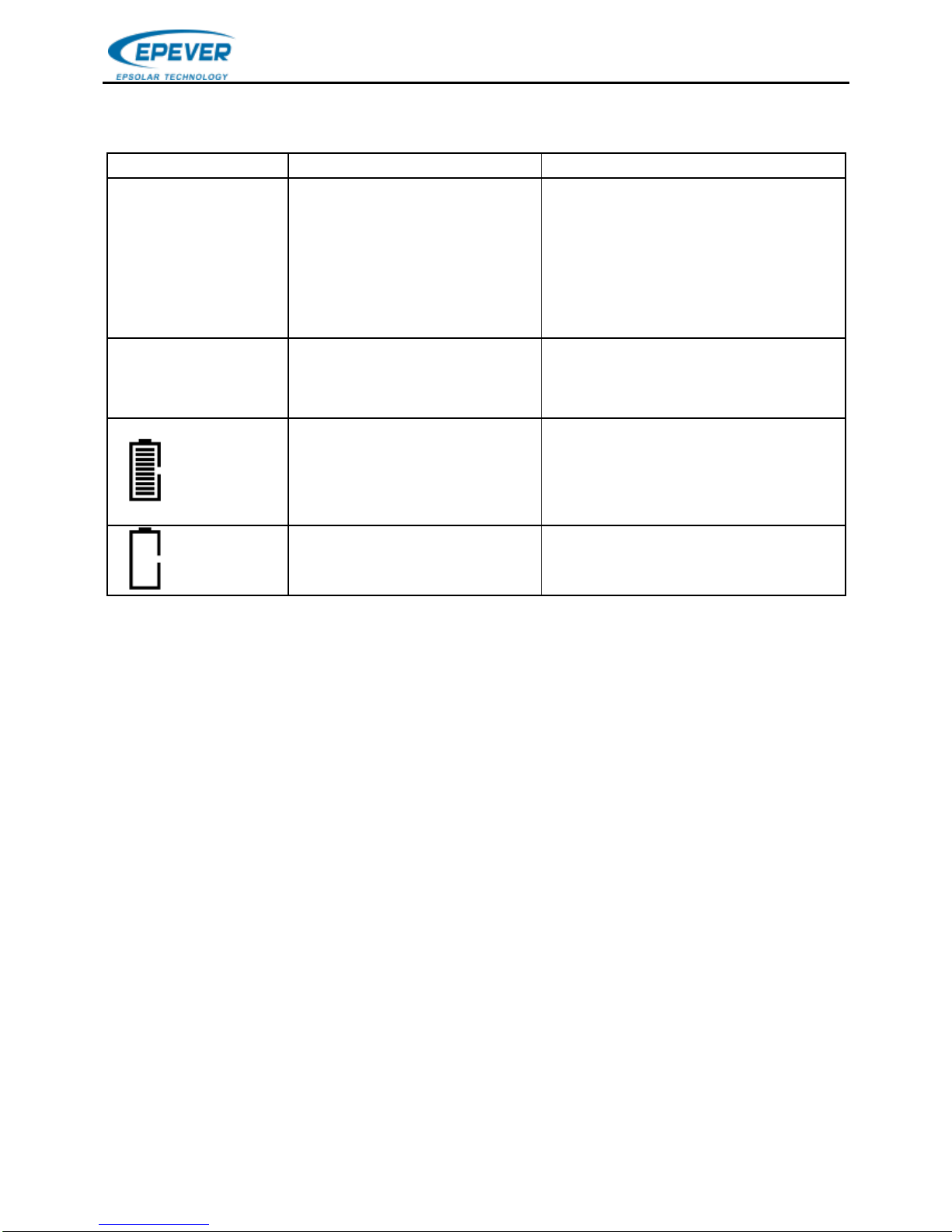

5) System status icon

Icon

Phenomenon

Instruction

Solid

The system is normal but not charging

Energy bars are Flashing

Charging

Solid

Full

Flashing

Battery Overvoltage

Flashing

Battery Over Discharge

BEIJING EPSOLAR TECHNOLOGY CO.,LTD.

10

5. Protection

Protection

Instruction

PV Overcurrent

When the charging current of the PV array exceeds the

controller’s rated current, it will be charged at the rated

current.

PV Overvoltage

When the voltage of PV will exceed 50V, the controller will

stop charging and restart to charge when the PV voltage is

below 45V

PV short circuit

When the PV voltage is below 50V and short circuit, the

controller will stop charging; the controller restart to charge

when the fault is cleared, it doesn’t damage the controller.

PV Reverse

Polarity

When the polarity of the PV array is reversed, the

controller may not be damaged and can continue to

operate normally after the polarity is corrected.

Night Reverse

Charging

Prevents the battery from discharging to the PV module at

night.

Battery Reverse

Polarity

Fully protected against battery reverse polarity; no damage

will occur to the battery. Correct the wiring error to resume

normal operation.

Battery

Overvoltage

When the battery voltage reaches the overvoltage

disconnect voltage, it will automatically stop battery

charging to prevent battery damage caused by

over-charging.

Battery

Overheating

The controller can detect the battery temperature through

an external temperature sensor. The controller stops

working when its temperature exceeds 65 °C and restart to

work when its temperature is below 55 °C.

Controller

Overheating

The controller is able to detect the temperature inside the

battery. The controller stops working when its temperature

exceeds 85 °C and restart to work when its temperature is

below 75 °C.

TVS High

Voltage

Transients

The internal circuitry of the controller is designed with

Transient Voltage Suppressors (TVS) which can only

protect against high-voltage surge pulses with less energy.

If the controller is to be used in an area with frequent

lightning strikes, it is recommended to install an external

surge arrester.

BEIJING EPSOLAR TECHNOLOGY CO.,LTD.

11

6. Troubleshooting

Faults

Possible reasons

Troubleshooting

The PV of LCD

display 0 when

the sunshine

falls on PV

modules

properly

PV array

disconnection

Confirm that PV wire

connections are correct

and tight

LCD is no

display

Min.8V will start up

the controller.

Measure battery voltage

with multi-meter. Min.8V

can start up the controller.

Flashing

Battery Overvoltage

Disconnect the solar array

and measure the battery

voltage whether is too

high;

Flashing

Battery Over

Discharge

Charge the battery

BEIJING EPSOLAR TECHNOLOGY CO.,LTD.

12

7. Technical Specifications

Electrical Parameters

Item

GM3024N

Nominal System

Voltage

12/24VDC or Auto

Battery Input

Voltage Range

8V~32V

Rated Charge Current

30A

Max. PV Short Circuit

Current

30A

Max. PV Open

Circuit Voltage

50V

Battery Type

Sealed(default)/Gel/Flooded/User★

Self-consumption

≤4.2mA/12V;≤2.6mA/24V

Temperature

Compensate Coefficient

-3mV/℃/2V(Default)

Charge Circuit

Voltage Drop

0.21V

★The battery type of User can be set via the PC software, APP software and

MT50. Refer to table 1(Page 13).

Environmental Parameters

Storage Temperature

Range

-30℃~+80℃

Working Environment

Temperature

-20℃~+55℃(100% input and output)

Relative Humidity

≤95%, N.C.

Enclosure

IP30

Grounding

Common negative

Altitude

5000m

Pollution Degree

PD2

Mechanical Parameters

Dimension (L×W×H)

178.5×105.5×48.3mm

Mounting dimension

166.5×93.5mm

Mounting hole size

Φ5mm

Terminal

16mm2/6AWG

Recommended cable

10mm2/8AWG

Net Weight

0.31kg

BEIJING EPSOLAR TECHNOLOGY CO.,LTD.

13

Lead-acid Battery Voltage Parameters Table1

Parameters are in the 12V system at 25℃, ×2 in 24V.

Item

Sealed

Gel

Flooded

User

Over Voltage Disconnect

Voltage

16.0V

16.0V

16.0V

9~17V

Charging Limit Voltage

15.0V

15.0V

15.0V

9~17V

Over Voltage Reconnect

Voltage

15.0V

15.0V

15.0V

9~17V

Equalize Charging

Voltage

14.6V

——

14.8V

9~17V

Boost Charging Voltage

14.4V

14.2V

14.6V

9~17V

Float Charging Voltage

13.8V

13.8V

13.8V

9~17V

Boost Reconnect

Charging Voltage

13.2V

13.2V

13.2V

9~17V

Low Voltage Reconnect

Voltage

12.6V

12.6V

12.6V

9~17V

Under Voltage Warning

Reconnect Voltage

12.2V

12.2V

12.2V

9~17V

Under Volt. Warning Volt.

12.0V

12.0V

12.0V

9~17V

Low Volt. Disconnect Volt.

11.1V

11.1V

11.1V

9~17V

Discharging Limit Voltage

10.6V

10.6V

10.6V

9~17V

Equalize Duration

120min.

——

120min.

0~180min.

Boost Duration

120min.

120min.

120min.

10~180min.

(1)When the battery type is sealed, gel, flooded, the adjusting range of equalizing

duration is 0 to180min and boost duration is 10 to180min.

(2) The battery type of User should follow the rules as below when modifying the

value of parameters in user battery type (factory default value is the same as sealed

type):

a. Over Voltage Disconnect Voltage > Charging Limit Voltage ≥ Equalize Charging

Voltage ≥ Boost Charging Voltage ≥ Float Charging Voltage > Boost Reconnect

Charging Voltage.

b. Over Voltage Disconnect Voltage > Over Voltage Reconnect Voltage

c. Low Voltage Reconnect Voltage > Low Voltage Disconnect Voltage ≥ Discharging

Limit Voltage.

d. Under Voltage Warning Reconnect Voltage > Under Voltage Warning Voltage ≥

Discharging Limit Voltage.

e. Boost Reconnect Charging voltage > Low Voltage Disconnect Voltage.

BEIJING EPSOLAR TECHNOLOGY CO.,LTD.

14

8. Disclaimer

The following situations are not covered by the company policy of

warranty:

Damage from improper use or use in an unsuitable environment.

PV or load current, voltage or power exceeding the rated value of the

controller.

The controller working temperature exceeds the range of working

temperature.

User disassembles and attempts to repair the controller without

permission.

The controller is damaged due to natural causes such as lightning.

The controller is damaged during transportation and shipment.

BEIJING EPSOLAR TECHNOLOGY CO.,LTD.

15

9. Dimensions

Any changes without prior notice! V1.1

.

.

BEIJING EPSOLAR TECHNOLOGY CO., LTD.

Tel: +86-10-82894896 / 82894112

Fax: +86-10-82894882

E-mail:info@epsolarpv.com

Website: www.epever.com

This manual suits for next models

1

Table of contents

Other Epever Batteries Charger manuals