Epiroc YT29A Specifications

Secoroc YT29A, T29AE,

YT29AE(T), 7655D

pusher leg rock drills

Operator’s instructions

Spare parts list

2

Table of contents

Introduction �����������������������������������������������������������������3

Safety instructions ������������������������������������������������������3

Scope of application����������������������������������������������������8

Specification���������������������������������������������������������������������������������������� 8

Operation ���������������������������������������������������������������������9

Using the rock drill for the first time ������������������������������������������������� 9

Preparations before starting �������������������������������������������������������������� 9

Fitting and removing the tool ���������������������������������������������������������� 10

Before fitting the working tool��������������������������������������������������������� 10

Fitting the working tool �������������������������������������������������������������������� 10

Removing the working tool�������������������������������������������������������������� 10

Attaching the pusher leg to the rock drill���������������������������������������� 10

Controls ��������������������������������������������������������������������������������������������� 10

Throttle lever������������������������������������������������������������������������������������� 10

Feed control �������������������������������������������������������������������������������������� 10

Trigger ����������������������������������������������������������������������������������������������� 10

Oil regulating valve ���������������������������������������������������������������������������11

Drilling ������������������������������������������������������������������������������������������������11

Starting the rock drill �������������������������������������������������������������������������11

Stopping the rock drill�����������������������������������������������������������������������11

Re-positioning the pusher leg ����������������������������������������������������������11

Blow-cleaning the drill hole��������������������������������������������������������������11

When you have finished drilling ������������������������������������������������������11

Maintenance�������������������������������������������������������������������������������������� 12

Selection of spare parts�������������������������������������������������������������������� 12

Once a shift (after 8 hours of operation)����������������������������������������� 12

Once a week (after 40 hours of operation) ������������������������������������� 12

Once a month (after 200 hours of operation)��������������������������������� 12

Measures to prevent freezing ���������������������������������������������������������� 13

Scrapping and waste disposal��������������������������������������������������������� 13

CE Declaration of Conformity ���������������������������������������������������������� 14

Trouble shooting��������������������������������������������������������15

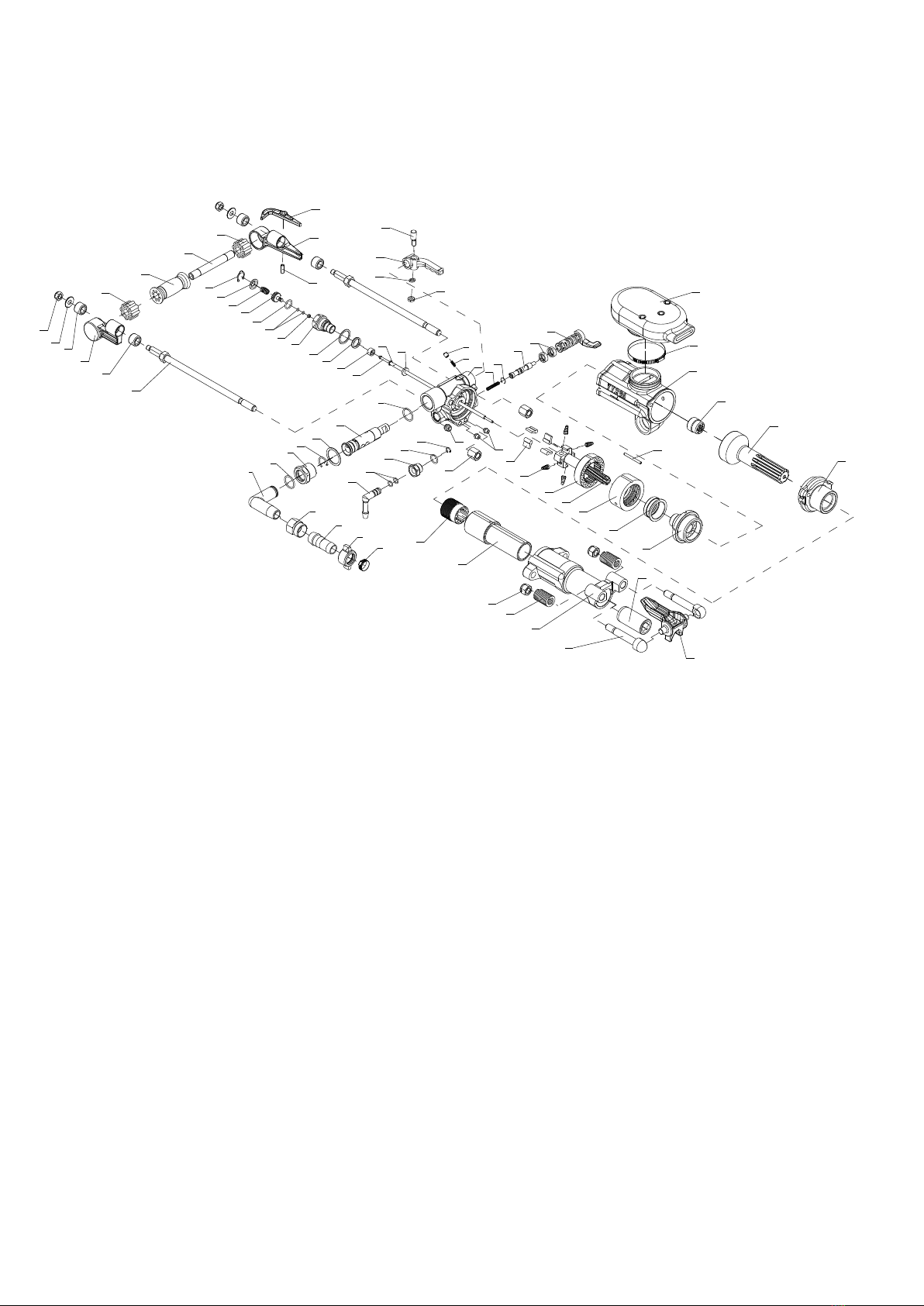

Spare parts list and exploded drawing �������������������16

Foreword

Thank you for selecting the SecorocYT29A,YT29AE,YT29AE(T) or

7655D pusher leg rock drill�

These instructions were developed to help you get the best per-

formance and productivity from the use of your new rock drill�

Please refer to them also for correct maintenance of the machine�

3

Introduction

Thank you for choosing a product from Epiroc� We have a strong

global sales and service network, consisting of customer centers

and distributors worldwide� Our experts are highly trained

professionals with extensive product knowledge and application

experience� In all corners of the world, we can offer product

support and expertise to ensure that our customers can work at

maximum efficiency at all times�

For more information please visit: epiroc�com

Epiroc Drilling Tools AB, Sweden�

About the Safety and operating instructions

The aim of the instructions is to provide you with knowledge

of how to use the rock drill in an efficient, safe way� The

instructions also give you advice and tell you how to perform

regular maintenance on the rock drill� Before using the rock drill

for the first time you must read these instructions carefully and

understand all of them�

Safety instructions

To reduce the risk of serious injury or death to yourself or

others, read and understand the Safety and operating instruction

before installing, operating, repairing, maintaining, or changing

accessories on the machine� Post this Safety and operating

instruction at work locations, provide copies to employees,

and make sure that everyone reads the Safety and operating

instruction before operating or servicing the machine� In

addition, the operator or the operator's employer must assess

the specific risks that may be present as a result of each use of

the machine�

Safety signal words

The safety signal words Danger, Warning and Caution have the

following meanings:

Indicates a hazardous situation which, if not avoided, will

result in death or serious injury�

DANGER

Indicates a hazardous situation which, if not avoided, could

result in death or serious injury�

WARNING

Indicates a hazardous situation which, if not avoided, could result

in minor or moderate injury�

CAUTION

Personal precautions and qualifications

Only qualified and trained persons may operate or maintain

the machine. They must be physically able to handle the

bulk, weight, and power of the tool. Always use your common

sense and good judgement.

Personal protective equipment

Always use approved protective equipment� Operators and all

other persons in the working area must wear protective equip-

ment, including at a minimum:

• Protective helmet

• Hearing protection

• Impact resistant eye protection with side protection

• Respiratory protection when appropriate

• Protective gloves

• Proper protective boots

• Appropriate work overall or similar clothing (not loose-fitting)

that covers your arms and legs�

4

Drugs, alcohol or medication

Drugs, alcohol or medication�

WARNING

Drugs, alcohol or medication may impair your judgment and pow-

ers of concentration� Poor reactions and incorrect assessments

can lead to severe accidents or death�

• Never use the machine when you are tired or under the influ-

ence of drugs, alcohol or medication�

• No person who is under the influence of drugs, alcohol or medi-

cation may operate the machine�

Installation, precaution

Whipping air hose�

DANGER

A compressed air hose that comes loose can lash around and

cause personal injury or death�To reduce this risk:

• Check that the compressed air hose and the connections are not

damaged, replace if necessary�

• Check that all compressed air connections are properly attached�

• Never carry a pneumatic machine by the air hose�

• Never attempt to disconnect a compressed air hose that is pres-

surized� First switch off the compressed air at the compressor and

then bleed the machine by activating the start and stop device�

• Do not use quick disconnect couplings at tool inlet�

Use hardened steel (or material with comparable shock resist-

ance) threaded hose fittings�

• Whenever universal twist couplings (claw couplings) are used,

we recommend that lock pins are installed and whipcheck safety

cables are used to safeguard against possible hose to tool and

hose to hose connection failure�

Ejected insertion tool�

WARNING

If the tool retainer on the machine is not in a locked position, the

inserted tool can be ejected with force, which can cause personal

injury�

• Never start the machine while changing the insertion tool�

• Before changing the insertion tool or accessories, stop the

machine, switch off the power supply and bleed the machine by

activating the start and stop device�

• Never point the inserted tool at yourself or anyone else�

• Make sure that the insertion tool is fully inserted and the tool

retainer is in a locked position before the machine is started�

• Check the locking function by pulling the inserted tool outwards

forcefully�

Moving or slipping insertion tool�

WARNING

An incorrect dimension of the inserted tool’s shank can result in

that the inserted tool is lost or is slipping out during operation�

Risk of severe injury or crushed hands and fingers�

• Check that the insertion tool has the shank length and dimen-

sions that the machine is intended for�

• Never use an insertion tool without a collar�

Operation, precautions

Explosion hazard�

DANGER

If a warm insertion tool comes into contact with explosives, an

explosion could occur� During operation with certain materials as

well as use of certain materials in machine parts, sparks and igni-

tion can occur� Explosions will lead to severe injuries or death�

• Never operate the machine in any explosive environment�

• Never use the machine near flammable materials, fumes or dust�

• Make sure that there are no undetected sources of gas or explo-

sives�

• Never drill in an old hole

Unexpected movements�

WARNING

The inserted tool is exposed to heavy strains when the machine

is used�The inserted tool may break due to fatigue after a certain

amount of use� If the inserted tool breaks or gets stuck, there may

be sudden and unexpected movement that can cause injuries�

Furthermore, losing your balance or slipping may cause injury�

• Make sure that you always keep a stable position with your feet

as far apart as your shoulder width, and keeping a balanced body

weight�

• Always inspect the equipment prior to use� Never use the equip-

ment if you suspect that it is damaged�

• Make sure that the handles are clean and free of grease and oil�

• Keep your feet away from the inserted tool�

• Stand firmly and always hold on to the machine with both

hands�

• Never drill in an old hole�

Unexpected movements�

WARNING

The inserted tool is exposed to heavy strains when the machine

is used�The inserted tool may break due to fatigue after a certain

amount of use� If the inserted tool breaks or gets stuck, there may

5

be sudden and unexpected movement that can cause injuries�

Furthermore, losing your balance or slipping may cause injury�

• Make sure that you always keep a stable position with your feet

as far apart as your shoulder width, and keeping a balanced body

weight�

• Always inspect the equipment prior to use� Never use the equip-

ment if you suspect that it is damaged�

• Make sure that the handles are clean and free of grease and oil�

• Keep your feet away from the inserted tool�

• Stand firmly and always hold on to the machine with both

hands�

• Never drill in an old hole�

• Never start the machine when it is lying on the ground�

• Never ‘ride’ on the machine with one leg over the handle�

• Never strike or abuse the equipment�

• Check regularly for wear on the insertion tool, and check whether

there are any signs of damage or visible cracks�

• Pay attention and look at what you are doing

Stalling hazard�

WARNING

If the insertion tool gets caught during operation, the whole

machine will start to rotate if you lose your grip on it�This unex-

pected rotation of the entire machine may cause serious injury or

death�

• Stand firmly and always hold onto the machine with both hands�

• Make sure that the handle or handles are clean and free from

grease and oil�

• Never drill in an old hole�

Trapping hazard�

WARNING

There is risk of neck ware, hair, gloves and clothes getting

dragged into or caught by a rotating insertion tool or accessories�

This may cause choking, scalping, lacerations or death�To reduce

the risk:

• Never grab or touch a rotating drill steel�

• Avoid wearing clothing, neck ware or gloves that may get

caught�

• Cover long hair with a hair net

Always make sure that the rock drilling tools are in good con-

dition before use�

CAUTION

Dust and fume hazard�

WARNING

Dusts and/or fumes generated or dispersed when using the

machine may cause serious and permanent respiratory disease,

illness, or other bodily injury (for example, silicosis or other irre-

versible lung disease that can be fatal, cancer, birth defects, and/

or skin inflammation)� Some dusts and fumes created by drilling,

breaking, hammering, sawing, grinding and other construction

activities contain substances known to the State of California

and other authorities to cause respiratory disease, cancer, birth

defects, or other reproductive harm� Some examples of such

substances are:

• Crystalline silica, cement, and other masonry products�

• Arsenic and chromium from chemically-treated rubber�

• Lead from lead-based paints�

Dust and fumes in the air can be invisible to the naked eye, so do

not rely on eye sight to determine if there is dust or fumes in the

air�To reduce the risk of exposure to dust and fumes, do all of the

following:

• Perform site-specific risk assessment�The risk assessment

should include dust and fumes created by the use of the machine

and the potential for disturbing existing dust�

• Use proper engineering controls to minimize the amount of

dust and fumes in the air and to minimize build-up on equipment,

surfaces, clothing, and body parts� Examples of controls include:

exhaust ventilation and dust collection systems, water sprays, and

wet drilling� Control dusts and fumes at the source where pos-

sible� Make sure that controls are properly installed, maintained

and correctly used�

• Wear, maintain and correctly use respiratory protection as in-

structed by your employer and as required by occupational health

and safety regulations�The respiratory protection must be effec-

tive for the type of substance at issue (and if applicable, approved

by relevant governmental authority)�

• Work in a well ventilated area�

• If the machine has an exhaust, direct the exhaust so as to reduce

disturbance of dust in a dust filled environment�

• Operate and maintain the machine as recommended in the oper-

ating and safety instructions

• Select, maintain and replace consumables/ inserted tools/ other

accessory as recommended in the operating and safety instruc-

tions� Incorrect selection or lack of maintenance of consumables/

inserted tools/ other accessories may cause an unnecessary

increase in dust or fumes�

• Wear washable or disposable protective clothes at the worksite,

and shower and change into clean clothes before leaving the

worksite to reduce exposure of dust and fumes to yourself, other

persons, cars, homes, and other areas�

• Avoid eating, drinking, and using tobacco products in areas

where there is dust or fumes�

• Wash your hands and face thoroughly as soon as possible upon

leaving the exposure area, and always before eating, drinking, us-

ing tobacco products, or making contact with other persons�

• Comply with all applicable laws and regulations, including oc-

cupational health and safety regulations�

• Participate in air monitoring, medical examination programs,

and health and safety training programs provided by your em-

ployer or trade organizations and in accordance with occupational

health and safety regulations and recommendations� Consult with

physicians experienced with relevant occupational medicine�

6

• Work with your employer and trade organization to reduce dust

and fume exposure at the worksite and to reduce the risks� Effec-

tive health and safety programs, policies and procedures for pro-

tecting workers and others against harmful exposure to dust and

fumes should be established and implemented based on advice

from health and safety experts� Consult with experts�

• Residues of hazardous substances on the machine can be a risk� Be-

fore undertaking any maintenance on the machine clean it thoroughly�

Projectiles�

WARNING

Failure of the work piece, of accessories, or even of the machine

itself may generate high velocity projectiles� During operating,

splinters or other particles from the working material may be-

come projectiles and cause personal injury by striking the opera-

tor or other persons�To reduce these risk:

• Use approved personal protective equipment and safety helmet,

including impact resistant eye protection with side protection�

• Make sure that no unauthorised persons trespass into the work-

ing zone�

• Keep the workplace free from foreign objects�

• Ensure that the work piece is securely fixed�

Splinters hazard�

WARNING

Using the insertion tool as a hand struck tool can result in splin-

ters hitting the operator and can cause personal injury�

• Never use an insertion tool as a hand struck tool� They are spe-

cifically designed and heat-treated to be used only in a machine�

Slipping, tripping and falling hazards�

WARNING

There is a risk of slipping or tripping or falling, for example trip-

ping on the hoses or on other objects� Slipping or tripping or

falling can cause injury�To reduce this risk:

• Always make sure that no hose or other object is in your way or

in any other person’s way�

• Always make sure you are in a stable position with your feet as

far apart as your shoulders width and keeping a balanced body

weight�

Motion hazards�

WARNING

When using the machine to perform work-related activities, you

may experience discomfort in the hands, arms, shoulders, neck,

or other parts of the body�

• Adopt a comfortable posture whilst maintaining secure footing

and avoiding awkward off-balanced postures�

• Changing posture during extended tasks may help avoid dis-

comfort and fatigue�

• In case of persistent or recurring symptoms, consult a qualified

health professional�

Vibration hazards

WARNING

Normal and proper use of the machine exposes the operator to

vibration� Regular and frequent exposure to vibration may cause,

contribute to, or aggravate injury or disorders to the operator’s

fingers, hands, wrists, arms, shoulders and/or nerves and blood

supply or other body parts, including debilitating and/or perma-

nent injuries or disorders that may develop gradually over peri-

ods of weeks, months, or years� Such injuries or disorders may

include damage to the blood circulatory system, damage to the

nervous system, damage to joints, and possibly damage to other

body structures� If numbness, persistent recurring discomfort,

burning sensation, stiffness, throbbing, tingling, pain, clumsiness,

weakened grip, whitening of the skin, or other symptoms occur at

any time, when operating the machine or when not operating the

machine, stop operating the machine, tell your employer and seek

medical attention� Continued use of the machine after the occur-

rence of any such symptom may increase the risk of symptoms

becoming more severe and/or permanent� Operate and maintain

the machine as recommended in these instructions, to prevent

an unnecessary increase in vibration�The following may help to

reduce exposure to vibration for the operator:

• Let the tool do the job� Use a minimum hand grip consistent

with proper control and safe operation�

• If the machine has vibration absorbing handles, keep them in a

central position, avoid pressing the handles into the end stops�

• When the percussion mechanism is activated, the only body

contact with the machine you should have are your hands on the

handle or handles� Avoid any other contact, for example support-

ing any part of the body against the machine or leaning onto the

machine trying to increase the feed force� It is also important not

to keep the start and stop device engaged while extracting the

tool from the broken work surface�

• Make sure that the inserted tool is well-maintained (including

sharpness, if a cutting tool), not worn out, and of the proper size�

Insertion tools that are not well-maintained, or that are worn out,

or that are not of the proper size result in longer time to complete

a task (and a longer period of exposure to vibration) and may

result in or contribute to higher levels of vibration exposure�

• Immediately stop working if the machine suddenly starts to

vibrate strongly� Before resuming the work, find and remove the

cause of the increased vibrations�

• Never grab, hold or touch the inserted tool when using the

machine�

• Participate in health surveillance or monitoring, medical exams

and training programs offered by your employer and when re-

quired by law�

• When working in cold conditions wear warm clothing and keep

hands warm and dry�

•The exhaust air is strongly chilled and shall not make contact

with the operator� Always direct the exhaust air away from hands

and body�

See the ”Noise and vibration declaration statement” for the

machine, including the declared vibration values�This information

can be found at the end of these Safety and operating instruc-

tions�

See the ”Noise and vibration declaration statement” for the

machine, including the declared vibration values�This information

can be found at the end of these Safety and operating instruc-

tions�

7

• Comply with the recommended air-pressure when operating the

machine� Either higher or lower air-pressure has the potential of

resulting in higher levels of vibration�

Electrical hazard�

DANGER

The machine is not electrically insulated� If the machine comes

into contact with electricity, serious injuries or death may result�

• Never operate the machine near any electric wire or other source

of electricity�

• Make sure that there are no concealed wires or other sources of

electricity in the working area�

Concealed object hazard�

WARNING

During operating, concealed wires and pipes constitute a danger

that can result in serious injury�

• Check the composition of the material before operating�

• Watch out for concealed cables and pipes for example electricity,

telephone, water, gas and sewage lines etc�

• If the inserted tool seems to have hit a concealed object, switch

off the machine immediately�

• Make sure that there is no danger before continuing�

Involuntary start�

WARNING

Involuntary start of the machine may cause injury�

• Keep your hands away from the start and stop device until you

are ready to start the machine�

• Learn how the machine is switched off in the event of an emer-

gency�

• Release the start and stop device immediately in all cases of

power supply interruption�

• Whenever fitting or removing the insertion tool, switch off the air

supply, bleed the machine by pressing the start and stop device

and disconnect the machine from the power source�

Noise hazard�

WARNING

High noise levels can cause permanent and disabling hearing loss

and other problems such as tinnitus (ringing, buzzing, whistling,

or humming in the ears)�To reduce risks and prevent an unneces-

sary increase in noise levels:

• Risk assessment of these hazards and implementation of appro-

priate controls is essential�

• Operate and maintain the machine as recommended in these

instructions�

• Select, maintain and replace the working tool as recommended

in these instructions�

• If the machine has a silencer, check that it is in place and in good

working condition�

• Always use hearing protection�

• Use damping material to prevent work pieces from ‘ringing’�

Maintenance, precautions

Machine modification�

WARNING

Any machine modification may result in bodily injuries to yourself

or others�

• Never modify the machine� Modified machines are not covered

by warranty or product liability�

• Always use original parts, working tools and accessories ap-

proved by Epiroc�

• Change damaged parts immediately�

• Replace worn components in good time�

Hot insertion tool�

CAUTION

The tip of the insertion tool can become hot and sharp when

used�Touching it can lead to burns and cuts�

• Never touch a hot or sharp insertion tool�

• Wait until the insertion tool has cooled down before carrying out

maintenance work�

Working tool hazards�

WARNING

Accidental engagement of the start and stop device during main-

tenance or installation can cause serious injuries, when the power

source is connected�

• Never inspect, clean, install, or remove the working tool while

the power source is connected�

Storage, precautions

• Keep the machine and tools in a safe place, out of the reach of

children and locked up�

The machine should not be used in environment where there

is a risk of explosions� Local regulations must be followed�The

machine is not certificated according to ATEX requirements�

CAUTION

8

Scope of

application

SecorocYT29A,YT29AE,YT29AE(T)and 7655D is a heavy-duty

pusher leg Rock Drill featuring high efficiency and low air con-

sumption� It is primarily designed for drilling in mines, hydro-

power stations, and road construction projects� It is also a new

product suitable for tunneling and other stone works in mining

and metallurgical industry�

SecorocYT29A is suitable for both horizontal and upward anchor

holes in medium-hard and hard rocks (100–350 MPa)�The hole

diameter range is from 32 mm to 45 mm with depths up to 5

meters�The Rock Drill is equipped with lubricator FY250� Secoroc

YT29A is intended to be used together with pusher leg FT160A,

FT160B, FT160C for different tunneling and work conditions� It is

also designed for dry drilling or wet drilling mounted on rigs�

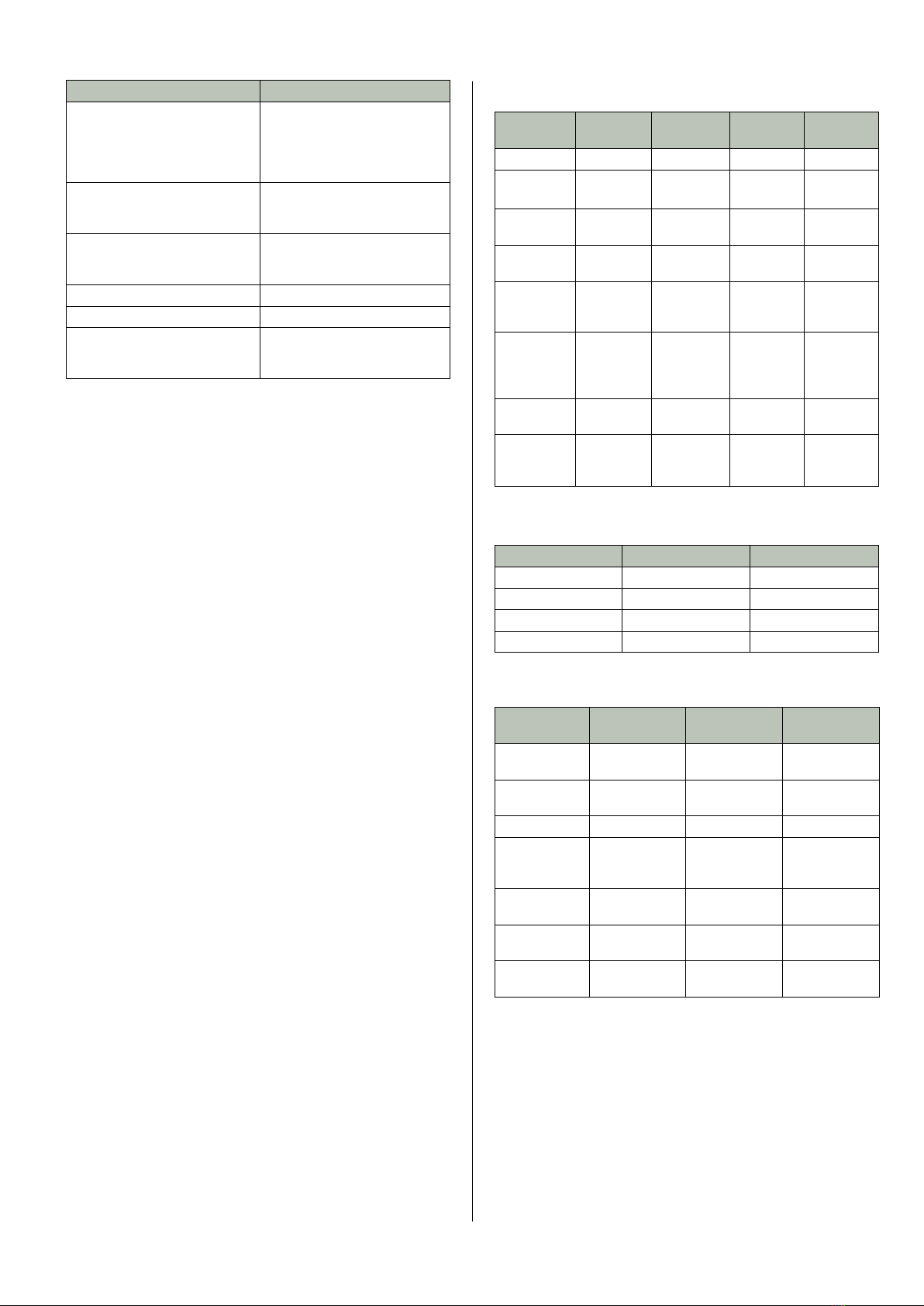

Specification

Pneumatic

rock drill

YT29A,

YT29AE

YT29AE

(T)

7655D

Weight 27 32 24 Kg

Dimension

(L x W xH) 659x248x205 807x450x255 668x232x202 mm

Cylinder

Diameter 82 82 70 mm

Piston

Stroke 60 60 70 mm

Working

Pressure 4-6,3 4-6,3 4-6,3 Bar

Impact

Energy (at

5 bar (e))

≥70 ≥70 ≥57 J

Air

Consump-

tion (at 5

bar (e))

≤65 ≤65 ≤52 l/s

Impact

Frequency

(at 5 bar (e))

≥37 ≥37 ≥31 Hz

Water

Pressure

Working

Pressure -1

Working

Pressure -1

Working

Pressure -1 Bar

Air Hose

Inner

Diameter

25 25 19 mm

Water

Hose Inner

Diameter

13 13 13 mm

Drilling

Diameter 32-45 32-45 34-42 mm

Max

Drilling

Depth

5 5 5 m

Working

Temp-

erature

-30 to + 45 -30 to + 45 -30 to + 50 ºC

Shank

Size H22/25x108 H22/25x108 H22x108 mm

Lubricator

FY250

Lubricator

FY250

Lubricator

FY200

Weight 1�2 1�2 1,2 Kg

Capacity 0�25 0�25 0,2 litre

Safety instructions

To reduce the risk of serious injury or death to yourself or others,

carefully read through this instruction booklet before putting

the rock drill to use� Always follow the instructions given in this

manual�

• Always wear a safety helmet, goggles and ear protectors during

drilling� Any local regulations that exist must also be observed�

• When drilling in certain minerals, there is a risk of spark genera-

tion� Before starting work, check that the machine is approved (in

accordance with local regulations) for work under such condi-

tions�

• Always take great care when using the machine�The working

tool is subjected to heavy loading and can break, with a risk of

injury to personnel�

• Check that the hoses used are of the right quality, and that all

hose connections are in good condition and properly tightened�

• Before starting work on any of the systems, make sure that the

air and water systems are without pressure�

• Make sure that there are no concealed wires or other sources of

electricity� Never drill near any electric wires or other sources of

electricity�

• Always make sure that main valve on the main hose is switched

off when the rock drill is not in use� This is needed to avoid the risk

of unintentional start of the machine�

• During drilling, stand firmly and always hold the machine with

both hands� Do not hang or lean over the machine during opera-

tion, as there is a risk of injuries due to falling� Always use PPE

(Personal Protective Equipment) when operating the rock drill�

Overview

To reduce the risk of serious injury or death to yourself or others,

read the Safety instructions section found on the previous pages

of this manual before operating the machine�

Labels

The machine is fitted with labels containing important information

about personal safety and machine maintenance�The labels must

be in such condition that they are easy to read� New labels can be

ordered from the spare parts list�

Data plate

A� Machine type

B� Maximum permitted compressed air pressure

C� Serial number

D�The warning symbol together with the book symbol means that

the user must read the safety and operating instructions before

the machine is used for the first time�

E�The CE symbol means that the machine is EC-approved� See the

EC declaration which is delivered with the machine for more infor-

mation� If the CE symbol is missing, it means that the machine is

not EC-approved�

9

Lubricant recommendation

Use a mineral-based air tool oil

Ambient temperature ºC Viscosity grade (ISO 3448)

-30 to 0 ISO VG 32-68

-10 to +20 ISO VG 68-100

+10 to +50 ISO VG 100-150

4� Air/water pressure and hose dimensions

Air pressure

Ensure that the compressor can deliver the required air pressure

of 5 bar at the machine�

• High pressure (>6�3 bar) causes rough operation and damage�

• Low pressure (<4 bar) results in a slow drilling speed�

Water pressure

Make sure that the water pressure is set to around 3 bar�

Note! Maximum water pressure is 1 bar less than the working

pressure� For example if the air pressure is 5 bar, the water pres-

sure must be below 4 bar to prevent water entering the impact

mechanism�

Note! Dry drilling is strictly prohibited� Operation without air- and

water tubes is not allowed as it will result in poor drilling perfor-

mance�

Hose dimensions

The air hose diameter must be no less than 25mm� Inner diameter

of connection nipple and hose must be no less than 19mm�The

ideal overall air hose length is less than 15m�

Drill steel

Ejected insertion tool�

WARNING

If the tool retainer on the machine is not in a locked position, the

inserted tool can be ejected with force, which can cause personal

injury�

• Before changing the insertion tool, stop the machine, switch off

the compressed air supply and bleed the machine by activating

the start and stop device�

Before fitting the insertion tool

Check that the tool shank is of the correct size and length for the

chuck used�The shank must be clean and the tool must be in good

condition� Shanks which are chipped, rounded, out of square or

too hard on the striking end will operate inefficiently and cause

premature piston failure� Inspect the drill steel:

A dull drill steel will slow down the drilling speed and overstrain

the drill mechanism� When changing drill steel make sure that

the new one is the correct size to follow your previous bore�

Before drilling, check that the flushing hole in the drill steel is not

blocked�

Safety label

A

B

C

DE

To avoid injury, before using or servicing tool, read and under-

stand separately provided safety instructions�

Operation

Using the rock drill for the first time

When the rock drill arrives from the factory, the inside of the tool

is coated with heavy oil to prevent corrosion�

After unpacking and installing the tool, pour a small amount of lu-

brication oil into the air connection and operate the tool on partial

throttle to clean the interior� Follow this immediately with a liberal

amount of air tool oil�

The rock drill and pusher leg are lubricated with oil mixed with

compressed air, which is taken to the parts that need continu-

ous lubrication� Oil is metered into the compressed air using the

FY250 lubricator connected to the air line�

Preparations before starting

1� Check the drilling equipment

• Check that all of the drilling equipment is in good working order�

• Check that the impact surface of the drill steel shank is flat with

no signs of wear�

• Make sure that the air inlet and exhaust ports are free from

obstructions�

• Check that the flushing holes in the drill steel and drill bit are

not blocked and that the flushing air/water flows through without

obstruction�

• Ensure that the fittings are tight and leak-proof�

Always check for damaged or loose hoses and fittings before

operation�Whipping hoses can cause serious injury�

WARNING

2� Blow out the air hose

Every day before using the drill, blow out the air hose to clear it

from accumulated dirt and moisture�

3� Fill the lubricator with oil

• Fill the lubricator (located on top of the cylinder) with oil if nec-

essary�The rock drill is lubricated with oil mixed with compressed

air, which is taken to the parts that need continuous lubrication�

Oil is metered into the compressed air�

• Use Atlas Copco Rock Drill AIR-OIL as a lubricant�

10

Hot insertion tool�

CAUTION

The tip of the insertion tool can become hot and sharp when

used�Touching it can lead to burns and cuts�

• Never touch a hot or sharp insertion tool�

• Wait until the insertion tool has cooled down before carrying out

maintenance work�

Note: Never cool a hot insertion tool in water, it can result in brit-

tleness and early failure�

Fitting the drill steel

Whenever fitting the drill steel the following instructions must be

observed:

Fitting and removing the tool

Before fitting the working tool

• Check that the tool shank is of the correct size and length for the

chuck used�

•The shank must be clean and the tool must be in good condition�

•The suitable quenching hardness of the shank is HRC48-53�

Harder end face will cause piston damaged and breakage of the

end face of the piston� If the shank face is too soft, it will be easily

deformed by the piston, which will result in difficulty in removing

the working tool�

• Shank end face shall be flat and perpendicular to the axis�

• Remove sharp edges from the shank's end face� Rough shank

surface will cause premature piston failure�

• Inspect the bits: Dull bits will slow down the drilling speed and

overstrain the drill mechanism� When changing bits make sure

that the new bit is the correct size to follow your previous bore�

• Before drilling check that the flushing hole in the working tool is

not blocked�

Fitting the working tool

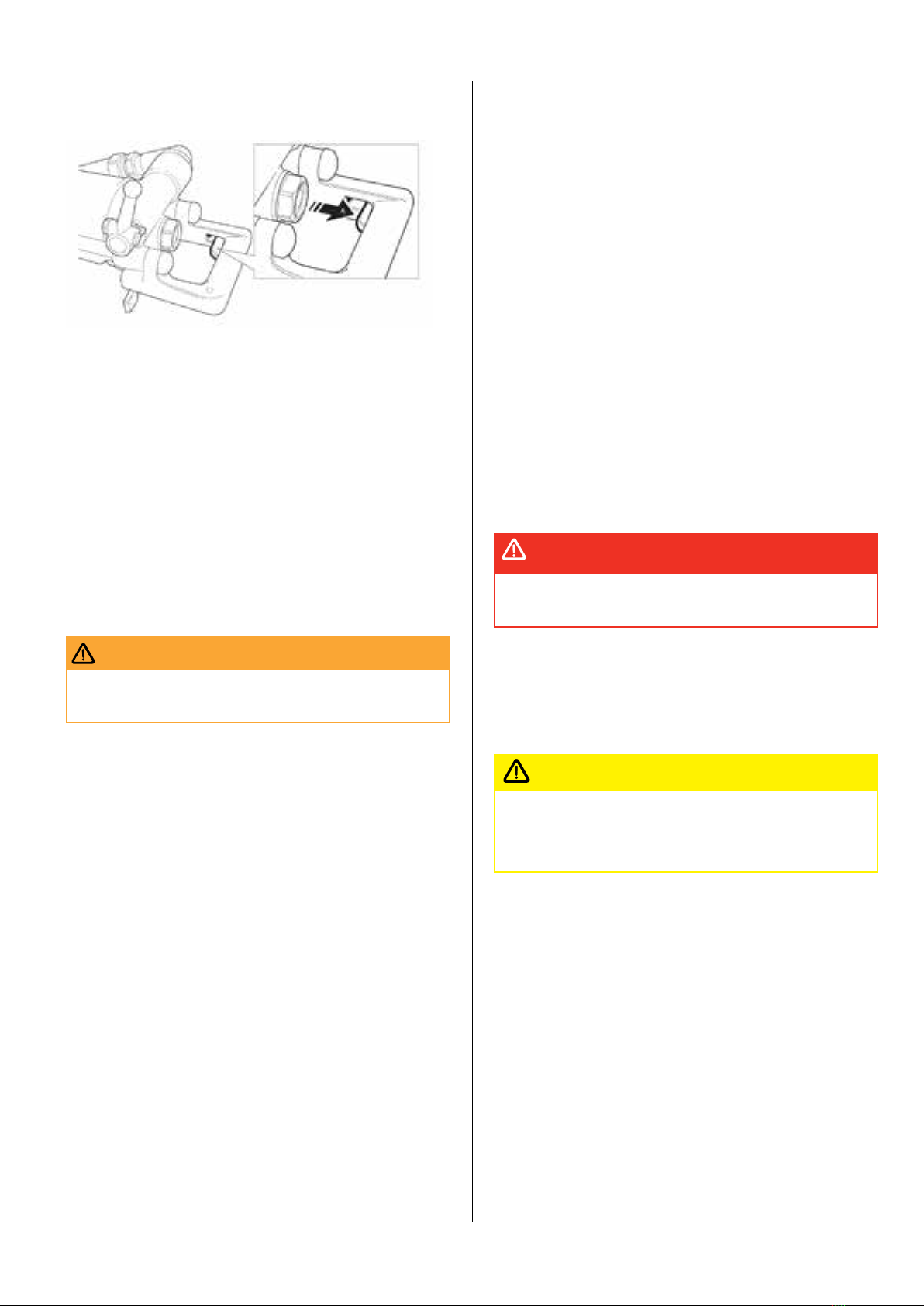

1� Push the retainer outwards in the direction of the arrow (see

picture below), until the front portion of the retainer is able to ac-

commodate the working tool collar�

2� Insert the drill in the chuck�

3� When the drill bottoms, push back the retainer to lock it�

Removing the working tool

1� Push the retainer outwards in the direction of the arrow until the

working tool collar disengages from the front of the retainer�

2� Pull the working tool out�

3� Push back the retainer�

Attaching the pusher leg to the rock drill

• Mount the pusher leg (1), lock sleeve (2), rubber pad (3), washer

(4) and locking nut (5) in the order shown in the picture below�

•Turn the locking nut clockwise with a wrench until you hear a

"click"�

Controls

Throttle lever

The rock drill is equipped with a throttle lever for regulating both

the compressed air to the percussion mechanism and the flushing

water�

A� Extra blowing, water flushing off, impact and rotation off�

B� Stop position, air and water off

C� Low throttle, air to pusher leg, water flushing

D� Medium throttle

E� Full throttle

Feed control

Adjust the feed force by means of the feed control lever as fol-

lows:

A� Extra blowing, water flushing off, impact and rotation off�

B� Stop position, air and water off

Trigger

When the trigger (A) is pushed in, the feed force stops abruptly

and the setting on the feed control lever is overridden�The piston

rod in the pusher leg retracts automatically�This function is used

for example to adjust the height of the rock drill, when rigging up

11

the pusher leg, or when there is a tendency to jam� When the trig-

ger is released, the feed control setting is activated again�

Oil regulating valve

Oil dosing is controlled by means of a screwdriver�

Check that sufficient lubrication is obtained by putting your hand

in front of the exhaust port while adjusting the regulating valve�

If the hand is covered by a thin film of oil after a few seconds, the

lubricator has been correctly adjusted�

The amount of oil going into the rock drill increases when turning

the valve counter clockwise, and it decreases when turning the

valve clockwise� Oil consumption is 2�5–6 ml/minute�

Note!Tighten the nut after regulation�

Note!To much oil will have negative effects on the operation

whilst to little will result in damage to parts as the temperature

rises during operation�

Operation

Involuntary start�

WARNING

Involuntary start of the machine may cause injury�

• Keep your hands away from the start and stop device until you

are ready to start the machine�

• Learn how the machine is switched off in the event of an emer-

gency�

• Stop the machine immediately in all cases of power supply

interruption�

Drilling

Starting the rock drill

1� Open the main valve for compressed air�

2� Open the cock for the flushing water�

3� Adjust the feed control lever to give a suitable feed force for

collaring the hole�

4� Align the rock drill so that the working tool touches the desired

collaring point�

5� Move the throttle lever forward a little, which will start water

flushing, percussion and rotation�

6� Collar the hole with reduced feed force�

7� Move the throttle lever fully forward once the working tool has

gained a secure footing in the rock�

Adjust the feed force by means of the control lever so that the 8�

maximum penetration rate is obtained�

The start-and-stop device of Pusher Leg Rock Drill YT29A can

cause a risk of an unimtentional start�To reduce and avoid causing

the risk of unintentional start, the control valve og inlet hose must

be switched off while the rock drill is put aside for long time�

Note! Do not bend the working tool as this will increase wear of

the shank bushing and piston� Furthermore, it can also affect drill-

ing efficiency and increase the risk of working tool breakage�

Stopping the rock drill

Pull the throttle lever backwards, which will stop percussion, rota-

tion and flushing water�

Re-positioning the pusher leg

1� Switch off the rock-drill percussion and flushing by means of

the throttle lever�

2� Press the trigger, whereupon the piston rod is pulled back into

the pusher-leg cylinder automatically�

3� Re-position the pusher leg�

4� Release the trigger, whereupon the piston rod will move out-

wards again�

5� Move the throttle lever forward into the working position�

Note!The feed control lever does not need to be touched through-

out this operation�

Blow-cleaning the drill hole

Whipping air hose�

DANGER

A compressed air hose that comes loose can lasharound and

cause personal injury or death

• Check that the compressed air hose and the connections are not

damaged�

• Check that all compressed air connections are properly attached�

Move to the side and cover your eyes before starting to blow-

clean the drill hole� When blow-cleaning, particles and dirty

flushing water can emerge at speed from the drill hole��

CAUTION

• Always wear impact resistant eye protection with side protection

to avoid injury�

• Make sure that no co-workers are in range when blow-cleaning�

If powerful blow-cleaning of the drill hole is required, turn the

throttle lever fully backwards beyond the stop position for extra

blowing, whereupon the rock drill stops�This can be done during

drilling� When the drill hole is clean, turn the throttle lever for-

wards again to re-start the rock drill�

When you have finished drilling

Run the rock drill at medium speed when retracting the working

tool from the drilled hole�

Lay down the rock drill on a stone, wooden plank or similar ob-

ject, so as to prevent drill cuttings and other foreign matter from

entering the chuck�

Turn off the water pressure before the air pressure� Run the rock

drill for a few seconds to clean out water and moisture after the

water has been shut off�

12

Always switch off the main control valve on the air inlet hose to

prevent unintentional start of the rock drill�

Maintenance

Regular maintenance is a prerequisite for machine safety� Replace

damaged and worn components in good time� For a major service

to the machine, contact your nearest authorized workshop�

Check the machine and tools for wear and damage at regular

intervals� Do not use very worn or damaged tools�

When cleaning mechanical parts with a solvent, make sure that

you comply with current health and safety regulations and ensure

that there is sufficient ventilation�

Daily maintenance, regular checking of wearing parts and carrying

out repairs in good time prevents breakdowns and increases the

service life of the machine�

• Always oil the rock drill and pusher leg well, before you put

them into storage�

• Store in a clean and dry place�

• Make sure that no foreign matter enters the machine�

• Protect the chuck using a wooden plug or a clean piece of cotton

waste�

• Always hose down and wipe clean the rock drill and pusher leg

after use�

• In the case of long-term storage, pour a quantity of oil directly

into the rock-drill's air intake and then turn on the air briefly�This

will protect the machine from corrosion�

Once a shift (after 8 hours of operation)

• Check the wear in the chuck bushing� If the wear limit has been

exceeded, the working tool shank will wear more quickly, or

become deformed�This will lead to stoppages and increased

working tool consumption�

• Check the tightness of the side-bolt nuts�

•The tightening torque shall be 150 Nm�

• Check the rock drill's connection to the pusher leg�

• Check the hoses, couplings and controls for leakage and dam-

age�

• Check that the rock drill and pusher leg are receiving enough

lubrication� Fill the lubricator as necessary�

• Drain the water separator�

• Check the air and water pressure� Make sure that the water pres-

sure is at least 1 bar lower than the air pressure�

Once a week (after 40 hours of operation)

Carry out a basic check of all functions of the drilling equipment�

Once a month (after 200 hours of operation)

• Send the rock drill to a workshop for inspection� The local operat-

ing conditions will determine whether or not this is a suitable

interval for overhauling the drill�

• Dismantle and clean the lubricator�

• Clean out the water separator�

Differences between original parts and

pattern parts

When buying a part, the first thing to do is to verify that the part is

an Atlas Copco part� Most parts can be identified�

Every day

Before undertaking any maintenance or changing the insertion

tool on pneumatic machines, always switch off the air supply and

bleed the machine by depressing the start and stop device then

disconnect the air hose from the machine�

• Clean and inspect the machine and its functions each day before

the work commences�

• Conduct a general inspection for leaks and damage�

• Check that the air inlet nipple is tightened and that the claw

coupling is free from damage�

• Check the function of the throttle handle� Make sure that it

moves freely up and down�

• Check the function of the retainer� Make sure that it locks the drill

steel�

• Change damaged parts immediately�

• Replace worn components in good time�

• Check the through bolts of the machine� Make sure that they are

tightened�

• If the machine is equipped with a silencer, check for damage�

Checking for wear

1� Check the wear in the chuck

bushing using the Atlas Copco

gauge 90002668 (22 mm),

90002669 (25 mm)� If the wear

limit has been exceeded, the drill

steel shank will wear more quickly,

or become deformed�This will

lead to stoppages and increased

drill-steel consumption�

2� Check the tightness of the side-

bolt nuts (A)�Tighten to a torque

of 80 Nm�

3� Check the rock drill's connection

to the pusher leg�

4� Check the hoses, couplings and controls for leakage and dam-

age�

5� Check that the rock drill and pusher leg are receiving enough

lubrication� Fill the lubricator if necessary�

6� Check the air and water pressure� Make sure that the water

pressure is at least 1 bar lower than the air pressure�

Periodic maintenance

After each operating period of approximately 100 working hours

or three times a year the machine must be dismantled and all

parts be cleaned and checked�This work must be performed by

authorized staff, trained for this task�

Selection of spare parts

This machine is a heavy-duty rock drill; there are strict require-

ments on selecting spare parts� Use only genuine parts for

replacement, to ensure stable performance� Do not use pattern

parts, which not only have a short working life but also cause con-

sequential damage to other parts, due to differing measurements

and methods of manufacturing�

Damage patterns

Worn or broken parts must always be studied carefully before

they are replaced�They can give important information about the

condition of the drill and about the way it is used and maintained�

13

Problem Cause

Steel parts are a bluish colour The parts have been

subjected to excessive

heat� This can be caused by

insufficient lubrication or

idling

Steel parts have small almost

microscopic fissures on the

wear surfaces

See above

Irregular cavities on the

surface See above of bronze

parts

See above

Cutting marks Secondary damage

Dirt inside the drill

Interior misalignment due to

uneven tension of the side

bolts

Measures to prevent freezing

In low ambient temperatures, ice can form in the machine�This

can be avoided if the water in the compressed air is removed�This

can be done by equipping the air lines with water separators and

drainage points for water condensate�

If the rock drill ices up, it must not be heated to melt the ice� Let

the ice thaw at room temperature�

Note! Do not pour methylated spirits or similar substances into

the rock drill, as they will interfere with the lubrication and lead to

increased wear�

Scrapping and waste disposal

Used and worn-out machines must be disposed of in such a way

that as much of the material as possible can be recycled and the

impact on the environment is kept to a minimum�

Noise and vibration declaration statement

Noise level is meassured according to ISO15744:2002� Vibration

in handle is meassured according to ISO28927-10:2011� See table

"Noise and vibration data" for the value�These declared values

were obtained by laboratory type testing in accordance with the

stated directive or standards and are suitable for comparison with

the declared values of other tools tested in accordance with the

same directive or standards�These declared values are not suit-

able for use in risk assessments and values measured in individu-

al work places may be higher�The actual exposure values and risk

of harm experienced by an individual user are unique and depend

upon the way the user works, in what material the machine is

used, as well as upon the exposure time and the physical condi-

tion of the user, and the condition of the machine� We, Epiroc

DrillingTools AB, cannot be held liable for the consequences of

using the declared values, instead of values reflecting the actual

exposure, in an individual risk assessment in a work place situa-

tion over which we have no control�This tool may cause hand-arm

vibration syndrome if its use is not adequately managed� An EU

guide to managing hand-arm vibration can be found at http://

www�humanvibration�com/humanvibration/EU/VIBGUIDE�html

We recommend a programme of health surveillance to detect

early symptoms which may relate to vibration exposure, so that

management procedures can be modified to help prevent future

impairment�

Technical data

Parameter/

Model YT29A YT29AE YT29AE

(T) 7655D

Product nr 96000010 96000896 96001048 96000004

Product

code

9605-0-

3312300312

9605-0-

3312300340

9605-0-

3312300342

9601-0-

3312300301

Weight

(Kg) 27 27 32 24

Shank size

(mm)

Hex

22 / 25

Hex

22 / 25

Hex

22 / 25

Hex

22

Piston

stroke

(mm)

60 60 60 70

Impact

frequency

(Hz) at 5

bar

≥37 ≥37 ≥37 ≥31

Impact

energy (J) ≥70 ≥70 ≥70 ≥57

Air con-

sumption

(l/s)

≤65 ≤65 ≤65 ≤52

Noise and vibration data

Machine Noise Vibration

YT 29 A 107 dB(A) 7,3 m/s2

YT 29 AE 104 dB(A) 6,6 m/s2

YT29AE(T) 104 dB(A) 6�6m/s2

7655 D 107 dB(A) 5,7 m/s2

Pusher Legs

Parameter\

Model FT160A FT160B FT160C

Product

Number 96000038 96000039 96000040

Product Code 9616-0-

3312300608

9617-0-

3312300609

9619-0-

3312300610

Weight kg 17 16 18

Length

retracted

mm

1688 1488 1820

Length

extracted mm 3026 2586 3310

Feed length

mm 1338 1098 1490

Piston bore

mm 65 65 65

14

Pusher Legs

Parameter\

Model 215PL 215PLA 215PLB

Product

Number 96000991 96001037 96001038

Product Code 9620-0-

3312300630

9620-0-

3312300636

9620-0-

3312300637

Weight kg 18 20 17

Length

retracted

mm

1570 1910 1100

Length

extracted

mm

2570 3210 1700

Feed length

mm 1000 1300 600

Piston bore

mm 62 62 62

EC Declaration of Conformity

(EC Directive 2006/42/EC)

We, Epiroc DrillingTools AB,hereby declare that the machines

listed below conform to the provisions of EC Directive 2006/42/EC

(MachineryDirective), and the harmonised standards mentioned

below�

Rock Drills Part number Pmax (bar)

YT29A 96000010 6�3

YT29AE 96000896 6�3

7655D 96000004 6�3

YT29AE(T) 96001048 6,3

Following harmonised standards were applied:

• EN ISO 11148-5

Technical Documentation authorised representative:

Thomas Greijer,

Epiroc DrillingTools AB,

Box 521,

SE-737 25 Fagersta, Sweden

Vice president Design and Development:

Jonas Falkestrom,

Epiroc DrillingTools AB,

Box 521,

SE-737 25 Fagersta, Sweden

15

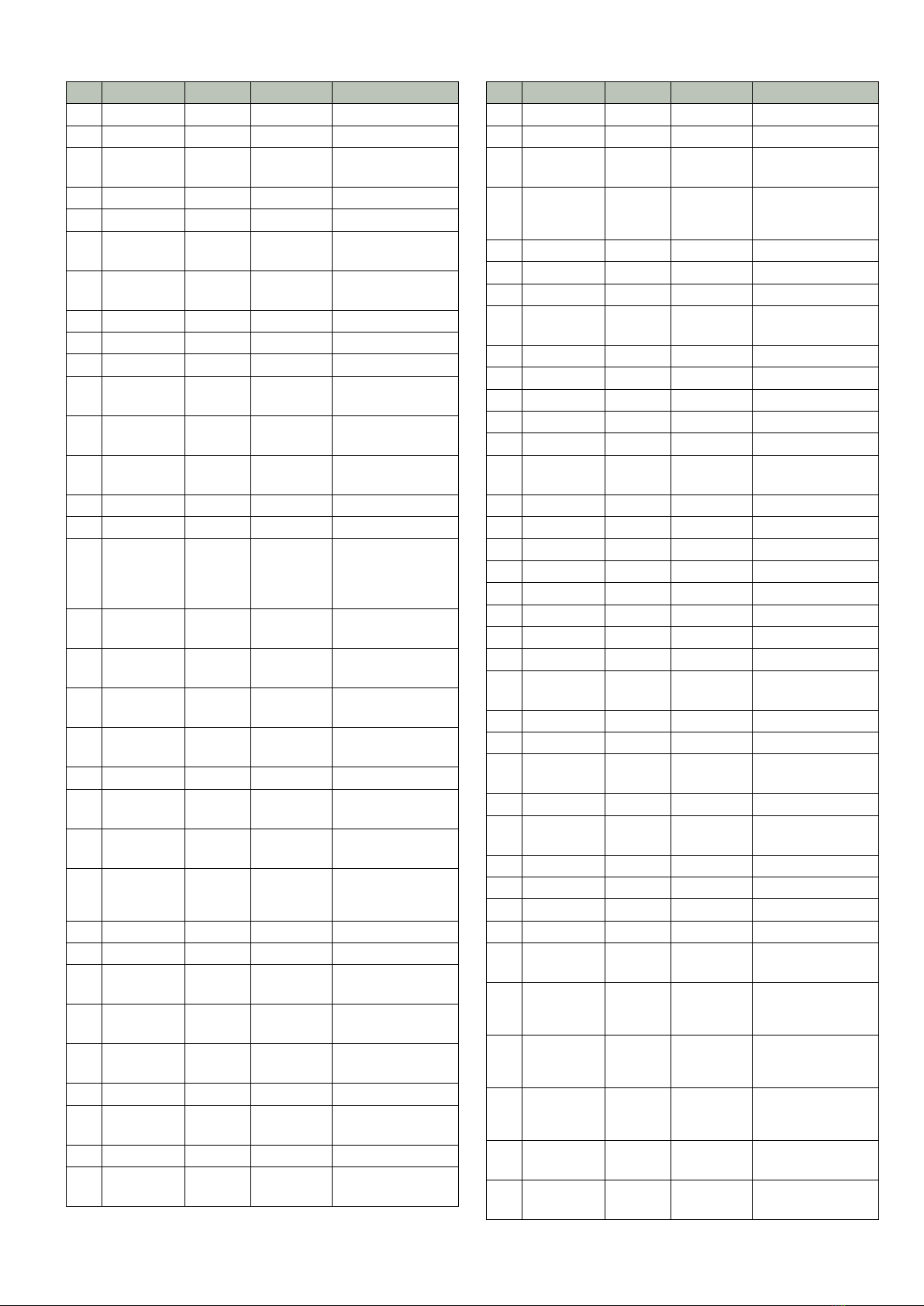

Trouble shooting

Problem Cause Solution

Decreased

penetration rate

Air leakage in hoses, couplings Change packings, and where required, change parts in

the throttle valve�

Shank sleeve Check the shank sleeve for excessive wear� Replace if

necessary�

Air leakage due to worn piston/cylinder Replace the piston and/or cylinder

Air leakage due to worn guide sleeve/pilot guide Change the worn part

Insufficient feed

force

Piston rod seal (in pusher leg) worn or deformed Change the seal

O-rings on pusher leg coupling worn or deformed Change the o-rings

Poor rotation Splines of the rifle nut worn Replace the rifle nut if the splines are worn

Splines of the rifle bar worn down Replace the rifle bar when needed

Splines on the piston worn down Replace the piston when needed

The toothing in the ratchet housing is worn out Replace the ratchet housing if the tooth housing is so

worn that the pawls have difficulty catching

The toothing in the ratchet wheel is worn out Replace the ratchet wheel if the toothing is so worn that

the pawls have difficulty catching

Chuck nut worn out Replace the chuck nut if the splines have been worn to

1/2 of the spline width

Pawls worn Replace all pawls, all pawl springs and all pawl pins�

Uneven running Piston has seized in the guide sleeve or the piston guide Replace the guide sleeve/piston guide� If required,

polish the piston� Check the piston for heat damage

such as blue colouring and/or fissures� If it is damaged

in this way, replace the piston as well�

Dirty or damaged main valve� Caused by impurities or

foreign matter entering the drill with the compressed air

Clean and polish the valve so that it seals against the

corresponding cylindrical and plane sealing surfaces� If

this is not possible because the defects are too serious,

the valve must be replaced�

Freezing� Caused by leakage in the flushing system or

by excess water in the compressed air or by excessive

water pressure

Check the flushing tubes and seals and the water

pressure� Drain water from the compressed air system�

If the problem continues, fit a water separator in the

airline system�

Uneven running

(continued)

The side bolts are unevenly or insufficiently tightened�

Can cause the various parts to lose their alignment,

resulting in the seizure of the movable parts� Abnormal

strains on the side bolt may result in fracture at the

threads

Check and repair any damage to the contact points and

tighten the bolts with the correct tightening torque

The drill gets hot Lack of oil Add oil and check that it runs through� It is not sufficient

that there is oil in the exhaust air� There must also be an

oil coating on the shank of the working tool�

Freezing High level of humidity in the compressed air Use water traps

Water pressure higher than the air pressure Lower the water pressure

Water pipe

breakage

Misalignment of the shank Change working tool or shank sleeve or both

Damaged flushing hole in the shank Change working tool

Chipping of the

piston tip

Misalignment of the shank Change the working tool or shank sleeve or both

Excessive wear of the piston tip Change piston

Spline breakage

Lack of lubrication Lower the water pressure if it is the same as or greater

than the air pressure

Increase lubrication or change oil

Dirt intrusion (specially when drilling upwards) Increase service intervals

Piston breakage

Lack of lubrication Lower the water pressure if it is the same as or greater

than the air pressure

Increase lubrication or change oil

Uneven tension in the side bolts Tighten the bolts correctly

Worn guide sleeve/piston guide (can be confirmed by

the cushion test)

Change the worn part

Side bolt breakage Uneven tension on the bolts Tighten the bolts correctly

16

Spare parts list and exploded drawing YT29A

17

No� Description Quantity Product no� Product code

1 Spring 1 96000179 9605-1-3312310169

2 Pin 1 96000180 9605-1-3312310170

3Conical pipe

connector 1 96000186 9605-1-3312310176

4 Hoop 1 96000540 9605-1-3312310723

5 Wing nut 1 96000185 9605-1-3312310175

6Pipe

connector 1 96000187 9605-1-3312310177

7Air pipe

swivel 1 96000825 9600-1-3312310022

8 Air pipe nut 1 96000823 9600-1-3312310020

9 O-ring 2 96000486 9605-1-3312310633

10 Pad 1 96000174 9605-1-3312310164

11 Retaining

ring 1 96000182 9605-1-3312310172

12 Water pipe

connector 1 96000154 9603-1-3312310143

13 Water pipe

nut 1 96000155 9603-1-3312310144

14 O-ring 2 96000482 9605-1-3312310627

15 O-ring 2 96000499 9605-1-3312310667

16

Water pipe

connector

retaining

ring

1 96000156 9603-1-3312310145

17 Control

valve 1 96000646 9605-1-3312311868

18 Control

handle 1 96000152 9603-1-3312310141

19 Standard

spring pad 1 96000534 9605-1-3312310716

20 Hex� thin

nut 1 96000524 9605-1-3312310704

21 Fixing pin 1 96000177 9605-1-3312310167

22 Change

valve 1 96000161 9603-1-3312310150

23 Retaining

ring 1 96000160 9603-1-3312310149

24

Pressure

regulating

valve

1 96000119 9602-1-3312310101

25 Expansion 2 96000118 9602-1-3312310099

26 Spring 1 96000157 9603-1-3312310146

27 Conical

spring 4 96000167 9605-1-3312310156

28 Ratchet

pawl 4 96000166 9605-1-3312310155

29 Large seal

sleeve 1 96000544 9605-1-3312310727

30 Seal sleeve 2 96000543 9605-1-3312310726

31 Right

handle 1 96000163 9603-1-3312310152

32 Left handle 1 96000165 9603-1-3312310154

33 Shockproof

handle 1 96000164 9603-1-3312310153

No� Description Quantity Product no� Product code

34 Trigger 1 96000162 9603-1-3312310151

35 Elastic pin 1 96000527 9605-1-3312310708

36 Spring

cover 1 96000169 9605-1-3312310159

37

Steel

retaining

ring

1 96000183 9605-1-3312310173

38 Spring 1 96000170 9605-1-3312310160

39 Rotation nut 1 96000146 9603-1-3312310135

40 Pad 1 96000184 9605-1-3312310174

41 Water valve

body 1 96000171 9605-1-3312310161

42 Water valve 1 96000173 9605-1-3312310163

43 O-ring 2 96000489 9605-1-3312310642

44 Seal 1 96000181 9605-1-3312310171

45 Rubber pad 1 96000175 9605-1-3312310165

46 Back head 1 96000091 9605-1-3312310050

47 Water tube

bush 1 96000835 9601-1-3312310035

48 Air tube pad 1 96000176 9605-1-3312310166

49 Ratchet 1 96000092 9605-1-3312310051

50 Dowel pin 1 96000839 9601-1-3312310039

51 Valve chest 1 96000093 9605-1-3312310052

52 Valve 1 96000094 9605-1-3312310053

53 Valve sleeve 1 96000639 9605-1-3312311860

54 Rifle bar 1 96000640 9605-1-3312311861

55 Rifle nut 1 96000095 9605-1-3312310056

56 Exhaust

deflector 1 96000562 9605-1-3312311050

57 Hoop 1 96000542 9605-1-3312310725

58 Cylinder 1 96000641 9605-1-3312311862

59 Guide

sleeve set 1 96000096 9605-1-3312310059

60 Piston 1 96000642 9605-1-3312311863

61 Hex� Thick

nut 2 96000518 9605-1-3312310697

62 Side bolt 2 96000643 9605-1-3312311864

63 Air tube 1 96000644 9605-1-3312311865

64 Water tube 1 96000645 9605-1-3312311866

65 Front head 1 96000647 9605-1-3312311875

66 Rotation

sleeve 1 96000648 9605-1-3312311876

67

Nonmetal

hex�

Locking nut

2 96000531 9605-1-3312310713

68

Steel

retainer

springs

2 96000818 9600-1-3312310013

69

Steel

retainer

bolt

2 96000634 9600-1-3312311820

70 Shank

sleeve 1 96000168 9605-1-3312310157

71 Working

tool retainer 1 96000635 9600-1-3312311821

18

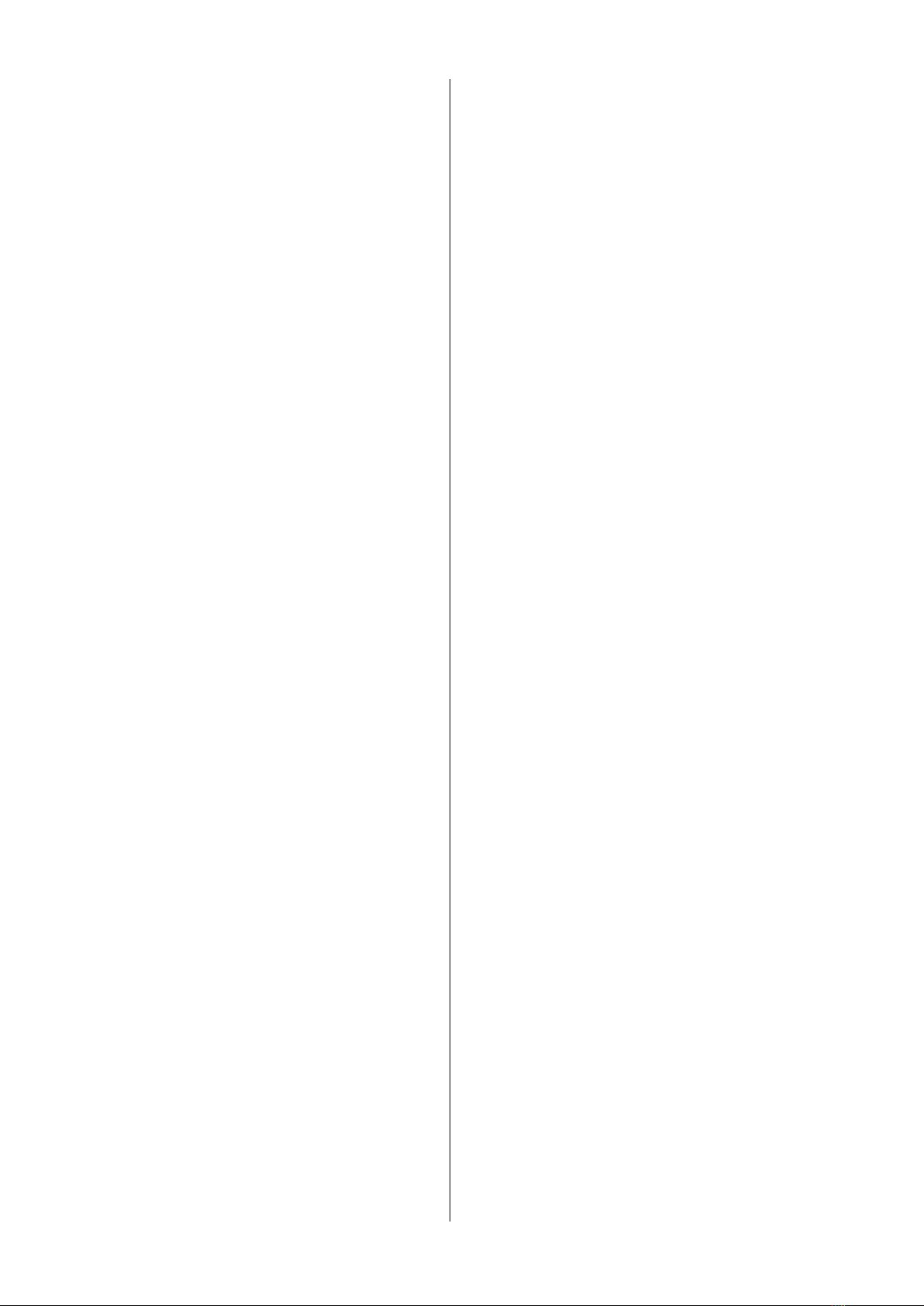

Spare parts list and exploded drawing YT29AE

72

73

74

31

74

62

4

5

3

6

7

9

8

11

10

17

9

12

15

13

14

16

1

2

46

26

23

22

25

24

48

63

64

47

44

40

41

45

43

14

42

38

36

37

34

32

35

21

18

19

20 56

57

58

55

60

59

61

30

29

28

27

49

54

51

50

52

53

39

66

67

68

65

70

69

71

75

33

76

75

19

No� Description Quantity Product no� Product code

1 Spring 1 96000179 9605-1-3312310169

2 Pin 1 96000180 9605-1-3312310170

3Conical pipe

connector 1 96000186 9605-1-3312310176

4 Hoop 1 96000540 9605-1-3312310723

5 Wing nut 1 96000185 9605-1-3312310175

6Pipe

connector 1 96000187 9605-1-3312310177

7Air pipe

swivel 1 96000825 9600-1-3312310022

8 Air pipe nut 1 96000823 9600-1-3312310020

9 O-ring 2 96000486 9605-1-3312310633

10 Pad 1 96000174 9605-1-3312310164

11 Retaining

ring 1 96000182 9605-1-3312310172

12 Water pipe

connector 1 96000154 9603-1-3312310143

13 Water pipe

nut 1 96000155 9603-1-3312310144

14 O-ring 2 96000482 9605-1-3312310627

15 O-ring 2 96000499 9605-1-3312310667

16

Water pipe

connector

retaining ring

1 96000156 9603-1-3312310145

17 Control valve 1 96000646 9605-1-3312311868

18 Control

handle 1 96000152 9603-1-3312310141

19 Standard

spring pad 1 96000534 9605-1-3312310716

20 Hex� thin nut 1 96000524 9605-1-3312310704

21 Fixing pin 1 96000177 9605-1-3312310167

22 Change

valve 1 96000161 9603-1-3312310150

23 Retaining

ring 1 96000160 9603-1-3312310149

24

Pressure

regulating

valve

1 96000119 9602-1-3312310101

25 Expansion 2 96000118 9602-1-3312310099

26 Spring 1 96000157 9603-1-3312310146

27 Conical

spring 4 96000167 9605-1-3312310156

28 Ratchet pawl 4 96000166 9605-1-3312310155

29 Large seal

sleeve 1 96000544 9605-1-3312310727

30 Seal sleeve 2 96000543 9605-1-3312310726

31 Right handle 1 96000887 9602-1-3312380076

32 Left handle 1 96000886 9602-1-3312380077

33

Anti-

vibration

handle

1 96000890 9602-1-3312380074

34 Trigger 1 96000162 9603-1-3312310151

35 Elastic pin 1 96000527 9605-1-3312310708

36 Spring cover 1 96000169 9605-1-3312310159

37

Steel

retaining

ring

1 96000183 9605-1-3312310173

38 Spring 1 96000170 9605-1-3312310160

39 Rotation nut 1 96000146 9603-1-3312310135

No� Description Quantity Product no� Product code

40 Pad 1 96000184 9605-1-3312310174

41 Water valve

body 1 96000171 9605-1-3312310161

42 Water valve 1 96000173 9605-1-3312310163

43 O-ring 2 96000489 9605-1-3312310642

44 Seal 1 96000181 9605-1-3312310171

45 Rubber pad 1 96000175 9605-1-3312310165

46 Back head 1 96000903 9605-1-3312380175

47 Water tube

bush 1 96000835 9601-1-3312310035

48 Air tube pad 1 96000176 9605-1-3312310166

49 Ratchet 1 96000092 9605-1-3312310051

50 Dowel pin 1 96000839 9601-1-3312310039

51 Valve chest 1 96000093 9605-1-3312310052

52 Valve 1 96000094 9605-1-3312310053

53 Valve sleeve 1 96000639 9605-1-3312311860

54 Rifle bar 1 96000640 9605-1-3312311861

55 Rifle nut 1 96000095 9605-1-3312310056

56

Exhaust

deflector�

Silencer

1 96000862 9602-1-3312311899

57 Hoop 1 96000542 9605-1-3312310725

58 Cylinder 1 96000641 9605-1-3312311862

59 Guide sleeve

set 1 96000096 9605-1-3312310059

60 Piston 1 96000642 9605-1-3312311863

61 Hex� Thick

nut 2 96000518 9605-1-3312310697

62 Side bolt 2 96000891 9602-1-3312380079

63 Air tube 1 96000644 9605-1-3312311865

64 Water tube 1 96000645 9605-1-3312311866

65 Front head 1 96000647 9605-1-3312311875

66 Rotation

sleeve 1 96000648 9605-1-3312311876

67

Nonmetal

hex� Locking

nut

2 96000531 9605-1-3312310713

68 Steel retainer

springs 2 96000818 9600-1-3312310013

69 Steel retainer

bolt 2 96000634 9600-1-3312311820

70 Shank sleeve 1 96000168 9605-1-3312310157

71 Working tool

retainer 1 96000635 9600-1-3312311821

72

Nonmetal

hex� Locking

nut

2 96000895 9602-1-3312311158

73 Pad 2 96000892 9602-1-3312380090

74

First-order

antivibration

bush

4 96000885 9602-1-3312380078

75

Second-order

antivibration

bush

2 96000888 9602-1-3312380075

76 Hollow pipe 1 96000889 9602-1-3312380091

20

Spare parts list and exploded drawing

YT29AE(T)

This manual suits for next models

7

Table of contents

Other Epiroc Drill manuals