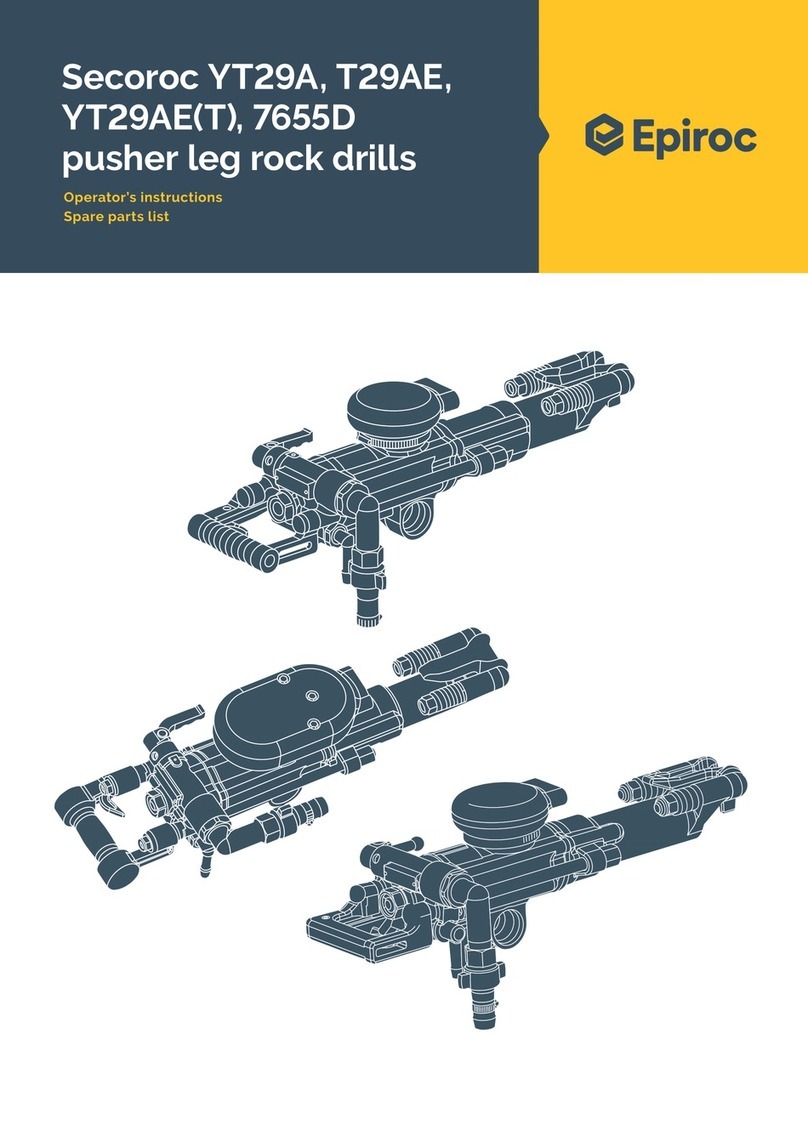

Epiroc Secoroc YT27 Specifications

Secoroc YT27

pusher leg rock drill

Operator’s instructions

Spare parts list

2

Foreword

Thank you for selecting the Secoroc pusher leg rock drillYT27.

These instructions were developed to help you get the best per-

formance and productivity from the use of your new rock drill.

Please refer to them also for the correct maintenance of the rock

drill.

Table of contents

Scope of application����������������������������������������������������3

Specification........................................................................................ 3

Safety instructions ������������������������������������������������������3

Operation ���������������������������������������������������������������������4

Using the rock drill for the first time ................................................. 4

Preparations before starting .............................................................. 4

Fitting and removing the drill steel ................................................... 4

Before fitting the drill steel................................................................. 4

Fitting the drill steel............................................................................ 4

Removing the drill steel ..................................................................... 5

Attaching the pusher leg to the rock drill.......................................... 4

Controls ............................................................................................... 5

Throttle lever....................................................................................... 5

Feed control ........................................................................................ 5

Trigger ................................................................................................. 5

Oil regulating valve ............................................................................ 5

Drilling ................................................................................................. 5

Starting the rock drill .......................................................................... 5

Stopping the rock drill........................................................................ 6

Checking the lubrication..................................................................... 6

Re-positioning the pusher leg .......................................................... 6

Blow-cleaning the drill hole............................................................... 6

When you have finished drilling ....................................................... 6

Maintenance........................................................................................ 6

Once a shift (after 8 hours of operation)........................................... 6

Once a week (after 40 hours of operation) ....................................... 6

Once a month (after 200 hours of operation)................................... 6

Selection of spare parts...................................................................... 6

Storage ................................................................................................ 6

Scrapping and waste disposal........................................................... 6

Trouble shooting����������������������������������������������������������7

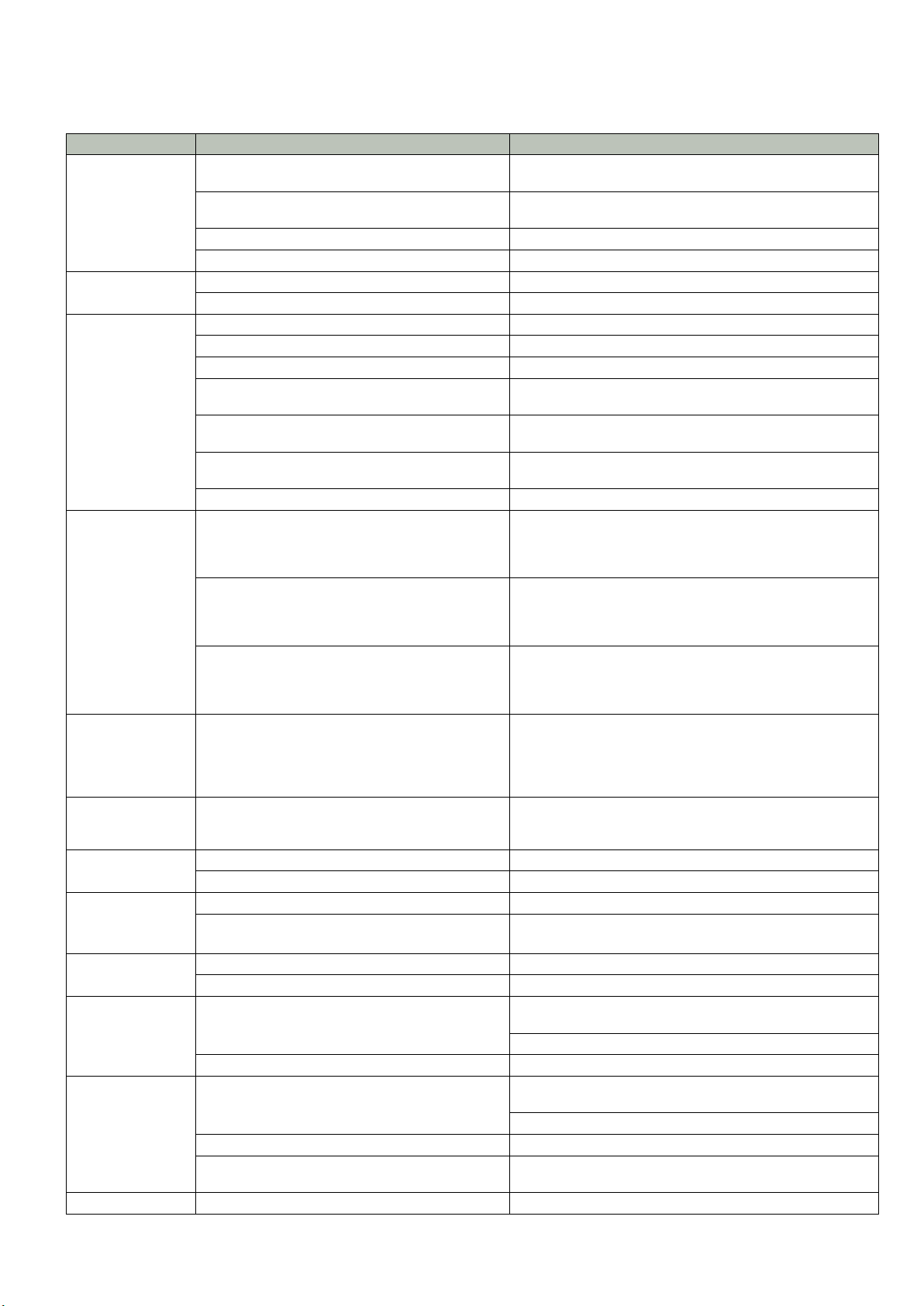

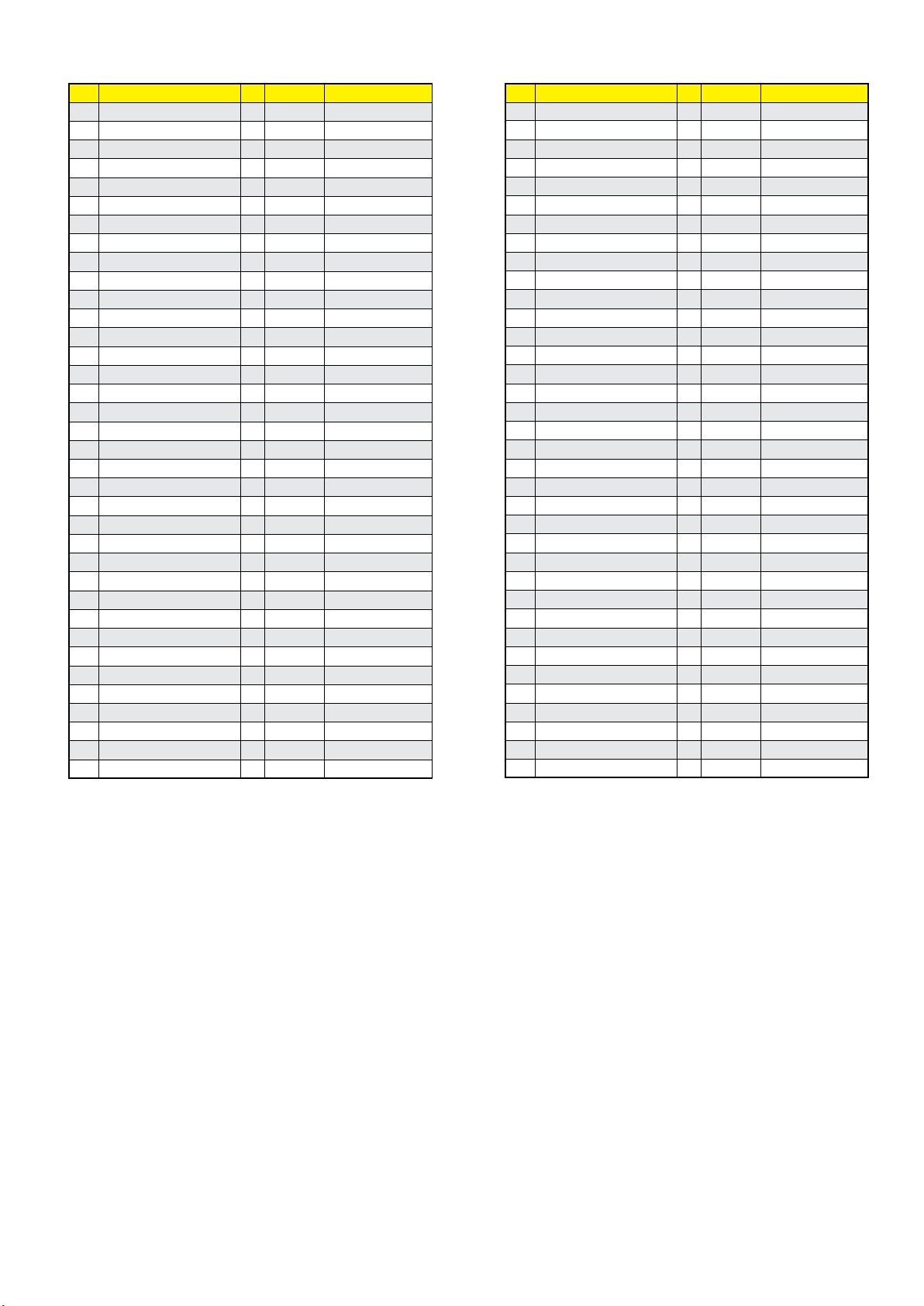

Spare parts list and exploded drawing ���������������������8

3

Scope of application

ModelYT27 is a highly efficient pusher leg rock drill. It is mainly

used in either rock drilling work such as mining and tunneling,

or in railway, water conservancy construction projects and stone

work. It is suitable for wet drilling on hard and medium hard

rock, or for drilling horizontal or inclined blast holes.YT27 can be

equipped with pusher leg FT160A and FY250 lubricator.

Specification

Pneumatic rock drill YT27

Weight 27 kg

Dimension (L x W x H) 668 x 248 x 202 mm

Cylinder diameter 80 mm

Piston stroke 60 mm

Working pressure 4–6.3 bar(e)

Impact energy (at 6.3 bar (e)) ≥70 J

Impact energy (at 5.0 bar (e)) ≥64 J

Impact energy (at 4.0 bar (e)) ≥48 J

Air consumption (at 6.3 bar (e)) ≤85 l/s

Air consumption (at 5.0 bar (e)) ≤57 l/s

Air consumption (at 4.0 bar (e)) ≤50 l/s

Impact frequency (at 6.3 bar (e)) ≥40 Hz

Impact frequency (at 5.0 bar (e)) ≥39 Hz

Impact frequency (at 4.0 bar (e)) ≥37 Hz

Torque (at 6.3 bar (e)) ≥19 Nm

Torque (at 5.0 bar (e)) ≥16 Nm

Torque (at 4.0 bar (e)) ≥13 Nm

Water pressure working pressure -1 bar(e)

Air hose inner diameter 25 mm

Water hose inner diameter 13 mm

Drilling diameter 34–45 mm

Max drilling depth 5 m

Working temperature -30 to +50 ºC

Shank size H22x108±1 mm

Lubricator FY250

Weight 1.2 kg

Capacity 0.25 litre

Safety instructions

To reduce the risk of serious injury or death to yourself or others,

carefully read through this instruction booklet before putting

the rock drill to use. Always follow the instructions given in this

manual.

• Always wear a safety helmet, impact resistant eye protection

with side protection and ear protectors during drilling. Any local

regulations that exist must also be observed.

• When drilling in certain minerals, there is a risk of spark genera-

tion. Before starting work, check that the machine is approved (in

accordance with local regulations) for work under such condi-

tions.

• Always take great care when using the machine.The drill steel is

subjected to heavy loading and can break, with a risk of injury to

personnel.

• Check that the hoses used are of the right quality, and that all

hose connections are in good condition and properly tightened.

• Before starting work on any of the systems, make sure that the

air and water systems are un-pressurized.

• Make sure that there are no concealed wires or other sources of

electricity. Never drill near any electric wires or other sources of

electricity.

• Exposure to crystalline silica (sometimes called 'silica dust') as

a result of drilling in rock may cause silicosis, cancer or death.

Never operate the rock drill without water flushing.

A compressed air hose that comes loose can lash around and

cause personal injury or death. Check that the compressed air

connections are not damaged and that they are properly attached.

4

Operation

Using the rock drill for the first time

When the rock drill arrives from the factory, the inside of the tool

is coated with heavy oil to prevent corrosion.

After unpacking and installing the tool, pour a small amount of lu-

brication oil into the air connection and operate the tool on partial

throttle to clean the interior. Follow this immediately with a liberal

amount of air tool oil.

The rock drill and pusher leg are lubricated with oil mixed with

compressed air, which is taken to the parts that need continuous

lubrication. Oil is metered into the compressed air using the

FY250 lubricator connected to the air line.

Preparations before starting

1� Check the drilling equipment

• Check that all of the drilling equipment is in good working order.

• Check that the impact surface of the drill steel shank is flat with

no signs of wear.

• Make sure that the air inlet and exhaust ports are free from

obstructions.

• Check that the flushing holes in the drill steel and drill bit are

not blocked and that the flushing air/water flows through without

obstruction.

• Ensure that the fittings are tight and leak-proof.

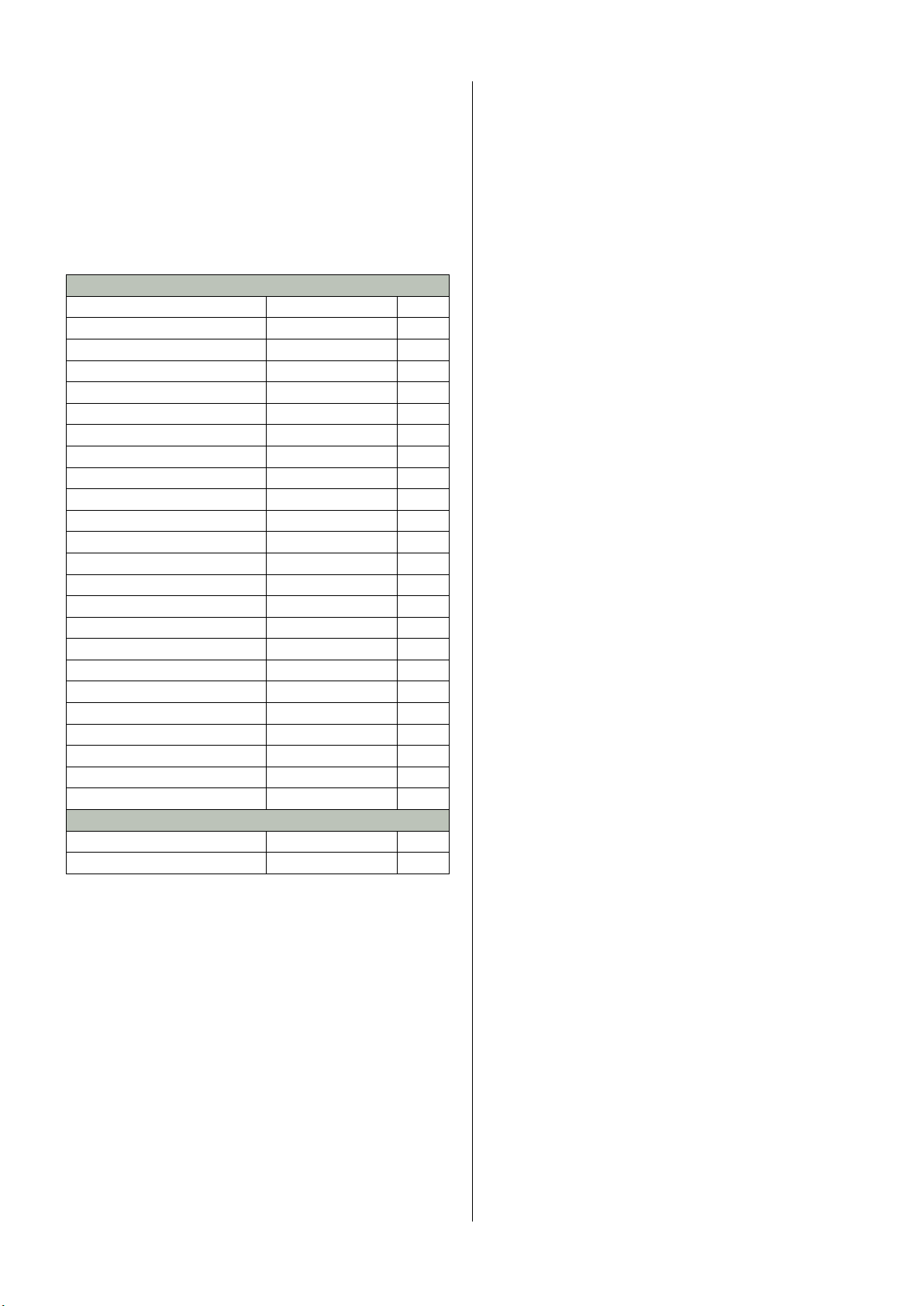

A compressed air hose that comes loose can lash around

and cause personal injury or death. Check that the com-

pressed air connections are not damaged and that they are

properly attached.

WARNING

2� Blow out the air hose

Every day before using the drill, blow out the air hose to clear it

from accumulated dirt and moisture.

3� Check the lubrication oil level

• Fill the lubricator with oil if necessary.

• Always use a recommended lubricant.

Lubricant Recommendation

Use a mineral-based air tool oil

Ambient

temperature ºC

Viscosity grade (ISO

3448)

-30 to 0 ISO VG 32-68

-10 to +20 ISO VG 68-100

+10 to +50 ISO VG 100-150

4� Air/water pressure and hose dimensions

Air pressure

Ensure that the compressor can deliver the required air pressure

of 5 bar at the machine.

• High pressure (>6.3 bar) causes rough operation and damage.

• Low pressure (<4 bar) results in a slow drilling speed.

Water pressure

Set the water preassure to around 3 bar. Maximum water pres-

sure is 1 bar less than the working pressure. For example if the air

pressure is 5 bar, then the water pressure must be below 4 bar to

prevent water entering the impact mechanism.

Air hose dimensions

The air hose diameter must be no less than 25 mm.The inner

diameter of connection nipples and hoses must be no less than 19

mm.The ideal overall air hose length is less than 15m.

Water hose dimensions

The water hose inner diameter must be no less than ½".

5� Prevent freezing

In low ambient temperatures, ice can form in the machine.This

can be avoided if the water in the compressed air is removed.This

can be done by equipping the air lines with water separators and

drainage points for water condensate.

If the rock drill ices up, it must not be heated to melt the ice. Let

the ice thaw at room temperature.

Do not pour methylated spirits or similar substances into the

rock drill, as they will interfere with the lubrication and lead to

increased wear.

Fitting and removing the drill steel

Before fitting the drill steel

• Check that the drill steel shank is of the correct size and length

for the chuck used.

•The shank must be clean and the drill steel must be in good

condition.

•The suitable quenching hardness of the shank is HRC48-53. A

harder end face will cause piston damage and breakage of the

end face of the piston. If the shank face is too soft it will be easily

deformed by the piston which will result in difficulty in removing

the drill steel.

•The shank end face shall be flat and perpendicular to the axis.

• Remove sharp edges from the shank's end face. A rough shank

surface will cause premature piston failure.

• Inspect the drill steel: A dull drill steel will slow down the drilling

speed and overstrain the drill mechanism. When changing drill

steel make sure that the new one is the correct size to follow your

previous bore.

• Before drilling check that the flushing hole in the drill steel is not

blocked.

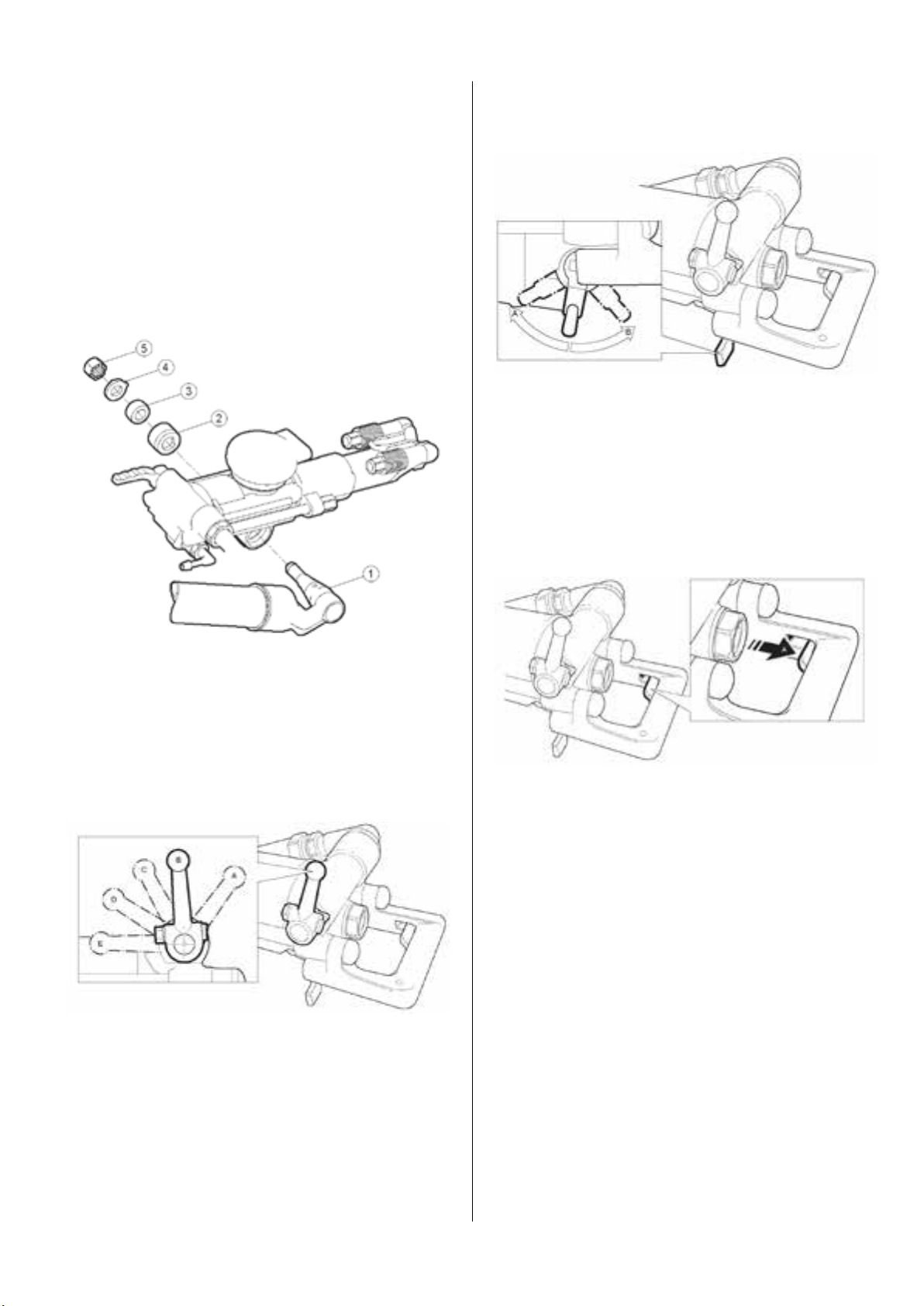

Fitting the drill steel

1� Push the retainer outwards in the direction of the arrow (see

picture below), until the front portion of the retainer is able to

accommodate the drill steel collar.

2� Insert the drill in the chuck.

3� When the drill bottoms, push back the retainer to lock it.

5

Removing the drill steel

1� Push the retainer outwards in the direction of the arrow until

the drill steel collar disengages from the front of the retainer.

2� Pull the drill steel out.

3� Push back the retainer.

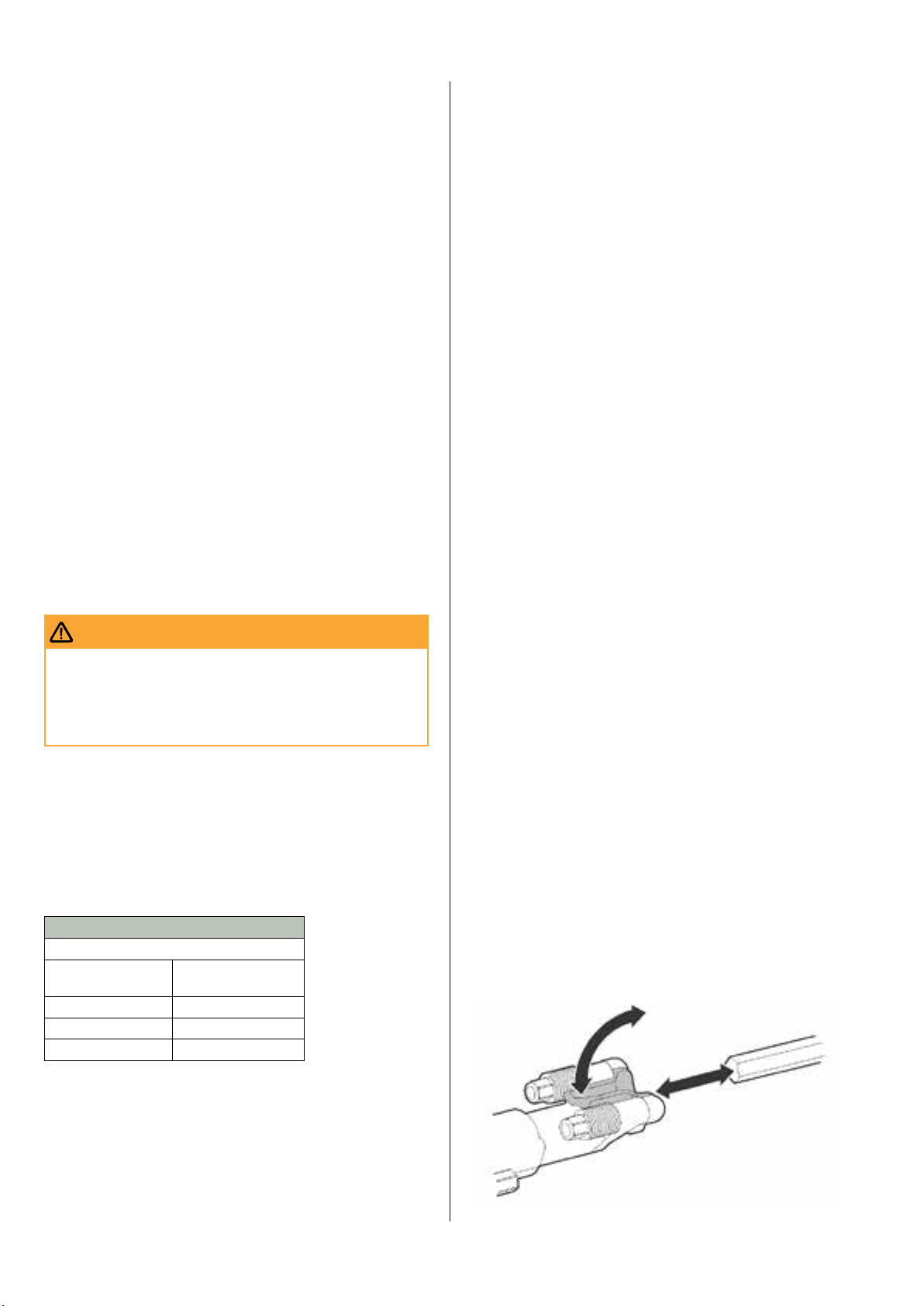

Attaching the pusher leg to the rock drill

• Mount the pusher leg (1), lock sleeve (2), rubber pad (3), washer

(4) and locking nut (5) in the order shown in the picture below.

•Turn the locking nut clockwise with a wrench until you hear a

"click".

Controls

Throttle lever

The rock drill is equipped with a throttle lever for regulating both

the compressed air to the percussion mechanism and the flushing

water.

A� Extra blowing, water flushing off, impact and rotation off.

B� Stop position, air and water off

C� Low throttle, air to pusher leg, water flushing

D� Medium throttle

E� Full throttle

Feed control

Adjust the feed force by means of the feed control lever as fol-

lows:

A� Pushing the lever in this direction will increase feed force.

B� Pulling the lever in this direction will decrease feed force

Trigger

When the trigger (A) is pushed in, the feed force stops abruptly

and the setting on the feed control lever is overridden.The piston

rod in the pusher leg retracts automatically.This function is used

for example to adjust the height of the rock drill, when rigging

up the pusher leg, or when there is a tendency to jam. When the

trigger is released, the feed control setting is activated again.

Oil regulating valve

Oil dosing is controlled using a screwdriver.Tighten the nut after

regulation.

Check that sufficient lubrication is obtained by putting your hand

in front of the exhaust port while adjusting the regulating valve.

If the hand is covered by a thin film of oil after a few seconds, the

lubricator has been correctly adjusted.Too much oil will have neg-

ative effects on the operation whilst too little will result in damage

to parts as the temperature rises during operation.

The amount of oil going into the rock drill increases when turning

the valve counter clockwise, and it decreases when turning the

valve clockwise. Oil consumption is 2.5–6 ml/minute.

Drilling

Starting the rock drill

1� Open the main valve for compressed air.

2� Open the cock for the flushing water.

3� Adjust the feed control lever to give a suitable feed force for

collaring the hole.

4� Align the rock drill so that the drill steel touches the desired

collaring point.

6

5� Move the throttle lever forward a little, which will start water

flushing, percussion and rotation.

6� Collar the hole with reduced feed force.

7� Move the throttle lever fully forward once the drill steel has

gained a secure footing in the rock.

8� Adjust the feed force using the control lever so that the maxi-

mum penetration rate is obtained.

Note! Do not bend the drill steel as this will increase wear of the

shank bushing and piston. It can also affect drilling efficiency and

increase the risk of drill steel breakage.

Stopping the rock drill

Pull the throttle lever backwards, which will stop percussion, rota-

tion and flushing water.

Checking the lubrication

The chuck and drill steel shank must always be covered by a film

of oil.

Re-positioning the pusher leg

1� Switch off the rock-drill percussion and flushing using the

throttle lever.

2� Press the trigger, whereupon the piston rod is pulled back into

the pusher-leg cylinder automatically.

3� Re-position the pusher leg.

4� Release the trigger, whereupon the piston rod will move out-

wards again.

5� Move the throttle lever forward into the working position.

Note!The feed control lever does not need to be touched through-

out this operation.

Blow-cleaning the drill hole

When blow-cleaning, particles and dirty flushing water can

emerge at speed from the drill hole.

• Move to the side and cover your eyes before starting to blow-

clean the drill hole.

• Always wear impact resistant eye protection with side protec-

tion to avoid injury.

• Make sure that no co-workers are in range when blow-cleaning.

CAUTION

If powerful blow-cleaning of the drill hole is required, turn the

throttle lever fully backwards beyond the stop position for extra

blowing whereupon the rock drill stops.This can be done during

drilling. When the drill hole is clean, turn the throttle lever for-

wards again to re-start the rock drill.

When you have finished drilling

Run the rock drill at medium speed when retracting the drill steel

from the drilled hole.

Lay down the rock drill on a stone, wooden plank or similar ob-

ject, so as to prevent drill cuttings and other foreign matter from

entering the chuck.

Turn off the water pressure before the air pressure. Run the rock

drill for a few seconds to clean out water and moisture after the

water has been shut off.

Maintenance

Regular maintenance is a prerequisite for machine safety. Replace

damaged and worn components in good time.

Check the machine and drill steel for wear and damage at regular

intervals. Do not use a very worn or damaged drill steel.

When cleaning mechanical parts with a solvent, make sure that

you comply with current health and safety regulations and ensure

that there is sufficient ventilation.

Daily maintenance, regular checking of wearing parts and carrying

out repairs in good time prevents breakdowns and increases the

service life of the machine.

• Make sure that no foreign matter enters the machine.

• Always hose down and wipe clean the rock drill and pusher leg

after use.

Once a shift (after 8 hours of operation)

• Check the wear in the chuck bushing. If the wear limit has been

exceeded, the drill steel shank will wear more quickly, or become

deformed.This will lead to stoppages and increased drill steel

consumption.

• Check the tightness of the side bolt nuts.

• Check the rock drill's connection to the pusher leg.

• Check the hoses, couplings and controls for leakage and dam-

age.

• Check that the rock drill and pusher leg are receiving enough

lubrication. Fill the lubricator as necessary.

• Every day before using the drill, blow out the air hose to clear it

from accumulated dirt and moisture.

• Drain the water separator.

• Check the air and water pressure. Make sure that the water pres-

sure is at least 1 bar lower than the air pressure.

Once a week (after 40 hours of operation)

Carry out a basic check of all functions of the drilling equipment.

Once a month (after 200 hours of operation)

• Send the rock drill to a workshop for inspection. The local oper-

ating conditions will determine whether or not this is a suitable

interval for overhauling the drill.

• Dismantle and clean the lubricator.

• Clean out the water separator.

Selection of spare parts

Use only genuine parts for replacement, to ensure stable per-

formance. Do not use pattern parts, which not only have a short

working life but also cause consequential damage to other parts,

due to differing measurements and methods of manufacturing.

Storage

• Always oil the rock drill and pusher leg well before you put them

into storage.

• Store the rock drill and pusher leg in a clean and dry place.

• In the case of long-term storage, pour a quantity of oil directly

into the rock-drill's air intake and then turn on the air briefly.This

will protect the machine from corrosion.

• Protect the chuck using a wooden plug or a clean piece of cotton

waste.

Scrapping and waste disposal

Used and worn-out machines must be disposed of in such a way

that as much of the material as possible can be recycled and the

impact on the environment is kept to a minimum.

7

Trouble shooting

Problem Cause Solution

Decreased

penetration rate

Air leakage in hoses, couplings Change packings, and where required, change parts in the

throttle valve

Shank sleeve Check the shank sleeve for excessive wear. Replace if

necessary.

Air leakage due to worn piston/cylinder Replace the piston and/or cylinder

Air leakage due to worn guide sleeve/pilot guide Change the worn part

Insufficient feed

force

Piston rod seal (in pusher leg) worn or deformed Change the seal

O-rings on pusher leg coupling worn or deformed Change the o-ring

Poor rotation Splines of the rifle nut worn Replace the rifle nut if the splines are worn

Splines of the rifle bar worn down Replace the rifle bar when needed

Splines on the piston worn down Replace the piston when needed

The toothing in the ratchet housing is worn out Replace the ratchet housing if the tooth housing is so worn

that the pawls have difficulty catching

The toothing in the ratchet wheel is worn out Replace the ratchet wheel if the toothing is so worn that the

pawls have difficulty catching

Chuck nut worn out Replace the chuck nut if the splines have been worn to 1/2 of

the spline width

Pawls worn Replace all pawls, all pawl springs and all pawl pins

Uneven running Piston has seized in the guide sleeve or the piston

guide

Replace the guide sleeve/piston guide. If required, polish

the piston. Check the piston for heat damage such as blue

colouring and/or fissures. If it is damaged in this way,

replace the piston as well

Dirty or damaged main valve. Caused by impurities

or foreign matter entering the drill with the

compressed air

Clean and polish the valve so that it seals against the

corresponding cylindrical and plane sealing surfaces. If this

is not possible because the defects are too serious, the valve

must be replaced

Freezing. Caused by leakage in the flushing system

or by excess water in the compressed air or by

excessive water pressure

Check the flushing tubes and seals and the water pressure.

Drain water from the compressed air system. If the problem

continues,

fit a water separator in the airline system.

Uneven running

(continued)

The side bolts are unevenly or insufficiently

tightened. Can cause the various parts to lose their

alignment, resulting in the seizure of the movable

parts. Abnormal strains on the side bolt may result

in fracture at the threads.

Check and repair any damage to the contact points and

tighten the bolts with the correct tightening torque

The drill gets hot Lack of oil Add oil and check that it runs through. It is not sufficient

that there is oil in the exhaust air. There must also be an oil

coating on the shank of the drill steel.

Freezing High level of humidity in the compressed air Use water traps

Water pressure higher than the air pressure Lower the water pressure

Water pipe

breakage

Misalignment of the shank Change drill steel or shank sleeve or both

Damaged flushing hole in the shank Change drill steel

Chipping of the

piston tip

Misalignment of the shank Change the drill steel or shank sleeve or both

Excessive wear of the piston tip Change piston

Spline breakage

Lack of lubrication Lower the water pressure if it is the same as or greater than

the air pressure

Increase lubrication or change oil

Dirt intrusion (specially when drilling upwards) Increase service intervals

Piston breakage

Lack of lubrication Lower the water pressure if it is the same as or greater than

the air pressure

Increase lubrication or change oil

Uneven tension in the side bolts Tighten the bolts correctly

Worn guide sleeve/piston guide (can be confirmed

by the cushion test)

Change the worn part

Side bolt breakage Uneven tension on the bolts Tighten the bolts correctly

1234

8

9

6

7

10

11

12

13

15 14

19

5

16

17

18

20

21

22

23

24

25

27

26

28

29

30

31

32

33

38 39

40 41

42

44

46

45

47

43

48

49

9

50

51

52

55

54

53

56

58

58

59

60

61

63

63 64

64

62

66

65

57

67

69

68

70

71

72

43

37

36

34

35

9853 1258 01 2013.08

Secoroc YT27 Pneumatic rock drill

Atlas Copco Secoroc AB

Box 521, SE-737 25 Fagersta, Sweden

Phone +46 223 461 00

www.atlascopco.com

Ref. Description Qty Prod. No. Product code

1 Right handle 1 96000163 9603-1-3312310152

2 Shockproof handle 1 96000164 9603-1-3312310153

3 Left handle 1 96000165 9603-1-3312310154

4 Roll pin 1 96000527 9605-1-3312310708

5 Trigger 1 96000162 9603-1-3312310151

6 Circlip 1 96000183 9605-1-3312310173

7 Spring cap 1 96000169 9605-1-3312310159

8 Spring 1 96000170 9605-1-3312310160

9 O seal ring 2 96000482 9605-1-3312310627

10 Water valve 1 96000173 9605-1-3312310163

11 O seal ring 2 96000489 9605-1-3312310642

12 Rubber pad 1 96000175 9605-1-3312310165

13 Water valve body 1 96000148 9603-1-3312310137

14 O seal ring 2 96000502 9605-1-3312310671

15 Pad 1 96000184 9605-1-3312310174

16 Water tube sleeve 1 96000149 9603-1-3312310138

17 Water tube 1 96000172 9605-1-3312310162

18 Air tube assembly 1 96000150 9603-1-3312310139

19 Air tube pad 1 96000176 9605-1-3312310166

20 Back head 1 96000147 9603-1-3312310136

21 Dowel pin 1 96000180 9605-1-3312310170

22 Spring 1 96000179 9605-1-3312310169

23 Ratchet pawl 4 96000166 9605-1-3312310155

24 Conical spring 4 96000167 9605-1-3312310156

25 Rifle bar 1 96000138 9603-1-3312310126

26 Ratchet 1 96000131 9603-1-3312310119

27 Dowel pin 1 96000135 9603-1-3312310123

28 Valve cover 1 96000142 9603-1-3312310130

29 Valve 1 96000133 9603-1-3312310121

30 Valve chest 1 96000132 9603-1-3312310120

31 Valve sleeve 1 96000134 9603-1-3312310122

32 Rifle nut 1 96000814 9600-1-3312310009

33 Piston 1 96000139 9603-1-3312310127

34 Fixing pin 1 96000177 9605-1-3312310167

35 Operating handle 1 96000152 9603-1-3312310141

36 Spring pad 1 96000534 9605-1-3312310716

Ref. Description Qty Prod. No. Product code

37 Hex nut 1 96000524 9605-1-3312310704

38 Spring 1 96000157 9603-1-3312310146

39 Pressure regulating valve 1 96000159 9603-1-3312310148

40 Expansion ring 2 96000158 9603-1-3312310147

41 Retaining ring 1 96000160 9603-1-3312310149

42 Change over valve 1 96000161 9603-1-3312310150

43 O seal ring 2 96000486 9605-1-3312310633

44 Control valve 1 96000153 9603-1-3312310142

45 Pad 1 96000174 9605-1-3312310164

46 Retaining ring 1 96000182 9605-1-3312310172

47 Air pipe nut 1 96000823 9600-1-3312310020

48 Air pipe swivel 1 96000825 9600-1-3312310022

49 Retaining ring 1 96000156 9603-1-3312310145

50 Water pipe nut 1 96000155 9603-1-3312310144

51 O seal ring 2 96000499 9605-1-3312310667

52 Water pipe connector 1 96000154 9603-1-3312310143

53 Cylinder 1 96000140 9603-1-3312310128

54 Muffler 1 96000137 9603-1-3312310125

55 Hoop 1 96000542 9605-1-3312310725

56 Guiding sleeve 1 96000141 9603-1-3312310129

57 Side bolt 2 96000151 9603-1-3312310140

58 Hex thick nut 2 96000518 9605-1-3312310697

59 Rotation nut 1 96000146 9603-1-3312310135

60 Rotation sleeve 1 96000144 9603-1-3312310133

61 Shank bushing 1 96000145 9603-1-3312310134

62 Front head 1 96000143 9603-1-3312310131

63 Hex lock nut 2 96000531 9605-1-3312310713

64 Drill retainer spring 2 96000818 9600-1-3312310013

65 Drill retainer bolt 2 96000634 9600-1-3312311820

66 Drill retainer 1 96000635 9600-1-3312311821

67 Pipe connector 1 96000187 9605-1-3312310177

68 Conical hose nipple 1 96000186 9605-1-3312310176

69 Wing nut 1 96000185 9605-1-3312310175

70 Hoop 1 96000540 9605-1-3312310723

71 Sealing sleeve 2 96000543 9605-1-3312310726

72 Large sealing sleeve 1 96000544 9605-1-3312310727

1234

8

9

6

7

10

11

12

13

15 14

19

5

16

17

18

20

21

22

23

24

25

27

26

28

29

30

31

32

33

38 39

40 41

42

44

46

45

47

43

48

49

9

50

51

52

55

54

53

56

58

58

59

60

61

63

63 64

64

62

66

65

57

67

69

68

70

71

72

43

37

36

34

35

9853 1258 01 2013.08

Secoroc YT27 Pneumatic rock drill

Atlas Copco Secoroc AB

Box 521, SE-737 25 Fagersta, Sweden

Phone +46 223 461 00

www.atlascopco.com

Ref. Description Qty Prod. No. Product code

1 Right handle 1 96000163 9603-1-3312310152

2 Shockproof handle 1 96000164 9603-1-3312310153

3 Left handle 1 96000165 9603-1-3312310154

4 Roll pin 1 96000527 9605-1-3312310708

5 Trigger 1 96000162 9603-1-3312310151

6 Circlip 1 96000183 9605-1-3312310173

7 Spring cap 1 96000169 9605-1-3312310159

8 Spring 1 96000170 9605-1-3312310160

9 O seal ring 2 96000482 9605-1-3312310627

10 Water valve 1 96000173 9605-1-3312310163

11 O seal ring 2 96000489 9605-1-3312310642

12 Rubber pad 1 96000175 9605-1-3312310165

13 Water valve body 1 96000148 9603-1-3312310137

14 O seal ring 2 96000502 9605-1-3312310671

15 Pad 1 96000184 9605-1-3312310174

16 Water tube sleeve 1 96000149 9603-1-3312310138

17 Water tube 1 96000172 9605-1-3312310162

18 Air tube assembly 1 96000150 9603-1-3312310139

19 Air tube pad 1 96000176 9605-1-3312310166

20 Back head 1 96000147 9603-1-3312310136

21 Dowel pin 1 96000180 9605-1-3312310170

22 Spring 1 96000179 9605-1-3312310169

23 Ratchet pawl 4 96000166 9605-1-3312310155

24 Conical spring 4 96000167 9605-1-3312310156

25 Rifle bar 1 96000138 9603-1-3312310126

26 Ratchet 1 96000131 9603-1-3312310119

27 Dowel pin 1 96000135 9603-1-3312310123

28 Valve cover 1 96000142 9603-1-3312310130

29 Valve 1 96000133 9603-1-3312310121

30 Valve chest 1 96000132 9603-1-3312310120

31 Valve sleeve 1 96000134 9603-1-3312310122

32 Rifle nut 1 96000814 9600-1-3312310009

33 Piston 1 96000139 9603-1-3312310127

34 Fixing pin 1 96000177 9605-1-3312310167

35 Operating handle 1 96000152 9603-1-3312310141

36 Spring pad 1 96000534 9605-1-3312310716

Ref. Description Qty Prod. No. Product code

37 Hex nut 1 96000524 9605-1-3312310704

38 Spring 1 96000157 9603-1-3312310146

39 Pressure regulating valve 1 96000159 9603-1-3312310148

40 Expansion ring 2 96000158 9603-1-3312310147

41 Retaining ring 1 96000160 9603-1-3312310149

42 Change over valve 1 96000161 9603-1-3312310150

43 O seal ring 2 96000486 9605-1-3312310633

44 Control valve 1 96000153 9603-1-3312310142

45 Pad 1 96000174 9605-1-3312310164

46 Retaining ring 1 96000182 9605-1-3312310172

47 Air pipe nut 1 96000823 9600-1-3312310020

48 Air pipe swivel 1 96000825 9600-1-3312310022

49 Retaining ring 1 96000156 9603-1-3312310145

50 Water pipe nut 1 96000155 9603-1-3312310144

51 O seal ring 2 96000499 9605-1-3312310667

52 Water pipe connector 1 96000154 9603-1-3312310143

53 Cylinder 1 96000140 9603-1-3312310128

54 Muffler 1 96000137 9603-1-3312310125

55 Hoop 1 96000542 9605-1-3312310725

56 Guiding sleeve 1 96000141 9603-1-3312310129

57 Side bolt 2 96000151 9603-1-3312310140

58 Hex thick nut 2 96000518 9605-1-3312310697

59 Rotation nut 1 96000146 9603-1-3312310135

60 Rotation sleeve 1 96000144 9603-1-3312310133

61 Shank bushing 1 96000145 9603-1-3312310134

62 Front head 1 96000143 9603-1-3312310131

63 Hex lock nut 2 96000531 9605-1-3312310713

64 Drill retainer spring 2 96000818 9600-1-3312310013

65 Drill retainer bolt 2 96000634 9600-1-3312311820

66 Drill retainer 1 96000635 9600-1-3312311821

67 Pipe connector 1 96000187 9605-1-3312310177

68 Conical hose nipple 1 96000186 9605-1-3312310176

69 Wing nut 1 96000185 9605-1-3312310175

70 Hoop 1 96000540 9605-1-3312310723

71 Sealing sleeve 2 96000543 9605-1-3312310726

72 Large sealing sleeve 1 96000544 9605-1-3312310727

1234

8

9

6

7

10

11

12

13

15 14

19

5

16

17

18

20

21

22

23

24

25

27

26

28

29

30

31

32

33

38 39

40 41

42

44

46

45

47

43

48

49

9

50

51

52

55

54

53

56

58

58

59

60

61

63

63 64

64

62

66

65

57

67

69

68

70

71

72

43

37

36

34

35

9853 1258 01 2013.08

Secoroc YT27

Pneumatic rock drill

Atlas Copco Secoroc AB

Box 521, SE-737 25 Fagersta, Sweden

Phone +46 223 461 00

www.atlascopco.com

Ref. Description Qty Prod. No. Product code

1 Right handle 1 96000163 9603-1-3312310152

2 Shockproof handle 1 96000164 9603-1-3312310153

3 Left handle 1 96000165 9603-1-3312310154

4 Roll pin 1 96000527 9605-1-3312310708

5 Trigger 1 96000162 9603-1-3312310151

6 Circlip 1 96000183 9605-1-3312310173

7 Spring cap 1 96000169 9605-1-3312310159

8 Spring 1 96000170 9605-1-3312310160

9 O seal ring 2 96000482 9605-1-3312310627

10 Water valve 1 96000173 9605-1-3312310163

11 O seal ring 2 96000489 9605-1-3312310642

12 Rubber pad 1 96000175 9605-1-3312310165

13 Water valve body 1 96000148 9603-1-3312310137

14 O seal ring 2 96000502 9605-1-3312310671

15 Pad 1 96000184 9605-1-3312310174

16 Water tube sleeve 1 96000149 9603-1-3312310138

17 Water tube 1 96000172 9605-1-3312310162

18 Air tube assembly 1 96000150 9603-1-3312310139

19 Air tube pad 1 96000176 9605-1-3312310166

20 Back head 1 96000147 9603-1-3312310136

21 Dowel pin 1 96000180 9605-1-3312310170

22 Spring 1 96000179 9605-1-3312310169

23 Ratchet pawl 4 96000166 9605-1-3312310155

24 Conical spring 4 96000167 9605-1-3312310156

25 Rifle bar 1 96000138 9603-1-3312310126

26 Ratchet 1 96000131 9603-1-3312310119

27 Dowel pin 1 96000135 9603-1-3312310123

28 Valve cover 1 96000142 9603-1-3312310130

29 Valve 1 96000133 9603-1-3312310121

30 Valve chest 1 96000132 9603-1-3312310120

31 Valve sleeve 1 96000134 9603-1-3312310122

32 Rifle nut 1 96000814 9600-1-3312310009

33 Piston 1 96000139 9603-1-3312310127

34 Fixing pin 1 96000177 9605-1-3312310167

35 Operating handle 1 96000152 9603-1-3312310141

36 Spring pad 1 96000534 9605-1-3312310716

Ref. Description Qty Prod. No. Product code

37 Hex nut 1 96000524 9605-1-3312310704

38 Spring 1 96000157 9603-1-3312310146

39 Pressure regulating valve 1 96000159 9603-1-3312310148

40 Expansion ring 2 96000158 9603-1-3312310147

41 Retaining ring 1 96000160 9603-1-3312310149

42 Change over valve 1 96000161 9603-1-3312310150

43 O seal ring 2 96000486 9605-1-3312310633

44 Control valve 1 96000153 9603-1-3312310142

45 Pad 1 96000174 9605-1-3312310164

46 Retaining ring 1 96000182 9605-1-3312310172

47 Air pipe nut 1 96000823 9600-1-3312310020

48 Air pipe swivel 1 96000825 9600-1-3312310022

49 Retaining ring 1 96000156 9603-1-3312310145

50 Water pipe nut 1 96000155 9603-1-3312310144

51 O seal ring 2 96000499 9605-1-3312310667

52 Water pipe connector 1 96000154 9603-1-3312310143

53 Cylinder 1 96000140 9603-1-3312310128

54 Muffler 1 96000137 9603-1-3312310125

55 Hoop 1 96000542 9605-1-3312310725

56 Guiding sleeve 1 96000141 9603-1-3312310129

57 Side bolt 2 96000151 9603-1-3312310140

58 Hex thick nut 2 96000518 9605-1-3312310697

59 Rotation nut 1 96000146 9603-1-3312310135

60 Rotation sleeve 1 96000144 9603-1-3312310133

61 Shank bushing 1 96000145 9603-1-3312310134

62 Front head 1 96000143 9603-1-3312310131

63 Hex lock nut 2 96000531 9605-1-3312310713

64 Drill retainer spring 2 96000818 9600-1-3312310013

65 Drill retainer bolt 2 96000634 9600-1-3312311820

66 Drill retainer 1 96000635 9600-1-3312311821

67 Pipe connector 1 96000187 9605-1-3312310177

68 Conical hose nipple 1 96000186 9605-1-3312310176

69 Wing nut 1 96000185 9605-1-3312310175

70 Hoop 1 96000540 9605-1-3312310723

71 Sealing sleeve 2 96000543 9605-1-3312310726

72 Large sealing sleeve 1 96000544 9605-1-3312310727

8

1234

8

9

6

7

10

11

12

13

15 14

19

5

16

17

18

20

21

22

23

24

25

27

26

28

29

30

31

32

33

38 39

40 41

42

44

46

45

47

43

48

49

9

50

51

52

55

54

53

56

58

58

59

60

61

63

63 64

64

62

66

65

57

67

69

68

70

71

72

43

37

36

34

35

9853 1258 01 2013.08

Secoroc YT27 Pneumatic rock drill

Atlas Copco Secoroc AB

Box 521, SE-737 25 Fagersta, Sweden

Phone +46 223 461 00

www.atlascopco.com

Ref. Description Qty Prod. No. Product code

1 Right handle 1 96000163 9603-1-3312310152

2 Shockproof handle 1 96000164 9603-1-3312310153

3 Left handle 1 96000165 9603-1-3312310154

4 Roll pin 1 96000527 9605-1-3312310708

5 Trigger 1 96000162 9603-1-3312310151

6 Circlip 1 96000183 9605-1-3312310173

7 Spring cap 1 96000169 9605-1-3312310159

8 Spring 1 96000170 9605-1-3312310160

9 O seal ring 2 96000482 9605-1-3312310627

10 Water valve 1 96000173 9605-1-3312310163

11 O seal ring 2 96000489 9605-1-3312310642

12 Rubber pad 1 96000175 9605-1-3312310165

13 Water valve body 1 96000148 9603-1-3312310137

14 O seal ring 2 96000502 9605-1-3312310671

15 Pad 1 96000184 9605-1-3312310174

16 Water tube sleeve 1 96000149 9603-1-3312310138

17 Water tube 1 96000172 9605-1-3312310162

18 Air tube assembly 1 96000150 9603-1-3312310139

19 Air tube pad 1 96000176 9605-1-3312310166

20 Back head 1 96000147 9603-1-3312310136

21 Dowel pin 1 96000180 9605-1-3312310170

22 Spring 1 96000179 9605-1-3312310169

23 Ratchet pawl 4 96000166 9605-1-3312310155

24 Conical spring 4 96000167 9605-1-3312310156

25 Rifle bar 1 96000138 9603-1-3312310126

26 Ratchet 1 96000131 9603-1-3312310119

27 Dowel pin 1 96000135 9603-1-3312310123

28 Valve cover 1 96000142 9603-1-3312310130

29 Valve 1 96000133 9603-1-3312310121

30 Valve chest 1 96000132 9603-1-3312310120

31 Valve sleeve 1 96000134 9603-1-3312310122

32 Rifle nut 1 96000814 9600-1-3312310009

33 Piston 1 96000139 9603-1-3312310127

34 Fixing pin 1 96000177 9605-1-3312310167

35 Operating handle 1 96000152 9603-1-3312310141

36 Spring pad 1 96000534 9605-1-3312310716

Ref. Description Qty Prod. No. Product code

37 Hex nut 1 96000524 9605-1-3312310704

38 Spring 1 96000157 9603-1-3312310146

39 Pressure regulating valve 1 96000159 9603-1-3312310148

40 Expansion ring 2 96000158 9603-1-3312310147

41 Retaining ring 1 96000160 9603-1-3312310149

42 Change over valve 1 96000161 9603-1-3312310150

43 O seal ring 2 96000486 9605-1-3312310633

44 Control valve 1 96000153 9603-1-3312310142

45 Pad 1 96000174 9605-1-3312310164

46 Retaining ring 1 96000182 9605-1-3312310172

47 Air pipe nut 1 96000823 9600-1-3312310020

48 Air pipe swivel 1 96000825 9600-1-3312310022

49 Retaining ring 1 96000156 9603-1-3312310145

50 Water pipe nut 1 96000155 9603-1-3312310144

51 O seal ring 2 96000499 9605-1-3312310667

52 Water pipe connector 1 96000154 9603-1-3312310143

53 Cylinder 1 96000140 9603-1-3312310128

54 Muffler 1 96000137 9603-1-3312310125

55 Hoop 1 96000542 9605-1-3312310725

56 Guiding sleeve 1 96000141 9603-1-3312310129

57 Side bolt 2 96000151 9603-1-3312310140

58 Hex thick nut 2 96000518 9605-1-3312310697

59 Rotation nut 1 96000146 9603-1-3312310135

60 Rotation sleeve 1 96000144 9603-1-3312310133

61 Shank bushing 1 96000145 9603-1-3312310134

62 Front head 1 96000143 9603-1-3312310131

63 Hex lock nut 2 96000531 9605-1-3312310713

64 Drill retainer spring 2 96000818 9600-1-3312310013

65 Drill retainer bolt 2 96000634 9600-1-3312311820

66 Drill retainer 1 96000635 9600-1-3312311821

67 Pipe connector 1 96000187 9605-1-3312310177

68 Conical hose nipple 1 96000186 9605-1-3312310176

69 Wing nut 1 96000185 9605-1-3312310175

70 Hoop 1 96000540 9605-1-3312310723

71 Sealing sleeve 2 96000543 9605-1-3312310726

72 Large sealing sleeve 1 96000544 9605-1-3312310727

9

10

Notes

11

Notes

9866 0023 01 Subjected to alterations without prior notice. © Epiroc Drilling Tools AB. All rights reserved. 2017.12.

United in performance.

Inspired by innovation.

Performance unites us, innovation inspires us, and

commitment drives us to keep moving forward.

Count on Epiroc to deliver the solutions you need to

succeed today and the technology to lead tomorrow.

epiroc.com

Epiroc Drilling Tools AB

Box 521, SE-737 25 Fagersta, Sweden

Phone: +46 223 461 00

Table of contents

Other Epiroc Drill manuals

Popular Drill manuals by other brands

Hitachi

Hitachi DS 18DGL Handling instructions

BDS

BDS MAB 825 V Translation of the original operating instructions

Metabo HPT

Metabo HPT DS 18DC Safety instructions and instruction manual

Black & Decker

Black & Decker HD450 instruction manual

HIKOKI

HIKOKI DV 18DSDL Handling instructions

Clas Ohlson

Clas Ohlson DJC123-108-UK manual