Epic Fans Brevis User manual

User’s Manual

Installation, Operations,

Maintenance and Parts

Part No. 6022110A

Do not install, operate or service this product unless you

have read and understand the Safety Practices, Warnings,

and Installation and Operating Instructions contained in

this User’s Manual. Failure to do so could result in death

or serious injury.

This manual applies to fans

manufactured beginning March

2019.

Brevis 3 Blade HVLS Fan

User’s Manual

E506041

2 6022110A — 3 Blade HVLS Fans April 2019

You may nd safety signal words such as DANGER, WARNING, CAUTION or NOTICE throughout this User’s

Manual. Their use is explained below:

SAFETY SIGNAL WORDS

Introduction.................................................................2

Safety Signal Words ..................................................2

Safety Practices..........................................................3

Owner’s Responsibilities ............................................5

Hardware....................................................................6

Fan Kit ........................................................................7

Installation Considerations .........................................8

Installation ................................................................12

Components and Specications...............................19

table of contents

Operating Instructions ..............................................20

Planned Maintenance...............................................21

Troubleshooting Guide .............................................22

VFD Fault Codes......................................................23

Fire Control System Fan Shutdown..........................25

Electrical Schematics ...............................................28

Parts List...................................................................31

Warranty Information ................................................32

Distributor Information ..............................................32

INTRODUCTION

Welcome and thank you for choosing this 3-Blade HVLS fan from Epic Fans.

This User’s Manual contains information that you need to safely install, operate and maintain the fan. It also

contains a complete parts list and information about ordering replacement parts. Please keep and read this User’s

Manual before using your new fan.

WARNING AND CAUTION SYMBOL

THIS IS THE SAFETY ALERT SYMBOL. IT IS USED TO ALERT YOU TO POTENTIAL

PERSONAL INJURY HAZARDS. OBEY ALL SAFETY MESSAGES THAT FOLLOW

THIS SYMBOL TO AVOID POSSIBLE DEATH OR INJURY.

DANGER SYMBOL

INDICATES AN IMMINENTLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED,

WILL RESULT IN DEATH OR SERIOUS INJURY

ELECTRICAL WARNING SYMBOL

INDICATES AN ELECTRICAL HAZARD WITH A MEDIUM LEVEL OF RISK THAT

COULD RESULT IN DEATH OR SERIOUS INJURY.

April 2019 6022110A — 3 Blade HVLS Fans 3

CAUTION SYMBOL

INDICATES A POTENTIALLY HAZARDOUS SITUATION, WHICH IF NOT AVOIDED

MAY RESULT IN MINOR OR MODERATE INJURY.

WARNING SYMBOL

INDICATES A POTENTIALLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED,

COULD RESULT IN DEATH OR SERIOUS INJURY.

NOTICE SYMBOL

NOTICE IS USED TO ADDRESS PRACTICES NOT RELATED TO PERSONAL

INJURY.

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

READ THESE SAFETY PRACTICES BEFORE INSTALLING, OPERATING, OR

SERVICING THE FAN. FAILURE TO FOLLOW THESE SAFETY PRACTICES

COULD RESULT IN DEATH OR SERIOUS INJURY.

READ AND FOLLOW THE OPERATING INSTRUCTIONS IN THIS MANUAL

BEFORE OPERATING THE FAN. IF YOU DO NOT UNDERSTAND THE

INSTRUCTIONS, ASK YOUR SUPERVISOR TO TEACH YOU HOW TO USE THEM

TO REDUCE THE RISK OF PERSONAL INJURY, DO NOT BEND THE BLADE

BRACKETS WHEN INSTALLING THE BRACKETS OR CLEANING THE FAN. DO

NOT INSERT FOREIGN OBJECTS IN BETWEEN ROTATING FAN BLADES.

TO REDUCE THE RISK OF FIRE, HVLS FAN MOTOR ASSEMBLIES MUST BE

INSTALLED WITH THE BLADE ASSEMBLIES THAT ARE MARKED ON THEIR

CARTONS TO INDICATE THE SUITABILITY WITH THIS MODEL. OTHER BLADE

ASSEMBLIES CANNOT BE SUBSTITUTED.

BE CERTAIN TO FOLLOW THE INSTRUCTIONS IN THIS MANUAL.

4 6022110A — 3 Blade HVLS Fans April 2019

INSTALLATION OF THE EQUIPMENT MUST COMPLY WITH LOCAL AND NATIONAL

ELECTRICAL CODES AND MUST BE IN ACCORDANCE WITH ANSI/NFPA 7-1999.

DO NOT USE THIS INDUSTRIAL FAN UNTIL YOU HAVE RECEIVED PROPER

TRAINING. IMPROPER USE COULD RESULT IN PROPERTY DAMAGE, BODILY

INJURY AND/OR DEATH. READ AND FOLLOW THE COMPLETE OPERATING

INSTRUCTIONS ON PAGES 20AND 21 BEFORE USE. IFYOU DO NOT UNDERSTAND

THE INSTRUCTIONS, ASK YOUR SUPERVISOR TO EXPLAIN THEM TO YOU OR

CALL YOUR LOCAL DISTRIBUTOR.

DO NOT USE THE FAN IF IT APPEARS DAMAGED OR DOES NOT OPERATE

PROPERLY. INFORM YOUR SUPERVISOR IMMEDIATELY.

DO NOT OPERATE THE FAN UNTIL ALL PERSONNEL, BUILDING STRUCTURE,

AND EQUIPMENT ARE CLEAR OF ALL MOVING PARTS AND EXCLUSION ZONES.

INSTALL GUARDS AS REQUIRED.

TO REDUCE THE RISK OF ELECTRICAL SHOCK, DO NOT EXPOSE TO WATER OR

RAIN.

SUPPORT DIRECTLY FROM BUILDING STRUCTURE. DO NOT INSTALL THE

FAN UNIT ONTO STRUCTURE OF INSUFFICIENT STRENGTH. CONSULT

A PROFESSIONAL ENGINEER OR REGISTERED ARCHITECT. IMPROPER

INSTALLATION OF THE FAN COULD RESULT IN DEATH OR SERIOUS INJURY.

BEFORE SERVICE, INSPECTION, OR CLEANING, MAKE CERTAIN THE POWER IS

DISCONNECTED AND PROPERLY LOCKED OUT.

IF THE FAN DOES OPERATE PROPERLY USING THE PROCEDURES IN THIS

MANUAL, BE CERTAIN TO REMOVE POWER FROM THE UNIT AND LOCK-OUT

THE DISCONNECT ON THE POWER CIRCUIT. CALL YOUR LOCAL DISTRIBUTOR

FOR SERVICE.

KEEP YOUR BODY CLEAR OF MOVING PARTS AT ALL TIMES.

ALL ELECTRICAL TROUBLESHOOTING AND REPAIR MUST BE DONE BY A

QUALIFIED TECHNICIAN AND MEET ALL APPLICABLE CODES.

IF IT IS NECESSARY TO MAKE TROUBLESHOOTING CHECKS INSIDE THE VFD

BOX WITH THE POWER ON, USE EXTREME CAUTION. DO NOT PLACE FINGERS

OR UN-INSULATED TOOLS INSIDE THE ENCLOSURE. TOUCHING WIRES OR

OTHER PARTS INSIDE THE ENCLOSURE COULD RESULT IN ELECTRICAL

SHOCK. DEATH, OR SERIOUS INJURY.

VARIABLE FREQUENCY DRIVE (VFD) FAN CONTROLLERS CONTAIN HIGH

VOLTAGE CAPACITORS. BEFORE WORKING ON THE FAN CONTROLLER,

ENSURE ISOLATION OF THE MAIN VOLTAGE SUPPLY AND VERIFY VOLTAGE

HAS BLED OFF PRIOR TO BEGINNING WORK. FAILURE TO DO SO MAY RESULT

IN DEATH OR SERIOUS INJURY.

IF YOU HAVE PROBLEMS OR QUESTIONS, CONTACT YOUR LOCAL DISTRIBUTOR

FOR ASSISTANCE.

April 2019 6022110A — 3 Blade HVLS Fans 5

TO REDUCE THE RISK OF INJURY TO PERSONS, INSTALL FAN SO THAT THE

BLADE IS AT LEAST 3.05M (10') ABOVE THE FLOOR.

INSTALLATION WORK AND ELECTRICAL WIRING MUST BE DONE BY QUALIFIED

PERSON(S) IN ACCORDANCE WITH ALL APPLICABLE CODES AND STANDARDS.

WHEN CUTTING OR DRILLING INTO WALL OR CEILING, DO NOT DAMAGE

ELECTRICAL WIRING AND OTHER HIDDEN UTILITIES.

EXERCISE CAUTION AND COMMON SENSE WHEN POWERING THE FAN. DO NOT

CONNECT THE FAN TO A DAMAGED OR HAZARDOUS POWER SOURCE. DO NOT

ATTEMPT TO RESOLVE ELECTRICAL MALFUNCTIONS OR FAILURES ON YOUR

OWN.

WHEN SERVICE OR REPLACEMENT OF A COMPONENT IN THE FAN REQUIRES

THE REMOVAL OR DISCONNECTION OF A SAFETY DEVICE, THE SAFETY DEVICE

IS TO BE REINSTALLED OR REMOUNTED AS PREVIOUSLY INSTALLED.

RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS DURING CLEANING

AND USER-MAINTENANCE. DISCONNECT THE FAN FROM THE POWER SUPPLY

BEFORE SERVICING.

STAY ALERT, WATCH WHAT YOU ARE DOING, AND USE COMMON SENSE

WHEN INSTALLING FANS. DO NOT INSTALL FANS WHEN TIRED, OR UNDER

THE INFLUENCE OF DRUGS, ALCOHOL, OR MEDICATIONS. A MOMENT OF

INATTENTION WHILE INSTALLING FANS MAY RESULT IN SERIOUS PERSONAL

INJURY.

THE INSTALLATION OF THIS FAN REQUIRES THE USE OF SOME POWER TOOLS.

FOLLOW THE SAFETY PROCEDURES FOUND IN THE OWNER'S MANUAL FOR

EACH OF THESE TOOLS AND DO NOT USE THEM FOR PURPOSES OTHER THAN

INTENDED BY THE MANUFACTURER.

OWNER’SRESPONSIBILITIES

The owner’s responsibilities include the following:

The owner should recognize the inherent danger of the interface between the 3 Blade fan and shop worker. The owner

should, therefore, train and instruct operators in the safe use of the 3 Blade fan.

Nameplates, cautions, instructions and posted warnings shall not be obscured from the view of operating or maintenance

personnel for whom such warnings are intended. Warnings which are worn or non-legible should be replaced.

Manufacturer’s recommended periodic maintenance and inspection procedures in eect a t d ate o f s hipment s hall be

followed, and written records of the performance of these procedures should be kept.

3 Blade fans that are structurally damaged or have experienced impacts from external sources, shall be removed from

service, inspected by the manufacturer’s authorized representative, and repaired as needed before being placed back in

service.

The owner shall see that all nameplates and caution and instruction markings or labels are in place and that the

appropriate operating and maintenance manuals are provided to users.

Modifications or alterations of 3 Blade fans shall be made only with written permission of the original manufacturer.

6 6022110A — 3 Blade HVLS Fans April 2019

HARDWARE

(x4) 1/2-13UNC x 2-1/2

Mount ─ Building

(x4) 1/2-13UNC lock nut

Guy wire assembly

Safety cable

(x20) 3/8-16UNC lock nut

Mount ─ Blade

Identification labels

Fan information

Fan diameter

Operating instructions

Fastener torque requirements

Description Torque Wrench size

1/2 dia mount hardware 44-48 ft-lbs. 3/4 hex

3/8 dia blade mount hardware 24-28 ft-lbs. 9/16 hex

Cable clamp, guy wire Secure tight 5/16 nut driver

Cable clamp, safety cable Secure tight 1/2 nut driver

(x4) 1/2-13UNC x 1-1/4 bolt

(x4) 1/2-13UNC lock nut

Mount ─ Motor frame

(x2) 1/2-13UNC x 4-1/2 bolt

(x4) 1/2 dia. washer

(x2) 1/2-13UNC nyloc lock nut

Mount ─ Assembly

NOTE:

Additional spare hardware is provided as a courtesy.

April 2019 6022110A — 3 Blade HVLS Fans 7

PACKING KIT (Standard)

1. Blade Box – 3 each

2. Fan Motor Box

a. Motor/gearbox assembly.

b. Mounting hardware. See page 5.

c. VFD box.

REQUIRED TOOLS

• Wrenches: 9/16, 3/4 (x2), 1/2

• Sockets: 1/2, 9/16, 3/4

• Nut drivers: 5/16

• Torque wrench: 15-60 Ft-lbs (for use with sockets)

• Wire strippers

• 1/4" cable cutter

• Tape measure

• Spirit level, short

• Gloves

•For laminated wood beam installs, a drill and 1/2" dia.

drill bit are required.

PRIOR TO FAN INSTALLATION:

1. Ensure that the supplied voltage matches the fan

voltage. A label containing voltage information specic

to the individual fan is located on the side of the VFD

box.

2. Ensure all mounting hardware shown on page 5 is

present.

FAN KIT

NATIONAL FIRE PROTECTION

ASSOCIATION STANDARD

In accordance with NFPA 13 Standard from the National Fire

Prevention Association as referenced in sections 12.1.4 and

11.1.7: High Volume Low Speed (HVLS) Fans: The installation

of HVLS fans in buildings equipped with sprinklers, including

ESFR sprinklers, shall comply with the following:

• The maximum fan diameter shall be 24 feet (6.1 m).

• The fan shall be approximately centered between four

adjacent sprinklers.

• The vertical clearance from the fan to sprinkler deector

shall be a minimum of 3 feet (0.9 m).

• All fans shall be interlocked to shut down immediately

upon receiving a water ow signal from the alarm system

in accordance with the requirements of NFPA 72- National

Fire Alarm and Signaling Code.

8 6022110A — 3 Blade HVLS Fans April 2019

INSTALLATION CONSIDERATIONS

ROOF SLOPE

NOTE:

For roof angles in excess of 20°, consult factory. The extension

lengths shown are minimum recommendations only, based

solely o roof pitch and fan diameter. Other considerations

must be evaluated when determining extension requirements,

such as placement of lights, sprinkler systems, HVAC

systems, etc. In addition, OSHA requirements state that fan

blades must be a minimum of 10' above the oor.

NOTE:

All fan blade parts must be greater

than 3' from all obstructions

including lights, cables, sprinklers

and other building components and

greater than one (1) fan diameter

from any wall to blade tip.

Failure to maintain exclusion

zones outlined on pages 7,

8 and 9 could result in fan

failures, including blade

separation, which could result

in death or serious injury.

DO NOT operate fans when

physical obstructions or HVAC

air ows extend into exclusion

zones. Regularly inspect fans

to ensure exclusion zones

remain clear of interference

before operating fan.

*Consult factory for assistance with fan placement and extension selection.

Fig. 1

300

300

300

Roof Slope* 2/12 4/12

Roof Angle* 9.5° 18.4°

Fan Diameter (Ft)

12 5 76

16 8 10

20 10 12

Hanging

Weight

(Lb)

Maximum

Torque

(Ft. Lb)

165

170

180

0

0

5

6

7

3/12

14.0°

9

11

Blade length (In.)

45.16

69.16

93.16

Distance from ceiling (Ft)

April 2019 6022110A — 3 Blade HVLS Fans 9

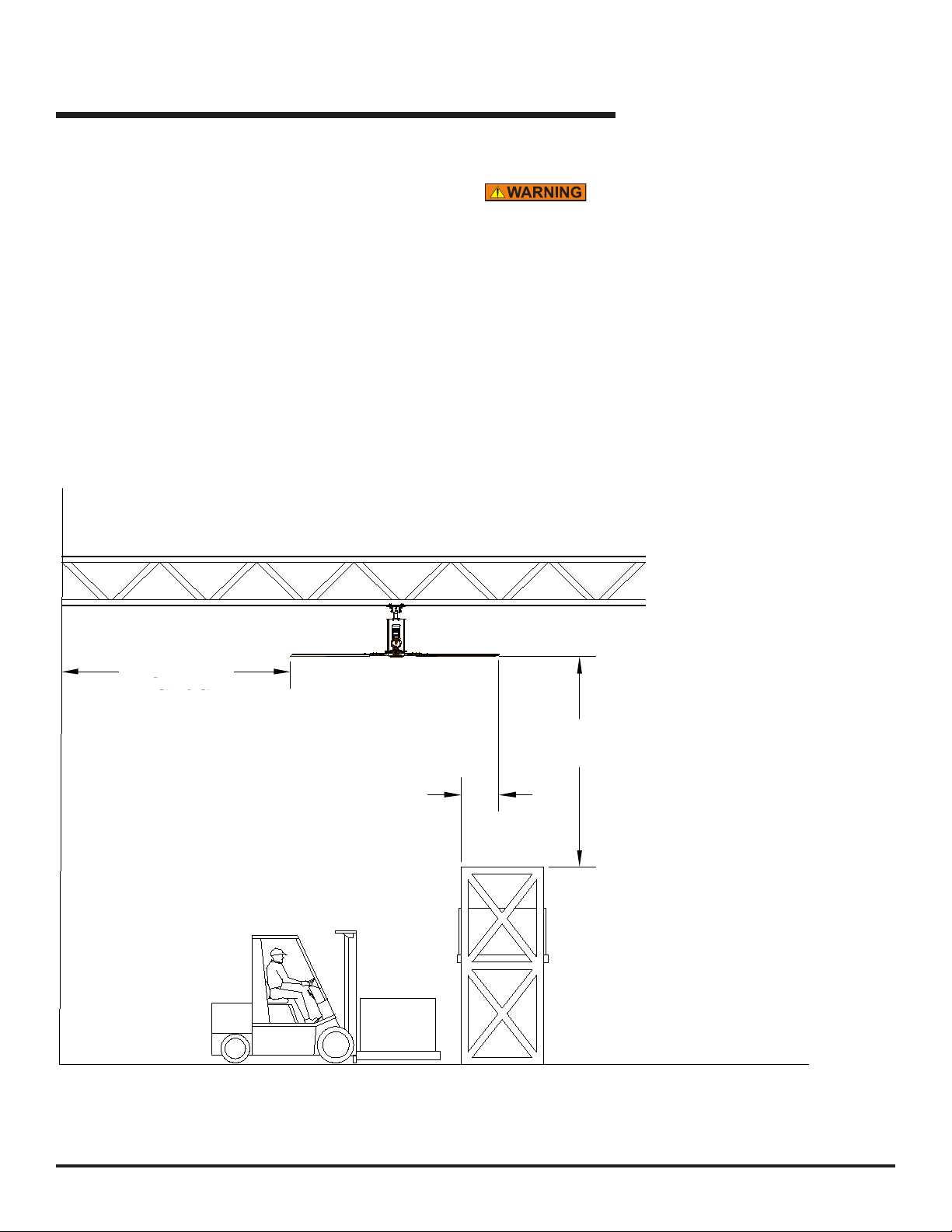

INSTALLATION CONSIDERATIONS,continued

CLEARANCE FROM HVAC EQUIPMENT

For applications near HVAC equipment (diusers, radiant

heaters, exhaust fans, louvers, etc.), the HVLS fan must be

installed at minimum distances.

• Fans located at or above HVAC equipment must have

a minimum clearance of greater than or equal to 1 fan

diameter. See Fig. 2.

• Fans located below HVAC equipment must have a minimum

clearance of greater than or equal to 2 fan diameters. See

Fig. 3.

Failure to maintain exclusion zones outlined on pages

7, 8 and 9 could result in fan failures, including blade

separation, which could result in death or serious injury.

DO NOT operate fans when physical obstructions or

HVAC air ows extend into exclusion zones. Regularly

inspect fans to ensure exclusion zones remain clear of

interference before operating fan.

Fig. 2

Fig. 3

Greater than

1 fan dia.

Greater than

2 fan dia.

10 6022110A — 3 Blade HVLS Fans April 2019

Failure to maintain exclusion zones outlined on pages

7, 8 and 9 could result in fan failures, including blade

separation, which could result in death or serious injury.

DO NOT operate fans when physical obstructions or

HVAC air ows extend into exclusion zones. Regularly

inspect fans to ensure exclusion zones remain clear of

interference before operating fan.

CLEARANCE FROM SOLID OBSTRUCTIONS

For applications near solid obstructions the HVLS fan must

be installed at minimum distances.

• Fans located above solid obstructions such as racks, walls,

etc. must have a minimum vertical clearance of greater than

or equal to 1/2 fan diameter above and less than or equal

to 1/4 fan diameter inside the fan blade arc. See Fig. 4.

Fig. 4

INSTALLATION CONSIDERATIONS,continued

Greater than

1/2 fan dia.

Less than

1/4 fan dia.

Greater than

1/2 fan dia.

April 2019 6022110A — 3 Blade HVLS Fans 11

INSTALLATION CONSIDERATIONS,continued

BUILDING STRUCTURE

For open structure roof designs, the fan should only be hung

from either I-beam or angle iron. Do not hang from purlins,

joists or truss structure.

For solid beam or laminated wood beam mounting, use

the laminated wood beam mounting kit available from

Epic Fans.

Consult a professional engineer or registered architect for

specic mounting concerns.

Ensure fan blade clearance meets the requirements. See

Fig. 1-4.

PLACEMENT AND SPACING

Consult your local distributor to help you plan the most

ecient installation of your fans.

Ensure fan placement is such that the fans blades are a

minimum of 10' from any manned working surface (oor or

mezzanine

Ensure fan blade does not extend into exclusion zone.

Extensions are available if required. See Fig. 1.

Avoid mounting fans directly under lights or skylights to

avoid visual strobing aect.

NOTE:

Be certain to comply with all local and national codes during

installation.

For fans that will be subjected to high cross winds (open

bay doors or air conditioning diuser ducts) the fan must

be at least two fan diameters (as measured from the end

of the winglet) from open bays or A/C ducts mounted

below the blade plane.

Fig. 5

1/2-13UNC x 4-1/2 (x2)

1/2 dia washer (x2)

Pivot bracket

Mount tube

Hardware should be GRADE 5 or better.

12 6022110A — 3 Blade HVLS Fans April 2019

INSTALLATION

Fig. 7

Building structure

Clamp plate

Shim

Fig. 6

Pivot bolt

Shim (x2)

(as req’d)

1/2-13UNC x 2-1/2 bolts (x4)

1/2-13UNC

lock nut (x4)

Angle

adjustment

bolt

Before installation, make certain that the power is

disconnected and properly locked out.

FAN MOUNT ASSEMBLY

1. Fasten pivot brackets to the extension tube with ears

outboard. Leave the 1/2" dia. x 4-1/2" bolts and nylock

nuts nger tight. See Fig. 5.

INSTALL FAN MOUNT

STANDARD I-BEAM

1. Locate fan mount assembly on bottom of building

support beam. Align mount assembly so that it is

centered and square to the beam.

2. Install clamps. For thick ange I-beams add shims as

required. Fasten using the supplied 1/2" dia x 2-1/2"

screws, lock nuts and washers. Torque to 44-48 ft-lbs.

See Fig. 7.

April 2019 6022110A — 3 Blade HVLS Fans 13

If building support beam is not level, ensure proper fan

clearance using the mounting information shown on

pages 7-9 or add mounting extensions as required to

ensure clearance. See Fig. 1.

LAMINATED WOOD BEAM MOUNTING —

(OPTIONAL KIT 6018641)

1. Attach laminated wood beam brackets to the wooden

beam using a minimum of four 1/2" dia. grade 5 thru

bolts and self-locking nuts (not supplied). Ensure

brackets are square to the bottom of the beam.

2. Attach mount assembly to the laminated wood beam

brackets using the supplied 1/2" dia x 2-1/2" screws,

nylock lock nuts and washers. Torque to 44-48 ft-lbs.

See Fig. 8.

TRUSS MOUNT

NOTE:

Do not span distances greater than 96".

To span two trusses with a distance of 96" or less, span the

gap using two 4" x 4" x 1/4" steel angle iron. See Fig. 9.

Consult a professional engineer or registered architect for

specic mounting concerns.

NOTE:

Drill Holes in appropriate locations to maintain proper

exclusion zone clearance.

NOTE:

Longest extension allowed is 20'. Any extensions longer than

12' must use the secondary guy wire kit (6020303 — standard

or 60020304 — stainless steel).

INSTALL POWERHEAD (MOTOR/GEARBOX ASSY)

NOTE:

Leave the protective bumper on the bottom of the power head

assembly until the power head is mounted in place.

1. Using a powered lift, orient the powerhead with the

blade hub down. Block motor as required for installation

using the bottom of the frame assembly. Do not support

using the hub or hub cap.

Fig. 8

INSTALLATION,continued

Laminated wood

beam bracket

Laminated wood beam

Fig. 9

Fig. 10

14 6022110A — 3 Blade HVLS Fans April 2019

Fig. 11

Fig. 12

NOTE:

Fan powerhead may be oriented as required for aesthetics

or commonality.

2. Raise the powerhead up until it contacts the bottom of

the fan mount assembly. See Fig. 11.

3. Fasten the powerhead to the mount assembly using

the supplied 1/2" dia x 1-1/4" bolts, self-locking nuts

and washers. Torque to 44-48 ft-lbs. See Fig. 12.

4. Immediately attach safety cable. See Fig. 13.

a. Slide two of the supplied 1/4" dia cable clamps over

each end of the cable spaced 6" apart.

b. Slide the ends through the cable clamps.

c. Make sure that the cable goes through the motor

frame. See Fig. 13.

e. Securely tighten the clamp fasteners. Make sure

the u-bolts are over the free ends of the cable.

f. Ensure assembly does not interfere with fan motor

housing.

Mount tube

Powerhead

1/2-13UNC x 1-1/4

bolt (x4)

1/2-13UNC

lock nut (x4)

Fig. 13

Safety cable

Motor frame

Space cable

clamps 6" apart

INSTALLATION,continued

April 2019 6022110A — 3 Blade HVLS Fans 15

INSTALLATION,continued

Fig. 14

Seal removal note

Plastic

shipping

seal

Ventillation

plug

GEARBOX VENT PLUG

1. Locate ventilation plug on gearbox. See Fig. 19.

2. Pull and remove plastic shipping brace and discard.

3. Remove the plastic cseal.

4. Remove orange brace removal note and discard.

INSTALL GUY WIRES

Guy wires are designed to constrain lateral movement of

the fan in operation. This movement may be due to impacts

on the fan or winds impinging on the blades that would

cause the fan to sway.

Failure to attach guy wires may result in loss of

warranty.

If a mounting extension has been used, ensure that

the longer guy wires accompanying the extension are

used. Ensure that the angle formed by the guy wire

with the roof structure is less than 45º. See Fig. 15.

Avoid any sharp edges or corners to reduce fatiguing

and fraying of the guy wires. Failure to attach guy

wires may result in severe injury or death.

1. Adjust turnbuckles to their longest position.

2. Attach the quick link with attached turnbuckle to the fan

as shown. Repeat for all four quick links.

3. Attach one end of the guy wire to the building structure.

Repeat for all four guy wires.

a. Slide two of the supplied 1/8" dia cable clamps over

one end of the wire.

b. Feed that end of the wire though the building

structure and back through the clamp fasteners.

c. Securely tighten the clamp fasteners so that it

cannot slip. Make sure the u-bolts are over the free

end of the cable.

4. Individually tighten the turn buckle on each cable

until each cable is taut and the powerhead unit hangs

<45º

Fig. 16

Fig. 15

Guy wires

Quick link

Turnbuckle

16 6022110A — 3 Blade HVLS Fans April 2019

Fig. 17

Fig. 19

Fig. 18

Spread slightly

Blade retention

lock nuts

plumb. Use a spirit level to verify powerhead unit hangs

plumb.

5. Tighten pivot and angle adjustment bolts on fan mount.

Torque to 44-48 ft-lbs. See Fig. 6.

INSTALL BLADES

To reduce the risk of personal injury, do not bend the

blade brackets when installing the brackets or cleaning

the fan. Do not insert foreign objects in between

rotating fan blades.

NOTE:

Blade assemblies come pre-assembled from the factory. Do

not attempt to disassemble.

1. The hub assembly has special blade retention lock nuts

pre-assembled to it. Remove them now and use them

to mount the blade assemblies in the steps below. Use

only the factory supplied lock nuts provided for blade

mounting.

2. With the blade oriented such that the blade retention

lanyard is on top, support the blade assembly from

below. Orient and guide the assembly onto the top

attachment studs on the hub assembly. Spread the

strut arms slightly onto the upper studs as shown.

Angle the blade upward as needed to slide blade onto

studs. See Fig. 16.

3. Still supporting the blade assembly, rotate the blade

assembly down as shown and allow the bottom blade

strut to ride up and over the bottom attachment studs

on the hub assembly. See Fig. 17.

Do not lean on blade. Damage to strut may occur.

4. Install blade retention lock nuts. Hand tighten nuts

ensuring strut arms are rmly pressing against hub.

INSTALLATION,continued

April 2019 6022110A — 3 Blade HVLS Fans 17

INSTALLATION,continued

Fig. 20

Turnbuckle strap

Torque blade retention nuts to 24-28 ft-lbs. See Fig. 18.

5. Repeat for each blade assembly.

VERIFY CLEARANCE AND CABLE TENSION

1. Rotate fan by hand and observe clearance of each

blade with closest obstruction. If necessary, reposition

fan. Blade tips droop when not in operation and rise

when in operation. Reference chart on page 7 for min.

clearance.

2. Verify guy wire tension by attempting to move

powerhead in any horizontal direction. If movement is

detected, re-tension guy wires.

3. Lock the individual turnbuckles using the stop nut on

each and secure it with the turnbuckle strap. See Fig.

20.

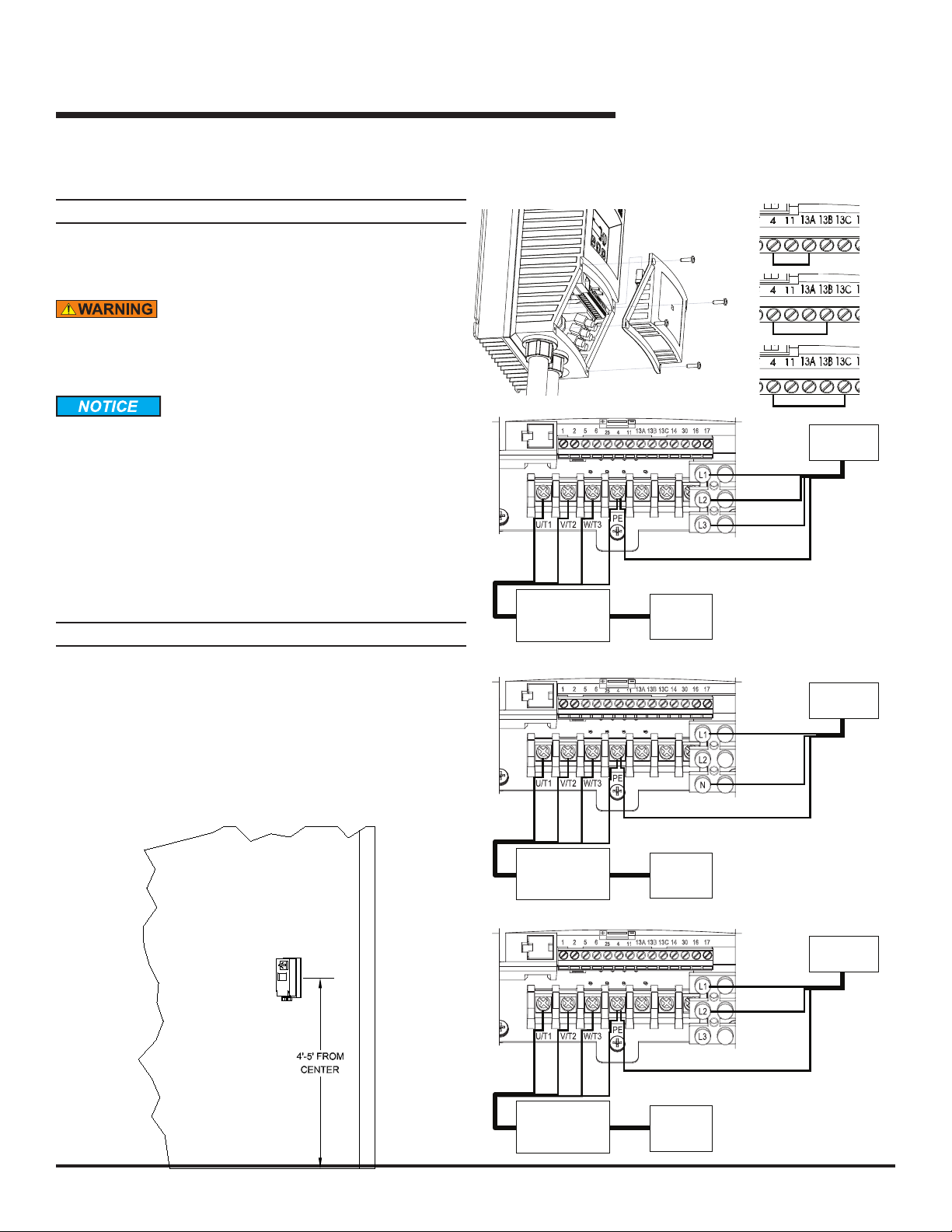

ELECTRICAL INSTALLATION

Before doing any electrical work, make certain the

power is disconnected and properly locked or tagged

o. Failure to do so may result in death or serious

injury. All electrical troubleshooting and repair must be

done by a qualied technician and meet all applicable

codes. Do not route control wiring for any other device

through the control box. Ensure that the voltage and

phase of the incoming power agrees with the label

located on top of the VFD box and fan. Be certain

power is o when wiring to the control box. Failure to

do so could result in electrical shock, death or serious

injury.

18 6022110A — 3 Blade HVLS Fans April 2019

INSTALLATION,continued

Fig. 22

STANDARD UNITS

NOTE:

Reference wiring diagrams on pages 25-27 for all eld

connections.

INSTALL VFD

The VFD must be mounted approximately 53" above

the ground on the wall; use no more than 82 linear feet

(25m) of wire between VFD and fan motor.

Verify voltage and phase before mounting. Ensure

voltage shown on VFD box is correct.

2. Mount VFD approximately 53" above the oor on the

wall. See Fig. X. Cable will need to be extended. Use

junction box and extend using either SO or conduit and

appropriately rated wire.

3. Route the fan SO cable from the fan to the VFD box.

Ensure the cable is supported throughout its routing.

NOTE:

Factory S.O. cable is 20 ft long. Additional cable/conduit

provided by others.

4. Route supply power from the building source to the

VFD box.

5. Wire VFD box. See Fig. 22 and electrical schematics

located on pages 35-37.

Fig. 21

Red

White

Black

Junction

Box

(PROVIDED BY OTHERS)

To Fan

Motor

Incoming

Power

Red

White

Black

Green

Three phase wiring

Red

White

Black

Green

Junction

Box

(PROVIDED BY OTHERS)

To Fan

Motor

Incoming

Power

Black

White

Green

120VAC single phase wiring

Red

White

Black

Junction

Box

(PROVIDED BY OTHERS)

To Fan

Motor

Incoming

Power

Red

Black

Green

240VAC single phase wiring

Jumper settings for fan size

12'

16'

20'

GreenGreen

April 2019 6022110A — 3 Blade HVLS Fans 19

COMPONENTS AND SPECIFICATIONS

VFD – NEMA4X, Solid State VFD (Variable Frequency

Drive), 120VAC/1PH, 208-240VAC/1PH, 208-600VAC/3PH.

No line reactor. UL and UL-C listed panel. Power

disconnect. FUSED BY OTHERS.

MOTOR

NEMA standard T.E.F.C., 1 HP, continuous duty three

phase

GEARBOX

Double helical gear reduced, sealed lubrication.

VFD unit

Blade

Powerhead

Safety cable

Clamp

Universal mount

Guy wires

Fig. 23

20 6022110A — 3 Blade HVLS Fans April 2019

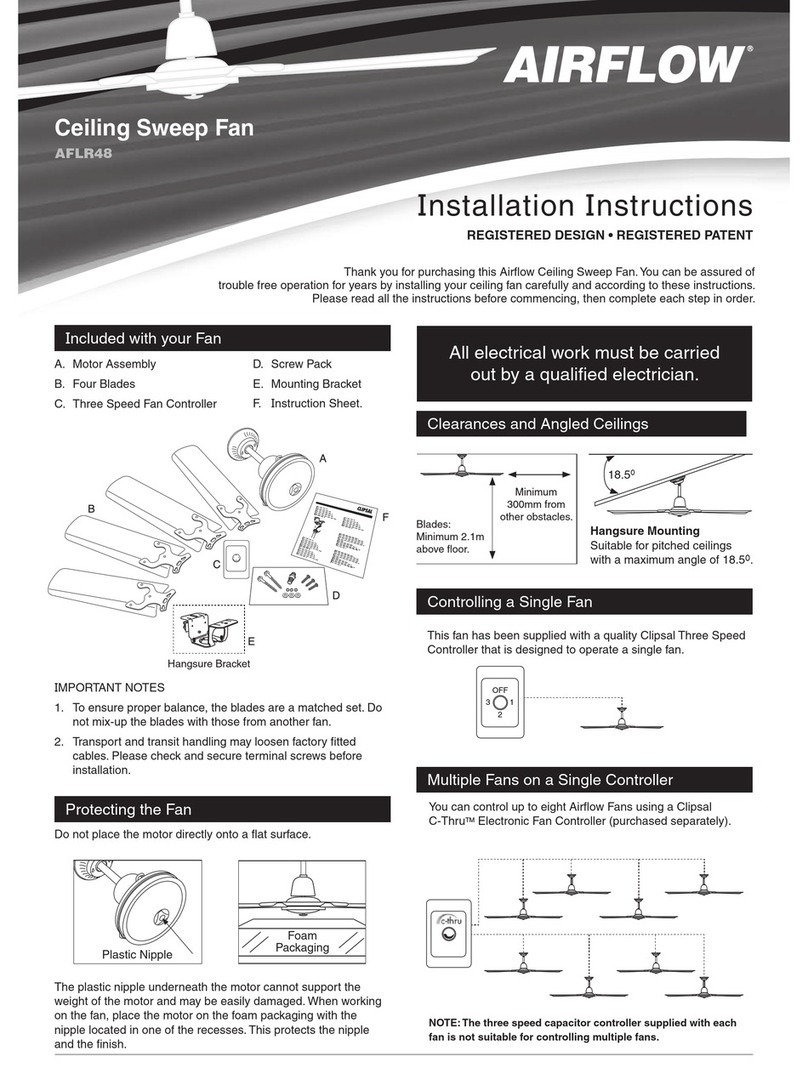

OPERATING INSTRUCTIONS,continued

Fig. 24

Stop

RunUp arrow

Down arrow

Enter

Reverse/Forward

VFD Touchpad

Before operating the industrial 3 Blade fan, read and

follow the Safety Practices, Warnings and Operating

Instructions in this manual. Use by untrained

personnel could result in death or serious injury.

VERIFY PRIOR TO OPERATION

1. Voltage/phase.

2. Obstruction clearance.

3. Safety cables present and properly installed.

4. All fasteners are properly torqued.

RUNNING THE FAN

1. Verify correct direction from the front display by visually

inspecting for the forward or reverse led lit on the

touchpad. See Fig. 24.

2. To change directions press the Reverse/Forward button

and then within 2 seconds press the enter button.

3. Using the up and down arrows select the desired speed

(1-5).

4. Press the green RUN button and the fan will begin

motion.

CHANGING DIRECTION DURING MOTION

1. To change direction while in motion press the Reverse/

Forward button then within 2 seconds press the enter

button.

2. It is not necessary to stop the fan prior to changing

directions.

CHANGING SPEED DURING MOTION

1.

Using the up and down arrows set the desired speed

(1-5).

2. The display will change automatically back to running

speed after 2 seconds.

3. To verify speed change the fan will slowly start to

increase/decrease speed indicated on the display.

STOPPING THE FAN

1. To stop the fan press the red stop button

2. The current speed will start decreasing to 0.0 where

the display will change to STOP

3. The set speed and direction at shutdown remains in

memory and upon a consecutive run signal will resume

last used speed and direction.

FAULT CODES

If a fault code alarm appears, select the Fault Codes

button to display the fault codes,.

To navigate back to the main screen, Select the green

return arrow.

The fault code screen will display the current fault code

number and gives a description of each fault code. If the

fan is currently under fault, the error code being displayed

in the box under the green arrow will be displaying a

number that caused the fault. Match the number with the

error codes and remove the fault condition. Once the

condition has been removed, pressing the reset button will

reset the fan and allow operation again. The Fault History

of the last 4 faults are displayed. Finally, the green arrow in

the upper right corner will navigate back to the diagnostic

screen. See Fig. 24.

Table of contents

Popular Fan manuals by other brands

Bionaire

Bionaire BASF1016G instruction manual

Home Decorators Collection

Home Decorators Collection MERWRY SW1422 Use and care guide

Inverter

Inverter iV14-MaxAir installation instructions

Sapir

Sapir SP-1760-DC6 instruction manual

Alf

Alf ISIV-01 user manual

BLAUBERG Ventilatoren

BLAUBERG Ventilatoren Iso-ZS user manual